International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1

1,2,3,4 Rao Bahadur Y Mahaballeswarappa Engineering Collage Ballari 583104 ***

Abstract - In the present electric vehicle scenario, diesel engines are playing a major role in heavy vehicles. This is the motivation for analyzing the influence of air in the combustion chamber of a diesel engine for Bio diesel with a modified engine head. This modified head provides immense excitement for a smooth mixture of air/fuel combustion. This may have an impact on the reduction of emission parameters like HC, CO, and NOx in diesel engines. Based on this, to comprehend engine behavioral patterns of bio diesel influence, along with engine head modification by air swirl. To initiate the swirl inside the combustion chamber, various methods like changing the cylinder head, piston, and inlet manifold system is relevant. We select a diesel engine cylinder to modify in to generate air swirl. The air swirl ratio is assessed with conventional and modified cylinder heads. The performance of modified and conventional cylinder heads is compared in the experimental investigation work. Based on the comparison, the performance parameters for modified cylinder head with Biofuel have increased, like BTE and other efficiencies, BSFC has lowered, and emission levels such as HC, CO, and NOx could indeed be compared. When compared to traditional cylinder heads, modified cylinder heads with biodiesel produce fewer greenhouse gas emissions.

Key Words: Engine head modification, Bio-diesel, Mahua oil, Karanja oil, 20% blend with diesel....

Thespark-ignitionengineinitiallyinventedin1876GermaninventorNicolausA.Otto,whereasthecompression-ignition enginefirstinventedbyRudolfDieselin1892.Theyinvestigatedinternalcombustionenginesamongthefirsttodoso.Diesel engineshavebeenproventobemoreattractivetopetrolenginesbecauseoftheirlowerfuelconsumption,loweremissionsof carbonmonoxide,andhighertorques.However,theytooareamongofthemostapparentdriversofairpollutiontoxins,thusit iscrucialtolimittheirusetoaminimuminordertoavoidissuesfromairpollution.

"BioFuel"referstotheprocessofconvertingbiomassintoliquidfuel.Thisisusedasasubstitutefuelfor"fossilfuel." EthanolandbiodieselarethemostregularlyutilizedBiofuel.

1.2 Classification of Biofuel.

1.Ethanol.

2.Biodiesel.

1. Ethanol (CH3CH2OH).

Itisasustainablefuelmadeupofvariousplantresourcescalledas"biomass."Ethanolisanalcoholthatisusedasamixing ingredientwithgasolinetoboostoctanenumberwhileloweringemissionparametersandpollution.Themostfrequentblends areE10andE15,whichareethanol10%andpetrol90%andethanol15%andpetrol85%,respectively.

Thefermentationisthemostprevalentmethodofmanufacturingethanol.Bacterialandfungusdigestthecellulosetoproduce alcoholusingplantsugar.

Itisafuelsourcemadefromneworoldvegetableseeds,blossoms,plants,andotherplantmaterials,aswellasanimalfat. Biodieselisanontoxicandbiodegradablealternativetopetroleum-baseddieselfuelthatburnscleanly.Itismadebymixing alcoholwithvegetableoil,animalfat,andotheringredients.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Biodiesel,likediesel,isemployedtopowercompression-ignitionengines.Itmaybeblendedwithjustaboutanyamount,even B100(purebiodiesel),althoughthemostfrequentblendsareB10(Biodiesel10%diesel90%)andB20(Biodiesel20percent anddiesel80percent).

EngineData

1500rpm,CR:18,4-stroke,SingleCylinder,220o isvalveopen andclosecrankangle

InletBoundary VelocityInlet6m/sisgivenbycalculatingitfromenginerpm

LowandHighliftapproachisusedforValve,fullvalveliftis 8mmand110o isthecrankangleatthatposition.Piston positionissetcorrespondingly.

ThefollowingmethodologieswereinvestigatedforstudyingtheflowdynamicswithinthecylinderusingCFD:Cylinderanalysis testbench,creatinggenuineCADgeometryfromanexistingdiesellabengineforthevalves,cylinderhead,piston,andcylinder.

•Atthisstage,theCADgeometrythatwillbeusedfortheanalysisisimportedintotheCFDapplication.

•Onlytheinternaldomainsintheinletandcylinderswouldbeevaluated;thisisknownasfluiddomainextraction.

•Afterextractingthefluiddomain,thesurfaceis2Dmeshedforlaterprocessing;a3Dvolumecellisgeneratedinsidethedomain usingthe2Dmeshing,andthegoverningequationsaresolved.

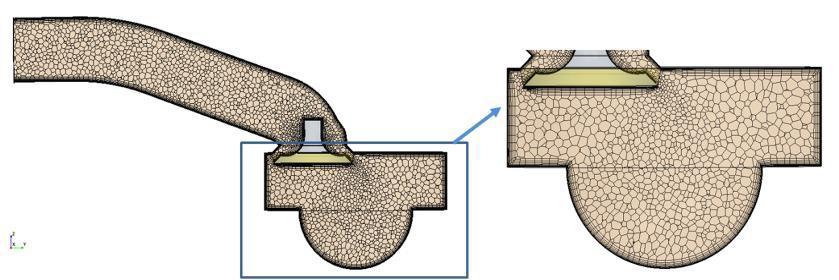

•After developing 3D volume cells, the cells' consistency will be evaluated to confirm that the governing equations are appropriately converging. A polyhedral shape volume cell is employed in this investigation. The figure below depicts the distributionofvolumecellsinthemodel.

Thefundamentalbenefitofpolyhedralmeshesisthateachcellhasahighnumberofneighbors,allowingforprecisegradient approximation.Furthermore,polyhedronsarelesspronetostretchingthantetrahedrons,resultingingreatermeshconsistency andnumericalstabilityofthesystem.Furthermore,numericaldiffusionisreducedduetomassinterchangeacrossseveral faces.Asaresult,theanswerismoreexactwithasomewhatlowercount.

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page642

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Inthisinvestigation,62cellswithdiameterssmallerthan1mmwereselectedbecausethebulkofincylinderexperiments employthisnumber.

Thesolverconfigurationiscompleteafterthepreprocessingprocessesmentionedbelowaredone.

Inthisphase,themodelsrequiredtosolvethefluidflowarechosen,andboundaryconditionsareappliedattheintakeand outflow.Reportsandcontoursceneriesarealsogeneratedasneeded.Additionalinformationisprovidedinthetablebelow.

Air IdealGas Air flow in cylindermodeled as airmediumusing Idealgasapproach

Time TransientState

Turbulence K-Epsilon

Transientapproachisapproachisusedinwhichflowfield willvarywithrespecttotime.

TocaptureTurbulenceinthemodelK-Epsilonmodelisused whereKisturbulentkineticenergyandEpsilonisturbulent dissipation

FlowNature TurbulentFlow ReynoldsnumberofthisstudyisRe>3000

Table - 2:Modelsforaddressingflowfieldproblems.

EngineData

1500rpm,CR:18,4-stroke,SingleCylinder,220o isvalveopenand closecrankangle

InletBoundary VelocityInlet6m/sisgivenbycalculatingitfromenginerpm

ValveAndPiston

LowandHighliftapproachisusedforValve,fullvalveliftis8mm and110o isthecrankangleatthatposition.Pistonpositionisset correspondingly.

Table 3.2:Themodelintroducesaboundarycondition.

Contoursand report generation: Prior to executing theevent, reportsare created to measure swirl,tumble, and TKE,and contourscanbegeneratedeitherduringorafterthisstep.

At thispoint,thesimulationwill provide results, and the next step will be to test the convergence of documents and flow variables.Reportvariablesandcontourinformationwillberetrievedifallconvergencerequirementsaresatisfied.

Fig -2:CFDanalysis

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Thefirstimageillustratesstrain,thesecondexhibitsvectorplotsindicatingflowdirection,andthethirddepictsthevector plotitselfbutintheformoflinelinkingvectors;tinyfluctuationsintheflowfieldareseeninthisplot.

AllthreephasesofmodelingarecompletedusingSTARCCM+V12.02technology.ItisaCFDsoftwareindustryleader,with applicationsspanningfromaviationtoelectroniccooling.

ThenameStarCCM+standsforSimulationofturbulentflowinanyregionusingcontinuumcomputationalmechanics.

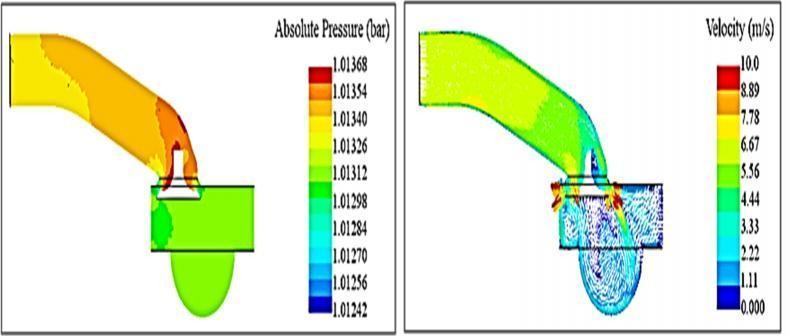

CAD Model of Head modification: Circular cut cylinder head: Dimensionforcircularcut3x3mm.

Fig -3:CADModel

Fig -4:Bio-DieselBlending

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1. Dieselenginewithasinglecylinder.

2. Aloadededdycurrentdynamo.

3. Asystemformeasuringfluidflow.

4. Amethodofwatercooling.

5. Motoroil.

6. ALV5EmissionTestingKit.

1. Verifythereisenoughfuelfortheexperiment.

2. Onwaterwithaflowratesuitableforcoolingjackets.

3. Beforecommencingtheexperiment,removetheburden.

4. Takethenecessaryreadingsatcertainintervalsandgraduallyraisetheload.

5. Repeattheexperimentafter15-minuteintervals.

6. Calculatedataobtainedinatable.

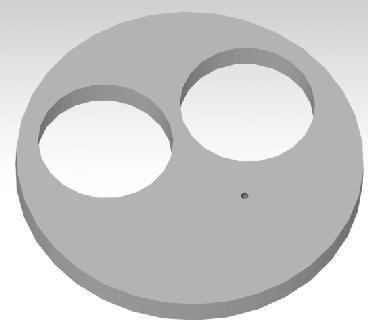

AscomparedCOemissionisreducedslightlywithbiodieselcomparedwiththediesel.Biodieseldoesnotcontaminatethe environment.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

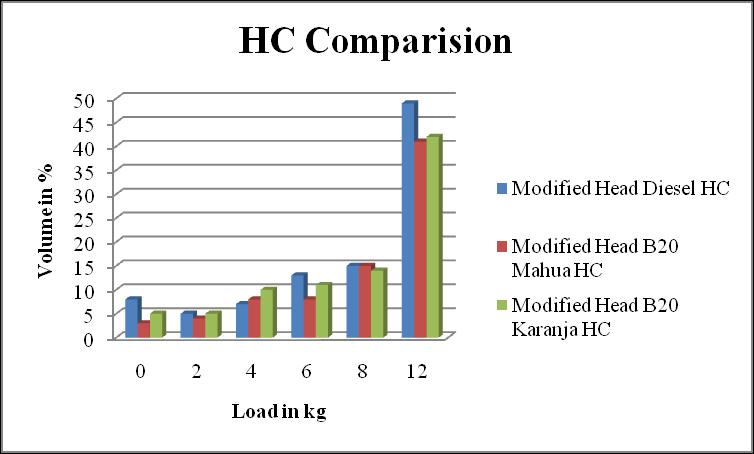

As compared HC emission is reduced significantly due to the presence of bio diesel. Bio diesel does not contaminate the environment.

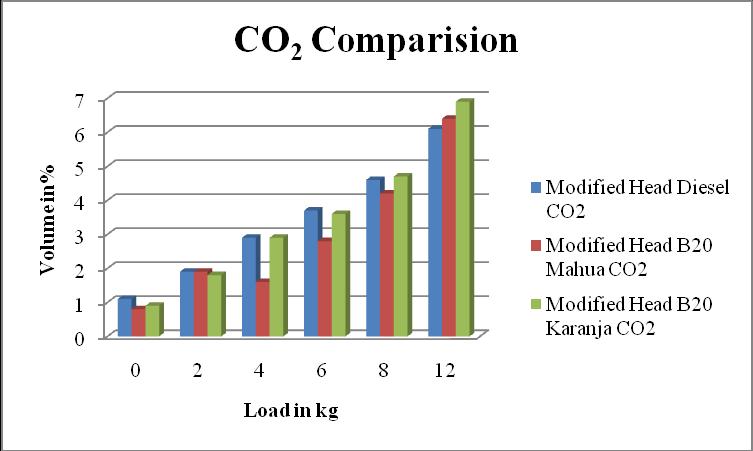

AscomparedCO2 emissionisincreasedslightlyduetothecompletecombustionoccurringinsidethecombustionchamber.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

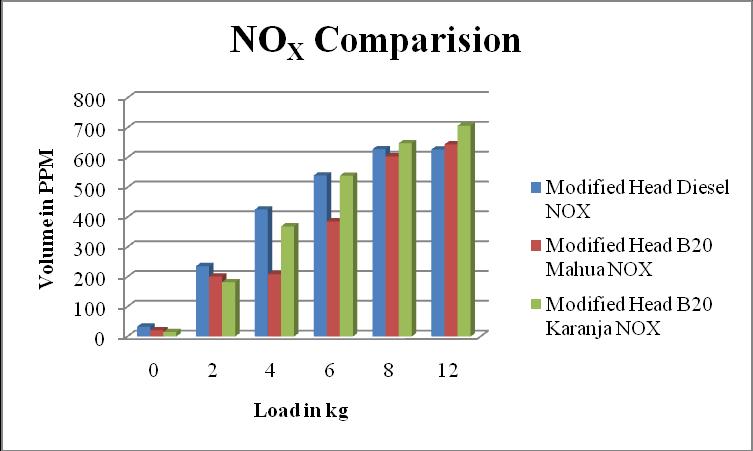

AscomparedNOXemissionisreducedinMahuabutslightlyincreasedinKaranjathisismainlyduetothechemicalcomposition oftheoil.

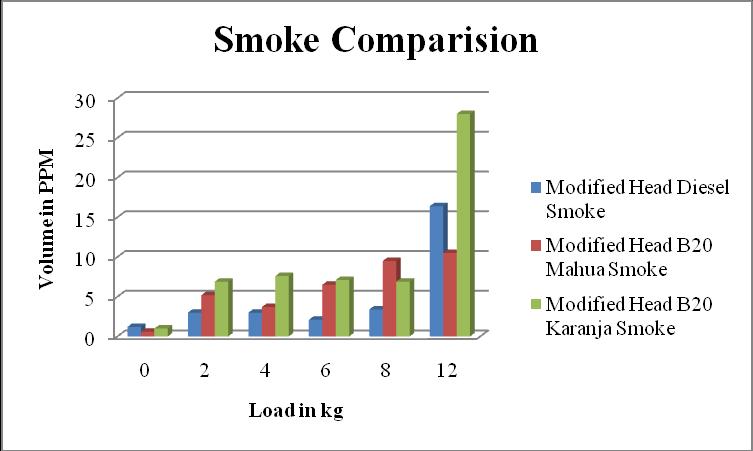

SmokeistheindicationofburningofHydro-carbonswhichishighinbiodieselcomparedtoregulardiesel.Smokeisproduced mainlyduetoextractionprocessoftheoilfromseed.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1. Duetothemodificationofengineheadtheemissionparameterisdrasticallyreduced.

2. Smokeisincreaseddrastically.

3. COandHCemissionisdrasticallyreducedinmodifiedheadbiodiesel.

4. NOXandCO2arereducedinmodifiedheadbiodiesel

1. Useofanti-smokingagentisrequired.

2. Blendsofhigherpercentagetobeused.

3. Antisoothingagentbehaviouralpropertiestobestudied.

1. PERFORMANCEANDEMISSIONCHARACTERISTICSOFACIENGINEFUELEDWITHDIESEL -BIODIESEL (MAHUA/MUSTARD) BLEND WITH DIETHYL ETHER ADDITIVE - N.Vadivela,* P.Somasundaram M.Krishnamoorthi.

2. ACOMPARATIVESTUDYOFSTABILITYCHARACTERISTICSOFMAHUAANDJATROPHABIODIESELAND THEIRBLENDS- N.Acharya P.Nanda S.Panda S.Acharya

3. BIODIESEL PRODUCTION FROM MAHUA (MADHUCA INDICA) OIL HAVING HIGH FREE FATTY ACIDSShashikant Vilas Ghadge Hifjur Raheman

4. EMISSIONSANALYSISONMAHUA OILBIODIESEL ANDHIGHER ALCOHOL BLENDSIN DIESEL ENGINEArulprakasajothi Mahalingam Yuvarajan Devarajan Santhana krishnan Radhakrishnan Suresh Vellaiyan Beemkumar Nagappan

5. InternalCombustionengineby V GANESHAN 4th edition.

6. InternalCombustionEnginefundamentalsby John B Heywood 2nd edition.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page648