International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Abhishek Gokul Dandgavhal1 , Ratnadip Sudhakar Patil2

1Student, Mechanical Engineering, Walchand College of Engineering, Sangli, Maharashtra, India

2Student, Mechanical Engineering, D. Y. Patil College of Engineering, Pune, Maharashtra, India ***

Abstract The following paper is on 3D printing & its other topics which become notable points in technological aspects. The 3D printing technique is a fast emerging technology. This technology can print the object layer by layer deposition of material directly from a CAD model. Prototyping can be classified into different processes such as FDM, SLA, SLS, DLF, LOM, DMLS. These processes can be use as per the requirement of models. The material used for the printing determines the quality of the model. Different processing parameters of printing affect the efficiency, quality, production rates of the parts, objects, components, etc. On the basis of optimized parameters the mechanical properties & manufacturing time can be enhanced. It is widely used across the world owing to its variety of applications in various sectors. As well as it will play vital role in day to day human life in future.

Key Words: 3D Printing, Processing, additive manufacturingtypes,materialselection,processparameters, applications,marketsize,futurescope.

3Dprintingorrapidprototypingcanalsoreferasadditive manufacturing. It is the process of making a 3D object of differentshapefroma3DCADmodelorotherelectronicdata sources. [1] In additive processes, successive layers of materialarelayingdownunderprogrammingcontrols.Each of these layers is sliced in horizontal cross section of the object.Ithasabilitytoproducecomplexgeometries,hollow parts,internal truss structure, etc. byscanning& then just clickonprinttobuildaphysicalreality.

3DprintingtechnologywasinventedbyCharlesHullin1984. They gives a birth 3D technology which known as stereo lithography.Inthisprocess,layersof0.1mmdepthareadded by curing photopolymers by ultraviolet light to achieve melting & solidification effect. [2] In 1990, the Stratasys developedplasticextrusiontechnologywhichknownasthe FusedDepositionModeling(FDM).Afterthattherehasbeen large growth in the 3D printing technology. The prices of printer machines & its processing drops gradually & increasesthescopeforrapidprototypingprocess.

3Dprintingprocessisadvantageouscomparetoconventional processes.Thisprocessincludes11%ofinnovationofthat manufacture,16%consumesforproductdevelopmentinany 3Ddesignsoftware.Afterthat25%ofworkrequiredduring prototyping process. So it is helpful in increasing the efficiencyupto10%aswellascostreductionby9%.Hence,

it results in the overall development of industrial technologicalfactors.

Today,rapidprototypinghasawiderangeofapplicationsin different fields of human life such as medical industry, research engineering, military, aerospace, construction, architecture, fashion, computer industry, electronics, robotics,education&manyothers.

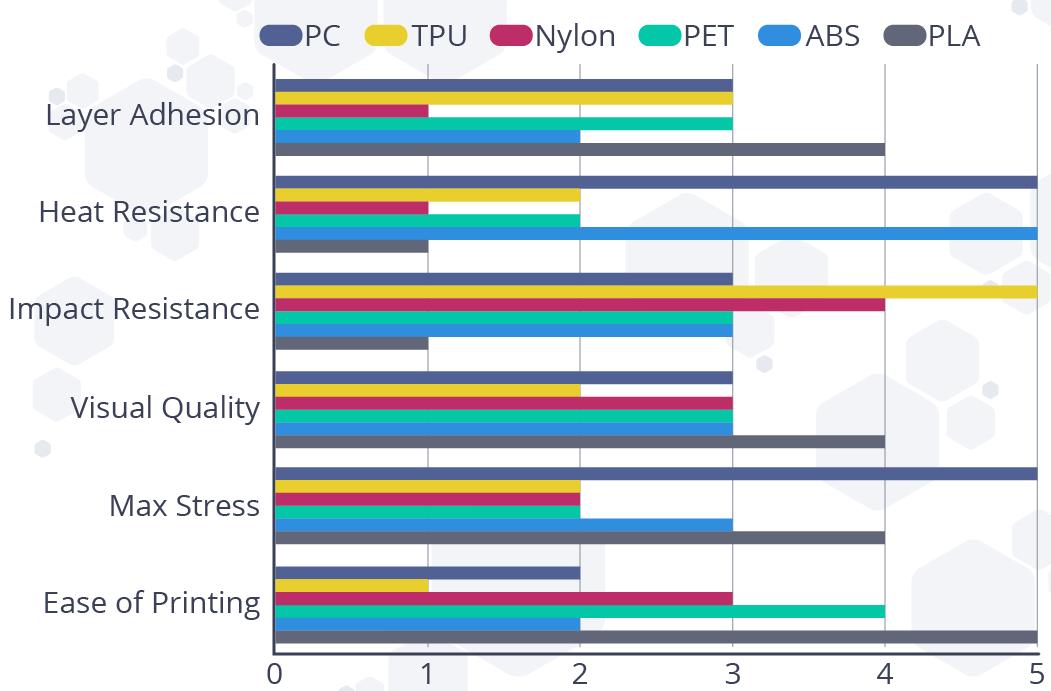

VinodG.Gokhare,Dr.D.N.Rather,Dr.D.K.Shindestudiedon the 3D printing processesused in industries. They explain about the various materials & their properties which is importanttopicintechnologicalaspects.Theycomparethe propertiesofmaterialsbydifferentparameters. Theyalso discuss about advantages, limitations & applications of3D printing.Theyconcludedthattheadvancesinthistechnology can significantly change & improve the process of manufactureproducts&producegoodsworldwide[3].

Dr. Muhammad Abu Khaizaran & their group of students, elaborated the 3D printing technology in detail. They includedthehistoryof3Dprintingaswellasthecomponents & operation of the 3D printer. At the end, they discussed about some printing technologies & their pros cons. They gives aspects about 3D printer that these printers will be driveoffacomingrevolutionthatwillchangewholefaceof industry[4].

Mr. Mahesh S. Kadam & their team of students studied on processparametersofFDM3Dprinter.Theydiscussabout experimentonaffectoflayerthickness,shellthickness&fill densityonthepropertiesaslikesurfaceroughness,hardness & tensile strength which gives result that overall strength improvebydecreasingthethickness&increasingfilldensity. TheygivestheinformationaboutTaguchimethodoftesting [5].

K.G.JayantChristiyan,U.Chandrasekhar,K.Venkateswarlu studiedoninfluenceofprocessparametersonpropertiesof 3dprintedABScomposite.TheyfollowedtheASTMD638& ASTMD760standardsforcarryingouttensiletests&flexural tests. They studied tensile behavior of ABS composite at different printing speed & layer thickness. After doing experimenttheyconcludedthatABS+anhydrousmagnesium silicatecompositematerialhasmaximumflexural&tensile strengthatlowerthicknessof0.2mm&printingspeedof30 mm/s[6].

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Arup Dey & Nita Yodo did the systematic survey of FDM processparameters&theirinfluenceonpartcharacteristics. TheygivetheinformationaboutcommercializationofFDM technology. They elaborated the how process parameters affect on the FDM produced products considering layer thickness, build orientation, raster width, printing speed. They implement the product development by controlling parameters. They concluded as the FDM process is very complex & it can compared with layer thickness, build orientation, raster width for getting consistency in production[7]

In modelling of 3D models forms by CAD model of a part whichistobemanufactureisbuildup,thenitisconvertedto .STL format i.e. Stereo lithography file format which will ready for printing process. The Pre processing process of preparinggeometriccontentfor3Dcomputergraphicsisas same as to method sculpting. 3D modeling is a process of analyzing, collecting data & information regarding to its shape,aestheticandappearanceofanobject[3].

Thedifferenttypesofprintingtechnologiesusedinadditive process are done by large & expensive printers. Additive processescanbeclassifiedas

a) Photopolymer systems startswithaliquidresin,whichis then solidified by discriminating exposure to a specific wavelengthoflight.

b) Thermoplastic systems begins with a solid material, whichisthenmelted&fusesuponcooling.

Fig 1:ProcessingStepsof3DPrinting

Duringprinting/buildingamodel,wemusthaveconverted the.STLfileintoG codefileformatbyslicingandorienting process.Bycreatingtheslicedlayersofthemodel,firstlayer ofthesolidmodelisformed.Afterthatthemodelislowered down by the thickness of the layer by layer & process is repeated upto completion of project model. This layers, whichcorrespondingtothevirtualcrosssectionsfromthe CAD model & they are joined or fused to create the final shapeofanobject[10].

During printing the model, there will be chances of productionofoversizedversionofobjectduetouncertainty, vibrations in nozzle of printer. For the achieving standard resolution&betterprecision,oncethemodelcompletedthe supportcolumnsareremovedbywashing.Thenitssurface keepcleaned&finishedverywell[3].

Fig -2:Classificationof3DPrintingProcessses

Forthemanufacturingof3Dprintedmodelsdifferenttypesof metals&non metalsareusedlikeasPlastics,Photopolymers, Ceramic parts, Plaster & starch parts, Foundry sand parts, Metals. The following table shows the material used in different3Dprintingprocesses.

Table 1: Materialusedasrespectiveoftheprocess[10] Sr. No.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

4. Directmetallaser sintering

Aluminum alloys, nickel alloys, maragingsteel,titaniumalloy,cobalt chrome alloy, copper chromium zicroniumBetaStage

5. Laminatedobject manufacturing Sheet of plastic, paper coated with adhesive, Thermoplastic as PVC, composite of ferrous & nonferrous metals,ceramics.

6. Directedlight fabrication

Titaniumpowder,copper,aluminum, tungsten,molybdenumdisilicide,nickel aluminides,stainlesssteel.

Materialselectionforthemanufacturingofmodelisdepend on their mechanical, physical, chemical properties like as durability, weight, toughness, hardness, heat resistance, composition of material, time requirement, cost, etc. The following table shows the comparison between different materialsconsideringtheirproperties.

2.

then,itiscalled as negative air gap[7].

It is defined as the way to orientthemodel in a build platform with respect to horizontal & verticalaxes.

hardness, etc.

Itaffectson the compressiv e strength betweenthe layers, model.

The3Dprintingprocesshasseveral processparameters& they have significant impact on efficiency of production, propertiesofmodels,etc.Dependingontheparameterscost of production, production rate, quality of model, time requirement,andexpenditurevaries.Someofthecommon processparametersaregivenbelow.

Sr. No. Process Parameter Principle sketch/ figures

1. Airgap

Description Effect

It is gap between adjacent roasters on depositedlayer. When two adjacent layers are overlapped

Negativeair gap improves the mechanical properties as like toughness,

3.

It is width of depositionbead which depends on extrusion nozzlediameter. Orientation is angleisgivento nozzledirection duringprinting.

Smaller rasterangle increases the tensile strength of model[11].

4.

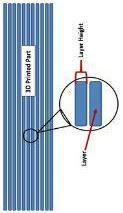

In AM method, layer by layer printingisdone. It plays important role in mechanical, physical properties which varies from 0.06 to 0.4mm diagnosis.

Largerlayer height will decrease the resolution as well as quality of the print [6].

5.

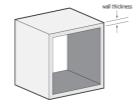

It is the thickness of outershellofthe part.Thishelps in combination withfilldensity selected for printing[5].

Increasing the shell thickness helps in increase in strength of model & robust object printed.

6.

Itis percentage of infill volume ofmaterialtobe printed. 100% forsolidpart& 0% for empty part is considered.

7. Infill pattern

Different patterns are used for produce a durable&strong internal

It reduces gap between printed lines & increased adhesion between layers[7].

Itaffectson the print time, weight, quality & object

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

structure. strength.

8. Printing speed

Itisthespeedof printing happens by movement of printing head Forgoodquality, printing speed mustbeslower. Welladjusted printer has speed of 150mm/s[5].

Quality of themodelis reducesdue to higher printing speed[6]as shown in fig.

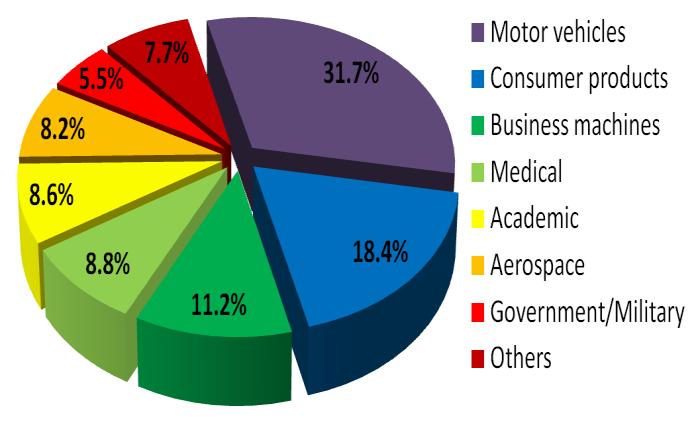

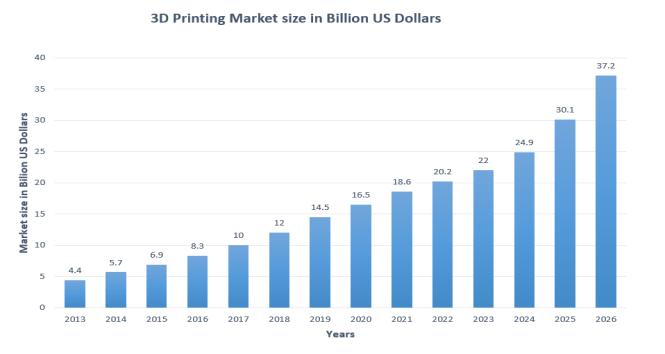

3Dprintingtechnologyiswidelyusedinthevarioussectors of our day to day life. Following pie chart gives different typesofusageof3Dprintingwhichincludesmotorvehicles, architecture, military, academic institutions, medical, consumerproducts,industrialmachines,aerospace&other content.

9. Extrusion temperatur

e

The temperature at which filament of material is heated & fused together[7].

Higher temperatur e improves layer bonding & make physically strong.

It helps to designers by realize their concepts beyond their virtual visualization & leads to innovation.

8.1. Architecture & construction :

Thereispossibletomakechangesinphysicalmodel instantlybyaskingcustomersfeedback.

3D printing is used to making models of buildings, infrastructure for taking the basic idea about the construction. They give the prior information about data collection,costestimation,requirementsforconstructionof houses,buildings,bridges,etc.InChina,theybuildahousein aday&constructskyscrapersinfewofweeks.Ex.Winsun Decoration Design Engineering was build a houses in Shanghaiby4giant3Dprinters[9].

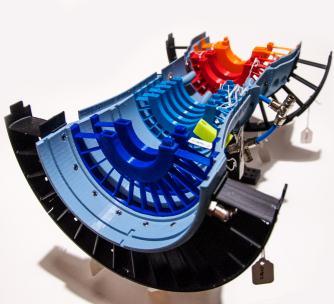

8.2. Automobiles & Aeronautics industries :

Itprovidesthefastrateofproductiontoindustry& givesproximitytomarket.

The creation of tools & parts by 3D printing has lower rates than traditional machining. So, cost reductionisachieved[3,10,12].

For the large size & large quantities of goods, AM will be difficult & require increase the spec of 3D printing.

3Dprintingsoftwareisusedformodeldesign,prototyping, testing & production for manufacturing more efficient car. Thechassis,bodywork&otherpartsprintedinlesstimeby usinglargeprinters.3Dprintingmakesthevehicleslighter& stronger. Local motor Strati is the 1st 3D printed car manufacturedwithCincinnatiIncorporatedandOakRidge NationalLaboratory[9].

Thereplicationofrealproduct&systemisfailsby 3dprinting.

Thereislimitationofmaterialsthatcanbeusedin printingduetoinsufficientresearchinprocess.

Changes in atmospheric conditions, whether & temperature may affect the quality of model [3,10,12].

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

3Dprintingplaysimportantroleinthemedicalsector.Itis used for printing organs or body parts for educational purpose.Someofthepartsusedforimplantsovertheactual bodyparts[9].Now,peopleareused3Dprintedorgansas likefaketeeth,hands&legsforahandicappedperson.

Building Materials and Automotive : MIT Media Lab is experimentingonprintinghugemouldsforconstructionby usingspraypoly urethanefoam.ContourCraftingproposes 3Dprintingentirehouseof2500sq.footin20hrs.Itwillhelp in the emergency housing system. Self healing military vehicles,printedaircraftcanbedeveloped[10].

Healthcare : Organtransplantispossibledueto3Dprinting. Medical Instruments, Nano scales medicines can be produced. On the pandemic of Covid 19, Birla Institute of Technology & Science Pilani, Hydrabad [12] as well as Anatomiz3D,Mumbaidevelopedtheartfaceshieldsmasks to offer complete protection for essential workers. It has manufacturingcostaboutRs.40pershield.

Inthispaper,comprehensiveinformationabout3Dprinting, their types as per different principles, controlling process parameters&itsoveralleffectonthemodelcharacteristics wassummarized.Thevariousmaterialsusedin3Dprinting inwhichPLA&ABSaremostwidelyusedmaterialsdueto itsspecialproperties.Theprocessparametersuchaslayer thickness, printing speed, infill density, build orientation majorly affect on quality of the printed model. When the printingspeed,layerthicknessislessthenproductionrate reducesbutitgivesmaximumtensile&flexuralstrength.It results in increase in the quality as well as cost of production. If Infill density high, then weight increases & strengthofobjectimproves.3Dprintedproductsconsumed lessenergyandrequiredlessmaterial.Ashifttoplastics& metals resulting in higher energy demands because of its negligible waste. 3D printing has limited size or scale of producingproductsbutitformsreliable&durablethings.3D printingplaysvitalroleintheautomotive,defense,fashion, healthcare, food technology & construction sector. Nowadays,itisusedinhealthcarebymanufacturingofface shield & face mask for prevention from Covid 19 to our Corona fighters. Prototyping has been wide scope in the futureforutilizinghumanneeds.

IwouldliketothanksProf.R.M.Chanmanwar,MechEngg Dept. of Walchand college of Engineering, Sangli. for their kind & continuous support. I would also thanks to my parentsformotivatingmecontinuously

Fig 4:3DprintedFastfood[GrabCAD]andFaceShield[12]

The

[1] DongkeonLee,YasuhiroTakaya,TakashiMiyoshi,and TaehoHa,“3DMicrofabricationofPhotosensitiveResin Reinforced with Ceramic Nanoparticles Using LCD Microstreolithography”, Journal of Laser Micro/Nano engineeringVol.1,No.2,2006.

[2] RubenPerezMananes,PabloGil,JoseRojo Manaute,“3D Surgical printing and pre contoured plates for acetabularfractures”,JournalofELSEVIER2016.

[3] Vinod G. Gokhare, Dr. D. N. Raut, Dr. D. K. Shinde, “A Review paper on 3D Printing Aspects and Various Processes Used in the 3D Printing”, International JournalofEngineeringResearch&Technology(IJERT), Vol.6Issue06,June 2017.

[4] Dr.MuhammadAbu Khaizaran,SamerMukhaimar,Saed Makhool,QaisSamara,“3DPrintingTechnology”,Birzeit University,12/11/2014

[5] Mr. Mahesh Shivaji Kadam, Yash Magdum, Divyansh Pandey, Akash Bankar, Shantanu Harshe, Vasudev Parab, “Process Parameter Optimization for FDM 3D

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Printer”, Journal of International Research Journal of EngineeringandTechnology(IRJET),Volume:06Issue: 04,Apr2019,p ISSN:2395 0072

[6] K.G. Jaya Christiyan, U. Chandrasekhar, K. Venkateswarlu, “A study on the influence of process parametersontheMechanicalPropertiesof3Dprinted ABScomposite”,MaterialsScienceandEngineering114 (2016) 012109, doi:10.1088/1757 899X/114/1/012109.

[7] ArupDeyandNitaYodo,“ASystematicSurveyofFDM ProcessParameterOptimizationandTheirInfluenceon Part Characteristics” Journal of Manufacturing & Materialprocessing,Published:29July2019.

[8] N.Shahrubudin,T.C.Lee,R.Ramlan,“AnOverviewon3D Printing Technology: Technological, Materials & Apllications”,ScienceDirect,ProcediaManufacturing35 (2019)1286 1296.

[9] Thabiso Peter Mpofu, Cephas Mawere, Macdonald Mukosera,“TheImpactandApplicationof3DPrinting Technology”,JournalofInternationalJournalofScience andResearch(IJSR),ISSN(Online):2319 7064.

[10] AmanSharma,HarishGarg,“Utilityandchallengesof3D Printing”, IOSR Journal of Mechanical and Civil Engineering (IOSR JMCE, e ISSN: 2278 1684, p ISSN: 2320 334X.

[11] S.R.RajpurohitandH.K.Dave,“EffectofRasterAngleon TensilePropertiesofPLAPartFabricatedUsingFused DepositionModelingProcess”,InternationalConference on Precision, Meso, Micro & Nana Engineering, December2017.

[12] https://nptel.ac.inonrapidprototypingreport

[13] Healthworld, Economic Times Newspaper, 14 April. 2020.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal