International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1 Mr. Sarvesh Goshwami, 2Mr.Ravinder, 3 Ms. Sheela Malik, Anil Kumar4

1.M.Tech Scholar Ganga Institute of Technology and Management Kablana, Jhajjar

2.Assistant Professor(CE) Ganga Institute of Technology and Management Kablana, Jhajjar

3.Assistant Professor(CE) Ganga Institute of Technology and Management Kablana, Jhajjar

4.M.Tech Scholar Ganga Institute of Technology and Management Kablana, Jhajjar ***

Abstract:StructuralHealthMonitoringisoneofthepreferredresearchtopicsinstructural engineeringbutpractical applicationsarestillbehind,atleastinthecivilsector.Thepaperisaimedatreviewingthemainresearchachievementsonthe subject and to argue aboutthe reasons because practical applications still encounter difficulties in becoming a standard practiceincivilengineering.Structuralhealthmonitoringconceptsandcurrentdesignapproachesarealsodiscussedwith considerationofthesafetyofmonitoredstructuresversusconventionalnon monitoredones.Existingstandardsonstructural monitoring and the need for the development of new standards integrating design, maintenance and management of constructedfacilitiesareaddressed.

Observationofstructuralbehaviorisaveryolddisciplinethathasaccompaniedtheoretical developmentsinstructural mechanics since its origins (Benvenuto 1991), providing basic knowledge of physical phenomena and verification of computationalprocedures.However,inthelasttwentyyearsthisdisciplinehasalsotakendifferentroles,graduallybecoming thebasictoolforfacingtheso called time dependent safety problem (MoriandEllingwood1993) incivilengineeringpractice.

TheshiftfromsimpleexperimentalobservationtoStructuralHealthMonitoringhasbeendrivenbytwofactors:ontheone hand,bytheconsequencesledbydegradationofmodernconstructionmaterialsandfunctionalobsolescenceontoinfrastructure economics and, on the other hand, by the availability of cheap, effective and durable innovative instrumentation and hardware/softwaretoolstoaccomplishcomplexdataacquisitionandsignal processingfunctions.StructuralHealthMonitoring (SHM)isindeedjustthecombinationoftraditionalexperimental/theoreticalstructuralmechanics,electronics,materialscience, and information andcommunications technologies. Applications of this discipline can lead to the definition of monitored structures,a class ofstructures the characteristicsof whichin terms ofsafetyand reliability indicesshould be considered differentlyfromtraditional structures,wheresafetyreliesonpassiveresistanceonly,inordertoderivespecificintegrated designapproaches(DelGrosso2008).

In developed countries, the greater percentage of infrastructures have been built just after WorldWar II using steel, reinforced, composite or pre stressed concrete structural systems. These techniques still are the most commonly used constructionsystemsworldwide.Materialsdegradationandobsolescenceareakeyissueininfrastructuremanagementnotonly whereinfrastructurestocksaresoold(Aktanetal.2007)butalsowhere,asinrecentlydevelopedcountries,theyrepresenta probleminperspective.Indeed,thephysicalandmechanicalpropertiesoftheseconstructionmaterialstendtodegradewith timeatarelativelysignificantspeed,thuscausingalossintheeconomicvalueof theinfrastructureassets.Forexample,recent studieshavestatedthattheglobaleconomicconsequencesofcorrosionmaybeevaluatedtoreach3to4GDPpoints peryear (Schmittetal.2009).

Considering concrete structures, which are largely the most diffused ones, the most common and serious in terms of consequences,causeofdeteriorationinstructuralmembersisduetocorrosionofreinforcingsteelinducedbychlorideion ingressintoconcrete.Otherlesscommoncausesofdeteriorationinconcretearecarbonationinducedcorrosion,freeze thaw attack,alkali silicareaction,andexternalandinternalchemicalattack.Concretedegradationandespeciallychlorideioningress andconcretecarbonationisresponsiblefor creatinga corrosionpotentialforthesteelbars,buttheactualdevelopmentof corrosionandtherateoftheprocessarealsodependentontemperatureandmoisturecontentinthesurroundingconcrete (DanglaandDridi2009),thusrenderingthephenomenonverycomplex.Besidescorrosion,fatigueisalsoanimportantcauseof degradationinsteelstructuressubjectedtomovingloadsorvibrations.Inbridges,degradationofjointsandsupportsbecauseof fatigue,corrosionandageingisalsoanimportantissueinfluencingmanagementstrategiesandcosts.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Corrosionandmaterialdegradationcauseadecreaseintheresistingsectionofmembersandfastenerswhichinturnresults in a degradation of resistance and stiffness of the whole structuralsystem. Detection of the presence and progress of the phenomenacanbemadebydirectmonitoringoftheelectrochemicaldrivingparametersor,indirectly,byanalyzingthechanges withtimeofthestructuralresponse(DelGrossoetal.2008,2011).

The concept of obsolescence is more related to the evolution of the needs of infrastructure users,for example (for transportation infrastructures) in terms of commercial speed, traffic volumes, size and weight of vehicles etc., but obsolescence can also be produced by the unfavorablelevelsofmaintenancecostsinducedbydegradation.Evaluationof obsolescence results from complex considerations involving direct, indirect and social costs for decommissioning and substitution,butthecorrespondingdecisionmakingprocessisbasedonparametersthatcanbequantitativelyestimatedfrom directandindirectobservations.

Duetothelargeeconomiceffortneededtokeeptheexistingandfutureinfrastructuresystemsinefficientandsafeconditions, intherecentyearsseveralstudiesandpracticalapplicationshavebeenperformedonmaintenancestrategiesandmaintenance costoptimization.

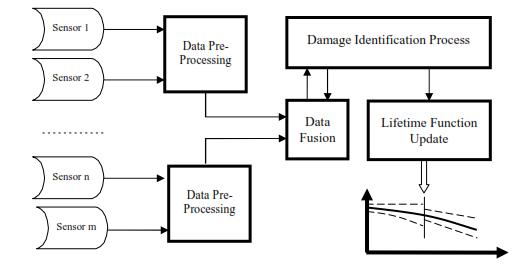

Theapproachthathasrecentlyreceivedconsiderableattentionandthatisconsideredthemost attractive for practical applicationsisbasedontheuseof lifetime functions.Smartsensors,withtheiron boardcomputationalandcommunication capabilities,offernewopportunitiesforSHM.Withouttheneedforpowerorcommunicationcables,installationcostcanbe broughtdowndrastically.Smartsensorswillhelptomakemonitoringofstructureswithadensearrayofsensorseconomically practical.DenselyinstalledsmartsensorsareexpectedtoberichinformationsourcesforSHM.

(Figure1)representsthedecayintimeofaperformanceindexthatmayeventuallyrepresentthereliabilityindexoramore complexweightedsumofseveralindicators.

Standardsandregulationsconcerninginfrastructuresafetyimposeperformanceof traditionalinspectionsat fixedtimeintervals;thisobligationcannotbelegallyavoidedusingSHMsystems.

Althoughaconsistentnumberofdamageidentificationalgorithmshavebeenproposedandvalidatedinthe literature, the reliability of the determination of the structural conditions from the SHM data is still to be widely experienced.

Although very reliable, durable and stable sensors technologies are nowadays available on the market, the sensorysystemsalwaysshowsomemalfunctions;thisneedsredundanciesatsensorinstallationandmaintenanceduring operations.

The operational life of electronics (data loggers, computers, etc.) is shorter than that of any other system components and much shorter than the operational life of the structure; this will require frequent substitutions of electroniccomponents.

EducationonSHMsystemsandglobalinfrastructuremonitoringapproachesisstillnotenoughdiffusedincivil engineeringuniversityprograms;consequently,engineers ininfrastructureownersorganizationsarereluctanttorelyon SHM.

Insynthesis,theeconomicandtechnicaladvantageofusingSHMsystemsininfrastructuremanagementisstillquestionedby potentialusers.Recentdiscussionsheldatanacademicworkshop(6thIASCMInternationalWorkshoponStructuralControland HealthMonitoring,Sydney,2012)havepointedoutsuchsituationandtracedresearchneedsforpossiblyovercomingtheabove difficultiesinthediffusionofSHMtechnologies.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Figure2.LifetimefunctionsupdateviaSHM.

Averylargeamountofstudiesandexperiencesonmonitoringsystemshavebeenmadeavailableintherecentyearsbut someissuesstillremainopen.Abriefsummaryofresearchresultsandsomeopenquestionsarepresentedhere.

Bypermanentmonitoringitisintendedamonitoringsystemthatispermanentlyinstalledandmaintainedinoperationon thestructure,typicallyfromtheconstructionstage.ThisisthemostcompleteapproachtoSHM,allowingtoobtaincontinuous time series of data comprisingstructural response parameters (static and dynamic), environmental parameters, load characteristics,andotherquantitiesimportanttothecontrolofmaterialsdegradationprocesses.

The conceptual advantage of permanent monitoring systems is that the time series of data canbeprocessedinmany differentways,includingon lineandmulti stageprocessing,disclosingfeaturesthatmayalsorevealunexpectedstructural behaviors.Eventslikeearthquakes,shocks,stormsetc.canbecompletelydescribedallowingacomprehensiveevaluationofthe phenomenaandofthecorrespondingstructuralresponse.

Thisisimportantnotonlyforassessingtheconditionsofthesinglestructureunderstudybutalsoforcharacterizingevents thathavealowprobabilityofoccurrenceandthatarenotconsistentlymodeledindesigncodes.Inaddition,dataprocessingcan beperformedon lineallowingwarningsandalarmstoberaisedinreal time.Rain flowcountscanbeperformedonstresstime histories to provide on line evaluations of the accumulated damage and of the residual fatigue life. The disadvantage of permanentmonitoringsystemsisthattheyarerelativelyexpensive,theyneedtobedesignedverycarefullyandtheyproducea very large amount of data, thus requiring a dedicated organization and complex architectures for data transmission, managementandpermanentstorage.

Periodicmonitoringisperformedbytemporarilyinstallinganappropriatesensorysystemonthestructureandgathering dataforashorttime(fromafewhourstoafewweeks).Featureextractionisperformedforeverymeasurementcampaignand thehealthconditionsofthestructurearedeterminedfromthetime historiesofthecharacteristicfeaturesofthecampaigns.

ThedevelopmentofdamageidentificationordiagnosticalgorithmsisaverycommontopicinSHMresearch.Fordamage identificationitisintendedaprocedureabletoanalyzethemonitoringdataanddetermineoccurrence,locationandintensityof damage.Hundredsofjournalandconferencepapershaveproposedalargevarietyofsuchprocedures.Theireffectivenessis usuallyprovenbyanalyzingcomputersimulateddata,benchmarkstudiesandsmallscalelaboratoryexperiments.Relativelyfew papersarereportingaboutdamageidentificationonrealstructuressubjectedtoartificiallyinduceddamages,normallyusing measurementsofdynamicresponsebeforeandafteraknowndamagelevelhasbeeninducedinthestructure.IntheAuthor’s

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

knowledge,thereisnocasereportedintheliteraturewherealgorithmsofthistypehaverevealedinsurgenceofdamageinreal structuresbutcasesarereportedwherebehavioralanomalieswithrespecttopredictionsgivenbydesignmodelshavebeen detected. In the Author’s opinion, the development of diagnostic algorithms has reached a substantial maturity and the preparation ofa comprehensive review paper will be very fruitful fordisseminatingthem topotential practical users and identifyingtheneedsforfutureresearch.

Alimitednumberofguidelinesandstandardshasbeenreleasedtodate.TheonlyofficialinternationalstandardsaretheISO 14963:2003 MechanicalVibrationandshock Guidelinesfordynamictestandinvestigationsonbridgesandviaductsandthe ISO18649:2004 Mechanicalvibrations Evaluationofmeasurementresultsfromdynamictestsandinvestigationsonbridges. ThesestandardsrefertotheuseofdynamicmeasurementstoperformperiodicSHMfunctionsonbridges. Otherguidelines, morewidelyaddressingtheissueofSHMandthedesignofmonitoringsystemshavebeenpublishedbyresearchorganizations likeISISCanada(ISISManualn.2 Guidelinesforstructuralhealthmonitoring)orhavebeenproducedintheframeworkof internationalresearchprojectsliketheEuropeanSAMCOandIRIS.IntheIRISframework,aproposalforstandardscoveringthe useoflifetimefunctionshasbeenelaboratedbyCENWG63.

An interesting standard has been recently issued in Russia (GOST P 53778 2010 Building and Structures Technical inspectionsandmonitoringregulations).ThisstandardismandatoryintheRussianFederationandbroadlyaddressesstructural andgeotechnicalinspectionandmonitoringduringservicelife.

Rulesforinspectionandmanagementofvarioustypesofinfrastructureshavebeenissuedbyseveralagenciesintheworld, buttheydonotexpresslyaddressissuesrelatedto structuralhealthmonitoringasdescribedinthiscontext.

It ishoweverrecognizedthatthelackofinternationalstandardsandregulationsonbuildingsandstructuresconsideringthe useofSHMrepresentsanobstacletothediffusionoftheapplications. Theneedforworkingonthissubjectisthereforepointed out.

Aparticularaspectthatstillneedtobeinvestigatedfromthetheoreticalstandpointinviewofimpactingondesignstandards is related to the reliability of monitored structures versus non monitored ones. In conventional structural design codes accordingtotheEuropeanlimitstateformatortheAmericanLRFD,characteristicvaluesofloadsandresistanceofmaterialsare deducedfromstandardprobabilitydistributionsand,inaddition,safetyverificationsareperformedbyapplyingappropriate safetyfactorstocharacteristicvalues,toreflecttheuncertaintiesinvolvedintheprocess.

Aquestionnowarisesregardingtheappropriatenessofthosesafetyfactorswhenuncertaintiesarereducedbythepresence of a permanent monitoring system on the structure providing information on the structural conditions and allowing interventions to be made for keeping theprobabilityoffailurebelowtheacceptablelimits.Todatethereisnostudy,inthe Author’sknowledge,addressingthisquestioninasystemicway.Itisenvisagedthatthebackwarduseofthelifecyclefunctions couldprovideausefulapproach.

ThepaperhassummarizedthemainresearchandapplicationsachievementsinSHMtechnologies.Severalopenproblems stillremainunsolvedandmaybethesubjectoffutureresearch.Apartfromstandardizationneeds,asalreadymentionedinthe previousparagraph,thefirstandprobablymostimportantissueisrelatedtothesafetycoefficientsthatshould beadoptedinthe designofmonitoredstructures. Thisrelatestorefurbishmentdesignofexisting structuresaswell astothedesignofnew structures,wherebythepresenceofthemonitoringsystemcanredefinetheprobabilisticmodelingofdesignuncertainties.A secondissueisrelatedtotheuseofupdatedbehavioralmodels(FEmodels)thatconstantlyreflectthestateandtheevolutionof structuralconditions.Reliabletechniquestoconstructandusethesemodels,sometimesreferredtoas“numericaltwins”ofthe realstructure,stillhavetobedevelopedandexperienced.

Aktan,AE,Ellingwood,BRandKehoe,B.2007.Performance basedengineeringofconstructedsystems.

Journal of Structural Engineering 133(3):311 323.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Benvenuto,E.1991. An Introduction to the History of Structural Mechanics.SpringerVerlag,BerlinDangla, P and Dridi, W. 2009.Rebar CorrosioninCarbonated ConcreteExposed toVariable Humidity

Conditions.InterpretationoftheTuutti’sCurve. Corrosion Science,51:1747 1756.

DelGrosso,A.2008.OntheReliabilityofSmartMonitoredStructures, 14th World Conference on Earthquake Engineering,Beijing, China.

DelGrosso,AE.2012.Onthestaticmonitoringofbridgesandbridge likestructures. Bridge maintenance, Safety, Management, Resilience and Sustainability,F.Biondini&D.M.Frangopoleds.,CRCPress/Balkema,Leiden.362 367.

DelGrosso,A,Lanata,F,Pardi,L,Mercalli,A.2008.HealthMonitoringforCorrosionDetectioninReinforcedConcreteBridges, 4th Int. Conf. on Bridge Maintenance, Safety and Management,KohAndFrangopoleds.,TaylorandFrancis.

Del Grosso, A, Inaudi, D, Lanata, F, Posenato, D. 2011. SHM of Ageing Reinforced Concrete Structures, First Middle East Conference on Smart Monitoring, Assessment and Rehabilitation of Civil StructuresSMAR 2011,Dubai,UAE,papern.265.

Del Grosso, AE and Lanata, F. 2011, Uncertainties in Damage Identification and Lifetime Functions of Ageing Concrete Structures. Structural Health Monitoring 2011,F KChangEd.,DESTechPublication,Lancaster.1871 1878.

DelGrosso,AEandLanata,F.2012.Reliabilityestimateofdamageidentificationalgorithms. Reliability Engineering and Risk Management (3),Y.G.Zhao,J.Li,Z.H.Lu,T.Saitoeds.,CentralSouthUniversityPress,Shanghai.350 355.

Frangopol,DMandLiu,M.2006. Life cycle cost and performance of civil structures.McGraw Hill2006YearbookofScienceand Technology,McGraw Hill,NewYork.

Miyamoto, A, Kawamura, K, and Nakamura, H. 2001. Development of a Bridge Management System forExisting Bridges. Advances in Engineering Software, 32:821 833.

Mori,YandEllingwood,BR.1993.Reliability basedService LifeAssessmentofAgingConcreteStructures. Journal of Structural Engineering 119(5):1600 1621.

Schmitt, G, Schütze, M, Hays, GF, Burns, W, Han, E H, Pourbaix, A, and Jacobson, G. 2009. Global Needs for Knowledge Dissemination, Research, and Development in Materials Deterioration and Corrosion Control, White Paper, The World CorrosionOrganization

Wenzel,H,Veit Egerer,RandWidmann,M.2011.RiskBasedCivilSHMandLifeCycleManagement.

Structural Health Monitoring 2011,F KChangEd.,DESTechPublications,Lancaster.717 724.

Sarvesh Goshwami

M.TechScholar.GangaInstituteof TechnologyandManagement

Anil Kumar

M.TechScholar GangaInstituteof TechnologyandManagement

Ravinder Assist.Professor Ganga Institute of Technology and Management She ela Malik Assist.Professor GangaInstituteof TechnologyandManagement