International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

2

1Student, KIT’s College of Engineering, Kolhapur, Maharashtra, India

2Professor, Dept. of Mechanical Engineering, KIT’s College of Engineering, Kolhapur, Maharashtra, India ***

Abstract Along with quantity the quality of finished part is examined strictly for the purpose and application of the finished part, the quality of production system is also important.Qualityofproductionsystemintermsofutilization ofmachinesandhumansinvolvedinsystemisimportant.Lean manufacturing concept is all about improving the performance continuously by eliminating the waste and to become competitive in production. The study focuses on a machine shop working in industrial sector with its sister companies, fluctuations in demands and also new critical developmentsforbatchproductionarethemainobstaclesthat shop is facing in their normal routine work. We are studying thenewlyintroducedbatchproductionsystemtoincreasethe productivityandutilizationoffacilities involvedinthesystem withworkstudyandsimulationtool.Theprocessofmachining isstudiedbymethodstudy, Thestandardtimesarecalculated by time study, the proposed modifications in current working system are examined using simulation tool FlexSim. Simulation assists to study precisely the different manufacturingscenariosandmachinearrangements;itgives sophisticated advantages than other methods like mathematical method. FlexSim is best way to compare the results obtained by certain changes in experiments in such cases.

Key Words: LeanManufacturing,MethodStudy,TimeStudy, Simulation,FlexSim,TheMachineshopunitisworkingalmostmorethan20years inautomobilepartsandancillary’sfield.Theyhaveachieved great success in developing and supplying of machining critical components to the exact needs. In previous stages industrywasnotinmassproductionbutworkinginbatch production.Inpastfewyearstheyarefacingfluctuationsin demands and new critical developments for batch production. These fluctuations lead them into loss of controlled production, production losses due to improper capacity planning. Fluctuations in demands and also new critical developments for batch production are the main obstaclesthatshopisfacingintheir normalroutinework. Duetosuchreasons,theyarefailingtomeetmonthlytargets also the loss of controlled production, idle machines and operators, difficulties in manpower planning. Aim of the studyistoobserveandanalyzethemachineshopworking havingcombinationofnewlyintroducedbatchandoldmass

productionandconfirmthattheshopisbalancedwelland putforwardthecorrectivemeasures.

Machineshopisfacingsomeproblemslike,Nostandardtime defined for the stages of machining, WIP Work in process inventory present in inaccurate amount, Idleness of machineries,Failuresinmeetingtheweeklydispatchtargets, Idlenessofworkers,Problemsfacedinmanpowerallocation anditsplanning WiththehelpofWorkstudyandsimulation tool we are going to identify the hidden reasons behind idleness, bottlenecks and provide the suggestions to minimizeit.

Inmostoftheindustriessomecommontypesofwastes arepresentlikedefects,excessproduction,excessprocessing, idleness,unnecessarymaterialmovements,etc.Thesewastes mayaffectasincreaseincostofendproducts.Basically,lean manufacturingisabunchofscientifictoolswhichbelongsto common departments present in an industry. Lean manufacturing is a way of enhancing productivity by eliminating or reducing these different wastes present in industries as well as eliminating the non value adding activities.[1.1] Reduction in waste results in reduction of total manufacturing time and improved quality of the product. There are different lean tools for identificationof sourcesofwastesinsystemandtostudyitseffectonoverall system,aftertheidentificationsomeleantoolsarehelpfulfor study how the wastes can be eliminated. Though the lean manufacturingismostlyamanagerialfunctionitsawareness inworkshopandlower levelpersonalisveryimportantto get the benefits of such philosophies.[1.2] The study of designedpartorproductforthepurposeofdefiningthebest suitablemethodofproducingitandalsospecifyingthetime toperformitbythechosenmethod.Therefore,itcomprises oftwoareasofstudyoneismethodstudyormotionstudy and time study that is work measurement. Method study knownasworkmethoddesign,itisapplicabletonewparts as well as used for existing parts to find better way of manufacturingthepartsthatissafe,requirelesseffort,and time.[2.1]Timestudyprovidesthestandardspecifiedtime thatisthetimeneededbyaworkertocompleteapartbythe suitablepreferredmethodorthemethodalreadydefinedby methodstudy.Timestudyisimportantforproperplanningof manpower,machinery,equipmentrequirementalsomaterial requirement planning, per unit cost of production, labor

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

budget,etc.Hencewiththeapplicationofmethodstudyand timestudyinindustries,wecanachievebetteroutput,quality atlowcostandhenceproductivitycanbeimproved.[2.3]In simplewordsVSMisatoolusedforcreationofmaterialand information flow map of a product or process. Different departmentsinanyindustryusevalueasawordfordifferent meanings,mostlyproductiondepartmentrelatesittocostof production.Avalueaddingactivityofaprocessisthatactivity for which the customer is willing to pay. A value stream consists of non value adding activities with all the manufacturing processesincludingsupportiveactivitiesto convert raw material into finished goods. It is a lean manufacturingtooltodevelopanefficientproductionprocess throughsystematicdatacollectionandanalysis.[3.1]Atmost ofsmallandmediumscaleindustriespartsareproducedin batchtypeproductionwithprocesstypeoflayout,thisresults in greater WIP, material handling, difficulties in achieving deliveryscheduletargets,frequentchangesinsetupswhich leads in improper utilization of machinery. For such situationsGTisthetechnologythataddstheadvantagesof mass production in to the batch production. [4.1] Line Balancing, the word ‘line’ used in following case is for productionorassemblylineanditsbalancingmeanstomake productionsystem smooth and efficient by runningall the operationsormachineswithsamepaceordividingtherateof work among the workstations, workers, and machines evenly.Alsoinanotherwaywecansayassignmentofproper quantity of machines and workers to each operation to achievetherequiredrateofproductionwithlessidletime. [6.1]

Themainobjectiveofthecurrentmachineshopstudymust begin by identifying and listing down the problem, then requireddatashouldbegatheredfortheanalysis.Thearea wheretheimprovementisneededtobeidentifiedbasedon theinformationcollected.Ananalysisshouldbedonetofind theexactpartthatismostlikelytobeimproved.Practical difficultiesduringactualimplementationwillbeidentified throughtrialexecutionandtheworkingshouldbeverified bysimulationsoftwareFlexSim.Discussionmustbemadeon theresultsofsimulationexperimentsanditsresultsbefore theconclusions.

Themachineshopuniteworksonroughfoundryproductsto makeitfullfinishedpartinvolvingsuperfinishingprocesses. By listing the parts that the machine shop having regular demandsforthepastfewyears,tounderstandtheworking of machine shop we observe each part, how it passes throughdiffermachiningprocess,thesequenceandtypeof materialhandlingsystemsused,iftheymovesinglepieceor form an unite load. And developed the process flows of respected part that is machined in machine shop. On collecteddata and bydiscussing withshopauthorities we selected MK 25 HUB for further studies considering

economic contributions, manual efforts involved and the technicalconsiderations.

By collecting all the information and specifications of machineshopfacilitieswedevelopedtheprocessflowchart andgeometriclayoutfortheMK25HUB.

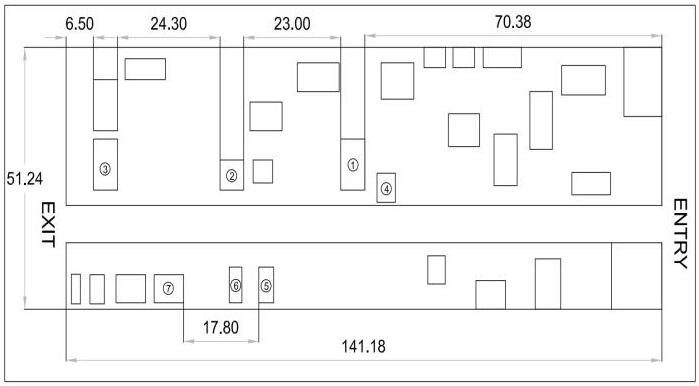

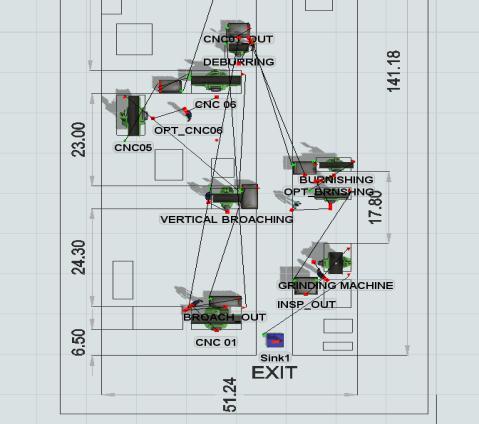

Fig 1:Geometriclayout

[1.CNC06,2.VerticalBroachingMachine,3.CNC01,4. DeburringTable,5.BurnishingMachine,6.Inspection Table,7.GrindingMachine]

As the name itself indicates, model that represents all the important elementsandits characteristicsastheyexist in actual machine shop. Man, Machine, Material, Material handlingequipment,inventories,inputorincomingmaterial, etc.arethemainelementsofmachineshopasweidentified andourmachineshopsimulationmodelshouldhaveinit

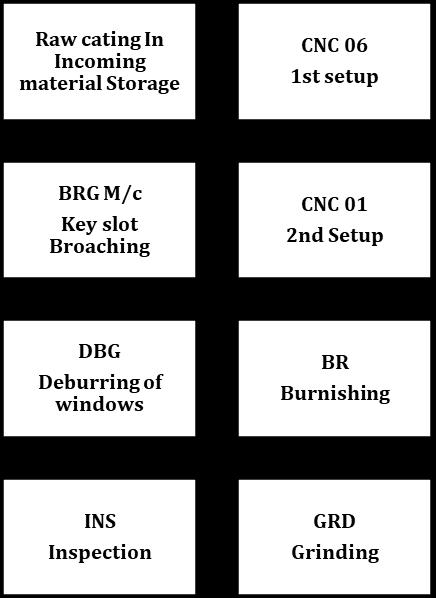

Fig 2:ConceptualModel

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

As the objective is to improve productivity the output of system is first performance variable, and second is utilizationofmachines.

Work measurement or simply the time study by video recording of each machining activity then breaking down them into small elements then summarizing and adding allowancestobasictimegivesthestandardcycletimesfor the processes involved in machining the Hub. Also the summerygivesthenonvalueaddingactivitiesthatshouldbe avoidedtoreducecycletimeorsetuptimewhichwillimpact positivelyontotalprocessingtime.

Table 1: TimestudysummeryreportforMK25HUB

Sr no. Operation Set up/Loading Unloading Time(sec.)

Processtime (sec.)

1 1stSetup 22 240 2 Broaching 46 30 3 Deburring 2 80 4 2ndSetup 24 80 5 Burnishing 10 41 6 Grinding 24 153 Total 128 624 Total(sec.) 752 Total(min.) 12.53

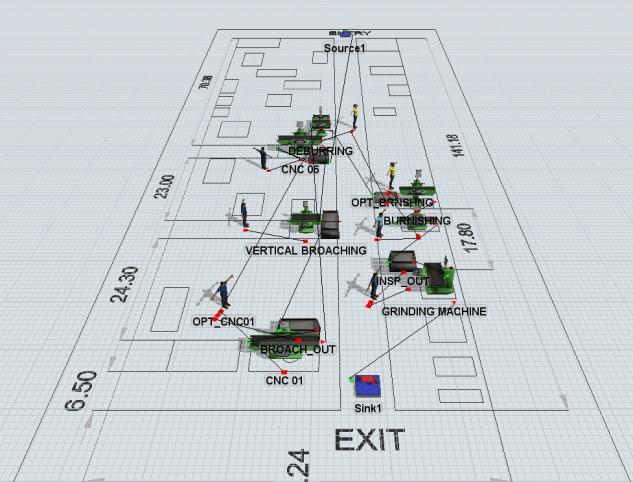

Using FlexSim Express the actual machine shop unite is imitedinflexSim.Thedimensionallayoutinimportedand theelementsprovidedbysoftwarefixedresourcesandtask executers the machines and operators are placed at the locaton.

Model verification is done by comparing the developed modelwithconceptualmodelandbydeterministicapproach usingaveragecycletimescrossverifyingtheconstantoutput that system gives on trial runs. Then by using the normal probability distribution for setup and process times of machinesvalidatedthemodelcomparingtheactualmachine shopdispatchesandtheoutputoftrailrunsofsystemforthe sameperiodoftime,whichwillbethestochasticmodelfor theexperiments.

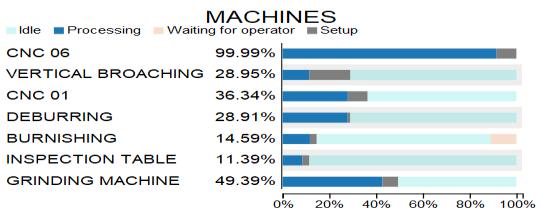

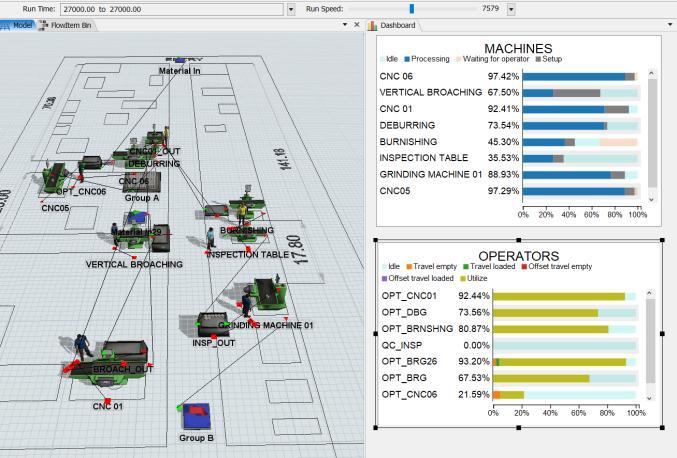

Fig -4:Existingsystemrunfor8Hrs.shift.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Bottleneckpresentatthe1st setupofprocessthatidlesthe othermachinesinsystem.Thecycletimeisalmostdouble theotherprocesseshenceintroducingadditionalCNCtothe systemtomatchthepace.

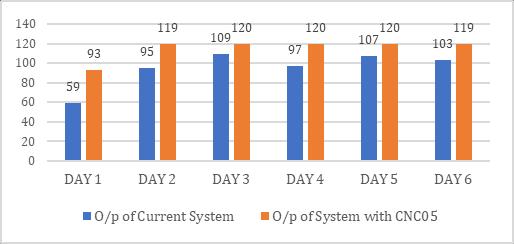

Chart 1:NameSystemoutputforaweekof8Hrs.shift.

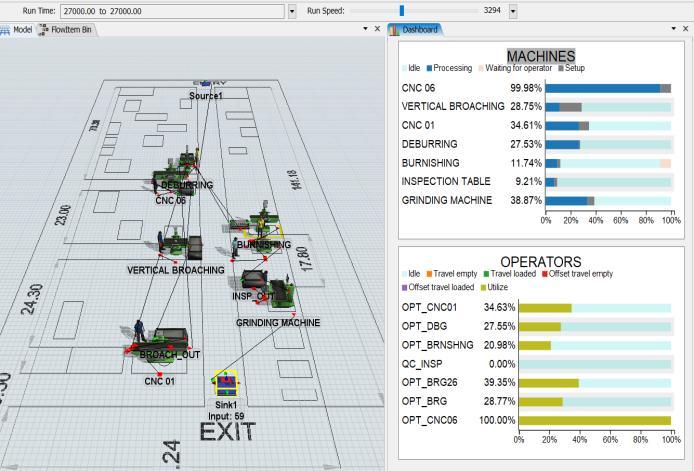

Current system shows the output of 59 Hubs. against the inputof120for8Hrs.dailyshift.Andtheutilizationofallthe machines except machine used for 1st setup, also the inventoriesremainunfinishedattheendofshift.

Focusing on the inventory levels remained unfinished decided to run the shift for 12 Hrs. and it shows that the targetsareachievedinfactthesystemprocessedtheHubs morethantherequirementbuttheutilizationofmachines andoperatorsremainbelovethe50%.

Fig -5:SystemwithadditionalCNC

Chart 3:Systemoutputforaweekof12Hrs.shift.

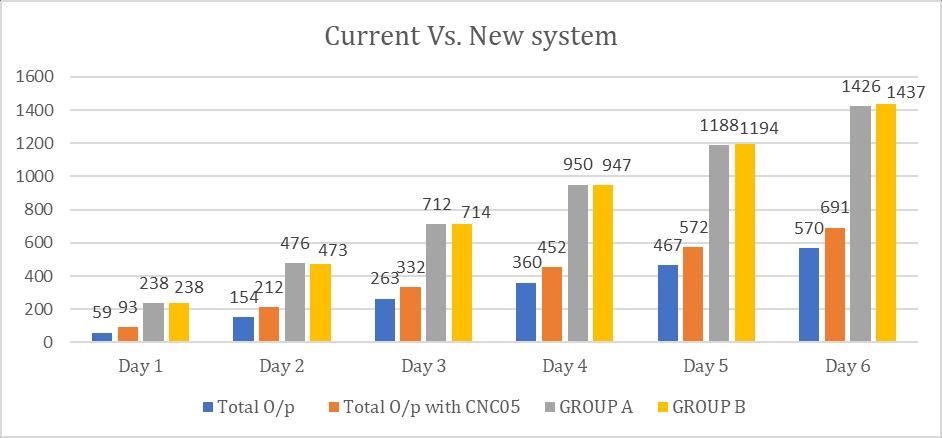

Chart 4:CurrentsystemVs.SystemwithadditionalCNC

Thissystemproducesnearlywhatactuallyrequiredbythe schedule per day. The output is improved by 21.22%. but looking at utilization rates the all the machines are under utilized also the operators are under utilized hence the systemnotfulfillsourprimeobjective.AdditionofCNCto the 1st setup the bottleneck is shifted from first two machines in the system but observed that the two CNC machinescanprocessbasicrequirementinhalfoftheshift. Andremainidlefortheotherhalf.Henceitisbettertodivide thesystemintwogroupsandrunthemalternately. Also,can request for double the input as the system capacity is increased.

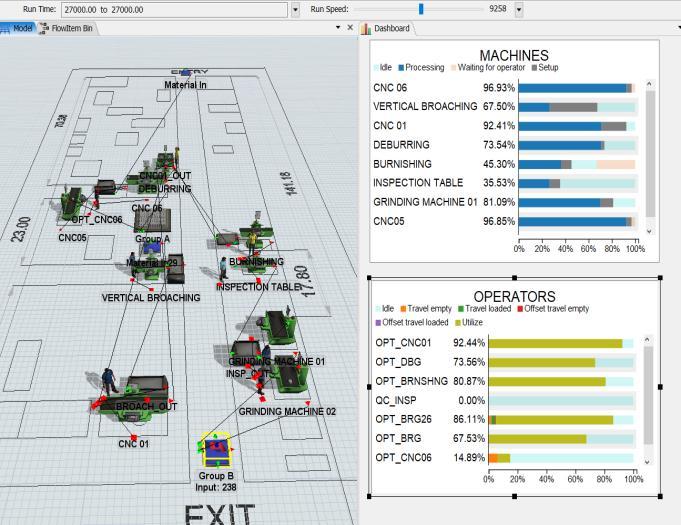

8.3

Dividingoursystemintwogroups,

GROUPA :CNC05andCNC06

GROUPB : Vertical Broaching, CNC01, Deburring, Burnishing,GrindingMachine.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Fortheaimofincreasingtheutilization runningtheGROUP Ainfirst8Hrs.shiftandtheGROUPBinsecond8Hrs.shift oftheday.

Fig 6:GROUPAandGROUPBrunfor8Hrs.shift

The output of the group A (200) is close to the target quantity240.Wearesuggestingthecycletimereduction,if possible,forthe1stsetupoperationwiththeuseofdifferent insertsandtoolingwhichcanbeusedathigherspeedfeed rates,andthesetuptimeof22sec.canalsobeminimizedby operatortraining.WeareaskingtoCNCsetterforreduction ofcycletomeby30sec.andsetuptimefor10sec.

Theoutputofthegroupis139whichisnotfeasible,Reason behindthatisthecycletimeofgrindingmachine.Grindingis thebottleneckoperationhere,astheinputtotheprocessis 240andtheoutputis139HUBs.

Grindingisafinishingprocessandbystudyingtheprocess itseemsthattheoperatorisfullyinvolvedthroughoutthe cycletimeandtherearesmallpossibilitiesofreducingthe cycletime.Hence,wearelookingforthegrindingmachine whichisundermaintenancepresentneartheGrinding machineinvolvedinthepresentsystem.

In this experiment working for removal of bottleneck present near last process grinding, to tackle the problem assumingthemachineundermaintenancepresentnearthe grindingmachineisreadyforperformingsameoperationas GrindingMachine01.SecondModificationisthesetupand processtimeof1st setupisreducedby10sec.and30sec. respectively.

The system run in groups for alternate shift matches the outputtotherequiredperdayinputandtheutilizationofall theoperatorsandmachinesinvolvedinprocessingHubsare above 70%. It seems that by that modifications all the objectivescanbeachieved.

In this study, by video recording and time study standard timesfortheprocessesinvolvedinthemachiningofMK25 HUBiscalculated.Thecycletimesandthetimestudydata canbeusedasbaseforthefurtherstudies,wheneverthe supplyanddemandfluctuateinthefuturethedatacanbe usedtosetoptimummachiningsystemfortheHUB.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

–

Currentsystemrunforextra 4Hrs.

i.e.,Dailyshiftof12workingHrs.

Output Targetachieved

MachinesandOperator Utilization ExceptCNC06 allareunder40%

Experiment

IntroducedCNC05inthe system.(bottleneck CNC06)

Increasesinproductivityby 21.22%(forsame8Hrs.)

Outputof570Hubsatthe endofweekincreasedto691 Hubs.

MachinesandOperator Utilization ExceptCNC06all areunder40%

Sixoperator havingAvg.daily wadges390Rs. Workedfor additional4Hrs.

Total30000Rs.Per month

[1.1] Dr. Manocher Djassemi “Lean adoption in Small Manufacturing Shops: Attributes and Challenges” The Journal of Technology, Management, and Applied Engineering,Volume30,January March2014.

1.2Lee,C.Y.JITadoptionbysmallmanufacturersinKorea, JournalofSmallBusinessManagement 35(3),98 108.1997

[2.1] Rishabh Mishra, Ujjain Engineering college, Ujjain “ProductivityimprovementinAutomobileindustrybyusing methodstudy”InternationalJournalofScientificEngineering andAppliedScience(IJSEAS) Volume 1,Issue 4,July2015 ISSN:2395 3470

MachineHr. rate(350)of CNC05addedto theexpenditure

Total2800Rs. Perday

Total72800Rs. Permonth

[2.2]ShantideoGujar1,Dr.AchalS.Shahare2“Increasingin Productivity by Using Work Study in a Manufacturing Industry”InternationalResearchJournalofEngineeringand Technology(IRJET)e ISSN:2395 0056Volume:05Issue:05 |May 2018p ISSN:2395 0072

[2.3] V. Ramakrishnan, S. Nallusamy “Optimization of ProductionProcessandMachiningTimeinCNCCellthrough theExecutionofDifferentLeanTools”InternationalJournal of Applied Engineering Research ISSN 0973 4562 Volume 12,Number23(2017)pp.13295 13302

[3.1]SantoshB.Dighe,AbhayKakirde“LeanManufacturing ImplementationUsingValueStreamMapping:ACasestudy ofPumpsManufacturingCompany”InternationalJournalof Science and Research (IJSR) ISSN (Online): 2319 7064 ImpactFactor(2012):3.358

Dividingsystemintwo groupsincreasinginputto 240unitesrunningthem alternately.

Utilizationofallthe machinesabove70%.

Bottleneckpresentingroup Bwhichgivesoutputof139 finishedhubsagainst240.

Introductionofgrinding machineno.02insystemfor bottleneckingneargrinding operation.

MachineHr. rate(350)of CNC05addedto theexpenditure

Total2800Rs. Perday

Total72800Rs.Per month

[3.2]HimanshuVasnani,AmitTiwari,3Dr.NeerajKumar,4 MahendraLabana“ProductionFlowAnalysisthroughValue StreamMapping”IJERSEVol.No.6IssueNo.10Oct2017

[4.1]NittayaNgampakandBusabaPhruksaphanratCellular ManufacturingLayoutDesignandSelection:ACaseStudyof ElectronicManufacturingServicePlant,Vol.IIIMECS2011

MachineHr. rate(280)of CNC05addedto theexpenditure

Total2240Rs. Perday

[4.2]ShishirBhat.B.NResearchScholar,Dept.ofMechanical Engineering, Dr. M. G. R. University, India “Cellular manufacturing The heart of Lean Manufacturing” ISSN 1854 6250APEM20085.Bottlenecks

Daily240outputafter16 Hrs.

Total58240Rs.Per month

[5.1] Prof. Wieslaw Urban “THE CASE STUDY OF BOTTLENECKS IDENTIFICATION FOR PRACTICAL IMPLEMENTATION TO THE THEORY OF CONSTRAINTS MAPE 2018” volume 1, issue 1, pp. 399 405Date of acceptanceofthearticlebytheEditor:07/2018

Allmachinesandoperator utilizationabove70%.

Operator10000 Rs.Permonth

[6.1]R.SuganthiniRekha1,P.Periyasamy1andS.Nallusamy “LeanToolsImplementationforLeadTimeReductioninCNC Shop Floor of an Automotive Component Manufacturing Industry” Indian Journal of Science and Technology, Vol. 9(45),DOI:10.17485/ijst/2016/v9i45/104841,December 2016

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[6.2] Shuang Liu Kunming University of Science and TechnologyKunming,China“AnAnalysisontheAutomobile InteriorAssemblyLineBalancingBasedonM plant”The2nd International Conference on Computer Application and SystemModeling(2012)

[6.3]GunjiVenkataPunnaRao,S.NallusamyandM.Rajaram Narayanan, Augmentation of Production Level using DifferentLeanApproachesinMediumScaleManufacturing Industries,InternationalJournalofMechanicalEngineering andTechnology8(12),2017,pp.360 372.

[6.4] Xiao meng Li College of Information System and Management, National University of Defense Technology, Changsha,China(lxm2769@126.com)“LayoutAnalysisand DesignoftheSpindleBoxProcessingWorkshop”©Atlantis Pressandtheauthor(s)2017E.Qietal.(eds.),Proceedingsof the23rdInternationalConferenceonIndustrialEngineering andEngineeringManagement2016,DOI10.2991/978 94 6239 255 7_32

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal