International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Danish Ahmad Lone1, Er. Sonia2, Er. Shivani Thakur3

1M.tech Civil (T.E) student ,Desh Bhagat University Gobindgarh,punjab,India

2professor,Dept.of Civil Engineering, Desh Bhagat University Gobindgarh, Punjab, India

3 Professor, Dept. of Civil Engineering, Desh Bhagat University, Gobindgarh, punjab , India ***

–

Common Sluice beach is precious due to devilish cost of transportation from natural sources. Also large scale reduction of these sources creates environmental problems. As environmental transportation and other constraints make the vacuity and use of aqueduct beach less seductive, a cover or relief product for concrete assiduity needs to be found. River beach is most generally used fine total in the product of concrete acts the problem of acute insufficiency in numerous areas. Whose continued use has started posing serious problems with respect to its vacuity, cost and environmental impact.

In such a situation the Chase gemstone dust can be an profitable volition to the aqueduct beach. Quarry Rock Dust can be outlined as remains, rolling or othernon voluble waste substance after the birth and processing of brilliants to form fine patches lower than4.75 mm. generally, Quarry Rock Dust is used in large scale in the roadways as a face finishing material and also used for manufacturing of concave blocks and featherlight concrete prefabricated rudiments. Use of Quarry gemstone dust as a fine total in concrete draws serious attention of experimenters and investigators

Key Words: Quarry dust, Classification of Concrete, Aggregates,PropertiesofCement,PropertiesofAggregates etc

Mortal mind has shown its excellence in different fields. Talking about the field of civil Engineering, the backbone of this field is construction and the main grade of construction is concrete. The concrete is primarily accepted as a material of construction. Concrete can be defined as the amalgamation of total with cement and water. The chance variation in the mixing of concrete providesdifferentpropertyatdifferentrates.Concretecan be moulded as per the specification and its face can be givenanyadditionintermsofcolorandtexture.Concreteis considerably used in construction of foundations, architecturalstructuresandinadditiontothatconcreteis

principlepartofconstructioninhighways,heads,elevated corridorsandfoundationsetc.

Compared to multitudinous other engineering paraphernalia analogous as brand, rubber,etc., concrete requireslowerenergyinputforitsmanufacture.Curently, a large number of material amalgamations, which are desolate products of other industriousness, are being beneficially used in making quality concrete. thus, from the consideration of energy and resource conservation and sustainability and terrain, concrete is the most favoredmaterial.

Asperthepresentscript,thechanceoperationofcrushed sand from limestone chases in construction is continuouslyadding.Thismodificationisdoneinorderto neutralizeessentialdifficultiesinsluicesand.Chasedustis a fine material attained as a by product from crushing process during quarrying exertion at chase point. In the growing request, the rate of sluice sand has touched the sky and in addition to that the vacuity of sluice sand has alsodropped.So,inordertoovercometheproblem,there is a need of an volition from surroundings analogous as Artificialwaste.Inthisstudy,chasedustwillbestudiedas relief material of sluice sand as a fine aggregate for concrete. Chase dust has been in use for various exertion in the construction sedulity analogous as for road construction and manufacture of structure paraphernalia analogous as feathery aggregates, bricks, ducts and autoclave blocks. These granite fines are constantly appertainedaschaseorrock

dust, a by product in the manufacture of concrete aggregates during the crushing procedure of jewels. This residue generally represents lower than 1 of aggregate product.Innormalconcrete,theprolusionofchasedustto mixes is limited due to its high fineness. The addition chase dust to fresh concrete would raise the water demand and accordingly the cement content for specified malleability and strength conditions. thus, the successful operation of chase dust in concrete could turn this waste materialintoapreciousresource.Anotherimplicitbenefit intheoperationofchasedustisthecostsaving.Obviously, thematerialcostsvaryhingingontheroot.Inthisrespect, the operation of chase dust could play a part in lowering

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

the force cost of concrete. bedeviled sand is extremely generous in limestone chases and its use could appreciably drop the paraphernalia cost of concrete, annihilate the dust disposal cost, reduces environmental desecrationsanddecayofnaturalresources

construction as well as trim down the level of prohibited withdrawal of sand from the river beds.Itwilldefinitelyhelptopreservethenatural resourcesandresolvesomesustainabilityissues.

The well known literature about the use of Quarry dust (Crusher dust) in concrete carried out in any part of the worldhasbeenreviewedandpresentedasunder:

1.1 Quarry dust (SUDHIR S.KAPGATE 2013) Concrete plays an important role in construction and its large quantityisutilizedinconstructionpractices.Naturalsand, oneoftheconstituentofconcrete,isexpensivebecauseof the high transportation cost from major sources. Diminution of sources creates environmental problems and to overcome this problem there is a requirement for cost effective and creative solution materials. This paper dealswiththeuseofquarrydust,awasteobtainedduring the extraction process, as good filler instead of fine aggregate.M25 concrete mix design with 0%, 20%, 25%, 30% and 35% of quarry dust was used in this paper. In thisexperimental studydifferent cubes were analysed for compressive strength, flexural strength and split tensile strength for concrete in hard form using quarry dust. Resultsfromthisstudyconcludesthatincreaseinquantity of dust up to 30% increases compressive strength of concrete,ifthe%ageofquarrydustismorethan30%thee compressivestrengthstartsdecreasinggradually.

● (Dr. P.B.Sakthivel 2013) This papers deals with the replacement of natural sand used in concrete with quarry dust (waste produced from stone quarry industry). In this study, sand has been partiallyreplacedwithquarrydustforM35grade of concrete. Samples has been casted with 0%,10%,20%,30%,40% quarry dust in replacement with sand. On the basis of experiments,thepaperconcludesthatM35grade concrete shows optimum results on 10% replacement of sand with quarry dust. The authors of this paper had emphasized that this methodwill helptodecreasetheusageofnatural sand in concrete which will decrease the cost of

● (G.Balamurugan 2013)Thisinvestigationalstudy presented the deviation in the strength of concrete on use of crusher dust instead of sand from 0% to 100% at intervals of 10%. For this study, M20 and M25 grades of concrete were taken into consideration. Slump was in this study was kept as a 60mm. Concrete cubes were tested after7daysand28daysatroomtemperaturefor compressive strength. Concrete gains utmost raiseincompressivestrengthat50%replacement of sand. The %age increase in strength as compare to control concrete was obtained as 24.04 & 6.10 correspondingly for M20 and M25. The outcome gives obvious image that quarry dust can be used in concrete mix as a fine option fornaturalriversandwithlargerstrengthat50% replacementwithquarrydust.

● Lohani T.K 2012)This study deals with utilize of crusher dust in concrete as partial substitute of sand. Utilization of river sand on huge scale produces ecological impact on society. Overall availability of river sand is fine, but it is most commonly used; Cost and environmental impact are the main factors to be considered (Ahmed et.al., 1989). To defeat this crisis, small substitution of sand with quarry dust, according to the study can be an economical option. In this study, M1, M2, M3, M4 and M5 samples had been casted with 0%, 20%, 30%, 40%, 50% replacement of dust for M20 grade concrete design mix for laboratory analysis i.e. the idea is to test them correspondingly for compaction factor test, compressive strength (cubic, cylindrical sample), split tensile strength, flexural strength, water absorption of hardened concrete. Depending on the investigational results of this study, it has been concluded that on adding crusher dust physical and mechanical properties of concrete will improve. Use of 30% of quarry dust content increases the compressive strength of concrete, compressive strength gradually begins to decrease for more than 30% dust material. According to this study, maximum split tensile strength, can be attained at 20% substitutionoffineaggregate.

● (Radhikesh P. Nanda 2010) this investigational study is about preparation of paving blocks with erusher dust. Physical and mechanical properties of paving blocks are investigated with sand substituted by various %ages of quarry dust. The analysis results clears that the substitution of sand by quarry dust till 50% by weight has a slight effect on the diminution of any physical, mechanical property where as money can be

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

easily saved till 56%. This also leads to the reduction of discarding crusher dust on earth to reduce the ecological contamination. The study concluded that substitution of sand by quarry dust till 50% by weight will have a negligible effect on the drop of split tensile strength, compressivestrength,flexuralstrengthetc.Water absorption is fine lower than the limit according to Indian codes. Also, there is not any sort of variationindurabilitywithuseofcrusherdust.

Concrete is an artificial compound with its main component as natural aggregates i.e.sand and gravel, cement and water and admixture if required. Concrete development has evolved over long period of time. It has definitepropertiesinitsfreshandhardenedstate,though fresh concrete is the primary hardened of concrete. state Concrete in hardened form may possibly be well thought outasnon naturalstone

In which the fine aggregates fill the voids of coarse aggregate and cement is used to fill the gaps of fine aggregates. In addition to filling the voids act as a binder hardening fine said cement slurry mixture of water, such ascement,concreteslurry, waterparticlestogetherintoa compact mass of concrete aggregates. Characteristic ratio and thickening of the mixture, its composition is dependentonthenature.

The main raw material for the production of cement is clinker. Clinker is an artificial rock made by heating limestoneandotherrawmaterialsinspecificquantitiesto averyhightemperaturein aspeciallymadekiln.Portland cementishydrauliccementmadebyfinelypulverizingthe clinkerproducedbycalciningtoincipientfusionamixture ofargillaceousandcalcareousmaterials.Itisthefinegrey

powder that is the moist important ingredients of concrete; hence the name cements concrete. Cement undergoes a chemical reaction with water and sets and hardens when in contact with air or underwater. The typical raw materials used for making cement are limestone(CaCO3),sand(Si02),staleclay(Si02,A1203,or Fe203), and iron ore (Fe203). Thus the chemical components of cement are calcium (Ca), silicon (Si), aluminum (Al), and iron (Fe). The calcareous component, lime (Ca0), is derived from limestone, chalk, marble etc. The argillaceous component (Si02, A1203, or Fe203), is derivedfromclay,shale.Cementselectedforcurrentstudy isOrdinaryPortlandCementof43grade.

Aggregates are the materials basically used as filler with bindingmaterialintheproductionofmortarandconcrete. They are derived from igneous, sedimentary and metamorphic rocks or manufactured from blast furnace slag,etc.Aggregatesformthebodyoftheconcrete,reduce theshrinkageandeffecteconomy.Theyoccupy70 80per centofthevolumeandhaveconsiderableinfluenceonthe properties of the concrete. It is therefore significantly important to obtain ight type and quality of aggregates at site. They should be clean, hard, strong, and durable and graded in size toachieve utmost economyfrom the paste. Earlier aggregates were considered to be chemically inert butthelatestresearchhasrevealedthatsomeofthemare chemically active and also that certain types exhibit chemical bond at the interface of aggregates and cement paste.To increasethe bulk densityofconcreteaggregates are used in two markedly different sizes the bigger ones known to be coarse aggregate (grit) and the smaller ones fineaggregate(sand).

Fine Aggregate: The fine aggregate which has been used forthisstudyisnaturalsand.Aggregatesthatpassthrough a sieve ofsize4.75 mmare consideredasfineaggregates. NaturalsandconfirmingtoZone IlIasperIS383 1970has beenused.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

QuarryDust:Quarrydustisatypeofwastematerialwhich is produced in stone crushing industry and is available in large amount. The problems like landfill disposal, apart from the problem like health and environmental hazards havebeenobservedwithperannumof200milliontonnes quarrydust.QuarryrockdustconfirmingtozoneIIIasper IS383 1970hasbeenusedinthisstudy.

Aggregate which cannot pass through 4.75 mm sieve are recognized as a coarse aggregate. They are obtained by naturalbreakdownorbynon naturalcrushingofrocks.80 mm can be the utmost size of aggregate. In this study, 10mm and 20mm size of coarse aggregates confirming to zoneIIIareusedasperIS383 1970.

Potable water confirming to IS: 456 2000 is used in this studyforcastingandcuringofcubes,cylindersandbeams. The purpose of using water with cement is to cause hydration of the cement. Water in excess of that required for hydration acts as a lubricant between coarse and fine aggregates and produces a workable and economical concrete. There is a definite optimum water requirement for a particular concrete and mortar. In case of excess water, the cement along with water comes to the surface by capillary action and forms a thin layer over surface known as laitance. This weakens bond between the successive lifts of concrete. The excess water may leak through the form work, resulting in honeycombed concrete and on evaporation makes the concrete porous. On the other hand lesser water makes it difficult to work with concrete and because of non uniform mixing the resultant concrete is weaker in strength. The amount of watermustthereforebelimitedtoproduceconcreteofthe quality required for a job. Water is also used for washing aggregatesandcuring.

If's planned to execute various tasks in order to come up withtrustworthydataandthesetaskscontain:

I.Collectingsamplesoffineaggregates

a)Naturalsand

b)Quarryfines

IIGradationforthefineaggregateandcoarseaggregates

I. Testing of cement so as to know its different properties Fineness

(i)Initialandfinalsettingtime

(ii)Specificgravity

(iii)ConsistencyTest

III.Testingofdifferentcharacteristicsoffineaggregates Sieveanalysis

Specificgravity

Waterabsorption

IV.. Testing of different properties of coarse aggregates

i)Sieveanalysis

(i)Specificgravity

(ii)Waterabsorption

V.Preparationofdesignmix

VI.Performslumptestforworkability

VII.Performcompactionfactortest

VIICastingofsamplesi.e.cubesandcylinders

VIII. Testing of prepared samples for different properties

(i)Compressivestrength

(ii)Splittensilestrength

(iii)Flexuralstrength

4.1 Results on properties of fresh conerete

4.1.1 Workability (slump value) The measured slump values of quarry dust with constant water/cement ratio i.e. w/c ratio (0.45) are 75, 78, 79, 81, 82 and 84 mm for

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

different mixes such as M1 (0% quarry dust), M2 (10% quarry dust), M3 (20% quarry dust), M4 (30% quarry dust), M5 (35% quarry dust), M6(40% quarry dust) respectively. It should be noted that slump was maintained between 75 85 mm with the addition of Plasticizer (Sikament 2002 NS). Plasticizer was added to mixinordertomakeitworkable.Plasticizerwasaddedin certain amount effective with the weight of cement as shown below. The variations of slump value with quarry dustpercentageare alsoshown below.It isobservedthat the percentage of plasticizer decreases with the increase in percentage of quarry dust and this is because the workability increases with the increase in percentage of quarrydust.

%

M1 O.59%ofcement 75

M2 O.54%ofcement 78

M3 O.47%ofcement 79

M4 0.40%ofcement 80

M5 0.35%ofcement 81

M6 0.32%ofcement 82

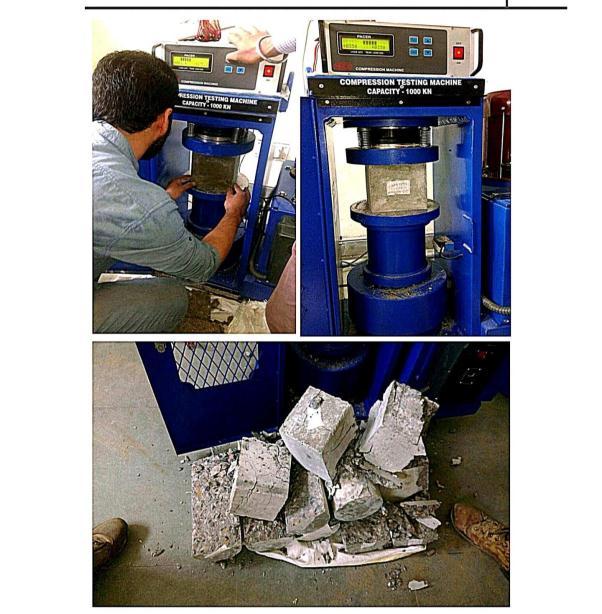

The results of compressive strength of cubes for (7, 28) days curing are shown in table. It should be noted that in mixM1,M2andM3compressivestrengthincreasesasthe daysofcuringareincreasedfrom7daysto28days.Butas the percentage replacement of quarry dust reaches the value30%,compressivestrengthinmixM4,M5,M6starts decreasingwiththeincreaseindaysofcuringfrom7days to28days.Furtherisillustratedinchart below

Rep l. No ; Of Spl.

M1 Spl 1 Spl 2 Spl3

M2 Spl 1 Spl 2 Spl 3

M3 Spl 1 Spl 2 Spl 3

M4 Spl 1 Spl 2 Spl 3

M5 Spl 1 Spl 2 Spl 3

CRUSHING LOAD (kn)

7 days 28 Days 716.8 1039 884 1072 810.3 1055

914 1139.1 1005.6 1102.8 907.7 1099.6

COMPRESSIVE STRENGTH (MPa)

7 Days 28 Days 31.85 46.18 39.28 35.7 47.64 46.9 36.01 46.88

40.62 50.63 44.69 42.81 49.01 49.50 43.13 48.87

937 1079 980.3 1150.5 998.6 1141.6

924 938.1 896.6 947.6 960 965

728 687 764.5 782 705.9 794

M6 Spl 1 Spl 2 Spl 3

41.64 47.95 43.57 43.20 51.13 49.94 44.38 50.74

41.06 41.09 39.85 41.20 42.11 42.23 42.70 42.88

32.35 30.53 33.97 32.56 34.75 33.87 31.37 33.52

660.5 729.2 642.7 730.8 685 696.1

29.35 32.41 28.56 29.45 32.48 31.94 30.44 30.94

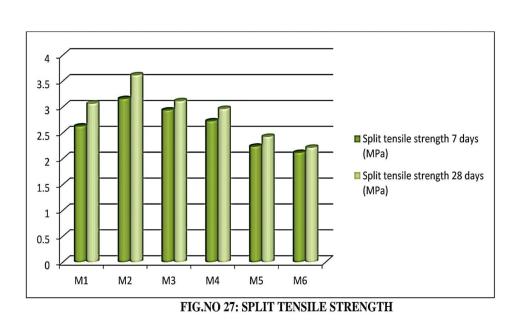

Theresultsofsplittensilestrengthofcylindersfor(7,28) days curing are shown in table. It should be noted that in mix M1 split tensile strength decreases as the days of curing are increased from 7days to 28 days. But as the percentage replacement of quarry dust reaches the value 10%, split tensile strength in mix M2, M3, M4, M5, M6 startsincreasingwiththeincreaseindaysofcuringfrom7 daysto28days.Furtherisillustratedingraphbelow.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

All the experimental data shows that the addition of the industrial wastes improves the physical and mechanical properties. These results are of great importance because this kind of innovative concrete requires large amount of fineparticles.Duetohighfinesofquarrydustitisfoundto be very effective in assuring very good cohesiveness of concrete. From the above study it is concluded that the quarry dust may be used as a replacement material for fine aggregate. Quarry dust has been used for different activities in the construction industry suchas for road construction

1. Non availability of sand at reasonable cost as finer aggregate in cement conerete for various reasons, search for alternative material stone crusher dust qualifies itself asasuitablesubstituteforsandatverylowcost.

2.Aggregateswithhighersurfaceareaarerequiringmore water in the mixture to wet the particle surfaces adequately and to maintain a specific workability. Obviously increasing in water content in the mixture will adverselyaffectthequalityofconcrete.

3. The measured slump values of quarry dust with constant water/cement ratio i.e. w/c ratio (0.45) are 75, 80, 78, 80, 79 and 75 mm for different mixes such as M1 (0%quarrydust),M2(10%quarydust),M3(20% quarry dust), M4 (30% quarry dust), M5 (35% quarry dust), M6 (40% quarry dust) respectively. It should be noted that slump was maintained between 75 80 mm with the additionofPlasticizer(Sikament2002NS).Plasticizerwas addedtomixinordertomakeitworkable.Plasticizerwas added in certain amount effective with the weight of cement as shown below. The variations of slump value with quarry dust percentage are also shown below. It is observedthatthepercentageoffplasticizerdecreaseswith the increase in percentage of quarry dust and this is because the workability increases with the increase in percentageofquarrydust

4. It should be noted that in mix M1, M2, M3, M4, M5 and M6 compressive strength increases as the days of curing areincreasedfrom7daysto28days.Butasthepercentage replacement of quarry dust reaches the value 20%, compressive strength shows maximum value and then startsdecreasingaswemoveaheadinreplacement.

6.Itshouldbenotedthatsplittensilestrengthincreasesas we replace the fine aggregate up to 10% and shows maximum strength in M2 mix. Then split tensile strength decreases as percentage replacements are increased further.Itisalsoobservedthatsplittensilestrengthinmix M1, M2, M3, M4, M5, M6 increases with the increase in daysofcuringfrom7daysto28days.

7.Itshouldbenotedthatflexuralstrengthincreasesaswe replacethefineaggregateupto10%andshowsmaximum strength in M2 mix. Then flexural strength decreases as percentage replacements are increased further. It is also observedthatflexuralstrengthinmix.

M1, M2, M3, M4, M5, M6 increases with the increase in daysofcuringfrom7daysto28days.

1.Book

ConcretetechnologybyM.L.Gambhir

2.ISCodes

1. Indian Standard Specification for coarse and fine aggregates from natural sources for concrete IS 383 1970.

2. Indian Standard Recommended guidelines for concretemixdesign IS10262 1982.

3. Specification for 43grade ordinary Portland cement IS12269 1987

04.IndianstandardmethodsofSamplingandAnalysis ofconcrete,IS1199 1959.

3.Researchpapers

1. SUDHIR S.KAPGATE AND s.R.SATONE "DUST AS PARTIAL REPLACEMENT OF SAND IN CONCRETE" Indian Streams Research Journal Volume 3, Issue. 5, June.2013.

2. Dr. P.B.Sakthivel, C.Ramya, M.Raja(May 2013) " AN INNOVATIVE METHOD OF REPLACINGRIVER SAND BY QUARRY DUST WASTE IN CONCRETE FOR SUSTAINABILITY"InternationalJournalofScientific& EngineeringResearchVolume4,Issue5,

3. Chandana Sukesh, Katakam Bala Krishn. P.Sri Lakshmi Sai Teja, S.Kanakambara "PARTIAL REPLACEMENT OF SAND WITH QUARRY DUST IN CONCRETE International Journal of Innovative Technology and Exploring Engineering (JITEE) ISSN: 2278 3075,Volume 2,Issue 6,

4. G.Balamurugan, Dr.P.Perumal(December 2013)"USE OF QUARRY DUST TO REPLACE SAND IN CONCRETE ANEXPERIMENTALSTUDYInternational Journal of Scientific and Research Publications, Volume3,Issue12,December2013,ISSN2250 3153

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

5. Lohani T.K., Padhi M., Dash K.P., Jena S. (2012) OPTIMUM UTILIZATION OF QUARRY DUST AS PARTIAL REPLACEMENT OF SAND IN CONCRETE Int. JournalofAppliedSciencesandEngineeringResearch, Vol.1,No.2,2012

6. Joseph 0. Ukpata, Maurice E. Ephraim and Godwin A. Akeke (JANUARY 2012 COMPRESSIVE STRENGTH OFCONCRETEUSINGLATERITICSANDANDQUARRY DUST AS FINE AGGREGATE" ARPN Journal of Engineering and Applied Sciences, VOL. 7, NO. 1, JANUARY2012,ISSN1819 6608

7. Radhikesh P. Nanda, Amiya K. Das, Moharana.N. C (2010) "STONE CRUSHER DUST AS A FINE AGGREGATE IN CONCRETE FOR PAVING BLOCKS" International Journal Of Civil And Structural EngineeringVOL.1,2010,ISSN0976 439

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |