UTILIZATION OF BLACK COTTON SOIL IN THE MANUFACTURE OF BRICKS

ABSTRACT

Over a past few decades, there are wide ranges of alternatives available in the field of construction with the changing in the raw material for the particulars. As concern with the brick there are some invention like fly ash brick, concrete blocks and brick. Here we are using black cotton soil as a raw material for the bricks and also using some admixture to alter the properties of the black cotton soil. Test results obtained indicate that it is possible to manufacture good quality bricks using locally available black soil by adding, suitable admixtures. The bricks manufactured using this method have good quality with acceptable strength and further, they can be manufactured in a cost effective manner.

1. INTRODUCTION:

A Brick is a type of block used to build walls, pavements and other elements in masonry construction. Properly, the term brick denotes a block composed of dried clay, but is now also used informally to denote other chemically cured construction blocks. Bricks can be joinedtogetherusingmortar,adhesivesorbyinterlocking them. Bricks are produced in numerous classes, types, materials, and sizes which vary with region and time period,andareproducedinbulkquantities.

The Process of manufacturing of bricks from clay involvespreparationofclay,moldingandthendryingand burning of bricks. The bricks are building materials which are generally available as rectangular blocks. The bricks do not require any dressing and brick laying is verysimplecomparedtostonemasonry.’

Brick is most artifact thing required to build walls, pavements and parts of masonry construction. Usually brick are unit stacked along or set as brick work along with mortar to build a permanent structure. Within the world Asia produces eighty seven of the overall productionofthebrick.Brickaretheunitgenerallymade incommonornormalsizeinbulkquantitiestheyneedto be considered one in all the longest enduring and strongestartifactemployedintwentiethcentury.

A Brick is a construction material used in the construction ofstructure.TheBricks andMortararestackedtighterand make the wall and any type of the structure. The Standard size of bricks is (19cm X 9cm X 9cm). The Nominal size of bricksis(20cmX10cmX10cm).TheStandardsizeofbricks andspecificationofbricksisgivenintheIS:2212(1991).In the bricks various material are used like clay, Silica, Alumina, etc. Normally bricks are made from the clay material.

2. MATERIALS USED

2.1

BLACK COTTON SOIL:

Black cotton soil is a clayey type of soil also known as “Expansive soil”. It has very low bearing capacity, high swelling and shrinkage characteristics. Hence stabilization is needed for this soil before subjecting it to any constructionpurpose.

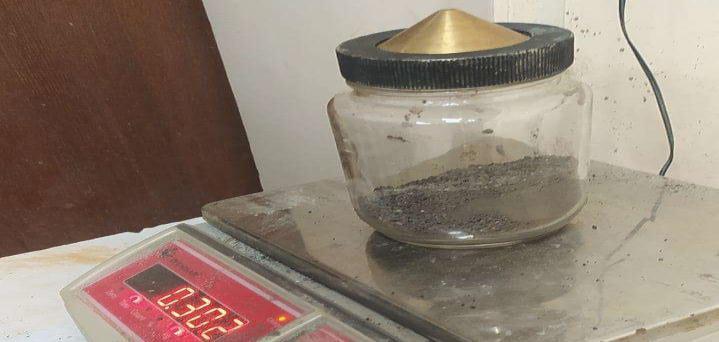

FIG 2.1 BLACK COTTON SOIL

2.2 RICE HUSK POWDER:

Rice husk is the hard protecting coverings of grains of rice. In addition to protecting rice during the growing season, rice husk can be put to use as an insulation material, fertilizer or fuel etc. It is used in its powder form

FIG 2.2 RICE HUSK POWDER

2.3 COAL POWDER:

This is the powdered form of coal, which is created by crushingofcoal.Thisisproductobtained duringmining. Coal powder is used in concrete. This is used to give stabilitytosoilinbrickmanufacture.

3. PROCEDURE FOR MANUFACTURING OF BRICKS:

CLAY

PREPARATIONS

MIXING MOULDING DRYING FIRING

3.1 CLAY PREPARATIONS:

For the preparation of ordinary black cotton soil was taken from local area of the black cotton soil region. The debris and unnecessary particles removed from the soil. Tempering is adding water to the soil in order to make it more workable whichtakes 5to 7 days in thecase of black cotton soil. An alternative to tempering is disintegration or weathering, which involves allowing clay to dry in the sun and accept moisture from rain and dew. The repeated drying and moistening of clay will bring clay to a plasticity and workability a proper Crushing will make the mixture morehomogeneous

3.2 MIXING:

Mixing is donetomake the clay soil homogeneousand

FIG 2.3 COAL POWDER

smooth.There are different techniques that can be used for mixing, including using animal power or letting humansmixtheclaywiththeirfeet.Different admixtures suchascoalorsawdustwereaddedtotheclayreasons:

2.4

LIME

Lime powder is obtained by calcification of limestone. It hascementing capability. It can be used in concrete ascementitious material. Lime is used inmanufacture ofcement. Lime powder enhances the strength of the blackcotton soil.

POWDER: FIG 2.4 LIME POWDER

fortwobeneficial

a)Reducecrackingduringdrying.

b)Reducefuelusageduringfiring.

In addition the rice husk, salt and lime was also added separately as well as combination of any rice husk-lime, salt-limeandsalt-ricehuskweightofthesoil.upto5% of total

FIG 3.2 MIXING

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

3.3 MOULDING:

The size of a mould for brick making was selected such that considered shrinkage effect of soil take in mind. Bricks will shrink when drying, so the mould size chose largerthantheintendedfinishedbrick.Theslopmoulding technique was adopted for the preparation of the mould. In slop moulding, a wet clay mixture is used the mix is put into a rectangular form without a top or bottom. The mouldwas selectedinsizeof200mmx100mmx100mm height with a frog 10 to 20 mm deep on one of its flat side.Thelimitationwiththistechniqueisthatbecausethe mixissowet,thebrickmaydeformunderitsownweight andthe surfacecanbemarkedeasily.Mouldedbrickscan beimprintedwiththebrickmanufacturer’sname,calleda "frog,"ontheflatsideofthebrick.Thisadvertising.helps the brick dry and fire better, and is a good form of advertising.

3.5 FIRING:

FIG 3.4 DRYING

Aclampisafieldkilnbuiltfromthegreen bricksthatwillbe fired.Clampsvarywithsizeandshapeandmustbeoriented with respect to wind direction. Once a clamp is laid scout andconstructed,itmustbeinsulated.

Finally, the process of firing the clamp will take place in several steps. First, pre- heating, or water-smoking, will remove the water leftover from the drying process. This process is still physical. The second stage is firing, where theclaybrickswillvitrifythroughachemicalprocess.The temperature must remain constant at this stage for complete verifications. Finally, for the cooling stage, the temperature must be slow and steady. A clamp may take twoweekstocool.

3.4 DRYING:

FIG 3.3 MOULDING

Water was added during clay preparation to increase workability of the mixture, but in drying it is removed for several reasons. First, there will be less cracking in fired bricks with less water content. Second, additional fuel is needed, beyond what is used for firing, to dry the bricks in the kiln. Proper drying of bricks will involve rotating the bricks for different exposures to ensure even drying rates. Forbestresults,dryingshouldbedoneslowly.Thiswillhelp withmoreevendrying.Also,thebestdryingtechnique may change from location to location, so the brick makers must gain experience todeterminethe best waytodry bricks for each production process. We dry the bricks under the normalatmospherictemperature(25˚C).

2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

4.1 SPECIFIC GRAVITY TEST:

Specific gravity of soil is defined as the weight of soil to weight of equal volume of water. It tells how much heavierorlighterthematerialisthanthewater.Thistest coversthedeterminationofspecificgravityofsoil.

Thestandardvalueis2.65.

FIG 4.1 SOIL IN PYCNOMETER

DETERMINATION TRIAL1 TRIAL2

Weightofpycnometer(W1)g 648 648

Weightofpycnometer+drysoil (W2)g 848 847

Weightofpycnometer+soil +water(W3)g 1600 1659

Weight ofpycnometer + water(W4)g 1471 1489 Specificgravity 281 231

Average SpecificGravity 2.56

4.2 LIQUID LIMIT TEST

The liquid limit is the moisture content at which the soil passes from the plastic state to the liquid state as determinedbytheliquidlimittest.

TRIAL

%Water added 20% 25% 30% 35% 40%

Noof blows 34 30 25 22 18

Empty weightof container (W1)

Weight of wetsoil+ container (W2)

33 31 32 36 30

FIG 4.2 LIQUID LIMIT TEST

376 337 3438 3769 3316

Weight of ovensoil+ container (W3)

Weight ofdry soil

Water content

46 27 23 16 31

396 348 352 382 343 Weight ofwet soil

66 38 32 22 43

6976 7094 73 7412 755

Averagewater contentof soil

4.3 PLASTIC LIMIT TEST

72.68

The plastic limit is the moisture content that defines

where the soil changes from a semi-solid state to the plasticstate.

It may also defined as that water content at which soil startscrumblingwhenrolledintothreadsof3mmdia.

FIG 4.3 PLASTIC LIMIT TEST

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

4.5 COMPRESSION STRENGTH TEST

DETERMINATIONNUMBERS 1

Container number 28

WeightofthecontainerW1(g) 30

Weightofthesoil+wetsoil (W2)g 34.5

Weightofcontainer+ovendry +soil(W3) 33

WeightofWetsoil 1.5

Weightofdrysoil 3

Watercontent 50

4.4

STANDARD PROCTOR COMPACTION TEST

Compaction is the application of mechanical energy to a soil so as to rearrange its particles and reduce the void ratio. it is applied to improve the properties of an existing soil or in the process of placing fill such as in the construction of embankments, road bases runways, earth dams

DETERMINATION

Massofmold+ compactedsoil(g) 6938 7053 7208 Massofmold 4554 4554 4554 Massof compactedsoil(g) 2384 2509 2654 BulkDensity g/cm3 2.52 2.65 2.81 Drydensityg/cm3 2.14 2.16 2.18

WATER CONTENT

Containerno34 22 21 Massof container(W1) 30 32 29 Massof container+wet soil(W2)

The average compressive strength of brick made from blackcottonsoilis5.68N/mm2.

The compressive strength of brick made from red soil is 4.25N/mm2

COMPRESSION STRENGTH CHART:

5.68 4.25

40.9 39.5 37.5

42.2 41.7 38.4 Massof Container+ drysoil(W3)

Water Content 11.9 19.6 10.5

5. RESULT AND DISCUSSION:

The specific gravity test for the black cotton soil is conducted according to IS-2720, the standard value for black soil lies between 2.57 to 2.35 respectively, in practical laboratory test we obtained the value of 2.56, hencetheresultsarewithinthelimitsandthesoilcanbe usedformanufacturingofbricks.

In standard proctor compaction test as per IS-2720, for different percentage of moisture content and corresponding valuesofdrydensityofsoilareobserved.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

The maximum dry density obtained is 2.16 gm/cc at optimum moisture content of black cotton soil at 21%of water. This results shows that soil gives better strength atthewatercontentof21%.

Valuesofliquidlimitandplasticlimitusedtoclassifyfine grainedsoil.Itgivesusinformationregardingthestateof consistencyofsoil.Thevaluesobtainedforliquidlimitis 72.68%andplasticlimitis50%forthesoilsample.

As per IS code provisions the standard dimensions of first class brick is 19cm x 9cm x 9cm. In the laboratory testthedimensionsofblackcottonsoilbricksare22cmx 11cmx8cm.

In the laboratory test as we performed the maximum compressive strength of brick using black cotton soil obtained is 5.68 N/ mm2. But the red soil brick compressive strength is 4.25 N/mm2. Hence the compressive strength of black cotton soil is more than red soil brick, so we can use this bricks in construction works.

6. CONCLUSION

Bricks are normally prepared from red soil or cementitiousmaterialssuchasflyash,GGBSetc.

The researches on the production of bricks using black cottonsoilisdoneveryrarely.

Thebricksmadefromblackcottonsoilarehighlyeffective comparedtonormalbricks.

Blackcottonisatypeofsoilwhichishavinghighbonding strengthwhenitismixedwithadmixtures.

Ithasmoreadhesive propertycomparedtoredsoil.

The strength of bricks is expected more compared to normalbricks.

Since, the bricks are more economical, soil is easily availableinlocalareasanditisstronger.

It is a good idea to use black cotton soil in the manufactureof bricksinplaceswhereblackcottonsoilis highlyavailable.

7. REFERENCES

1. Maruthi Balekatti, et al.,(2018), paper entitled as “UTILIZATION OF BLACK COTTON SOIL IN THE MANUFACTUREOFBRICKS”.

2. Patel Adit Kanti bhai, et al.,(2018), paper entitled as “APPLICATION OF BLACK COTTON SOIL BRICK IN CONSTRUCTIONINDUSTRY”.

3. HubliKiran,etal.,(2018),paperentitledas“ASTUDY ONMANUFACTURINGOFBRICKSUSINGBLACKCOTTON SOILANDREDSOIL”.

4. PragatiSaha,Kshamasingh,(2018),paperentitledas “COMPACTION OF BLACK COTTON SOIL BRICK WITH NORMALCLAYBRICK”.

5. Panchal Darshan, et al.,(2014), paper entitled as “COMPARISION OF BRICK MADE FROM BLACK COTTON SOIL WITH VARIOUS ADMIXTURE TO THE NORMAL BRICK”.