International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Prof.S.D.Chougule1 , G.Hrishikesh2 , K.Anuprita3 , K.Nidhi4 , M.Muskan5 , S.Anuj6

1Assistant Professor, Dept. of Mechanical engineering, Savitribai Phule Pune University, Maharashtra, India 23456UG student, Dept. of Mechanical engineering, Savitribai Phule Pune University, Maharashtra, India ***

Abstract Since high fuel prices and environmental damage are one in every, of the most concerns of the planet without delay, various styles of engines are developed to beat this environmental damage. one in all the most sorts of IC engines that play a significant role in overcoming this challenge is that the LHR engine during this project, a simulation study was conducted using the Ansys commercial software to research the impact of thermal protective coatings (TBCs) on the performance of a single cylinder engine There have been results made with a regular (uncoated) piston, derived as two separate thermal barriers of ceramic Magnesia Stabilized Zirconia (MSZ) and Yttria stabilized zirconia (YSZ) insulated pistons, fastened with a thickness the results of the pistons have shown better performance all told operating conditions over the unmodified piston. This analysis is intended for a good range of bounds coating and has significant differences in temperature distribution betweenthecoatedpistonandalsothenormalpiston.

Key Words: Magnesia Stabilized Zirconia, Yttria Stabilized Zirconia (YSZ), ANSYS, Thermal & Structural Analysis

This project deals with the employment of limit coating on the top of the piston so the temperature inside the chamberincreases. Theaim ofthispaperistoconvert a traditional engine into a low temperature engine and increase engine efficiency. it's answerable for the utilizationofboundarycoatingonthepistonheadsothe temperatureinsidethechamberrises.Effortstoenhance engineefficiencythroughconstructionrepairsareonthe increase today, applications for ceramic coverings for burning engines are growing rapidly to enhance engine performance, a low temperature combustion chamber that conducts pottery ends up in a rise in temperature and pressure on the inner combustion engine cylinders. in our own way to enhance the efficiency of diesel enginesistousealimitcoating(TBC)systemwithinthe combustion chamber. A layer of bond coat (BC) and a layer of ceramic top coat (TC) that may be employed in partswithvarioustechniquesarecalledTBCsystems.

The piston is one of the main and most heated components of IC engines. Where most heat is been produced and requires coating to reduce thermal losses in the IC engine. Piston plays an important role in IC engineitsfunctionisto

Acts as a seal to protect the high combustion pressuretoflowoutside.

And also to receive the explosion and transmit theforcetothecrankshaft.

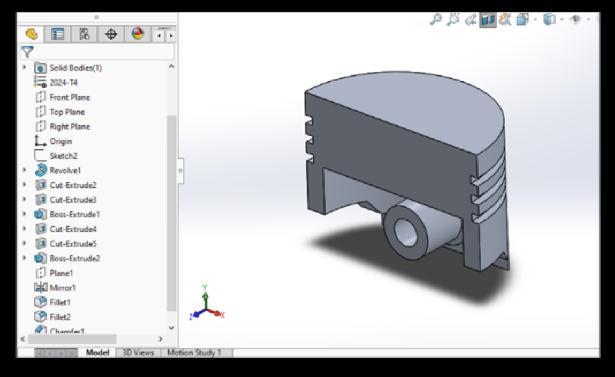

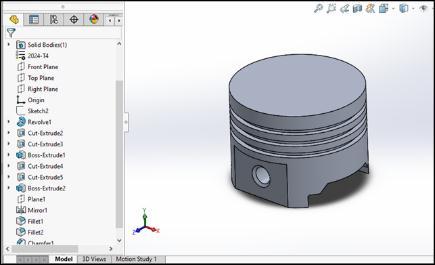

Following are the piston dimensions of the Hero bike 4 strokeenginethatwehaveconsidered.

Pistonlength 37mm

Pistondiameter 49.5mm

Exteriordiameterofapinhole 12.7mm

Interiordiameterofapinhole 6.6mm

Axialthicknessofthepistonring 0.8mm

Theradialthicknessofthering 2mm

Theringgroove'sdepth 2.01mm

Theseparationintherings 2.6mm

Heightofthetopland 5.6mm

Thethicknessofthepistonattop 6.65mm

Thepiston'sthicknessatitsopen end 1.64mm

Modeling is carried out in Solidworks 2020 software by referring to piston dimension table no.1. The material applied on the conventional piston is aluminum alloy andthefollowingarethepropertiesofaluminumalloy:

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

THERMAL BOUNDARY CONDITION

TEMPERATURE 0C HEAT TRANSFER COEFFICIENT (W/m2K)

COMBUSTION CHAMBER 350 300 REGION BETWEEN PISTON HEADANDLINER

330 160 RINGS 250 120 REGION BETWEENRINGS 200 140 PISTON UNDER SKIRT 140 600

Table -3: Temperatureandheattransfercoefficientfor pistonparts

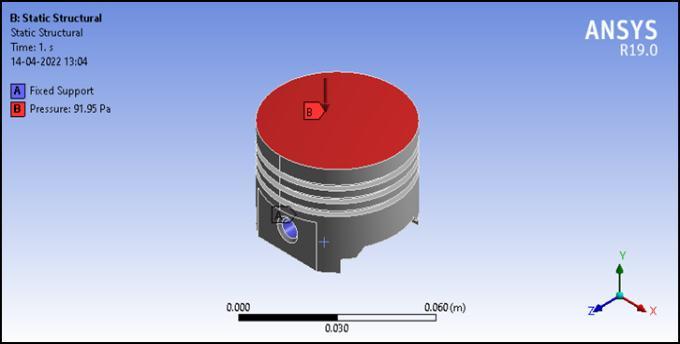

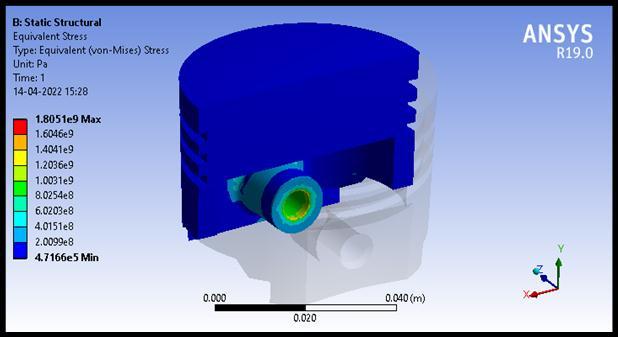

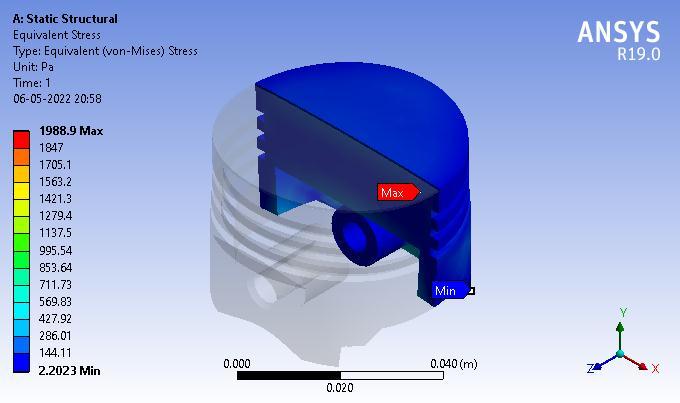

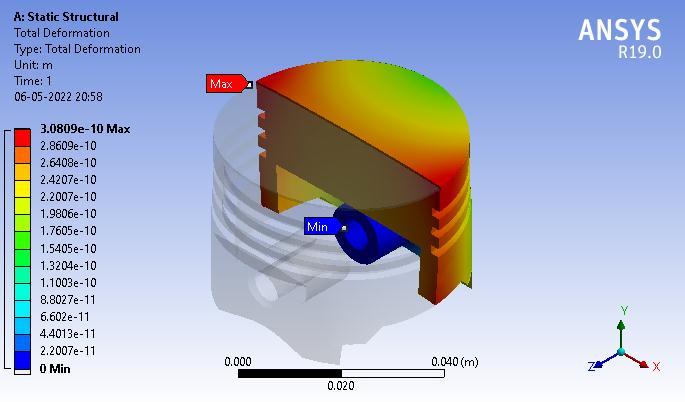

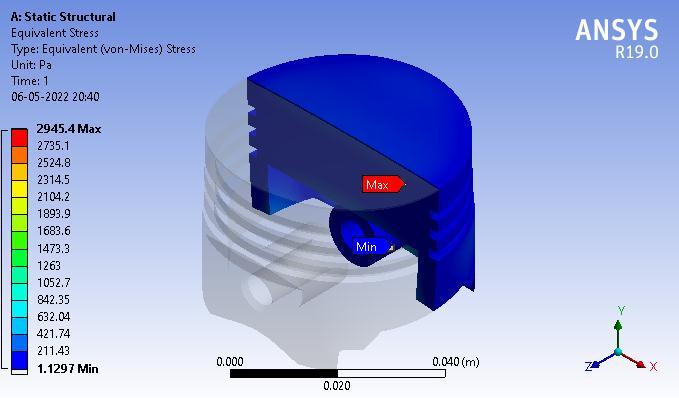

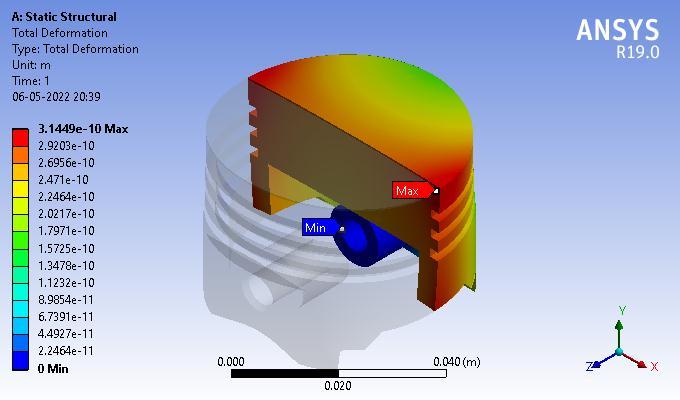

For structural analysis, we have taken fixed support at thesurfaceofthepinhole,andpressureforceisgivento thepistonheadasshowninfig 3.

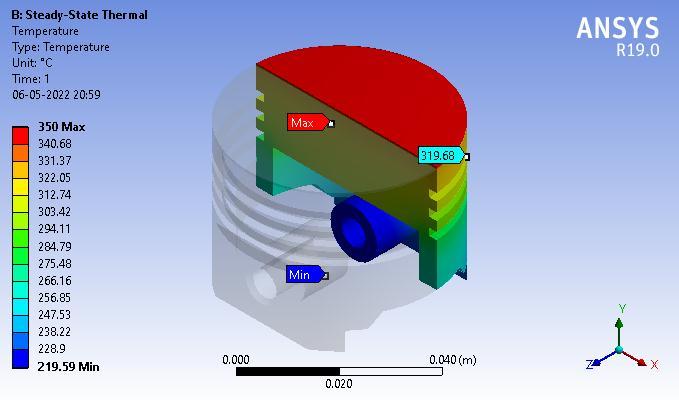

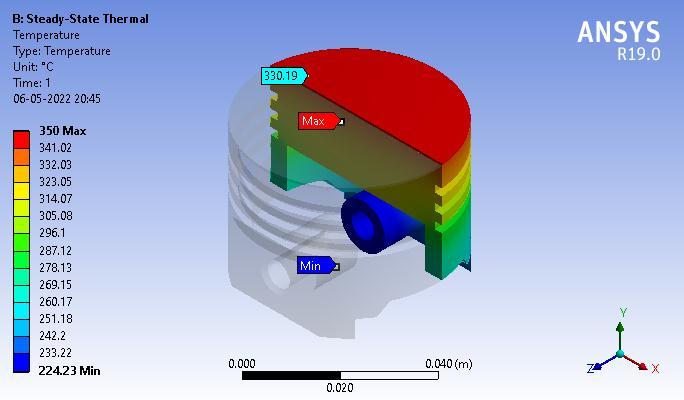

Thermal analysis is performed using the temperature distributionatthepistonhead,topland,ringregion,and skirtasshownintableno.3.

Fig -3: Boundaryconditionsforstructuralanalysis.

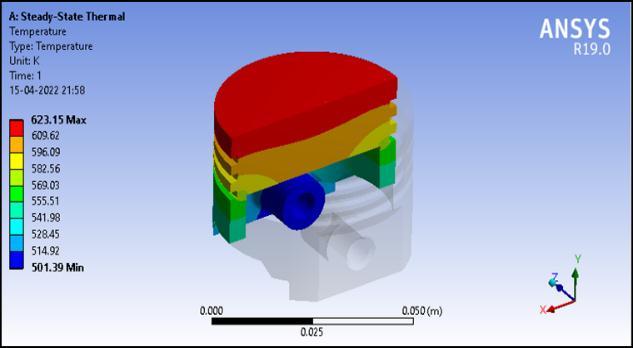

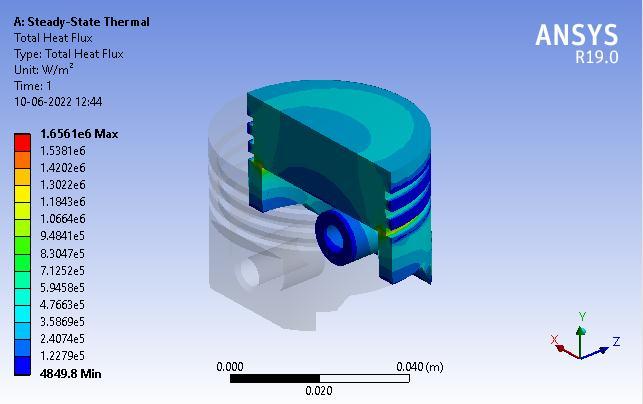

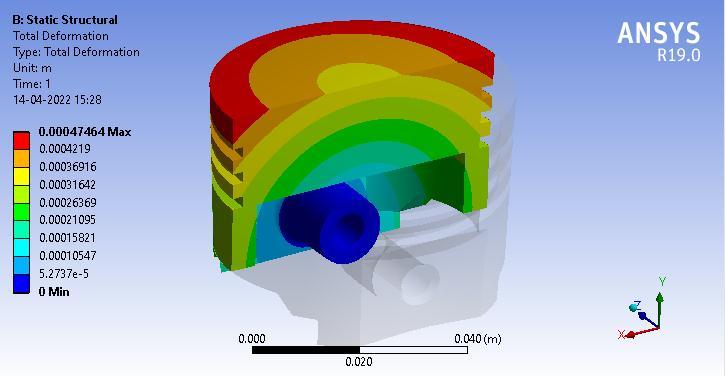

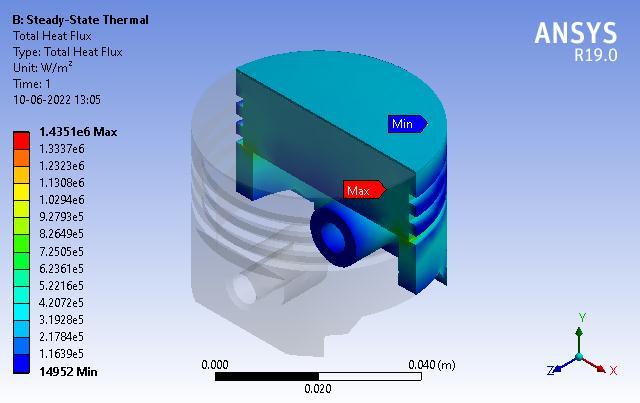

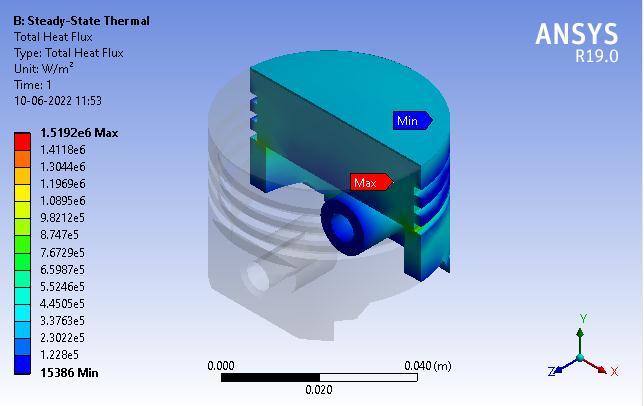

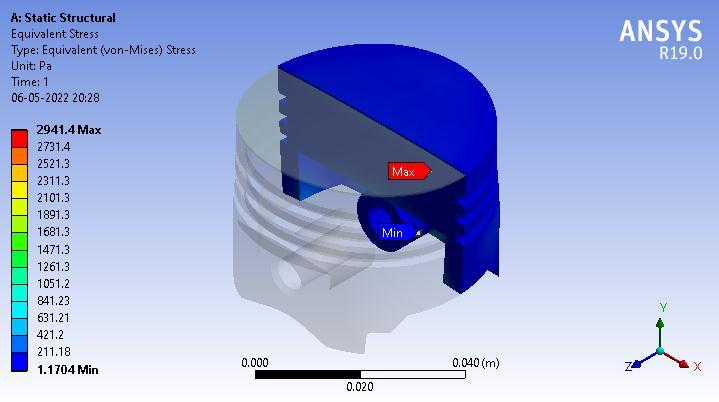

2.3 Ansys results for conventional piston

The analysis is carried out in Ansys software 2021. Following are Ansys results for conventional piston heads.

Fig 4: Temperaturedistributionalongtheuncoated piston

Anexceedinglysophisticatedtechnologycalledathermal barrier coating (TBC) is sprayed to metal surfaces, especially in gas turbine and aviation engine parts that work at extremely high temperatures. TBC should possess the following properties: a high melting point, low density, strong temperature resistance, corrosion free, a high thermal expansion coefficient, and elevated surfaceemissivity.

Any colorful hard, brittle, heat and erosion resistant accessory that is formed by shaping and firing an inorganic,non metallicmaterialatahightemperatureis referred as a ceramic. Ceramic coating is nothing but a chemical polymer result applied to the surface which acts as a thermal hedge coating. As a result, it reduces the heat loss so automatically effectiveness increases. Also, it protects the structural element against high temperature. The use of pottery as thermal hedge coatings has been seen profitable pre dominantly in repaying machines performing in homogeneous combustionsandreducingthermaldispersions.

Severalceramicaccoutrementscanbeusedforcoatings, for illustration, zirconia, magnesia, yttria, silicon nitride, siliconcarbide, beryllia,etc.It'sbeenseenthat the most extensively used ceramic for colorful operations is zirconia.

Acompletelystabilizedzirconia oxideisn'tfavorablefor specialized operations and hence it's incompletely stabilizedandunravelwithotherceramicaccoutrements like yttria, magnesia etc. which also makes it more desirableandeffectiveforoperations

It is a ceramic substance that is employed in severe service applications because of how resistant it is. Its combination of corrosion resistance, toughness, and longevity makes it perfect for machinery parts and valves in demanding applications.While performing the analysis of magnesia stabilized zirconia as a ceramic coating material different coating thicknesses are used i.e, 0.2mm, 0.4mm, 0.5mm, 0.6mm, 0.7mm, 0.8mm, and 1mmrespectively.InthefollowingTableno.7mentioned thematerialpropertiesofMagnesiaStabilizedzirconia:

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1.0 306 6 1.3378 3.0547 1988. 9 0.5 322.8 1.485 3.0826 2098. 3 0.7 316.27 1.4094 3.0743 1988. 9

From the above table 6, we can say that 0.6mm of Magnesia coating thickness is optimum because temperaturedifferenceremainsconstantforconsecutive thicknesses and equivalent stresses are also less as comparedtootherthickness.

Yttrium oxide is doped into zirconium oxide and hence stabilizes its crystal structure at room temperature. While performing the analysis of Yttrium stabilized zirconia as a ceramic coating material different coating thicknesses are used i.e, 0.2mm, 0.4mm, 0.5mm, 0.6mm,0.7mm, 0.8mm, and 1mm respectively. In Table no.7 the material properties of Yttrium Stabilized zirconiaarementioned:

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

temperaturedifferenceremainsconstantforconsecutive thicknesses and equivalent stresses are also less as comparedtootherthicknesses.

The TBC system can be affected by thermal cracking for which the root cause are the induced thermal stresses. These stresses cause varied thermal expansion further crackingthecoatedlayer

ByapplyingYSZcoatedmaterialpropertiesfromtable7 andsimilarboundaryconditionsasuncoatedpistonwe gettheresultsinAnsyssoftware2021.

Following Table 8 is the result table for all thicknesses consideredforYttriumStabilizedZirconiaAnalysis.:

Thick ness (in mm)

Temper ature Distrib ution (˚C)

Temper ature Differe nce in consecu tive thickne ss(˚C)

Heat flux (W/m^2 )*10^6

Total Deform ation (m)*10 ^ 10

Nickel chromium coatings are corrosion resistant coatings. They have a varied range of applications. NiCrAl helps reduce high stress and degradation. Nickel Chromium Alloy works well with Aluminum, steel, copper, brass, and zinc substrates. In the table, no 9 materialpropertiesofNiCrAlarementioned.

Equiv alent stress (Pa)

0.2 338.26 1. 3.166 2945.4 0.4 333.7 5 1. 3.1449 2945.4 0.6 330 4 1. 3.0607 1988.9 0.8 326.8 4 1. 3.1054 2870.2 1.0 322.49 4 1. 3.0866 2870.1 0.5 331.7 1. 3.1346 2945.4

0.7 328.17 1. 3.1151 2870.3

From the above table 8, we can say that 0.6mm of Yttrium coating thickness is optimum because

Thermalconductivity 161 ThermalExpansion 0.000012 Density 7870 Poisson’sratio 0.27 Young’smodulus 90000

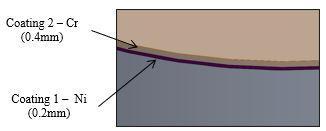

Fortheanalysis,wehaveconsideredatwo layercoating onthepistonasshowninFig16.

Fig -16:Closeviewofa2 layercoating

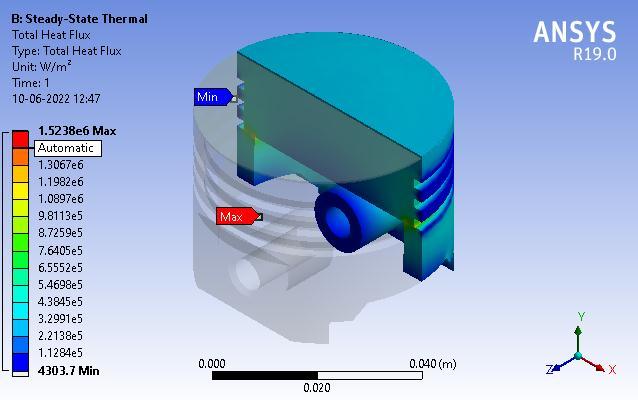

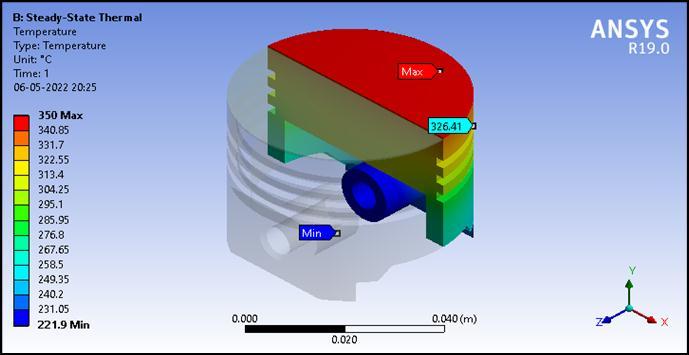

By applying the material properties from table 9 and similar boundary conditions as the uncoated piston, the Followingarethefinalresultsobtained:

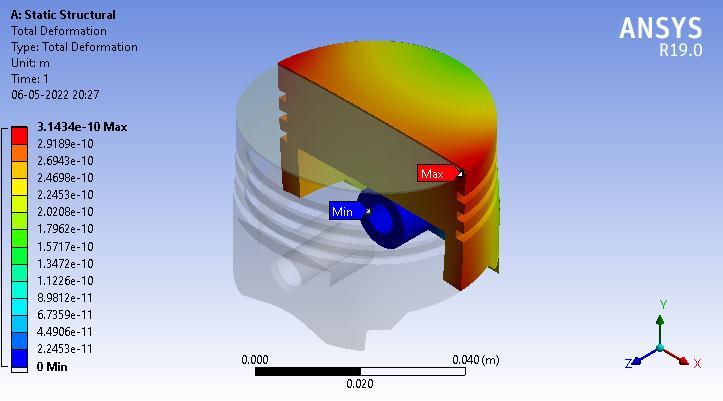

Fig 20: Totaldeformation

Temperature Distribution Heat flux(W/m2) Total Deformation(m) Equivalent stress(Pa)

326.41(inC) 1.523*10^6 3.1434*10^( 10) 2941.4

Table 10: Resultsforuncoatedpiston

VALIDATION

1.TemperatureDistribution:Ceramiccoatingshould resultinhightemperature 2.HeatFlux: Heatfluxishighestinuncoatedpiston

3.TotalDeformation:Zirconiacoatingshouldtendto resultinlessdeformationthanconventional Material Thickne ss (in mm)

Temperat ure Achieved (˚C)

Conventional Piston (Aluminium)

Heat flux (W/m^2 )

Total Deformatio n (m)

0 1.6561 * 10^6 2.9966* 10^ 5

Magnesia 0.6 22.34 1.4351 * 10^6 3.0809* 10^ 10 Yttrium 0.6 12.02 1.5192 * 10^6 3.0607* 10^ 10

Table 11: Validation

From the above validation table, In case of Magnesia resultsfor temperature distribution, Heat fluxandTotal Deformation are 6.38%, 13.34% and 99.5% achieved

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

respectivelyandsimilarly,IncaseofYttriumare3.43%, 8.26%and99.7%obtainedrespectively

This analysis was done for various thicknesses i.e 0.2mm,0.4mm,0.5mm,0.6mm,0.8mm,and1mmofthe thermal barrier coating, and it was found that there is a significant difference in the temperature distribution betweenthecoatedpistonandconventionalpiston.Also, it was found that the difference between the thermal distributions of consecutive thicknesses had a gradual change for both the ceramic materials. The thickness at which the optimum thermal distribution after which there is no significant change in thermal distribution is 0.6mm. A higher temperature was achieved in the ceramic coated piston as compared to conventional. Ceramic coatings of magnesia and yttrium stabilized zirconia helps reduce the thermal losses to the surrounding. Coatings of Ni Cr Al can be adapted to avoid the thermal cracking problem occurring in the pistonofanICengine

[1] SMART CERAMIC MATERIALS FOR HOMOGENEOUS COMBUSTION IN INTERNAL COMBUSTION ENGINES, Kannan CHIDAMBARAM, Tamilporai PACKIRISAMY, Vol. 13(2009),No.3

[2] CERAMIC MATERIALS FOR COATING APPLICATION IN TURBOCHARGED AUTOMOTIVE ENGINE: A REVIEW, Alias Mohd Noor, Fadzlun Nadrah Sharuddin, Uday M. Basheer, Srithar Rajoo, October 2016 DOI: 10.13140/RG.2.2.22618.13760

[3] CERAMIC COATING APPLICATIONS AND RESEARCH FIELDS FOR INTERNAL COMBUSTION ENGINES: Murat Ciniviz,MustafaSahirSalman,EyübCanlı,HüseyinKöse, andÖzgürSolmaz,February2012DOI:10.5772/29993

[4]DESIGN AND ANALYSIS OF PISTON DESIGN FOR 4 STROKE HERO BIKE ENGINE: Vinod Yadav, Dr. N D Mittalvolume2,Issue2,ISNN2277 5668,2013

[5]DESIGN AND STATIC THERMAL ANALYSIS OF PISTON USING THERMAL BARRIER COATING MATERIAL USING FEM: Mr. Vatti Sairam Krishna, Mr. K Murlidhar,Volum6,Issue1January2021.

[6]DESIGN AND STRUCTURAL ANALYSIS OF CERAMIC COATING PETROL ENGINE PISTON USING FINITE ELEMENTMETHOD:VinodKumarYadav,YogeshMishra Volume4,Issue6,June2015.

[7]PERFORMANCE OF THIN CERAMIC COATED COMBUSTION CHAMBER WITH GASOLINE AND METHANOL AS FUEL IN A TWO STROKE SI ENGINE: RameshBPoola,B.Nagalingam.

[8]MATERIAL COATING OPTIMIZATION AND THERMAL ANALYSIS OF A FOUR STROKE CI ENGINE PISTON: P V Shrikant,BVVPrasadaRao,KMohanLakshmiVolume8 Issue8August2017.

[9]ANALYSIS AND EXPERIMENTAL INVESTIGATION OF CERAMIC POWDER COATING ON ALUMINIUM PISTON :SPaul,ADeore,AChaudhary,VMadhavani,14th ICSET 2017.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072