International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Gamero-Inda, E1., Godínez-García, F.J2., Martínez-Rivera J.A3 ., Guerrero-Rivera R4 ., BetancourtMendoza, E5 .

1,2,3,4 TECNM/IT Durango, Professors, MSc. in Engineering, Durango, México.

5 TECNM/IT Durango, Student, MSc. in Engineering, Durango, México. -----------------------------------------------------------------------

The project presented consists of a temperature control system, based on a PID (Proportional, Integral, Derivative) controller in a pole placement scheme, for a cryogenic freezerthatallows atrajectorymonitoring controlto carry out the freezing of bovine semen samples according to internationally accepted temperature profiles. and thereby try to increase the survival rate of bovine sperm, which is currently only considered to be 50% by traditional means of freezing this type of sample. The system is based on discrete components that are very easy to acquire and handle to offer an alternative in the control of cryogenic systems and processes, seeking a satisfactory cost-benefit ratio. An important point to highlight is that this control system is designed ad-hoc as the first version for a cryogenic freezer that is also under development by the membersof this sameproject.

Keywords:

Temperature Control, cryogenic system, Preservation of bovine semen, PID control, Instrumentation.

Thisproject respondstothe need tooffera temperature control system for a cryogenic freezer used for freezing bovinesemensamples.Thisneedwasexpressedtousby the “Asociación Ganadera Local de Durango A.C.” (Local Livestock Association of Durango A.C.) since the associatesrequireanoptionforthedevelopmentoftheir cattle herds based on assisted reproduction (artificial insemination) to achieve genetic improvement and obtain greater economic and reproductive performance. In the city of Durango, there is a genetic improvement centerofthestategovernmentlinkedtotheAssociation, however,thesystemavailableisalargecryogenicsystem

for a large number of semen samples and that itself is neither economical nor attractive. The temperature controlsystemdescribedinthisworkaimstobeaviable alternative for its application in cryogenic freezers for applicationssuchastheonementionedabove,forwhich theproblemto besolvedisexplained below;Inthefirst place, it was thought to adapt an existing and available system, but in the end, it was decided to design and develop a fairly new cryogenic system whose characteristics include that it can be adjustable to the necessary volume according to the number of straws that an associate or a group of them needs. For this, the temperature control system must also be able to adjust to the variable volume and also be able to follow a temperatureprofilethatgoesfromroomtemperatureto almost 196°C below zero, which is the temperature of liquidnitrogen.

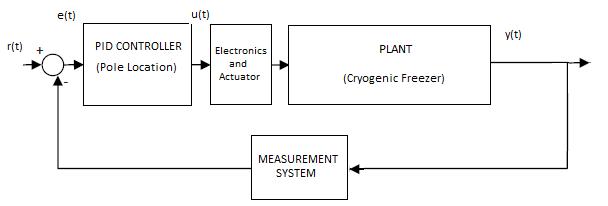

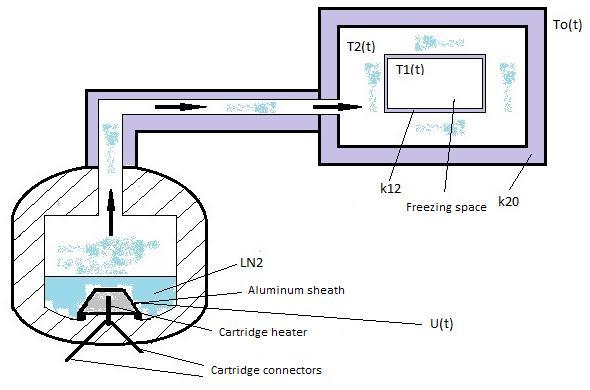

This control is based on the pole placement technique [3]thatallowstrackingofthetemperatureprofileasthe reference signal. The implementation of the control is doneusingdiscretecontinuousanddigitalelementsina PID control scheme with a model of a continuous plant. Theblockdiagramofthesystemisseeninfigure1

Figure 1.BlockDiagramoftheTemperatureControl System.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Most general-purpose temperature measurements occur withina fairlylimited range betweenfreezingwaterand boiling water ( -10°C to 120°C), but what happens whentemperatureswellbelow0°Chavetobemeasured? [2]. The laws of physics are still valid, however, the materials undergo important transitions and their characteristics and behaviors change radically. The performance, linearity, and other critical attributes of sensors and their materials change dramatically in very low°Cranges.Whilefamiliaritywithwaterturningtoice or steam is common, changes at cryogenic temperatures aremuchmoredifficulttograspandunderstand.[11].

For temperature reference in this project, we use the cryogenic thermometer “Traceable® model 6458” from ControlCompany.

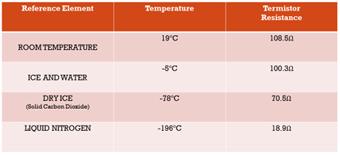

Toavoidasmuchaspossibletheproblemsandhighcosts in materials and sensors for cryogenic temperatures, in thisproject we decided to prove thetemperaturesensor Pt100RTD[12]sinceithasverylinearcharacteristicsin a wide range of temperatures. We practically prove the RTD by testing it to obtain its characteristic curve. The test consisted of obtaining various RTD resistance reference points relative to known temperature values. Thevaluescanbeseenintable1.

Table 1.ResistancemeasurementsofRTDPt100

Temperature ( ° C) Resistance Ω

-250 -200 -150 -100 -50 0 50 0 20 40 60 80 100 120

Figure 2.Experimentallyobtainedcharacteristiccurve ofthePt100RTD.

As can be seen in figure 2, the RTD has a quasi-linear characteristic in the region of interest for the temperaturemeasurements,whichfacilitatedthedesign ofthemeter.

2.2 End actuator handling.

Regardingthefinalactuatorofthecontrolsystem,which inthiscaseisa25-wattOMEGA®CYC320-HTRcartridge heater [13], which is placed at the bottom of the containerwithliquidnitrogen(LN2)inatruncatedcone type aluminum sheath to avoid direct contact with the LN2, see figure 3. In figure 4 we can see the cartridge heater in place in the LN2 container. When feeding the heater, it transfers heat to the LN2 which causes the evaporation of nitrogen and with the increase in pressure, it is forced a flow of nitrogen gas whose variation allows temperature control in the cooling chamberofthebovinesemensamplefreezer.

Figure 3.Cartridgeheaterandaluminumsheath

International Research Journal

Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

programmable freezing systems at different freezing rates, for which a commonly accepted curve is shown belowandisthebasisofwhatisintendedtobefollowed intheprojectwithsomesmallvariationsintheverylowtemperaturezone.

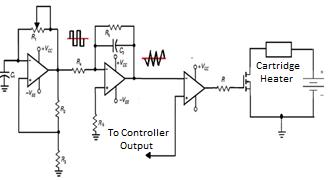

The heating cartridge power supply is 25 volts of direct currenttogenerateamaximumpowerof25watts,which is enough to vary the pressure of the container with the LN2. To supply the heater, a simple power circuit was designed with a Pulse Width Modulator (PWM) and a MOSFET power transistor. The system diagram for the freezercontrolfinalactuatorisshowninFigure5.

Figure 5.Powercircuitfortheendactuator.

In the specialized literature on the subject, it is mentioned that bovine semen can be preserved by freezingthesamplesemployingnitrogengas(N2),liquid nitrogen(LN2),orbyothermeansthatprovidecryogenic temperatures, through programmable automated systems capable of following a certain rate of freezing. [4].

The freezing curves of biological samples of bovine semen are not common in the literature; however, there are references [1] that describe various freezing rates that have been carried out experimentally and have achievedacceptableresults.Mostofthepublishedworks concerning cryopreservation use automated

0

-50

-100

-150

50 0 2 4 6 8 Temperature ( ° C)

-200

Time (minutes)

Figure 5.Freezingprofileofbovinesemensamples[1].

Figure 5 shows the curve with different freezing rates, each one for a specific time, which allows the biological samples to adapt to the ambient conditions by varying thetemperaturefromroomtemperaturetominus150°C after 8 minutes, the sample can be placed in liquid nitrogen for storage and preservation. The above process offers us the opportunity to obtain a better survival rate of the sample, than just dropping the sample directly into the liquid nitrogen at t=0, which is how it is practically done with a good number of cattle producersinthestateofDurango.

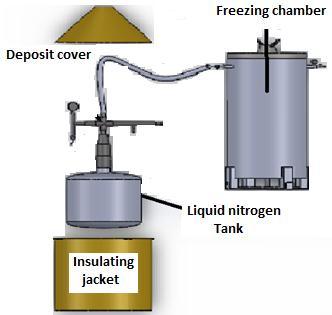

3.2 Description of the Plant to be Controlled.

The cryogenic freezer is a thermal system in which the heating element is embedded in the space where the liquid nitrogen is located so that when the temperature of the nitrogen increases, an increment in pressure is generated in the container and the nitrogen gas enters the freezing space where the straws containing the bovinesemensamplesarelocated.Aschematicdiagram oftheplantisshowninFigure6.

e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

temperature control system, therefore, to obtain the transfer function, the materials of the thermal system that are considered are glass as straw material, glycerol as bovine semen cryoprotectant, high density expanded polystyrene as insulating material and nitrogen as the transmissionmedium.

The plant to be controlled is a thermal system that, due to its structure and construction, the model results in a second-order system, which can be verified with the systemofsimultaneousequationsthatareappliedtothe plantthatiswrittenas:[5]

( ) ( ) ( ) (1)

( ) ( ( ) ( )) ( ( ) ( )) ( ) (2)

Where:

m1:Glycerolmass.

C1:Specificheatofglycerol.

k12:Thermalconductanceofglass.

Figure 6.Planttobecontrolled.

The prototype construction of the cryogenic freezer is showninfigure7.

k20:Thermalconductanceofexpandedpolystyrene.

m2:Nitrogenmass.

C2:Specificheatofnitrogen.

T0:Roomtemperature.

T2:Medium2temperature

T1:Medium1temperature

U:Controlsignal.

Manipulating the equations with numeric values for the constants and using Cramer's rule, the transfer function fortherelationshipbetweenT1andUisobtained:

( ) ( ) ( ) ( )( ) (3)

construction.

The materials with which the plant is built have a great influence on the design and performance of the freezing

Considering T0(s) as a system perturbation that can be handled.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

The proposed controller for the system is a PID controller designed by pole location whose design generates a control in continuous time. The controller approaches a reference tracker, which, in this case, the reference signal is a succession of ramps with different negativeslopesthatdrawthedesiredprofileforfreezing bovine semen samples, see figure 5. The proposed PID controllerequationisinitsparallelform:

(4)

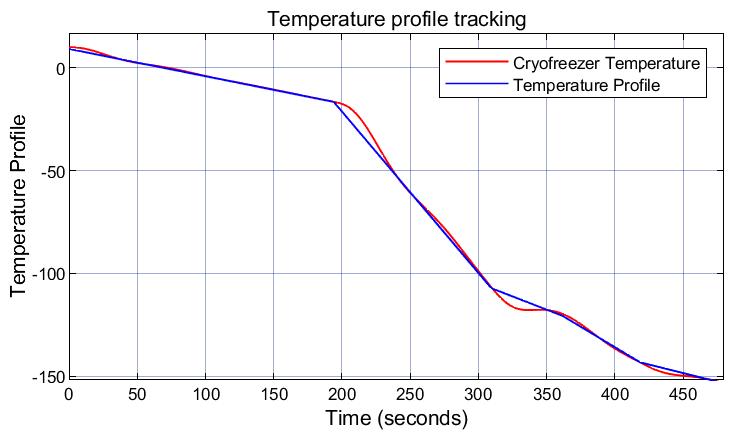

that the tracking of the ramps is achieved within 98% and the control corrections to the change in slope are achieved within the first 32 seconds, which is fast enough to ensure a smooth change in freezing temperature and minimally affect the process on the bovinesemeninthestraws.

WhereNisafilterfactorforthederivativepart.

Due to the characteristics of the reference signal, it is appropriate to think about the pole location scheme for the design of the controller, since this technique is the basis of the design of RST (Reference Signal Tracking) digitalcontrollers[6].

For the design by pole assignment, the plant must be at least of second order and counting on the model of our plant,weproceedtothedesignofthecontroltakinginto account the following design restrictions: Maximum settling time (Ts) of 45 seconds, and a maximum overshoot (Mp) of 5%. The simulation was carried throughthe Matlab®program.

The application of the control in a practical way has not been achieved 100% because the final version of the prototypeofthecryogenicfreezerisnotavailableyet.

Withtheresultsobtainedfromthesimulationsandsome of the partial practical measurements since the final versionoftheprototypehasnotbeenachieved,itcanbe saidthatwhatisobtainedis promisinginthesensethat, concerning the time constants of the controller, the response of the plant is fast enough to follow the temperature profile that is used as the reference of the controlsystem.

Although, the above would only be valid if in the final version of the prototype an efficiency of at least 79% is achieved in the energy transmission from the liquid phaseto thegaseous phase ofnitrogen, whichis theone that comes into direct contact with the straws that containbovinesemensamples.

The graph in figure 8 shows the tracking of the freezing profile of the bovine semen samples and it can be seen

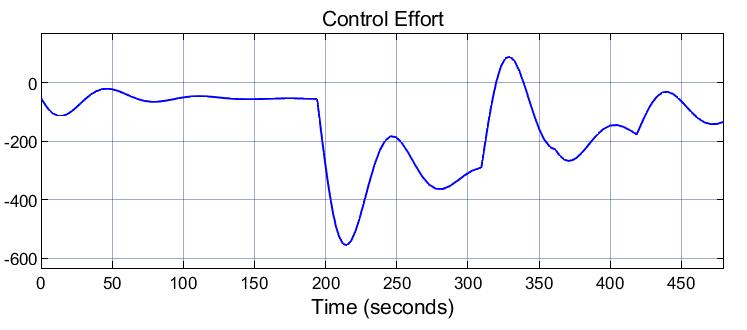

Figure 9 shows the control effort developed by the controller, which does not have sudden changes, and thatallowsustoensurethatthepowercircuitthatfeeds the cartridge heater works efficiently and the necessary power can be transmitted to modify the pressure in the containerwiththeliquidnitrogen.

Figure 9.Controlsignalofthesystem.

Regarding the results by simulation or practically obtainedonthefreezeritcanbeseenthatthisprojectis a viable alternative to other cryogenic freezers and applied methods far more expensive for the assisted reproduction of livestock. At the actual stage of the project, it is obvious that is needed to enhance some

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

characteristics of the cryogenic freezer to finally obtain the expected efficiency near the 80% to ensure the results we see in the simulations. At this time, the adaptationstoachievemoreefficiencyareinprogress.

WewanttoexpressourgratitudetoboththeTecnológico NacionaldeMéxico(TECNM)forthefinancialsupportto the project and the Instituto Tecnológico de Durango (ITD)forallthefacilitiesprovidedforthedevelopmentof thiswork.

[1]Arango,J.E.,Durán,C.M.,Lizarazo,J.E.,&Duarte,J.A. (2017). "Sistema automatizado para el congelamiento de semen bovino". Revista Colombiana de Tecnologías deAvanzada

[2] Bar-Cohen, Yoseph. (2016). "Low temperature materialsand mechanisms". Taylor&FrancisGroup.

[3]Castaño, S. A. "Control PID por Asignación de Polos", https://controlautomaticoeducacion.com/controlrealimentado/control-pid-por-asignacion-depolos/?unapproved=11306&moderationhash=3de69dda2d17adef83eb5cb6e9058a00#comm ent-11306.

[4]Dalal, J., Kumar, A., Dutt, R., Singh, G., & Chandolia, R. (2018). "Different Cooling Rates for Cryopreservation of Semen in Various Livestock Species: A Review". International Journal of Current Microbiology and AppliedSciences

[5] Jacquot, R.G.. Modern Digital Control Systems . Routledge,2nd ed.MarcelDekker,Inc.(1995).

[6] Landau, I. D., & Zito, G.. Digital Control Systems (Design, Identification and Implementation), SpringerVerlag,London,Ltd.(2006).

[7] Ribeiro-Peres, A., Munita-Barbosa, L., YumiKanazawa,M.,Mello-Martins,M.,&FerreiradeSouza, F. (2014). Criopreservación de espermatozoides bovinos extraídos de la cola del epidídimo utilizando los métodos convencional y automatizado. Arch Med Vet

[8] Santos, M., Sansinena, M., Zaritzky, N., & Chirife, J. (2013). “How important are internal temperature gradients in frenchstraws duringfreezingofbovine

sperm in nitrogen vapor?”, http://bibliotecadigital.uca.edu.ar/repositorio/invest igacion/how-important-are-internal-temperature.pdf

[9] Swartz, J. M., & Lawrence, G. R. (s.f.). Fundamentals forUsageofCryogenicTemperatureControllers. Lake ShoreCryotronicsApplicationNote,9.

[10] Vishwanath, R., & Shannon, P. (2000). Storage of bovine semen in liquid and frozen state. https://www.sciencedirect.com/science/article/abs/ pii/S0378432000001536?via%3Dihubi

[11]A.Alekseev,BasicsofLow-temperature RefrigerationLindeAG.Munich,Germany.

[12]Pallás,R.A.,“SensoresyAcondicionadoresdeSeñal”, Alfaomega-Marcombo,4ªed.(2008).

[13]https://mx.omega.com/pptst/CYC320.html.