International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN: 2395 0072

Experimental Work on Previous Concrete for Pavement Applications

D.Sravya1 , B.Srinivas2 , D.Kranthi3 , SK.Gouse Basha4, A.Gopi Krishna5

1Guide & Assistant Professor of Department of civil Engineering, Velaga Nageswara Rao (VNR)College of Engineering, (Approved by AICTE and affiliated to JNTUK, Kakinada), G.B.C. Road, Ponnur 522124, GUNTUR, A.P INDIA. 2,3,4,5 UG, Student, Department of civil Engineering, Velaga Nageswara Rao (VNR) College of Engineering, (Approved by AICTE and affiliated to JNTUK, Kakinada), G.B.C. Road, Ponnur 522124, GUNTUR, A.P (INDIA). ***

Abstract - Constructionactivitiesmainlydependon natural resources as a source of raw materials, leading to ecological imbalance. So, the construction industries tend to depend on alternative materials as the source of aggregates in concrete production. Generally, changes in the natural landscape have created a serious problem of rainwater drainage inmanycitiesinIndia.ThePreviousconcretehasbeen used inthis experimental work. Inthis study, pervious concrete 15% to 40% voids can be achieved without use of fine aggregate. Generally,singlesizecoarseaggregatesareusedfor the development of mixture design of pervious concrete. However, the quality of previous concrete resulting different from conventional concrete. Thus, this study aims to improve the property of previous concrete through different applications. Thevoidratiohasbeencomparedtopreviousand conventionalconcrete.TheCementcontentof250kg/m3 to400 kg/m3 with an interval of 50 kg/m3 was used in the developmentofmixturedesignofperviousconcrete.Thedensity of previous concrete is increased while improve of cement content. The development of mixture design of pervious concrete,twodifferentsizesofcoarseaggregatesof10mm 20 mmand4.75mm 10mmwereusedinthisexperimentalwork.

Key Words: Workability,Compressivestrength,VoidRatio, Density.

1. INTRODUCTION

Rapidlygrowinganduncontrolledchangesinthenatural landscape have created a serious problem of rainwater drainageinmanyIndiancities.Withnaturaldisasterslike floodsincreasingeveryyear,thereisaneedtosetupspecific waterdisposalsystemsinurbanandsemi urbanareas.Due to lack of modern drainage infrastructure in most of the citiesofIndia,thisproblemisincreasingdaybyday.During monsoons,mostoftherainwatercollectsontheroads.Due to lack of proper design ofdrainagesystem,rainwateris seenontheroad.Inmostcities,thedrainagesystemsare alreadycloggedandintheeventofarain,waterisseenonthe road.Duetothisreasontrafficisjammedintherainanditis alsoaserioushealthhazardforthelocals.Thisproblemis serious in large cities and industries, where roads are constructedwithoutdesigningaseweragesysteminmost openareas.Duringrains,roadwaterremainsstagnantfor hoursatatimeduetopoorstormwatermanagement.This causeserosionoftheroadanddecreasestheageoftheroad.

In the old cities, outlets were provided for rainwater disposalwhichdivertedrainwaterintotheriver.Thedesign of these outlets was so arbitrary that rainwater would reach the lower pointof its own topography. Foot wells were a common feature ofold cities designed to redirect rainwater into groundwater. This type of storm water management design is no longer seen dueto unplanned urbanization.Cities are also replacing impermeable land with impermeablesurfaces.Theproblemisexacerbatedby thefactthatthedrainsdonotgetenoughslopetodrawWater fromthesurfacewater.Inourcountry,industriesandcities are facing water crisis due to over exploitation of groundwater and lack of provision for ground water recharge. Groundwater level is constantlyfalling. Falling waterlevelsarealsodeepeningthewellinliftingwater.

Perviousconcreteshavebeenusedinmanyarea,but its applications are limited because of itsrelatively low strength.Tennisetal.(2004)reportedtheapplicationsof perviousconcretewereinmanyareassuchaslowvolume pavement,residentialroads,sidewalks,parkinglots,low water crossings, and tennis courts, sub base of conventional concrete pavement, patios,artificial reefs, slope stabilization, well linings, and tree gates in sidewalks, hydraulic structures, swimming pool decks, pavementedgedrainsandnoisebarriers.Indianeconomy is developingat a rapid pace and hence conservationof naturalresourcesisofutmostimportance.Pavementcan be considered as a life line for progress of any nation. Modern day infrastructure calls for use of impervious surfacesofpavementwhichresultsintolesserpercolation ofwaterintothesoil.

Thisleadstofaster,largervolumeandhighly polluted water from run off reaching treatment plant leading to imbalance in ecosystem.

Therefore,moderncementconcretepavement cannotbeaviableoptionforwaterrecharging.

Indiais mainlydependentonraintomeetits water requirement which is plenty during monsoonseason.

In monsoon, every city faces a serious problem of water logging and municipality

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page56

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN: 2395 0072

have to paya heavy cost to evacuate logged water.

The artificial reefs, slope stabilization, well linings,andtreegatesinsidewalks,hydraulic structures, swimming pool decks, pavement edgedrainsandnoisebarriers.

Table -1: ComparisonofPropertiesofConventional ConcreteandPerviousConcrete

Properties Conventional Concrete Pervious Concrete

VoidRatio 3% 5% 15% 40%

Compressive Strength 20MPa 50 MPa 5MPa 25 MPa

Density 2400kg/m3 to 2500kg/m3 1800kg/m3 to 2100kg/m3

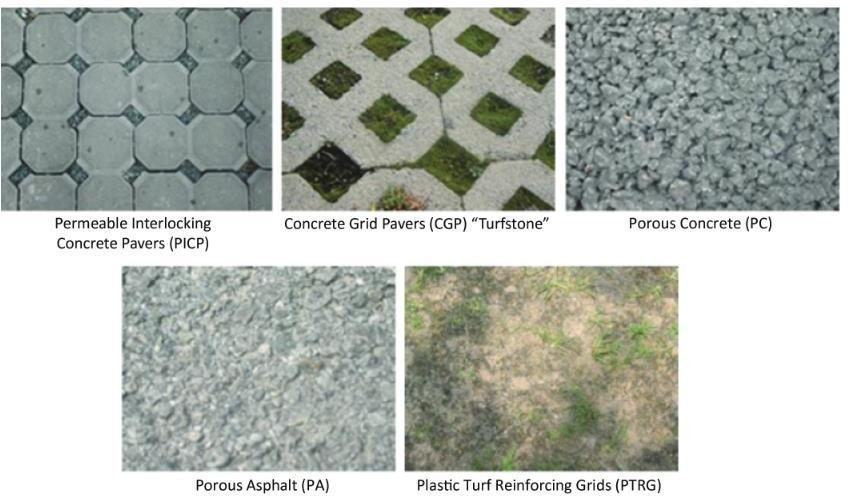

Fig 1:Methodsfor

1.1 Previous concrete

disposed

rainwater

Pervious concrete is a mixture of cement, coarse aggregates and water. Fine aggregates are notused in the mixtureofperviousconcrete.Inperviousconcrete15%to 40% voids can be achieved without use of fine aggregate Generally, single size coarse aggregates are used for the development of mixture design of pervious concrete. In perviousconcrete,carefullycontrolledamountsofwaterand cementitiousmaterialsareusedtocreateapastethatforms a thick coating around aggregate particles.

2. EXPERIMENTAL PROGRAMME

The materials used for preparing the pervious concrete during the present investigation are natural coarseaggregate,VSIcoarseaggregate,cement,waterand chemical admixture.OrdinaryPortland cement,asper IS 12269 (2013) is used for the present investigation. The physical properties of ordinary portland cement are presentedinTable 2

Table 2: PropertiesofphysicalofOPC

Propertiesfor53 gradeOPC Result Availed Specifica tion inIS 1226 9 (201 3)

Fig 2:Previousconcretecube

1.2 Applications

Pervious concretes have been used in many areas.

Its applications are limited because of its relativelylowstrength.

Theapplicationsofperviousconcretewerein many areas such as low volume pavement, residentialroads,sidewalks,parkinglots,low watercrossings,andtenniscourts,subbaseof conventionalconcretepavementandpatios.

Finenessin m2/kg 351 Min225 SoundnessByLe chateliermethod inmm

0.4 Max10

Initialsetting timeinminutes 35 Min30 Finalsettingtime inminutes 240 Max600 3days compressive strengthinMPa

28.75 Min27 7days compressive strengthinMPa

54.47 Min53

39.85 Min37 28days compressive strengthinMPa

SpecificGravity 3.15 3.15

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN: 2395 0072

2.1 Mix Proportion of Pervious Concrete

Fordevelopmentofmixtureproportioningofpervious concretetargetpropertiesareassumedasshowninTable 3.8.Targetpropertiesofperviousconcreteareassumed basedonNRMCA (2004)guideline.Targetpropertiesof pervious concrete are assumed for the construction of perviousconcretepavementforparkingareaatGujarat. By this study area same pattern can be applicable in Gunturcity,thatcanhelppublic.

Table 3: Studyreportofpropertiesofpreviousconcrete

Propertie s Target NRMCA (2004) Compres sive Strength

12MPa 15 MPa 3.5 MP a 28 MP a Void Ratio 20% 15% 25% Density 2000 kg/m3 2200 kg/m3

1600 kg/m3 2200 kg/m3 Permeabi lity 10mm/s 20mm/s 2mm/s 20mm/s

Presentinvestigationisalsocarriedouton20mm 10 mm coarse aggregates for the development of mixture proportioning for the pavement applications. Table 4 showsmixtureproportiondevelopedusing20mm 10mm (SizeB)naturalcoarseaggregates.Fortheenhancementof thepropertiesofperviousconcretefurtherinvestigationis carriedoutbyreplacingnaturalcrushedaggregateswith VSIaggregates.Anattempthasbeenmadetoimprovethe properties of pervious concrete using VSI aggregate on selectedmixtureproportion.

Casting procedure plays a very important role with respect to all properties of fresh as well ashardened pervious concrete. First of all weighing and batching process of all ingredients of pervious concrete such as cement, coarse aggregate and water is done with high accuracy before starting the mixing process. For the mixingofmaterialsofperviousconcretepanmixerisused. Firstaggregatesaretakeninthepanmixturefollowedby thecement.Drymixingofmaterialisdone.Waterisadded and mixing is done till the uniform consistence of the perviousconcretemixisachieved.Themixingofpervious concrete. No chemical admixture is used for the preliminary investigation of development of mixture proportionhasbeendone.

Table 4: Mix proportionforPerviousConcreteusing CoarseAggregate

Mixture No. Cement (kg/m3) Aggregates(kg/m3) W/C

M1 250 1000

0.3 M2 0.35 M3 0.4 M4 300 1200

0.3 M5 0.35 M6 0.4 M7 350 400

0.3 M8 0.35 M9 0.4 M10 375 1500

0.3 M11 0.35 M12 0.4 M13 400 1600

0.3 M14 0.35 M15 0.4

Fig 3:Roddingofpreviousconcrete

3. RESULTS AND DISCUSSION

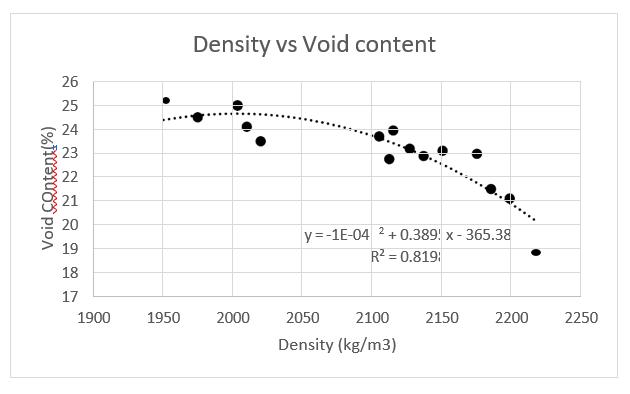

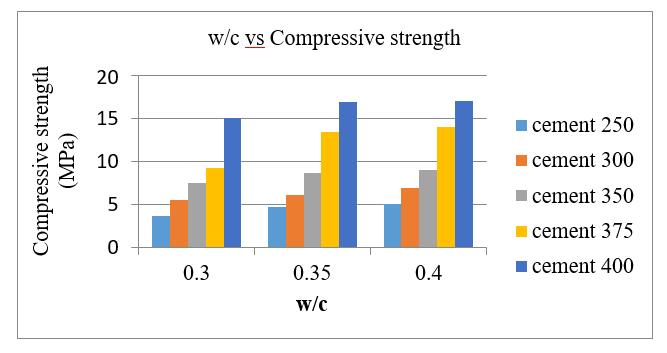

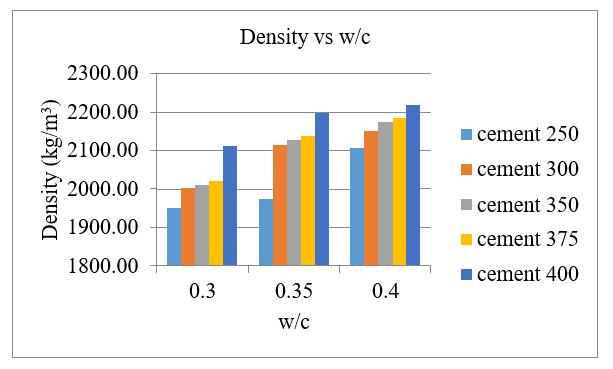

Preliminarylaboratoryinvestigationiscarriedoutto develop mixture proportioning for pervious concrete pavement. Tables 5 shows the mix proportions thatare selected for initial laboratory investigation for the developmentofmixtureproportionofperviousconcrete. Forthedevelopmentofmixturedesignthecementcontent is used in the range of 250 kg/m3 to 400 kg/m3 as presentedinTable 5 Laboratoryinvestigationhasbeen done on two sizes of aggregates for the development of mixture design of pervious concrete. For the mixture designdevelopment10mm 4.75mmand20mm 10mm of coarse aggregates are used. In the laboratory investigation properties of pervious concrete are found

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

suchascompressivestrength,voidratio,permeabilityand density. Details of investigation results are shown in followingsection.

Table 5: PropertiesofPerviousConcreteusingCoarse Aggregates(10mm 4.75mm)

Mi x No

Ceme nt (kg/m 3)

w/ c

Compress ive Strength Void conte nt%

Densit y (kg/m 3) (MPa)

Permeabil ity (mm/s)

M 1 0.3 3.71 25.12 23.28 1950. 5 M 2 250 0.4 4.67 24.5 22.21 1975. 1 M 3 0.4 5.12 23.7 21.98 2105 3 M 4 0.3 5.5 24.98 20.69 2003. 2 M 5 300 0.4 6.1 23.95 19.76 2115. 4 M 6 0.4 6.98 23.1 19.41 2150. 8 M 7 0.3 7.53 24.1 18.6 2010. 3 M 8 350 0.4 8.65 23.18 18.1 2127. 2 M 9 0.4 9.1 22.97 17 2175. 3 M 10 0.3 9.3 23.5 16.5 2020. 21 M 11 375 0.4 13.49 22.88 15.37 2137. 12 M 12 0.4 14 21.5 14.98 2185. 5 M 13 0.3 15.1 22.75 13.2 2112. 5 M 14 400 0.4 16.98 21.1 12.2 2198. 9 M 15 0.4 17.1 18.88 11.5 2217. 4

Chart 2:Relationshipbetweenw/candDensity

Chart 1:Compressivestrength

Chart 3:RelationshipbetweenDensityandvoidcontent

4. CONCLUSIONS

Cementcontentof250kg/m3 to400kg/m3 withan intervalof50kg/m3 wasusedinthedevelopmentof mixture design of pervious concrete. It has been observed that higher cementcontent created more cementpasteforperviousconcrete.Itfurtherreduced the void ratio and permeability of the pervious concrete.

Densityofperviousconcreteincreasedwiththeincrease of the cement content. On the other hand, lesser cement content reduced the compressivestrengthof theperviousconcrete.Thiswaycementcontentinthe rangeof350kg/m3to375kg/m3wasfoundtobegood enoughtogeneratecementpasteforbetterworkability andmeetingwiththerequirementofotherproperties forperviousconcrete.

For the development of mixture design of pervious concrete,twodifferentsizesofcoarseaggregatesof10 mm 20mmand4.75mm 10mmwereused.From the preliminary investigation results, it has been observedthatchangingthecoarseaggregatesizehada very limited influence on changes in the void ratio,

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page59

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

permeability and density as compared to the compressivestrengthforperviousconcrete.

It was observed that 4.75 mm 10 mm size coarse aggregateshavelargersurfacearea andhence,more cement paste is utilized in covering the coarse aggregates.Therefore,thecompressivestrengthofthe perviousconcreteisimproved.

Different ranges of w/c ratio i.e. 0.3, 0.35 and 0.40 were used for the development of mixture design of pervious concrete. Using 0.3 and 0.35 water cement ratio, the pervious concrete mix obtained was not foundtobemoreworkable.Useof0.4watercement ratio was found sufficient to prepare cohesive and workableperviousconcretemixture.

Theworkabilityofmixturewasmeasuredbypreparing a handball ofthe pervious concrete. Adequatepaste fortheperviousconcretewasgeneratedbyusing0.4 w/c ratio. The properties such as compressive strength, voidratioandpermeabilityof thepervious concretemadeaboverangeofw/cratiowerefoundin order.

REFERENCES

[1] American Concrete Institute (ACI). “Report on Pervious Concrete”, ACI 522 Committee Report, FarmingtonHills,MI:ACI(2010).

[2] Ajamu, S. O., A. A. Jimoh, and J. R. Oluremi. "Evaluationofstructuralperformanceof pervious concrete in construction." International Journal of EngineeringandTechnology2.5(2012):pp.829 836.

[3] Aoki,Yukari.“DevelopmentofPerviousConcrete.” Thesis of master of engineering, University of Technology, Sydney (2009):p.130

[4] Alaica,AmandaLidia,AntoS,MedhatS.“Optimizing the Strength and Permeability of Pervious Concrete.” The 2010 Annual Conference of the Transportation Association of Canada,(2010):p7.

[5] Anderson, Ian A., Mark Suozzo, and Mandar M. Dewoolkar. Laboratory and field evaluations of pervious concrete 13.07(2013).p50

[6] Solis,AndreaValdez.“Analyzingenvironmentaland structural charactersitics of concrete for carbon mitigationandclimateadaptationinurbanareas:A casestudyinRajkot,India” UniversityofColoradoat Denver (2013).

[7] Ashley, Erin. "Using pervious concrete to achieve LEED points." Concrete In Focus, NRMCA, Winter (2008).

[8] ASTMC1688“Standardtestmethodfordensityand voidContentofFreshlyMixedPerviousConcrete,” Annual Book of ASTM Standards 4.2(2008).

[9] ASTMC1701,“StandardTestMethodforInfiltration RateofInPlacePerviousConcrete."(2009).

[10]Bengtsson, Magnus, and C. Magnus Evertsson. “Measuring characteristics of aggregate Material from Vertical Shaft Impact Crushers.” Minerals Engineering,vol.19,no.15,(2006):pp.1479 1486

[11] Bean,E.,Hunt,W.,andBidelspach,D.“Field surveyofpermeablepavementsurfaceinfiltration rates”. Journal of Irrigation and Drainage Engineering 133(2007):pp.249 255

[12] Chopra, M., Wanielista, M., Ballock, C., & Spence, J., "Construction and maintenance assessment of pervious concrete pavements." Research supporting sustainable development (2007):pp.1 164

[13] Crouch,L.K.,JordanPitt,andRyanHewitt. "Aggregate effects on pervious portland cement concrete static modulus of elasticity." Journal of materials in civil engineering 19.7(2007):pp.561 568.

[14]Coleri, Erdem, Masoud Kayhanian, and John T. Harvey. "Permeability of Porous Friction Course Pavements:BeforeandAfterAcceleratedPavement Tests." Transportation Research Record 2456.1 (2014):pp.21 29.

[15]CRMCA Colorado Ready Mixed Concrete Association."Specifier’sGuideforPerviousConcrete PavementDesign Version1.2(2010):p24

[16]Delatte,Norbert,AleksandarMrkajic,andDaniel I. Miller."Fieldandlaboratoryevaluationofpervious concrete pavements." Transportation Research Record 2113.1(2009):pp.132 139.

[17]Deo, Omkar, and Narayanan Neithalath. "Compressive response of pervious concretes proportioned for desired porosities." Construction andBuildingMaterials 25.11(2011):pp.4181 4189.

[18] Fabro, F., Gava, G. P., Grigoli, H. B., & Meneghetti, L. C.“Influence of Fine Aggregates ParticleShapeintheConcreteProperties.” Revista Ibracon de Structures E Materials,Vol.4(2014):pp. 191 212.

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page60