International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

1 M.Tech. Student, Civil Engineering Department. SSCET, Badhani, Pathankot, Punjab, India. 2Assistant Professor, Civil Engineering Department. SSCET, Badhani ,Pathankot, Punjab, India. ***

Abstract - In this developing world, many countries are going to urbanization due to population growth. As India is one of developing countries, the construction will grow in the future.Thedevelopmentofacountryoracountrydependsnot only on technology, but also on infrastructure. Concrete is called the pillar of infrastructure. Cement production ranges from 8% to 10% of the world's total carbon dioxide. Consequently, cement production is not environmentally friendly, and cement is the most expensive material in the composition of concrete and, therefore, uneconomical. Therefore,itisnecessarytofindalternativematerialstomake the construction industry environmentally friendly and sustainable.Inthiswork,freshandhardenedpropertiesofthe concrete mix are determined like fresh concrete property i.e. workability of mix using slump cone test whereas the hardenedpropertiesofthe mixlikecompressivestrengthtest, split tensile strength test and flexural strength values are calculated after 7 and 28 days of curing. The findings suggestedthatthesuitabilityofeggshellpowderandceramic tileswithdifferentproportionsareapplicableinthestructural system of the buildings.

Key Words: Egg Shell Powder (ESP), Ceramic Tiles Waste (CWT), Compressive Strength, Split Strength, Flexural Strength, Workability, Concrete mix.

Portland cement clinker is the dominant binder used in concrete because of an abundance of raw materials, its relatively low cost and its excellent mechanical and durability properties. However, as reported by Meyer (2009),itsproductionprocessisenergyintensive(850kcal perkilogrammeofclinker)andemitsahighlevelofcarbon dioxide emissions to the atmosphere (about a tonne of carbon dioxide per tonne of cement). It has also been estimated that cement companies are responsible for the emissionofabouttwobilliontonnesofcarbondioxideper year, which is 6–7% of the planet’s total carbon dioxide emissions(Meyer,2009).Thecementindustryislookingfor alternativestoovercometheseproblemsandtocomplywith protocol obligations by making more sustainable binders andreusingwastesfromotherindustries.Cementisavery expensiveconstructionmaterialwhichisusedasabinding

agent in concrete. Due to high process of cement constructioncostsarequitehigh.Ontheotherhandwastes producedbydifferentindustrieslikecoconuthusk,EggShell andbrickswastearegettinguselessandareathreatforthe environment.Ifthesewastesarenotproperlydisposedthey may cause serious environmental pollution and health hazards.So,toreducetheconstructioncostandtoprotect our environment it is necessary to use the wastes from differentindustriesinconstruction.EggShellisoneofsuch wastes which is produced in large quantities by the food processingindustryandcanbeusedasapartialreplacement of cement. And Ceramic Tiles wastes are used to partially replacetheaggregatesinthemix.So,thisresearchwillaim on using Egg Shell powder and ceramic waste as a partial replacementofcementandcoarseaggregates,respectively and also to determine the various strength parameters of concrete.

Amarnath Yerramala (2014) describesresearchintothe useofpoultrymanureinconcretethroughthedevelopment ofconcretecontainingeggshellpowder(ESP).VariousESP concretes havebeendeveloped byreplacing5-15%ofthe ESP with cement. The results showed that the 5% ESP substitute exhibited higher strength than the control concrete, with 5% ESP being the optimum level for maximumstrength.Moreover,theperformanceoftheESP concreteupto10%ofhisESPsubstitutionwascomparable tothecontrolconcreteintermsoftransportproperties.The resultsfurtherindicatethataddingflyashalongwithESPis beneficialinimprovingconcreteperformance.

Doh Shu Ing And Chin Siew Choo Et Al., (2014) conducted aninvestigationoneggshellpowderaspotentialadditiveto concrete, showedconclusionofeggshellpowderinconcrete hasimprovedthecompressivestrengthofconcreteandwith additionof10%eggshellpowderinM25Gradeofconcrete.

Arun Kumar C et al. (2018) studiedthatpartoftheeggshell powdercouldbereplacedwithamixturethatcouldbeused asanalternativecementsource.Accordingtostatistics,large amountsofeggshellswerediscardedasgarbageinIndiaand sent to landfills. Therefore, due to its chemical properties

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page672

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

anditspresenceinnature,itcanbereplacedwithcement.In thiswork,experimentswereconductedusingeggshellsasa partialsubstituteforcement.Theconcretemixconsideredis M40 with a ratio of 1:1.5:2.3. Samples were prepared by replacing cement with 5%, 10%, 15%, 20%, and 25%. Mechanical properties such as compressive strength, split strengthandflexuralstrengthofeggshellpowderedconcrete weremeasuredatcuringtimesof7,14and28days,andthe resultswerecomparedwithconventionalconcrete.

Sherin Khan et.al.(2019) researched to determine the strength .properties of concrete by somewhat partial replacementofnaturalcoarseaggregatebythewastesfrom ceramiccollection.Resultsmaysustaintheenvironmentand alsoenhancetheconcretestrengthparameters.M30grade concrete mix was designed with variation of CWT as 0%, 10%,20%,30%,40%&50%toevaluateconcretestrength parameters.

R. Johnson Daniel et al. (2020) Thisresearchpaperdetails an experimental study to replace waste recovered from ceramicmanufacturingplantswithnaturalfineaggregatefor reuse in concrete. Due to this ceramic waste, natural fine aggregateextractioncanbereducedandthenominalcostof riversandishigher.comparedtoallotheralternativefine aggregatematerials.Groundandgranulatedwastepowder ceramictilesvaryfrom0%,5%,10%,15%and20%asafine aggregate replacement material. Mixed designs were preparedbyreplacingfineaggregatewithceramic(crushed tiles) at various percentages from 0% to 20% and substitutingM30gradeconcrete.Anexperimentalstudyon workabilitywascarriedoutonfreshconcrete.Varioustests havebeencarriedoutonhardenedconcrete.B.Compression tests,modulusandflexuralstrengthofconcretebeamswith different proportions of ground ceramic tiles at different stagesofcuringtimefrom7to28days.

Pramodini Sahu et al. (2020) worked on the strength effects of Jute Fiber Reinforced Cement Concrete while performingexperimentalworkonconcretewithadditionof JuteFiberatvariousproportions.Mainlymodulusofrupture andcompressivestrengthreadingaregenerallynoted.

OrdinaryPortlandCement,conformingtospecificationsfor 43 – grade ordinary portland cement, as per the IS code 8112-1989wasusedinthisstudy.

Water available in the laboratory with pH value of 7.0 correspondingtovaluesofIS456-2000isusedformaking concreteandcuringthespecimenaswell.

Materialfractionsrangesfrom4.75mmto150micronare considered as fine aggregates. River Sand which is locally availablewasusedasperIndianStandard383-1970.

In this study, locally available crushed coarse aggregate conformingtoIndianStandard383-1970wasused.Particle sizedistributionconfirmtorequirementsofasperIS(2386 partI).Nominalsizepassingthroughsize20mmandretain on10mmissieveused.

Eggshells are agricultural dump objects produced from poultries,bakeries,fastfoodrestaurantsamongothers.Its dampingontheopenlandcandamagethesurroundingsand as a result comprising ecological issues/contamination whichwouldneedanappropriatediffusionintoatmosphere. Thiscreateddifferentenvironmentalandhealthproblems

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Ceramic products are mostly produced using a natural materialthatcontainshighcontentofclayminerals.Broken tiles will be collected from the solid waste of ceramic manufacturingunitandfromdemolishedbuildingsites.

diameterwithbulletendrodisusedinthistestfortamping. Thistestissuitableformediumtohighworkabilityconcrete i.e.slumpvalues25mmto125mm.Andthistestislimitedto concretewithmaximumsizeofaggregatelessthan38mm.

Compressivestrengthof cubesofsize(15×15×15)cm was computedusingCompressionTestingMachine.Compressive strengthforanymaterialistheloadappliedatthepointof failure to the cross-section area of the face on which load wasapplied.

Compressive Strength= Load / Cross-sectional Area

Tensilestrengthofconcretemixismeasuredbytheunitsof Force per Cross-Sectional area (N/mm2 or MPa). The cylinderofsize15cmdiameterand30cmheightwascastto checkthesplittingtensilestrengthofconcrete.

The splitting tensile strength, Tsp = 2P / π DL

Figure 3.3: Ceramic Tiles Waste (CWT)

Table 3.2: Chemical Composition of CWT

Flexuralstrengthisessentialtoestimatetheloadatwhich theconcretemembermaycrack.Thespecimencastforthis test was of size (70×15×15) cm. Flexural strength is calculatedusingtheequation:

F= PL/ (bd2)

In this study, Egg shell powder and ceramic waste will be used as replacement of cement and natural coarse aggregatesrespectively,andthenvariousconcretestrength properties can be determined. In this study, the mix proportions were prepared according to Indian standard codeIS10262.Followingtestsareadoptedtoprecedethe work.

Slump cone test is most commonly used test for determination of consistency of concrete. The slump test indicates the behaviour of compacted concrete mix under action of gravitational force. The apparatus consists of a frustumofconedimensionsof10cmdiameterattop,20cm diameter at bottom and 30 cm height of cone. A 16mm

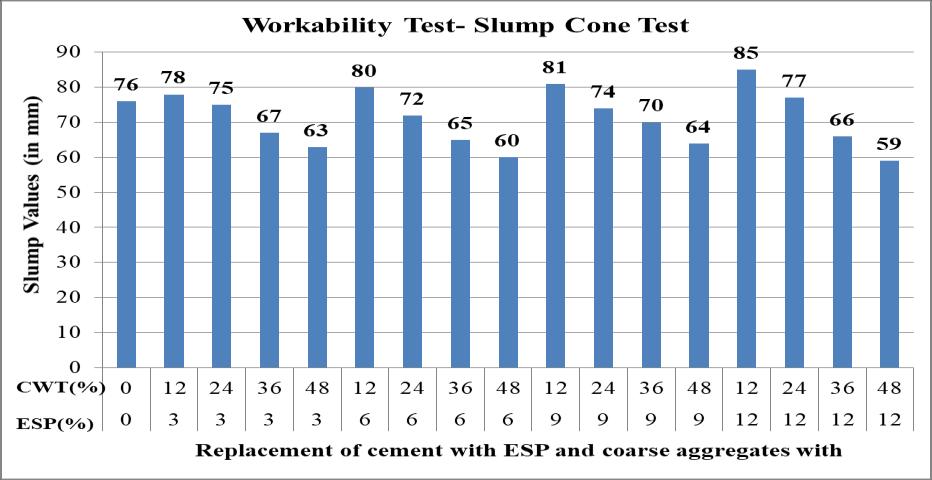

SlumpconetestofconcretemadewithEggShellPowderas replacementofcementatvaryingpercentageof0%,3%, 6%,9%&12%andCeramictileswasteasreplacementof coarseaggregatesatvaryingpercentageof0%,12%,24%, 36%& 48% wasdetermined.The resultsofSlumpcone testaregivenbelowinfigure5.1

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page674

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

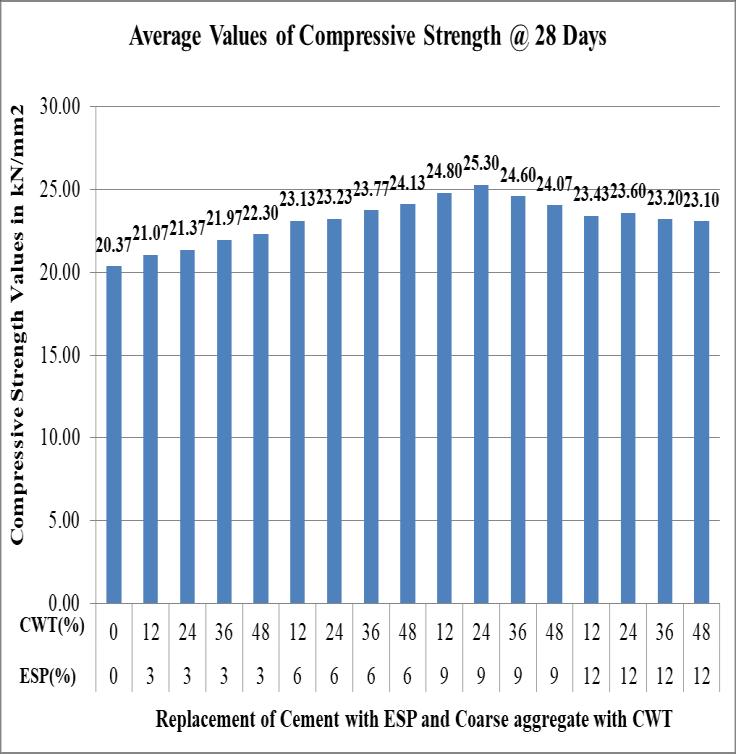

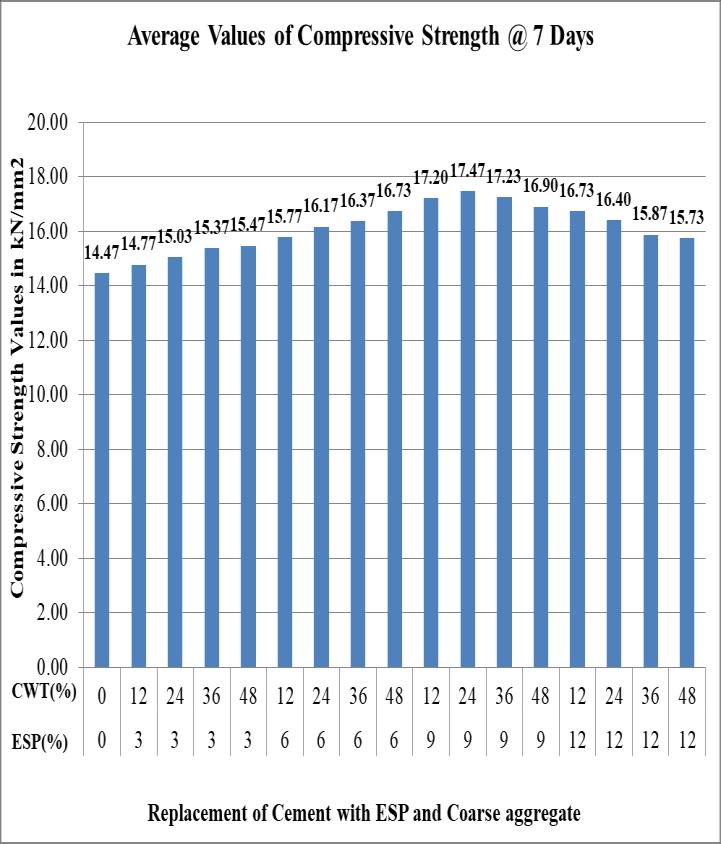

The compressive strength test is performed by testing a cube of size (150 x 150 x 150) mm. The compressive strength of concrete mixtures prepared using eggshell powderasasubstituteforcementandceramictilewaste asasubstituteforcoarseaggregatewasmeasuredafter7 and28days.Agraphicalrepresentationofthecompressive strengthofthecubesat7and28daysisshowninFigures 5.2and5.3

Figure 5.3: Compressive Strength of Concrete Mix using ESP and Ceramic Tiles Waste after 28 days of curing.

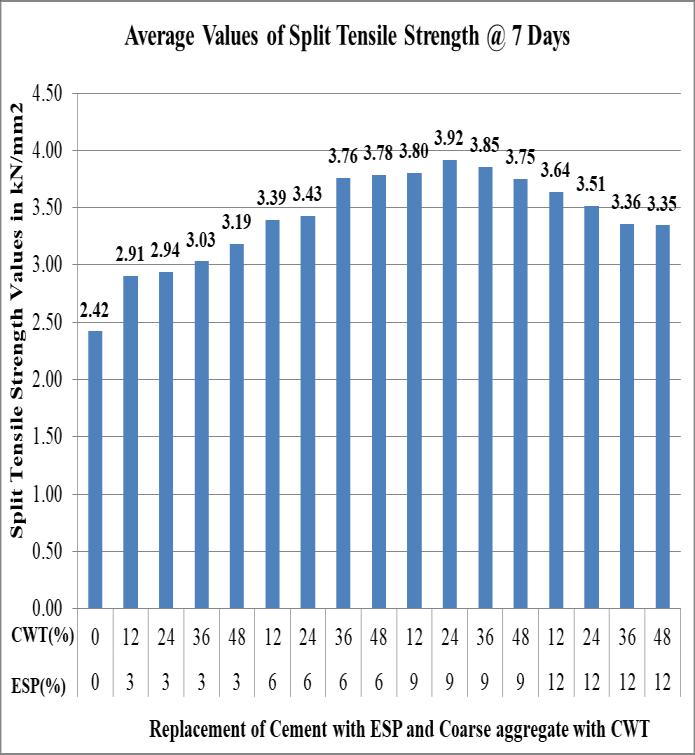

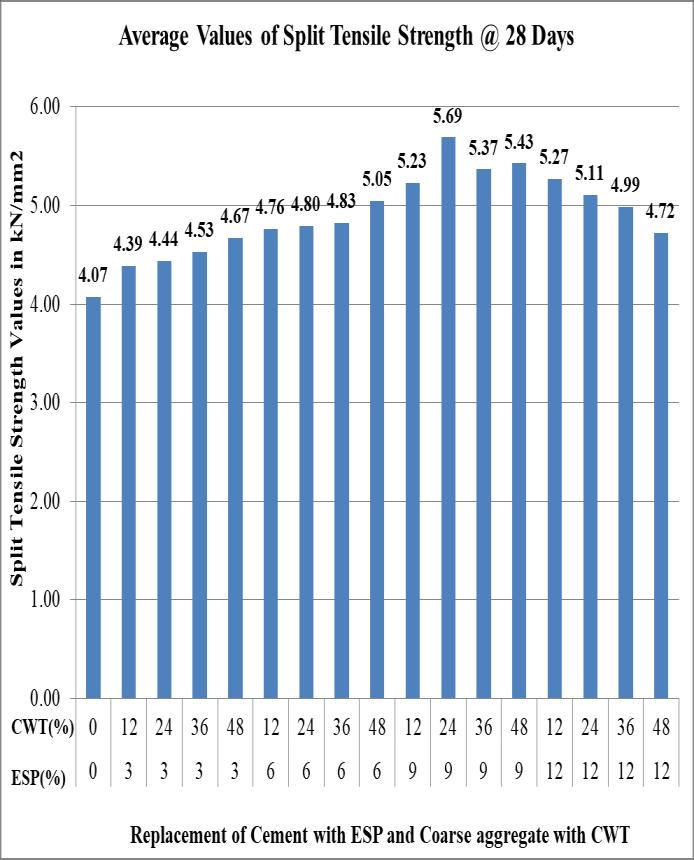

The results of Split Tensile Strength are determined on cylindricalspecimenusingUTM.Theresultsfor7daysand 28daysareshowninfigure5.4and5.5

Figure 5.2: Compressive Strength of Concrete Mix using ESP and Ceramic Tiles Waste after 7 days of curing.

Figure 5.4: Split Tensile Strength of Concrete mix using ESP and Ceramic Tiles Waste after 7 days of curing.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Figure 5.5: Split Tensile Strength of Concrete mix using ESP and Ceramic Tiles Waste after 28 days of curing.

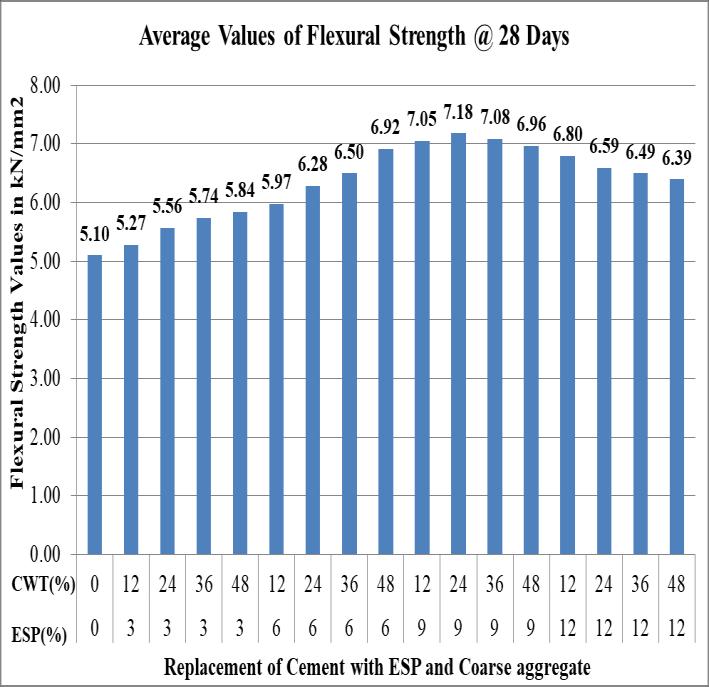

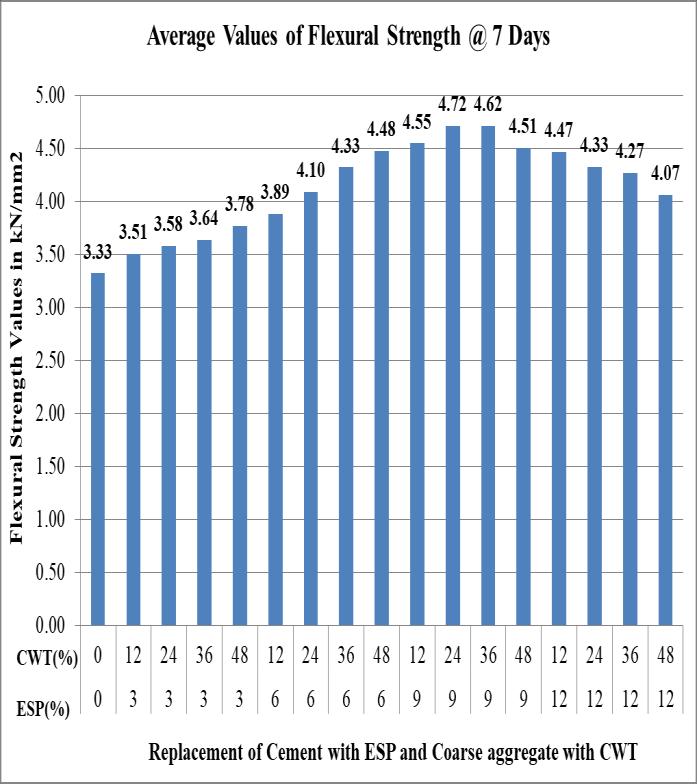

TheresultsofflexuralStrengtharedeterminedonbeam specimenusingUTM.Theresultsfor7daysand28days areshowninfigure5.6andfigure5.7

Figure 5.7: Flexural Strength of Concrete mix using ESP and Ceramic Tiles Waste after 28 days of curing.

Presentstudyconcludesthefollowing:

1. TheresultsofobtainedbySlumptestmethodconcluded thatworkabilityofmixincreaseswiththeincreaseinthe ESP content. This may be attributed to the extended settingtimepropertyofESP.Butincreaseinworkability ofconcretebyESPislimitedto9%replacement.

2. The strength results concludes that compressive strength,SplitTensilestrengthandFlexuralStrengthof concretecontainingESPandCWTaggregatesincreases upto 9% ESP and 24% CWT. The increase in strength maybecontributedduetoitsfinenessandbetterbinding propertywithotheringredients.

3. The results concluded that the maximum value of compressive strength obtained at ESP9%CWT24% are 17.47Mpaand25.30Mpaat7and28daysofcuring.

4. Themaximumvalueofsplittensilestrengthobtainedat ESP9%CWT24%are3.92Mpaand5.69Mpaat7and28 daysofcuring.

5. The maximum value of flexural strength obtained at ESP9%CWT24%are4.72Mpaand7.18Mpaat7and28 daysofcuring.

Figure 5.6: Flexural Strength of Concrete mix using ESP and Ceramic Tiles Waste after 7 days of curing

6. Concrete mix ESP9%CWT24% can be considered as optimummixintermsofstrengthandeconomy.Thusit canbeusedasstructuralconcretewithoutcompromising itsstrengthproperties.

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page676

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

1. BatritiMonhunR.Marwein(2016), “A REVIEW PAPER ON UTILISATION OF CERAMICWASTEINCONCRETE”, InternationalJournalofScientific&EngineeringResearch, Volume7,Issue4,April-2016ISSN2229-5518.

2. E.H.Wadie(2017), “The Use of Ceramic Tile Waste as Aggregate in Concrete”, International Journal of Scientific & Engineering Research, Volume 8, Issue 11, November-2017 ISSN2229-5518.

3. AmbikeshSingh(2018), “Ceramic wasteinconcrete - A Review”, Recent Advances on Engineering, Technology andComputationalSciences (RAETCS), 78-1-5386-16864/18/2018IEEE.

4. ARUNKUMARC(2018), “APARTIALREPLACEMENTOF EGG SHELL POWDER FOR CEMENT IN CONCRETE”, International Journal of Creative Research Thoughts (IJCRT), Volume6,Issue1February2018|ISSN:23202882.

5. Sathvik S, Edwin. A (2019), “Experiment of Partial Replacement of Egg Shell Powder and Coconut Fibre in Concrete”, International Journal of Innovative Technology and Exploring Engineering (IJITEE) ISSN: 2278-3075,Volume-8,Issue-6S4,April2019.

6. SherinKhan(2019), “USE OF CERAMIC TILE WASTE IN CONCRETE MIX BY PARTIAL REPLACEMENT OF COARSE AGGREGATE: AN EXPERIMENTAL STUDY”, JournalofEmergingTechnologiesandInnovativeResearch (JETIR), March 2019, Volume 6, Issue 3, (ISSN-23495162).

7. POORNIMA K (2019), “A Review Study of Egg Shell Powder as a Cement Replacing Material inConcrete”, International Research Journal of Engineering and Technology (IRJET),Volume:06Issue:05|May2019.

8. Vaibhav R. Shirodkar (2020), “The Effects of Nano Materials and Egg Shell Waste Material on the Physical and Strength Properties of Floor Tiles”, International Journal of Creative Research Thoughts (IJCRT), Volume8,Issue6June2020|ISSN:2320-2882.

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page677