International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN: 2395 0072

Harshank Chiram 1 , Kruti Jethwa2

1Research Scholar, Department of Transportation Engineering, SSTC, Bhilai 2Associate Professor, Department of Civil Engineering, SSTC, Bhilai ***

Abstract A bridge is a man made structure built to avoid physical obstacles without closing the path beneath it, such as a body of water, a valley, or a road. The objective of current research is to investigate the vibration characteristics of bridge structure using different materials. The modal analysis of bridge structure is conducted using ANSYS simulation package. The materials investigated inthe research is concrete material, silicone rubber and neoprene rubber. The mode shapes, natural frequency and mass participation factor is evaluated for different bridge materials. From modal analysis of silicone rubber material, the critical region is found to be at crash barrier which exhibited maximum deformation and susceptible to amplitude build up during resonance and for neoprene rubber material, the maximum deformation is observed to be at bearing region whereas the bridge structure and crash barrier have lower deformation

Key Words: Bridge,structuralanalysis,damage

A bridge is a “man made structure built to avoid physical obstacleswithoutclosingthepathbeneathit,suchasabody ofwater,avalley,oraroad.Itisdesignedtoensurepassage over an obstacle. The first bridges made by humans were probablyspansofcutwoodenlogsorplanksandeventually stones, using a simple arrangement of support and cross beam” [1]. The first arched type bridge structures were developedbyRomans.

basedonvariousconsiderationsliketerraintype,materialof bridgeandbudgetofbridge.

Jeong TaeKimet.al.[1]haveconductedresearchondamage detection of bridge structure using vibration response monitoring. From the vibration amplitude the accurate location of damage, severity of damage and effect of temperaturewereinvestigated.

Brownjohnetal[2]haveconductedresearchonvibration analysis of Humber Bridge located at Hong Kong. The damage detection was done using “Natural Excitation Technique/Eigensystem Realization Algorithm, Stochastic Subspace Identification, and the Poly Least Squares FrequencyDomainmethod”[2].Theresearchfindingshave shown the viability of these techniques for crack identificationandmonitoring.

Whelan et. al. [3] have conducted research on health monitoring of bridge structures. The health monitoring systems involves use of sensors for crack detection. The study found that the “use of stochastic SSI subspace identificationtechniquestoapproximatemodalparameters from only output experimental data was found to be preferable to the frequency domain decomposition FDD method despite the increased computational effort and subjectivityrequiredtorecognizethesystempoles”[3].

Wardhana and Hadipriono et. al. [4] have conducted research on damage of bridge structure due to various environmentalandoperationalfactors.Theenvironmental factorsinvestigatedareabrasion,corrosionandoperational factorsconsideredareoverloading.Fromtheresearchitwas found that major reason for collapse of bridge was overloading which accounted for more than 73% of total cases.

The reduction of strength on different regions of bridge structure made of stone was mitigated with the use of cement. As per the intended function of bridge different designs of bridge were constructed. These designs were

The objective of current research is to investigate the vibrationcharacteristicsofbridgestructureusingdifferent materials. The modal analysis of bridge structure is conductedusingANSYSsimulationpackage.Thematerials investigated in the research is concrete material, silicone rubber and neoprene rubber. The mode shapes, natural frequency and mass participation factor is evaluated for differentbridgematerials.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN: 2395 0072

TheFEAmodelanalysisisconductedonbridgestructureto determinenaturalfrequencyandmodeshapefor1st,2ndand 3rd natural frequencies. The analysis involves different stages.

FromtheFEAanalysisthenatural frequency,modeshape and mass participation factor is obtained for concrete material,siliconerubberandneoprenerubbermaterial.

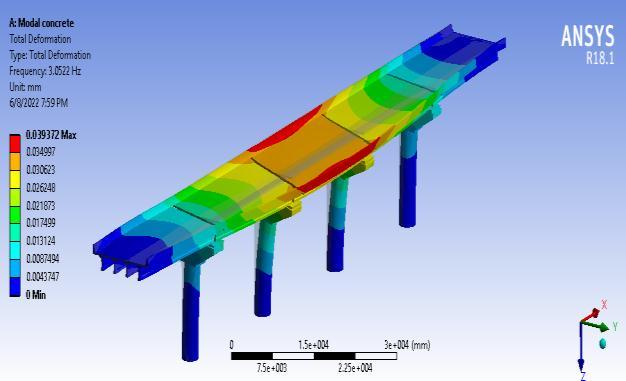

Forconcretematerialbridgedeckand1stnaturalfrequency modeshape,themaximumdeformationisobservedatthe bridge crash barrier zone where in the magnitude of deformationis.039mm.

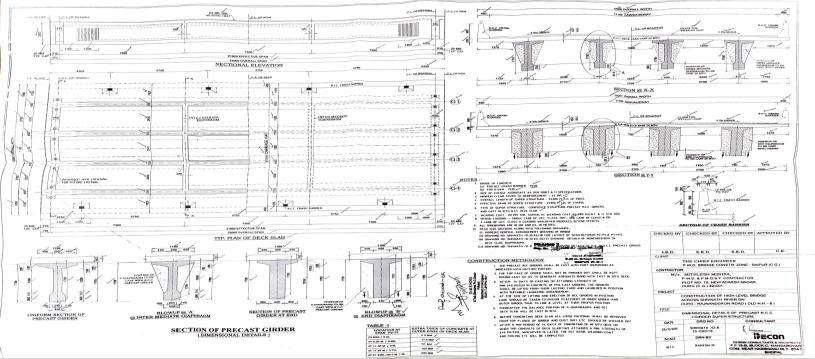

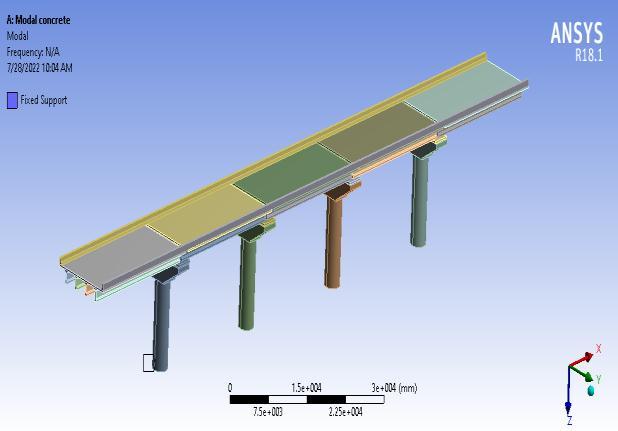

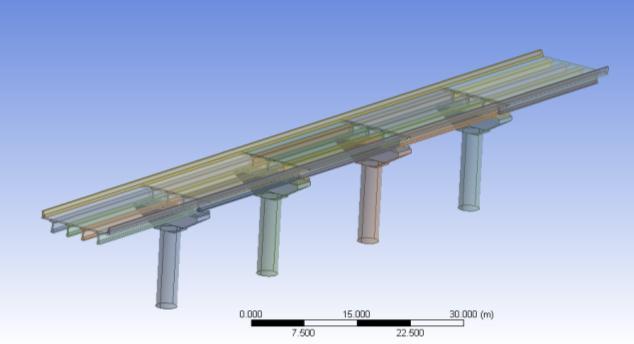

Thebridgestructureisdevelopedasperschematicshownin figure 2. The bridge structure model is checked for geometricerrorsandsurfacepatches.Thedevelopedmodel ofbridgestructureisshowninfigure3above.

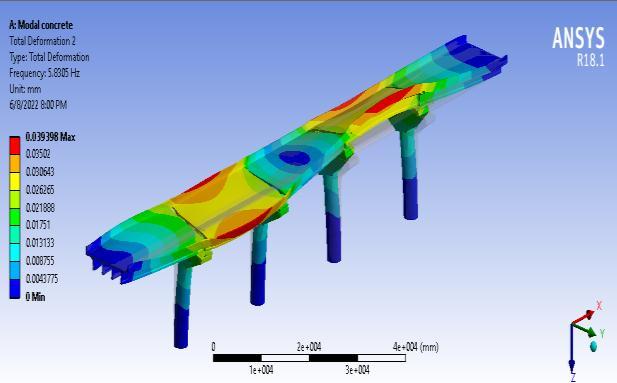

Forconcretematerialbridgedeckand2ndnaturalfrequency modeshape,themaximumdeformationisobservedatthe bridge crash barrier zone where in the magnitude of deformationis.0393mm.

The boundary conditions are applied on the structure for modal analysis. Under modal analysis, the base of the structureisappliedwithfixedsupport.TheFEAsimulation isrunusingsparsematrixsolverandnumberofiterations arecarriedout.

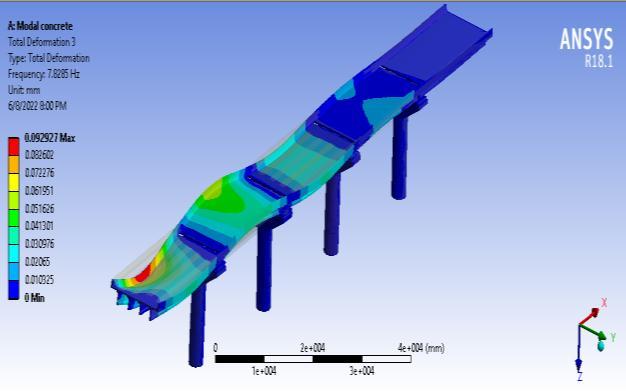

Figure7:

Forconcretematerialbridgedeckand3rdnaturalfrequency modeshape,themaximumdeformationisobservedatthe bridge crash barrier zone where in the magnitude of deformationis.092mm.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page31

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN: 2395 0072

Table1: Massparticipationfactorforconcretematerial

***** PARTICIPATION FACTOR CALCULATION ***** Y DIRECTION

EFF.MASS

CUMULATIVE RATIO

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 3.05217 0.32764 42.967 1.000000 1846.12 0.955685 0.572179

2 5.83046 0.17151 0.42157 0.009812 0.177720 0.955777 0.550817E04

3 7.82853 0.12774 0.48238 0.011227 0.232689 0.955897 0.721186E04

4 8.17151 0.12238 0.51682 0.012028 0.267100 0.956036 0.827837E04

5 8.63898 0.11575 4.7948 0.111593 22.9899 0.967937 0.712539E02

6 8.78618 0.11382 7.8700 0.183166 61.9370 1.00000 0.191965E01

sum 1931.73 0.598710

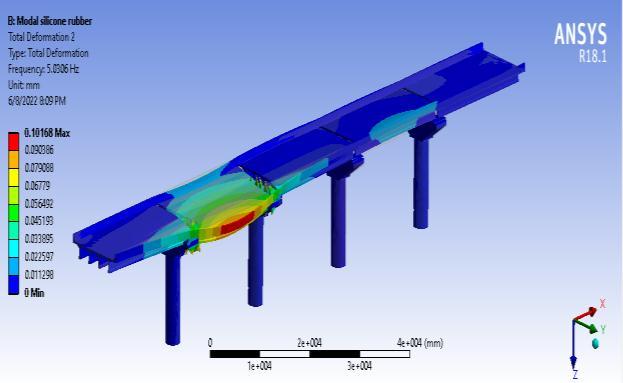

For silicone rubber material bridge deck and 2nd natural frequency mode shape, the maximum deformation is observed at the bridge crash barrier zone where in the magnitudeofdeformationis.101mm.

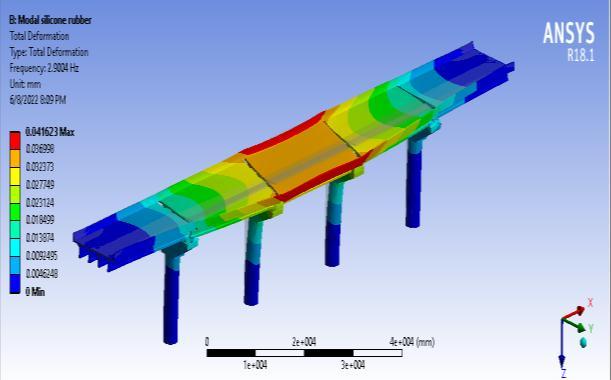

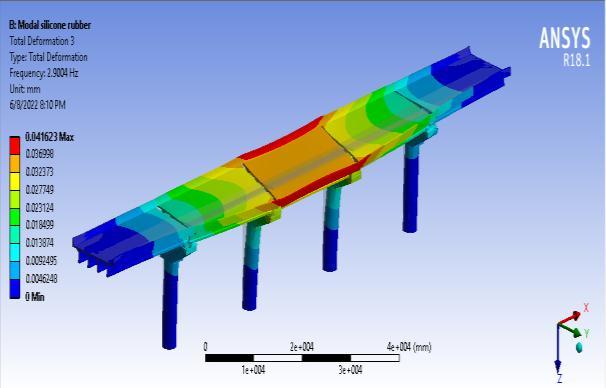

Figure8:1st frequencymodeshapeforsiliconerubber

For silicone rubber material bridge deck and 1st natural frequency mode shape, the maximum deformation is observed at the bridge crash barrier zone where in the magnitudeofdeformationis.041mm.

Figure10:3rd frequencymodeshapeforsiliconerubber

For silicone rubber material bridge deck and 3rd natural frequency mode shape, the maximum deformation is observed at the bridge crash barrier zone where in the magnitudeofdeformationis.041mm.

Table2: Massparticipationfactorforsiliconematerial

Y DIRECTION CUMULATIVE RATIO

EFF.MASS MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 2.90045 0.34477 41.445 1.000000 1717.68 0.919134 0.536681 2 5.03064 0.19878 4.6726 0.112744 21.8336 0.930818 0.682180E02

3 5.27097 0.18972 6.1424 0.148205 37.7285 0.951006 0.117881E01 4 5.33261 0.18753 9.1381 0.220489 83.5053 0.995690 0.260908E01 5 5.49448 0.18200 2.7555 0.066487 7.59301 0.999753 0.237240E02 6 5.53050 0.18082 0.67921 0.016388 0.461326 1.00000 0.144139E03

sum 1868.80 0.583898

Figure9:2nd frequencymodeshapeforsiliconerubber

Factor

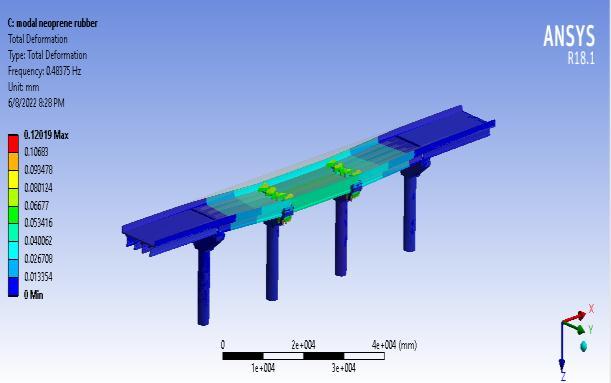

Figure11:1st frequencymodeshapeforneoprenerubber

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN: 2395 0072

For neoprene rubber material bridge deck and 1st natural frequency mode shape, the maximum deformation is observed at the bearing zone where in the magnitude of deformationis.12mm.

02 0.999998 0.140443E05

6 1.24749 0.80161 0.45203E01 0.001453 0.204334E 02 1.00000 0.637787E06

sum

968.609 .302331

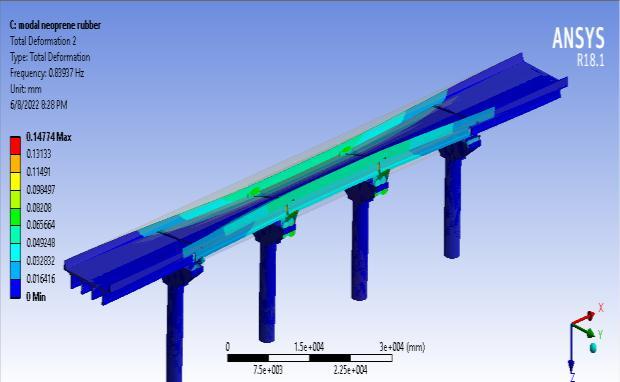

Forneoprenerubbermaterialbridgedeckand2nd natural frequency mode shape, the maximum deformation is observed at the bearing zone where in the magnitude of deformationis.147mm.

The FEA is a viable tool in evaluating the vibration characteristicsofbridgestructure.Fromthemodalanalysis, thenaturalfrequenciesandmodeshapesareevaluatedfor bridgewithconcrete,siliconerubberandneoprenerubber material.

1. Fromthemodalanalysis,thecriticalregionsofhigh deformationareidentified.

2. From modal analysis of concrete material, the criticalregionisfoundtobeatcrashbarrierwhich exhibitedmaximumdeformationandsusceptibleto amplitudebuildupduringresonance.

3. Frommodalanalysisofsiliconerubbermaterial,the criticalregionisfoundtobeatcrashbarrierwhich exhibitedmaximumdeformationandsusceptibleto amplitudebuildupduringresonance.

4. Frommodalanalysisofneoprenerubbermaterial, the maximum deformation is observed to be at bearing region whereas the bridge structure and crashbarrierhavelowerdeformation.

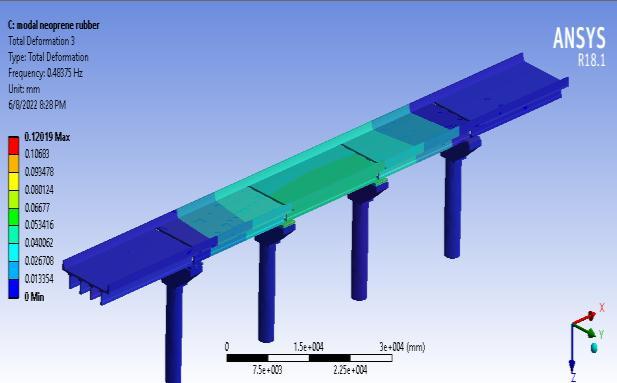

Figure13:3rd frequencymodeshapeforneoprenerubber

Forneoprenerubbermaterialbridgedeckand3rd natural frequency mode shape, the maximum deformation is observed at the bearing zone where in the magnitude of deformationis.1201mm. Table3: MassparticipationfactorforNeoprenematerial

[1]. Jeong Tae Kim_, Jae Hyung Park, Byung Jun Lee ” Vibration baseddamagemonitoringinmodel plate girder bridges under uncertain temperature conditions”, EngineeringStructures29;1354 1365.2007

[2]. J.M.W. Brownjohn,_, Filipe Magalhaes, Elsa Caetano , Alvaro Cunha , ” Ambient vibration re testing and operational modal analysis of the Humber Bridge” , Engineering Structures , (2010), doi:10.1016/j.engstruct.2010.02.034

1 0.483751 2.0672 31.109 1.000000 967.775 0.999139 0.302071 2 0.839370 1.1914 0.90011 0.028934 0.810205 0.999976 0.252888E03

3 0.938499 1.0655 0.83937E01 0.002698 0.704539E 02 0.999983 0.219907E05

4 1.21398 0.82374 0.98624E01 0.003170 0.972664E 02 0.999993 0.303597E05

5 1.23503 0.80970 0.67078E01 0.002156 0.449952E

[3]. Matthew J. Whelan, Michael V. Gangone, Kerop D. Janoyan , Ratneshwar Jha “Real time wireless vibration monitoring for operational modal analysis of an integral abutment highway bridge” , Engineering Structures 31 ; 2224_2235,2009

[4].WardhanaK,HadiprionoFC.“Analysisofrecentbridge failures in the United States” , J Performance Construct Fac;17(3):144_50.2003

[5]. Pakzad SN, Kim S, Fenves GL, Glaser SD, Culler DE, DemmelJW.“Multi purposewirelessaccelerometerforcivil infrastructure monitoring”, In: Proceedings of the 5th international workshop on structural health monitoring, Stanford\(CA);2005.

[6].PaekJ,JangOGK Y,NishimuraD,GovindanR,CaffreyJ, Wahbeh M, Masri S. “ A programmable wireless sensing systemforstructuralmonitoring”,4thworldconferenceon structuralcontrolandmonitoring,SanDiego(CA);2006.

[7].LynchJP,WangY,LohKJ,YiJ H,YunC B.“Performance monitoringoftheGeumdangbridgeusingadensenetwork of high resolution wireless sensors”, Smart Mater Struct;15(6):1561_75.2006

[8] Components Parts of a Bridge Concrete and Steel BridgesParts(theconstructor.org)

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal