International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Abstract Concrete is an important material which is widely used for construction purposes. Due to the increase in cost of the concrete, the construction becomes very expensive. This project is conductedtoreducethecostofconcretethereby the cost of construction can be reduced and also increase the strength and durability of concrete. This can be done by partially replacing fine aggregate usingsomematerialswhich are available at low cost or no cost. In this study foundry sand is used for the partial replacement of fine aggregate. Fine aggregate is replaced at different percentage, that is 10%, 20%, 30% & 40%. After all the test we found that the compression, flexural and tensile strength of the concrete is maximum at 20% of replacement of fine aggregate. The compressive strength has increased 12.64%, split tensile strength has increased 45.64% and the flexural strength has increased 83.33% than its original strength. The strength characteristics of concrete also studied in this project by adding basalt fiber to the optimum replacement of fine aggregate (20%). While adding 2.5% of basalt fiber by the weight of the cement the compressive strength has increased 7.86%, split tensile strength increased27.27%andtheflexural strength has increased 10.44% than its original strength.

Key Words: Foundry sand, Basalt fiber, Compressive strength test, Split tensile strength test, Flexural strength test

Concrete is a material which contain of sand, cement, aggregates, water and other essential materials for the construction.Sandisoneofthemajormaterialused.These sandcanbepartiallyreplacedusingseveralmaterials.This willhelpstoreducethecostofconstructionandimproves thestrengthanddurabilityofconcrete.Inthisstudyfoundry sandisusedforpartiallyreplacingfineaggregate.Foundry sandisavailableinlesscostornocostanditisalightweight fine aggregate. Foundry sand is an industrial waste which areusedformetalcasting.Sinceitisavailableatlowcost, thecostofconstructioncanbereduced.

To increase the strength and durability of concrete, severalfibrousmaterialsareusedsuchassteelfiber,copper fiber, basalt fiber etc… These will helps to strengthen the concrete.Inthisstudy,afterpartiallyreplacinffineaggregate usingfoundrysand,basaltfiberisaddedtostrengthenthe concrete.Basaltfiberisafiberobtainedfromigneousrock

which are available at the earth crust. These rocks are formed by the solidification of lava present in the earth surface.These rocksareexcavated,washedand melted at hightemperatureandturnedintothinfibers.Thesefibers canbeusedtostrengthentheconcrete.

Acementisamaterialusedforconstructionwhichhelps tobindtheothermaterialsinconcretetogether.Ithelpsto setandharden.ThecementusedinthisstudyisDalmiaOPC, grade53

Water is one of the main substance in concrete. This is transparent,tasteless,odorlessandnearlycolorless.

Sand is a mixture of small particles of rock. The size rangingofsandisfrom0.06mmto2mm.thesandusedin this study is M sand. The sand is finer size than coarse aggregateandcoarserthansilt.

Coarseaggregateiscrushedstones,irregularandgranular materialwhichisusedformakingconcrete.

Foundry sand is an industrial waste which is used for metalcasting.Thesesandisfineranduniformlysized.Itis usedinfoundrycastingprocessandisahighqualitysilica sand.

Basalt fiber is obtained from igneous rock. The igneous rocksareformedbythesolidificationofhotmoltenmagma. These solid magma excavated from the earth’s surface, washedandmeltedathightemperatureupto1500℃.Then these are turned into thin fibers. These fibers maybe continuousorfragmentedandcanbeusedforstrengthening concrete.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Mix design is done according to IS design method and numeroustrialmixesweredonetoget theoptimumM35mix. Whentheoptimummixisobtainedthefineaggregateinthe concreteispartiallyreplacedbyusingfoundrysandat10%, 20%, 30% and 40%. An optimum value of replacement obtainedafterperformingthecompressivestrengthtest,split tensilestrengthtestandflexuralstrengthtest.Thestrength after 7 and 28 days curing are evaluated. To the optimum percentagereplacementoffineaggregateusingfoundrysand, basalt fiber is added to strengthen the concrete. The percentageofadditionofbasaltfiberis2%,2.5%&3%bythe weightofcement.Testsareconductedonthespecimensafter 7and28daysofcuringtoobtaintheoptimumpercentageof adding basalt fiber. The percentage ofincreaseinstrength afterreplacefineaggregateusingfoundrysandandaddition of basalt is comparedtotheoriginal strength ofM35 grade concrete.

Table 1: Optimummixpreparation Materials Water (L) Cement ( K g) Coarse Aggregate ( K g) Fine Aggregate ( K g) Super Plasticizer (L) Quantity of1m3 of concrete

197.16 438.13 1119.85 730.50 2.5 Mix Ratio 0.45 1 2.6 1.6 0.006

Table 2:DetailsofReplacedConcreteSpecimen

Percentage of Replacement (%)

Cement (Kg) FA (Kg) CA (Kg) Foundry Sand (Kg) 0 18 28.8 46.8 0 10 18 25.92 46.8 2.88 20 18 23.04 46.8 5.76 30 18 20.16 46.8 8.64 40 18 17.28 46.8 11.52

Compressivestrengthtestisconductedtomeasurethe maximumamountofcompressiveloadamaterialcanbear before fracturing. The test is conducted on a cube of size 15×15×15 cm. the specimen is placed in the compression testing machine and gradually load is applied. The load

beforecrackingthespecimenisnoted.Thistestisallottedas pertherulegiveninIS3495 1992.Thetestisconductedina CompressionTestingMachine.Thistestisthencarriedout onthe7th and28th dayfromthedayofcasting.

Fig 1:CompressiontestingMachine

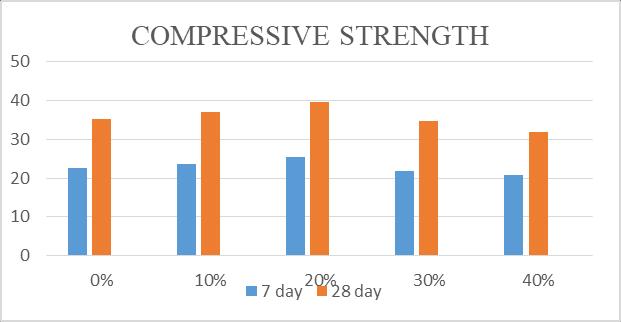

Table 3: CompressiveStrengthTestResults

SL No. Percentage of Replacement (%)

7 Day Test (N/mm2) 28 Day Tests (N/mm2)

1 0 22.67 35.11 2 10 23.55 37.11 3 20 25.33 39.55 4 30 21.77 34.66 5 40 20.88 32

Fromtheresultsobtained,thecompressivestrengthat thereplacementof10%and20%theincreaseinstrengthis 5.69%and12.64%.Atthereplacementof30%and40%the strengthisdecreasing1.28%and8.85%respectivelyfrom itsoriginalstrength.Fromtheseresultsoptimumpercentage replacement of fine aggregate with waste foundry sand is 20%. Themaximumcompressivestrengthobtainedatthe replacement of 20% and the percentage of increase in strengthis12.64%.

Graph 1:Compressivestrength

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

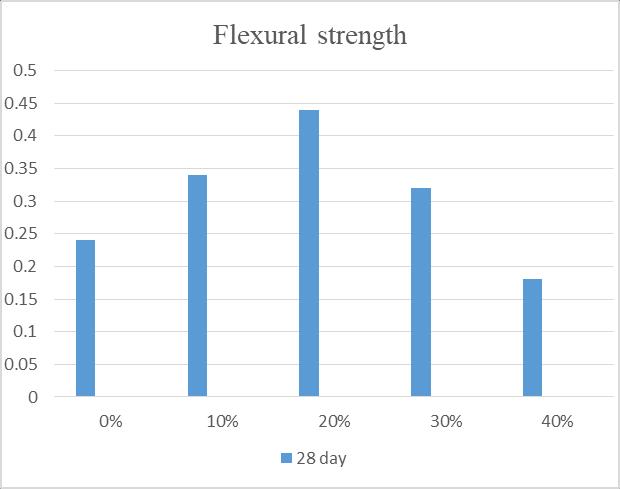

Flexuralstrengthtestisusedtomeasuretheresistance tobendingoftheconcrete.Thetestisconductedonanon reinforcedconcretebeamofsize50×10×10cmafter7and 28dayofcuring.

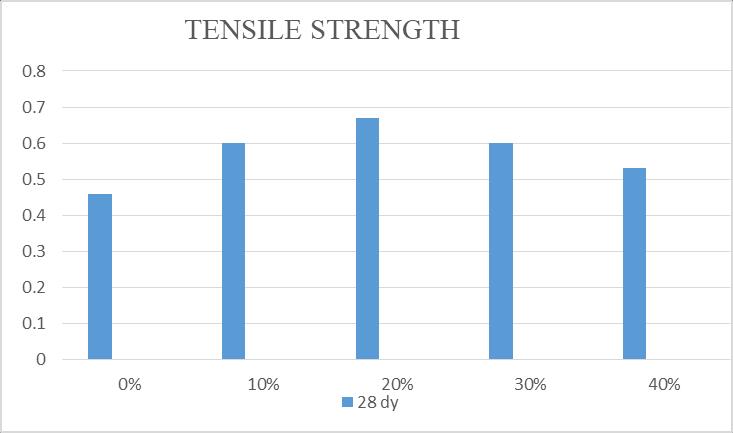

The split tensile strength test on concrete is conducted to measuretheresistancetensileforcewhen stressisapplied A cylindrical specimen is used for the test. The tensile strength of concrete is measured by the unit of force per cross sectional area. The most common machine used is universaltestingmachine.

Table 4: FlexuralStrengthTestResults

SL No. Percentage of Replacement (%)

28 Day Test (N/mm2)

1 0 0.24 2 10 0.34 3 20 0.44 4 30 0.32 5 40 0.18

Fromtheresultsobtained,theflexuralstrengthatthe replacement of 10%, 20% and 30% the percentage of increase in strength is 41.66%, 83.33% and 33.33% respectivelyfromitsoriginalstrength.Atthereplacementof 40%thestrengthisdecreasing54.16%.Fromtheseresults optimum percentage replacement of fine aggregate with wastefoundrysandis 20%. Themaximumflexuralstrength obtainedatthereplacementof20%andthepercentageof increaseinstrengthis83.33%.

Table

SI No. Percentage of Replacement (%)

28 Day Test (N/mm2)

1 0 0.46 2 10 0.60 3 20 0.67 4 30 0.60 5 40 0.53

From the results obtained, the split tensile strengthatthereplacementof10%,20%,30%and40%the increaseinstrengthis30.43%,45.65%,30.43%and15.21% respectively from its original strength. From these results optimum percentage replacement of fine aggregate with waste foundry sand is 20%. The maximum split tensile strength obtained at the replacement of 20% and the percentageofincreaseinstrengthis45.65%.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

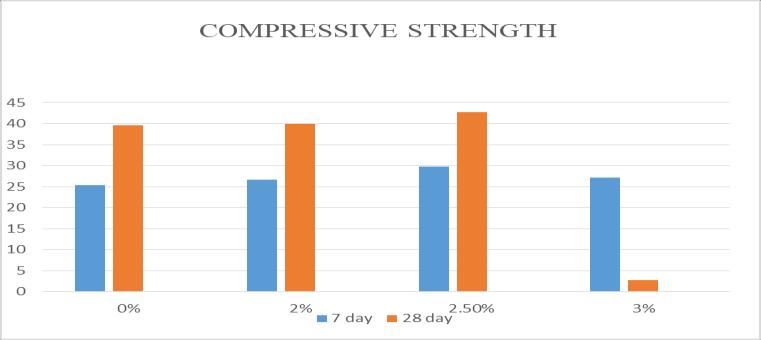

Table 6: CompressiveStrengthTest

SI No. Percentage of Adding (%)

7 Day Test (N/mm2) 28 Day Test (N/mm2)

1 0 25.33 39.55 2 2 26.66 40 3 2.5 29.77 42.66 4 3 27.11 39.11

Fromtheresultsobtained,thecompressivestrengthatthe additionof2%and2.5%theincreaseinstrengthis1.13% and 7.86% respectively than its original strength. At the additionof3%thesplittensilestrengthisdecreasing1.11% Fromtheseresultsoptimumpercentageadditionofbasalt fibertotheconcretebytheweightofcementis 2.5%. The maximumcompressivestrengthobtainedattheadditionof 2.5%andthepercentageofincreaseinstrengthis45.65%.

Graph 4: CompressiveStrengthTest

the addition of 2.5% and the percentage of increase in strengthis27.27%.

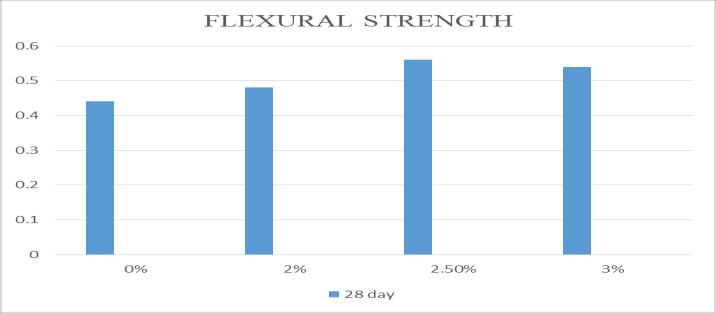

Graph 5:FlexuralStrengthTest

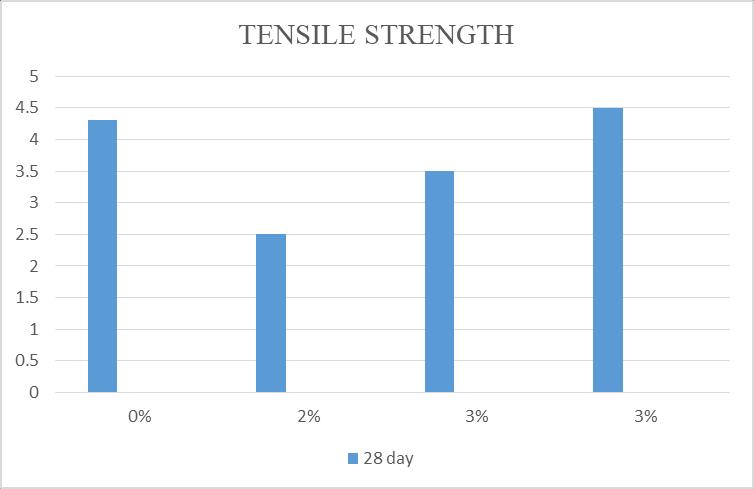

Table 8: SplitTensileStrengthTest

SI No. Percentage of Adding (%)

28 Day Test (N/mm2)

1 0 0.67 2 2 0.67 3 2.5 0.74 4 3 0.71

Fromtheresultsobtained,thesplittensilestrengthat theaddition of 2%thereis noincreaseinstrength.At the additionof2.5%and3%theincreaseinstrengthis10.44% and5.97%respectivelythanitsoriginalstrength.Fromthese resultsoptimumpercentageadditionofbasaltfibertothe concrete by the weight of cement is 2.5%. The maximum splittensilestrengthobtainedattheadditionof2.5%and thepercentageofincreaseinstrengthis10.44%.

Graph 6:SplitTensileStrengthTest

Table 7: FlexuralStrengthTest

SI No. Percentage of Adding (%)

28 Day Test (N/mm2)

1 0 0.44 2 2 0.48 3 2.5 0.56 4 3 0.54

Fromtheresultsobtained,theflexuralstrengthat theadditionof2%,2.5%and3%theincreaseinstrengthis 9.09%, 27.27% and 22.72% respectively than its original strength. From these results the optimum percentage addition of basalt fiber to the concrete by the weight of cementis 2.5%. Themaximumflexuralstrengthobtainedat

Factor value:

In this study the mechanical properties of the concrete by partial replacement of fine aggregate withfoundrysandby10%,20%,30%&40%were investigated.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

The compressive strength at 10% replacement of fine aggregate with waste foundry sand shows 5.69%ofincreaseandatthereplacementof20%, the percentage of increase is 12.64%.The compressivestrengthof30%and40%replacement shows 1.28% and 8.85% of decrease than its original strength. So as per compressive strength test,theoptimumpercentagereplacementobtained forcompressivestrengthtestis20%.

ofincreaseinstrengththanitsoriginalstrengthon M35mix.

The addition of basalt fiber improves the mechanicalproperties.

Basalt fiber increases durability and reduces workabilityofconcrete.

The Flexural strength at 10%, 20% and 30% replacementoffineaggregatewithwastefoundry sand shows 41.66%, 83.33% and 33.33% of increase in strength respectively. At 40 % replacement shows 54.16% decrease in strength thanitsoriginalstrength.Soasperflexuralstrength test,theoptimumpercentagereplacementobtained forflexuralstrengthtestis20%.

1. Vishal Pandurang Kumbhar (2017)BasaltRock Fibers New Construction Material”AGTI‟s Dr. Daulatrao Aher College of Engineering, Karad, India

The Split tensile strength at 10%, 20%, 30% and 40% replacement of fine aggregate with waste foundrysandshows30.43%,45.65%,30.43%and 15.21% of increase in strength than its original strength respectively. So as per Split tensile strengthtest,theoptimumpercentagereplacement obtainedforsplittensilestrengthtestis20%.

2.AGTI‟s Dr. Daulatrao Aher College of Engineering, Karad, India Rafat Siddique, Geert de Schutterb, Albert Noumowec,(2019) “Effect of used foundry sand on the mechanical propertiesofconcrete”, Constructionandbuilding materials, Elsevier, vol .23, Issue.2, pp. 976 980.

Thestrengthcharacteristicsofconcretealsostudied inthisprojectbyaddingbasaltfibertotheoptimum replacementofFAusingWFS(20%).

3. Gurpreet singh, (2019)“Strength and durability studies of concrete containing waste foundry sand”, Ph. D. Thesis, Department of Civil Engineering, Thapar University, Patiala, Punjab, India,.

Thecompressivestrengthattheadditionof2%and 2.5%ofbasaltfiberbytheweightofcementshows 1.13% and 7.86% of increase in strength than its originalstrength.Attheadditionof3%,thestrength isdecreasing1.11%thantheoriginalstrength.So the optimum percentage addition of basalt fiber obtainedforcompressivestrengthtestis2.5%.

4.Van de Velde K., Kiekens P., Van Langenhove L.(2019) “Basalt Fibres As Reinforcement For Composites” Department of Textiles,GhentUniversityTechnologiepark907,B 9052 Zwijnaarde, Belgium.

5. Jiri Militky, Vladimir Kovacic; (2020)„Ultimate MechanicalPropertiesofBasaltFilaments‟, Text. Res. J. 66(4), 225 229.

TheFlexural strengthatthe additionof2%,2.5% and 3% of basalt fiber by the weight of cement shows 9.09%, 27.27% and 22.72% of increase in strengththanitsoriginalstrength.Sotheoptimum percentage addition of basalt fiber obtained for flexuralstrengthtestis2.5%.

6.Tengiz Chantladze;(2020)„Industrialassimilation oftheeffectivetypeoffibrewithmulticomponent charge

7. Sergeev et al.; „Basalt Fibers (2021)A Reinforcing Filler for Composites‟, Powder Metallurgy andMetal Ceramics,33(9 10),555 557

The Split tensile strength at the addition of 2%, 2.5%and3%ofbasaltfiberbytheweightofcement shows 0%, 10.44% and 5.92% of increase in strengththanitsoriginalstrength.Sotheoptimum percentage addition of basalt fiber obtained for splittensilestrengthtestis2.5%.

8. Yuce Guney, Yasin Dursun Sari, Muhsin Yalcin, Ahmet Tuncan, Senayi Donmez , (2021)“Re usage of waste foundry sand in high strength concrete”, Waste management, Elsevier, vol. 30, Issue 8, pp.1705 1713.

From the results the optimum percentage replacementoffineaggregatewithwastefoundry sandandstrengtheningofconcreteusing2.5%of basaltfiberbytheweightofcementshows21.50%

9. U. Saveria Monosi, Daniela Sani and Francesca Tittarelli,(2021)“UsedFoundrySandinCement Mortars and Concrete Production”, The Open Waste Management Journal, Vol. 3, pp. 18 25.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

10. IS 10262(2009) Indian standard guidelines formixproportioning.

11. F. Irine, (2020), Strengthaspectsofbasaltfiber reinforced concrete, Int. J. Innovative Res. Adv. Eng.1(8)192 198,VITO.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal