International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1 M.Tech. Construction Management, Department Of Civil Engineering, Government College Of Engineering, Karad 415124, Maharashtra, India

2 Assistant Professor , Department Of Civil Engineering, Government College Of Engineering, Karad 415124,Maharashtra,India ***

Abstract Prefabricated buildings and structures are mountedfromuniformprefabricatedthreedimensionalunits, providing strength, preset thermal properties of structures, dynamic stability, and immutability of geometric dimensions of the prefabricated elements during their manufacture, transportation, and installation in special and difficult conditions. Prefabrication has been widely regarded as a sustainable construction method in terms of its impact on environmental protection. One important aspect of this perspective is the influence of prefabrication on construction wastereductionandthesubsequentwastehandlingactivities, including wastesorting,reuse,recycle,anddisposal.Thereare a couple of different popular forms of prefab with different benefits to offer. Depending on your specific construction project, you may want to consider implementing some of the options. We’ve pulled together information about the different kinds of prefab as well as the benefits of using this strategy in order to help you decide. In this project the replacement of non structural component with prefabrication element is proposed. The cost benefit analysis will be studied including prefabrication element in conventional building.

Key Words: Prefabrication, Pre Cast, Members Of The Building, Microsoft ProjectItisreallytheprocessofconstructingbuildingintegrityata manufacturing or other production facility before moving entireassembliesor inter andintra heretoconstruction siteswherethetowerwillbebuilt.Thewordisintendedto differentiatethistechniquefromamoretraditionalbuilding practiseofbringingbasiccomponentsheretoconstruction project where all assemblage is completed. A home construction example exemplifies the prefab process. The traditional technique of making a home involves transporting bricks, lumber, cement, sand, steel, metal constructionaggregate,amongotherresources,heretosite thenconstructingthestructureon sitefromsomeofthese components.Onlythecornerstonesarebuiltinthismanner inprefabricatedbuilding.Whileportionsofwalls,floors,the topareprefabconstructionswithwindows&doorframes incorporated,theyarecarriedtothatsamesite,raisedinto positionbyjustacrane,&boileddown.

Prefabricatedconstruction,sometimesknownas"prefab,"is aprominentbuildingstyle.Thistechniqueemploysoff site components manufactured in such a factory, which could then be transferred and assembled on site to form a building. There are many prominent types of prefab that eachhaveitsownsetofadvantages.Imaywishtoexplore usinganyofthesechoicesdependonyouruniquebuilding project. To assist you with making your decision, we've statistics demonstrate on the many types of prefab or the advantagesofemployingthistechnique.

•Helpsreducecosts

• Performance will increase since elements may well be createdbeneathregulatedcircumstances.

•Helpsexpeditebuildingalthoughnocureisrequired.

•Usethesubstanceswithinherentpropertiessuchaslow gravity, ease of achievability, barrier properties, & flammability.

•Usethesubstanceswithinherentpropertiessuchaslow mass,easeofachievability,insulation,&miscibility.

•Modularization

Long term process is described as building of an entire componentoff site before transporting thatto the jobsite. Withsimplicityofshipping,theunitsmighthavetobesplit food onto lesser parts. Typically, prefabrication requires upwardsofsingletransaction.

•Prefabrication

Oftenthisincludesaparticularprofessionofprofession&is commonlycharacterisedasa manufacturingprocesssin a specialised facility when diverse substances are mixed to make a constituent of a terminal. As much as this item is

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

created in a workshop & is not part of an entire unit, it is consideredpremade.

Prefabricationseemstobethemergingdiverseresources& premadeelementsataseperateplacebeforehandinstalling them as a station console. Such setup is related to the constructabilitymethodinthattheproducedelementsbeing constructedneartowardthesitebeforebeinginstalledon site.Prefabricatedcomponents,whichisoftenconsideredas a mix of reusability and blueprinting, typically includes operations from several trades & pieces of scientific disciplines.

•Industrialization

That word encompasses all 3 of the aforesaid outside development groups. Economy is centered upon that manufactureidea &isdescribedastheimplementation of systems,machinery,&premisestodrivegrowth,minimise physicallabor,&boostoutputquality.

•Flooring/Roofingsystem.

•PrecastBeams

•PrecastColumns

•Precastwallpanels

•PrecastSlabs

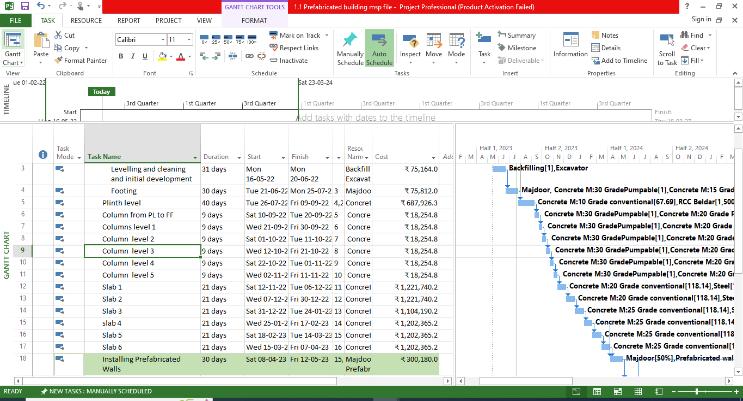

It's indeed essentially a gantt chart that has increased the capacity of internal stakeholders to share complicated concepts.Itisnowsimpletoproduce&utilizematerialfor buildings. It is indeed a CIEPM (Programmable Logic controller Industrial Project) idea that enables for such significantharvestingofprojectmanagementdata,material, & understanding for partners in ways that participation couldneverhaveimagined.

Microsoft Word is fundamentally a computer system that keepsarecordofyouassignmentusingtwomajordatabases ofinfo.Projectdataisstoredconcerningyourdevelopment's tasksinonedatabase&relevantdatatheother.Yourmay showyourprojectdetailsfromallofthesefieldsinavariety ofwaysbyutilisingthenumerousviewsofferedinVenture. TheProjectinterfacemaychangebasedonthechosenview, table, & filter. Yet, you must first get acquainted the with display's critical parts, as seen below. Mastering the interfacestructure,aswellasitsfeatures&vocabulary,can assistanyoneinutilisingMicrosoftTeams.

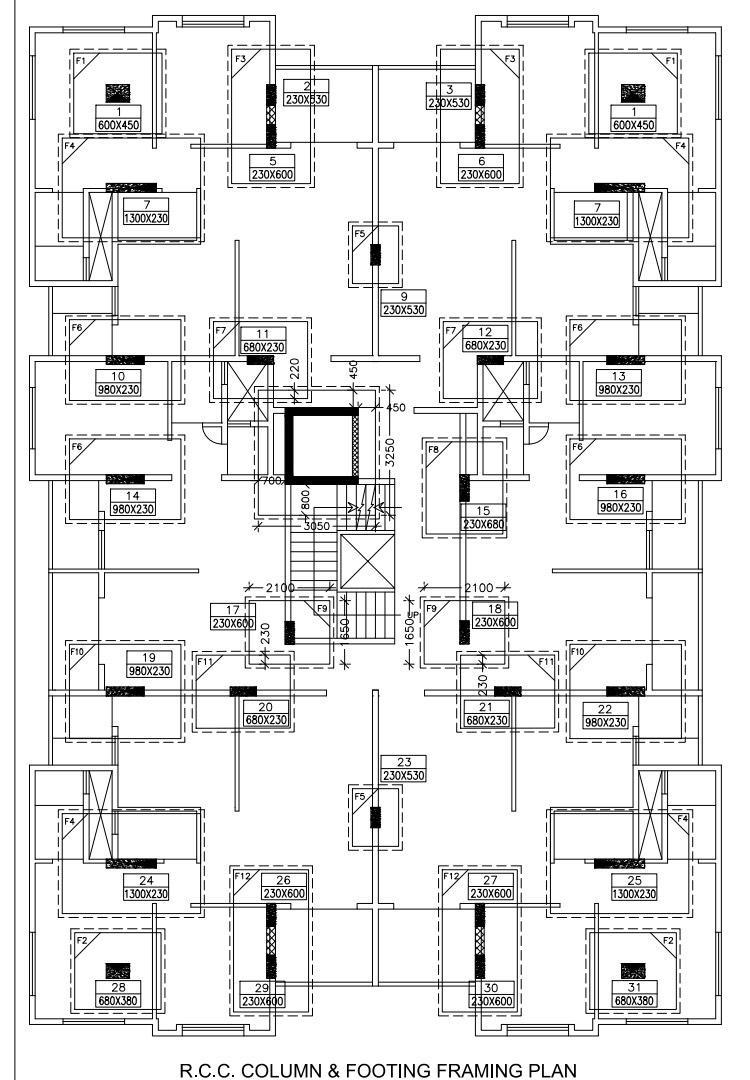

ShivSaiDevelopers(Showninfig.no.1)

Nameofsite:ShivSaidevelopers

Nameofbuilder:KiranVitthalNagawade

Location of site : Plot no. 25&26 at Nhawaretal. Shirur,Dist.Pune

Areaofsite:6000sqft

Costofproject:1.8cr

Nameofconsultant:MaheshKadam

Detailsofsite:

2bhk 3flatsperfloor

1bhk 2flatsperfloor

Presentcondition:excavationandprepforcentre linningforfoundation

Totalbuiltuparea:4800perfloorslabarea(P+4)

Owneranddeveloper:KiranNagawade

Architect:SidhheshSonawane

Structuralengineer;SachinSharma

Totalflats:20flats

12flats:2bhk

8flats:1bhk

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Thisstructureisconventionalresidentialbuilding.Thiscase studyhaving20flatsanditishaving(P+4)structure.

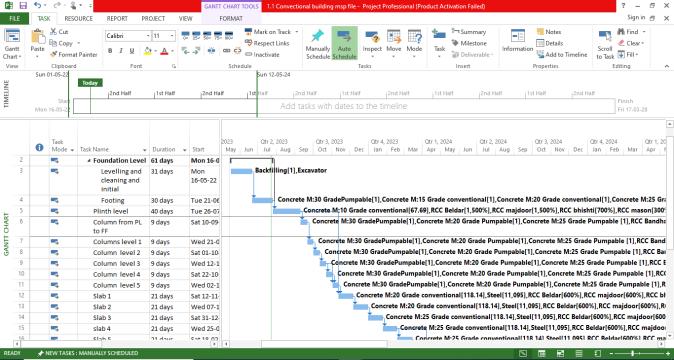

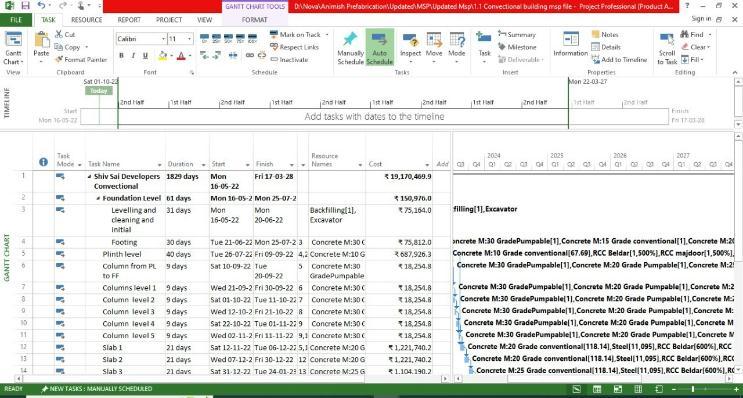

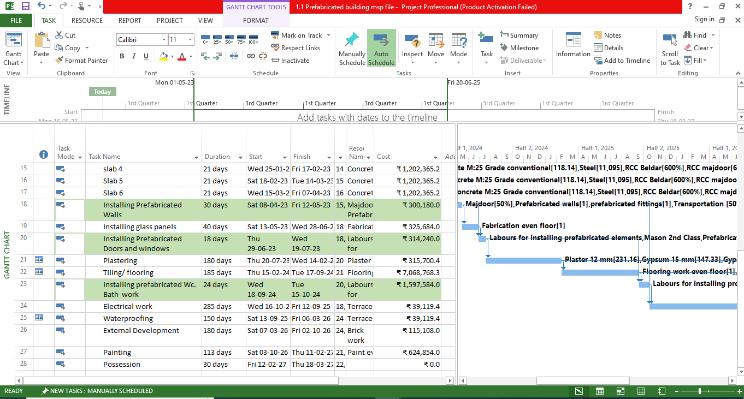

The fig. no.3 is Convectional Shiv Sai Work breakdown structure, it shows detail of all conventional construction task which are been done on the site and also shows the materialwhicharebeenrequiredatdifferentstagesofthe activities.

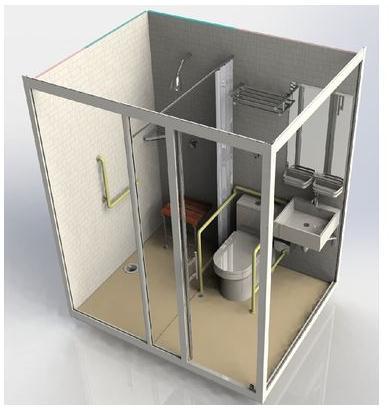

In the above case study we are going to replace the convectional building elements by prefabricated doors windowsframe,Walls,Wc.Bath.

1. Work breakdown structure of conventional construction

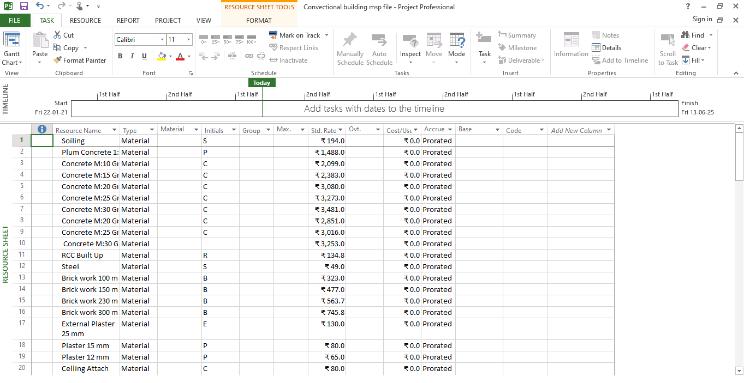

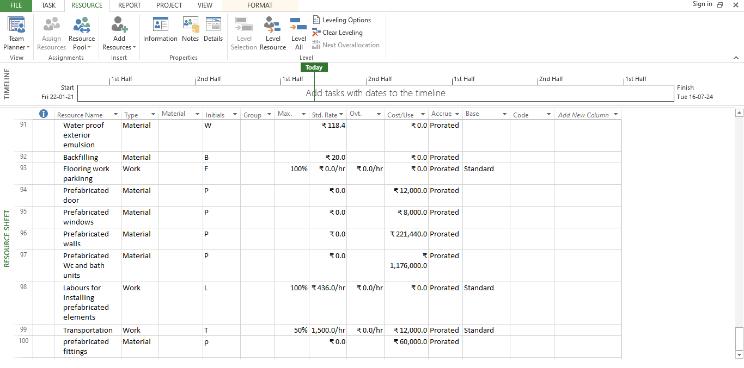

Thefig.no.4isascreenshotoftheresourcesheet,thissheet shows us all the resources that are been allotted in constructionsite.Italsoshowsusthestandardrateofthe materialandlabourperhourandperday.

Fig.No.3WBSofConventionalConstruction

The fig. no. 5 shows the detailed Foundation level , Plinth level,slabsetcofaconvectionalbuildingandthematerials whichareallotedonthesite.

2. Results from WBS of conventional construction from MSP is:

• No.ofdays 1829days

• Cost with material+labour and Machinery ₹ 19,170,983.1

TableNo.1 No.ofdays 1829 Cost 19,170,983.1

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

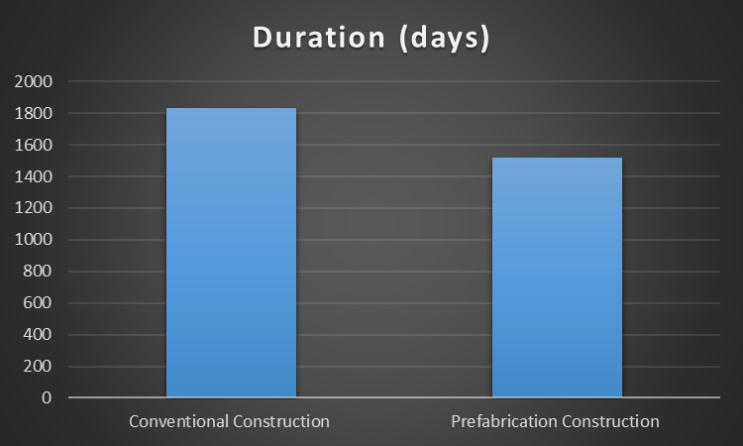

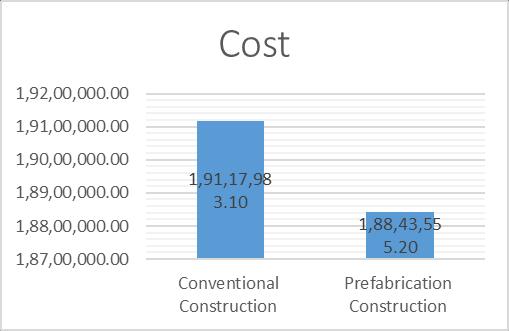

Comparisonofconventionalconstructiontoprefabrication construction:

TableNo.3

Type Duration (Days) Cost(Rs.)

ConventionalConstruction 1829 19,170,983.1 PrefabricationConstruction 1516 18,843,555.2

TheFig.No.11showsustheResoursesandstandardrate that is been alloted in the prefabrication building. The elementswithvariousmaterialtypeofprefabricatedwall, door and windows are been included in the convectional sheetwithcost.

The fig.no.12 shows detail in MSB of all construction of differentbuildingworkandelement.Thegreenhiglighted cost type shows of prefabricated wall and without highlightedcosttypeareofConventionalbuildingmaterials, suchasslabwall,wcandbath.

4. Result from WBS of Prefabricated Construction from MSP is:

• No.ofdays 1516days

• Costwithmaterial+labourandMachinery ₹ 18,843,555.2

TableNo.2 No.ofdays 1516 Cost(Rs.) 18,843,555.2

ChartNo.1ComparisonofDurationforConventional ConstructionToPrefabricationConstruction

Thechartno.1showsthecomparisonbetweenconventional construction and prefabrication construction for duration respectivelyas1829and1516.

ChartNo.2ComparisonofCostforConventional ConstructionToPrefabricationConstruction

Thechartno.2showsthecomparisonforcostinbetween conventionalconstructionandprefabricationconstruction respectively as Rs. 19,117,983.1/ and Rs. 18,843,555.2/ Which means we are saving Rs. 2,74,427.90/ from the convectionalstructurebymakingitaprefabricatedone.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

The cost of Prefabrication construction is reduced as the durationofdaysisreducedanditreducestheactivitieson siteandcostofthelaborsandthematerialcostisalsosaved on site , though the prefabricated structures are ready to install it reduces material on site for the particular items. Alsothetransportationandfittingchargesareincluded.

Theprocessisconcernedwiththescientificmachinerythat definesacategorizationofbuildabilityinbuilding.

1.Itdiscussestheparameterswhichitimpactsthechoiceto installreadymadepiecestoabuilding.

2.It also includes the findings of a study focusing on the utilisationofprecastsystems.

TheresearchersarethankfulShivSaiTechnologiesexperts forsharingallproject relateddata.Absenttheirassistance, theendeavorwillbeunfinished.

1. Abhishek K.Taware1’ Prefabrication, Sustainable TechniqueinBuildingConstruction’Volume1,Issue2, February2017

2. Aki Aapaoja “the Challenges Of Standardization Of Products And Processes In Construction” Proceedings IGLC 22,June2014

3. EvanjalineLibie “Impact Of Prefabrication On ProfitabilityOverTraditionalConstruction’’ISSN:2455 5797Vol.(2),No.(3):June2016

4. ElzbietaRadziszewska Zielina,MonikaGlen.“Studiesof the Prefabricated Housing Construction Market in Poland”JournalOfCivilEngineeringVol.9,Issue2,2014

5. Gerhard Girmscheid, “Industrialization in Building Construction ProductionTechnologyorManagement Concept”Vol.8,Issue1,2012

6. H. W. Lee “Macroeconomic Labor Productivity and Its Impact on Firm’s Profitability” Journal of the OperationalResearchSociety August2013

7. Hamza Khan “Study on the Trends & Usage of Prefabrication and Modularization: Increasing ProductivityintheConstructionIndustry”ISSN2278 3652Volume8,Number2(2017)

8. Hong Xue “Factors Affecting the Capital Cost of Prefabrication A Case Study of China” Published: 24 August2017

9. M. Muhammed Ansar T.Subramani1, “Impact Of Prefabricated Technology & Equipment On The ProfitabilityUsingPrimavera”ISSN2278 6856Volume 6,Issue3,May June2017

10. MohamedNorAzhariAzman“ThePerspectiveViewOf Malaysian Industrialized Building System (Ibs) Under Ibs Precast Manufacturing” The 4Th International EngineeringConference2012

11. N.Dineshkumar “ComparativeStudyonPrefabrication Construction with Cast In Situ Construction of ResidentialBuildings”ISSN2348 7968,29September 2016

12. OngYingRui1“TheProductivityRateofPrefabricated Pre Finished Volumetric Construction (PPVC)” ConstructionmanagementVol2, November2016

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal