International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Abstract - Sand casting is an indispensable manufacturing process which is used widely around the globe. It involves pouring molten metal into moulds havingcavities, so as to cast metal into the desired shape of the cavity. Sand casting is a study in itself, and is a blend of fluid mechanics and heat transfer. Common parameters that are variedinclude flowing velocity, filling time, porosity of mould material etc. The process of sand casting presents with its own set of challenges, one of them being casting defects. Casting defects compromise the quality of the castings, and make them weaker. The study of casting helps us predict the casting quality and defects without doing actual castings, and hence, save time, money and resources. The main aim behind this is to maximize the sand quality with the help of different methods and also work upon the casting defects therefore improving the overall casting.

Thepurposeof thisarticleistooptimizetheparameters ofthesand casting process,includingoptimallevels. The Taguchi method can beimplementedusing the following steps:

1. To determine the most important variables that influencequalityqualities.

2. Casting defects have been chosen as the most representative quality parameters in the green sand castingprocess(coldshuthottearetc.).Thegoalofthe green sand casting method is to obtain "reduced casting faults" while reducing the influence of uncontrollablevariables.

3. Make the green sand casting procedure according to the experimental conditions indicated by the orthogonal array and parameter values you have chosen.

Sand casting is an indispensable manufacturing process whichisusedwidelyaroundtheglobe.Itinvolvespouring moltenmetalintomouldshavingcavities,soastocastmetal intothedesiredshapeofthecavity.Sandcastingisastudyin itself, and is a blend of fluid mechanics and heat transfer. Common parameters that are varied include flowing velocity, filling time, porosity of mould material etc. The process of sand casting presents with its own set of challenges,oneofthembeingcastingdefects.Castingdefects compromise the quality of the castings, and make them weaker. The study of casting helps us predict the casting qualityanddefectswithoutdoingactualcastings,andhence, savetime,moneyandresources.Themainaimbehindthisis to maximize the sand quality with the help of different methodsandalsoworkuponthecastingdefectstherefore improvingtheoverallcasting.

A process which has to be optimized has many process parameterswhichaffectstheexpectedtargetvaluedirectly orindirectly.Optimizationinvolveschoosingtherightlevels oftheparametervaluestoobtainthedesiredvalue.Thisis knownastheStaticProblem.Thenoiseremainsinthewhole processbutthisshouldnotaffecttheoutputwhichisactually theprimaryaimofTaguchi’smethod.

4. To establish the statistical significance of the parameters,ananalysisof variance(ANOVA) table is created.Tofindthepreferredlevelforeachparameter, responsegraphsareplotted.

5. Predict the results of each of the parameters at their newoptimumvalues,inadditiontotheidealsettingsof thecontrolparameters.

Dataiscollectedfromthefoundriesofsmallscaleormedium scalelevels.Itiscollectedforalongerperiodoftimeandare observedbyplottingthegraphbetweentheproductionrate and rejection rate and suitable components are chosen whichhavehigherrejectionratescomparatively.Itisfound that these rejections are mainly due to the sand related defects.ParetoAnalysisisusedtoidentifythedefectswhich affectsthe final casting qualityona largerscale.Based on thistestingmade,approximately78%castingswererejected becauseofcoldshutdefectandhottear.IshikawaDiagramis usedtoidentifythemajorcausesbehindthecoldshutdefect and hot tear. Less fluidity of molten metal, high moisture contentinmouldingsand,impropergatingsystem,slowand medium pouring, residual stresses in the material and impropermoulddesignwereresponsiblemajorlytocause thecoldshutdefectandhottear.

Threeparametersarechosenforexperimentation.

1. Pouringtemperature

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Gatingsystem

Pouringtime Table 1: FirstsetofProcessparameters Sl. No. Parameter Level 1 Level 2 1 Pouring Temperature(°C) 13201390 13901420

GatingSystem Nochange Change 3 Pouring Time (Second) 15 13 Two levels are assigned to the parameters with some changesinthevaluesoftheparameters(someparameters remainconstantforalllevels). L4orthogonalarrayisusedfor3parametersand2levels.It givesusthepermutationforthesandcastingtobedonefor variouslevels. Processparameterswerechangedandthesameprocesswas followed.Thesecondsetofparameterschosenare: 1. CompressionStrength

trackedanddocumented.Thelowertheamountofcasting flaws, the higher the process performance. The objective functiontobemaximisedinthiscaseis:

S/N(SignaltoNoise)Ratio= 10log(∑(1/Y2)/n)

n=Numberofexperiments

Y=Percentageofapprovedcasting

ThelessertheS/Nvalue,thebetterthequality.

S/N ratios are calculated to assess the best experimental process with respect to the levels assigned to each parameter.Signalrepresentsthedesiredvalue(Percentage ofApproval)andNoiserepresentsundesirablevalue.

The number of control parameters and the interaction of interest influence the choice of an orthogonal array. The numberoflevelsforthecontrolparametersofinterestisalso aconsideration.ThestandardTaguchiL9OrthogonalArray (OA) format is chosen from preliminary work with three parameters namely the mould temperature, pouring temperature and as important casting process variables whichaffectthemechanicalproperties.Thecriteriausedfor choosing the three parameter levels are to explore a maximum range of experimental variables. The assigned levelsofparametersareshowninTable1andTable2.The experimental orthogonal array along with their levels are shownintheTable5

Table 3: Signallevels

The quality characteristic to be measured was casting flaws. The most prevalent problems in the foundry were

Parameter Range Level 1 Level 2 Level 3 Pouring Temperature (°C)

1300 1500 1300 1320 1350

Permeability (No) 130180 130 150 180 SandParticle size(AFS) 5055 50 52 54

Mould Hardness (Nu)

5080 50 60 75

Parameter Level 1 Level 2 Level 3 Moisture Content (%) 3.2 3.8 4.3

Green Strength (g/cm2) 1200 1400 1800

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Sand Particle size (AFS) 50 52 54 Mould Hardness (nu) 50 60 75

5:

array

1 1300 130 3.5 1200 50 50

2 1300 150 3.5 1500 52 60

3 1300 180 3.5 1700 54 75

4 1320 150 3.5 1200 52 75

5 1320 180 3.5 1500 54 50

6 1320 130 3.5 1700 50 60

7 1350 180 3.5 1200 54 60 8 1350 130 3.5 1500 50 75 9 1350 150 3.5 1700 52 50

Theexperimentswereconductedtwicefortwosamesetof parameters. The casting defects that occur in each trial conditionswerefoundandrecordedforoptimization.Itis donewiththehelpofMinitab16softwarebyTaguchiDesign of Experiment (DOE) technique. Only single defect Cold shut is considered for the inspection. The average of the castingdefects wasdetermined for eachtrial condition as shown in Table 9. The casting defects are the “lower the better”typeofqualitycharacteristics.LowerthebetterS/N ratioswerecomputedforeachofthe9trialsandthevalues aregiveninTable9:

Forexample,fortrialnumber1:

η= 10log[(Ʃy^2i)/3]

S/NRatio= 10log[(6.50^2)+(5.30^2)+(6.90^2)/3]

= 10log[(42.25+28.09+47.61)/3]

= 10log[(117.95)/3]

= 10log[39.31]

= 15.945

Experim ent Number

Signal Level for parameters Total Casti ng Pour ed

Pouring Tempera ture

Gati ng Syste m

Pouri ng Time

Numb er of Castin gs appro ved

Percent age of Casting s approv ed

1 1 1 1 36 27 75% 2 1 2 2 36 33 91.67% 3 2 1 2 36 31 86.11% 4 2 2 1 32 32 100%

Table 7: S/NRatiosoftheexperimentsperformed

Experiment Number Percentage of approvedCasting Signal to Noise Ratio Mean

1 75% 37.5012 75 2 91.67% 39.2445 91.67 3 86.11% 38.7011 86.11 4 100% 40.0000 100

Table 8: Optimumparametervalues

Parameters Level S/N Mean Optimum Value Pouring Temperature (°C)

2 39.35 93.06 1390 1420 Gating System 2 39.62 95.84 Change PouringTime (Second) 2 38.97 88.89 13

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

The analysis of variance technique (ANOVA)is used to examine the outcomes of the experiments after they have been completed.Forseveral trial settingsandparameters thatsignificantlyinfluencecastingdefects,importantfactors and/or their interactions are discovered. However, more information is required to arrive at an optimal parameter setting.

Table – 9: Defects percentage and S/N ratios compared withtherespectiveexperimenttrials

Trial No. % Defects in Experiment S/NRatio Average 1 2 3 Total

1 6.50 5.30 6.90 18.70 15.9450 6.23

2 5.50 3.80 5.30 14.6 13.7506 4.87

3 7.34 5.60 7.56 20.5 16.6884 6.83

4 3.50 4.20 4.01 11.71 11.8213 3.90

5 6.32 4.90 7.14 18.36 15.7350 6.12

6 7.43 6.67 6.00 20.1 16.5215 6.70

7 7.12 5.00 5.75 17.87 15.5049 5.96

8 3.33 7.32 4.50 15.15 14.0658 5.05

9 3.50 5.60 1.53 10.63 11.1501 3.61

Rejectionofthefinalcastproductscamedownto3.4% whichisagoodimprovement.

TheoutcomeofconductingtheTaguchiAnalysiswith thehelpofIshikawaDiagramandParetoAnalysis,has beensatisfying.Thismethodisefficientinbothways, i.e. when a single defect is identified and Taguchi methodisappliedtoremoveorreducethatparticular defectandalsowhenthismethodisusedtoreduce thedefectswhicharegenerallyseeninthefinalcast.

This method not only contributes as one of the efficientandfeasiblesolutionstoreducecastdefects directly, but this method has also become an importantfoundationformanyothersolutionswhich wereinspiredfromthistechniquethatwereproposed laterontoo.

[1] Defects Analysis and Optimisation of Process ParametersusingTaguchiDOETechniqueforSand Casting (International Research Journal of EngineeringandTechnology(IRJET),2017)byAnil Rathore1,Prof.F.Ujjainwala

[2] Optimisation of Casting Process Parameters using Taguchi Analysis (International Journal of Mechanical Engineering and Research, 2015) by SaravanaKumarM,JeyaPrakashK

[3] ReductionofCastingDefectsUsingTaguchiMethod (JournalofMechanicalandCivilEngineering(IOSR JMCE),2016)byArunBasilJacob,ArunkumarON

[4] MinimisationoftheCastingdefectsusingTaguchi’s Method (International Journal of Engineering Science Invention, 2016) by Harvir Singh, Aman Kumar

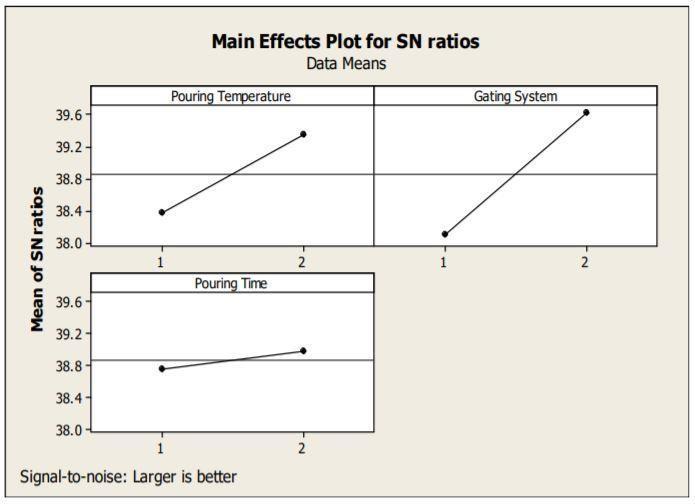

Figure 2: Graph depicting S/N ratios across the parameters

It was observed that all the first set of parameters providebetterresultswithrespecttothecastquality whenworkedinLevel2.Pouringtemperatureshowed 92 96% of approval, Gating system showed 96% approvalandPouringtimeofabout84 86%approval.

[5] TaguchiOptimisationofProcessParametersonthe hardness and Impact energy of Aluminium alloy Sandcasting(LeonardoJournalofSciences,2013) byJohnOOji,PamptoksHSunday

[6] Optimisation of Green Sand casting Process ParametersofaFoundrybyusingTaguchiMethod (InternationalJournalofAdvancedManufacturing Technology,2007)bySushilKumar,PSSatsangi,Dr. DRPrajapathi

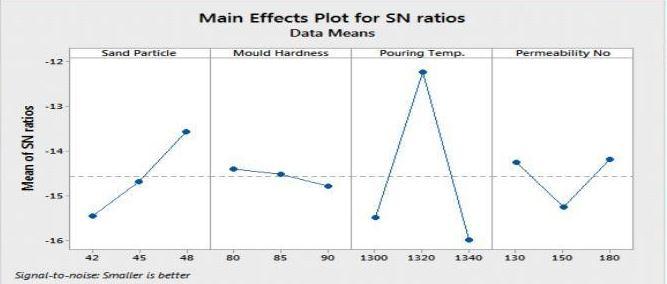

ItisobservedthatMoisturecontentandPermeability provide better results at Level 2 whereas, CompressionStrengthandMouldHardnessNumberat Level3.20 30%reductionindefectsvariationcould be seen and also the regression value was 85%.

[7] Optimization of Sand Casting Process Parameter Using Taguchi Method in Foundry (International Journal of Engineering Research & Technology (IJERT)byRasikAUpadhye,Dr.IshwarPKeswani

[8] Analysis of Casting Defects in Foundry by ComputerisedSimulations(CAE) ANewApproach

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

along with some Industrial Case Studies (IFEX, 2013)

[9] ReviewonAnalysisofFoundryDefectsforQuality Improvement of Sand Casting (Int. Journal of Engineering Research and Applications, 2014) by SunilChaudhari,HemantThakkar

[10] ReviewofOptimizationaspectsforCastingprocess (International Journal of Science and Research (IJSR), 2015) by Yazad N Doctor, Dr. Bhushan T Patil,AdityaMDarekar

[11] AnApplicationofParetoAnalysisandCausesEffect diagram for minimization of defects in manual Casting process (International Journal of MechanicalAndProductionEngineering,2014)by AniruddhaJoshi,PritamKadam

[12] Casting Defects Analysis in Foundry and Their Remedial Measures with Industrial Case Studies (IOSRJournalofMechanicalandCivilEngineering (IOSR JMCE))byAvinashJuriani

[13] Design Optimizationofgatingandfeedingsystem through Simulation technique for Sand casting of wearplate(EngineeringandMaterialSciences)by SachinLNimbulkar,RajendraSDalu

Harsh Verma is an undergraduate MechanicalEngineeringstudentat Vellore Institute of Technology, India. He is intrigued by ManufacturinganditsAutomation.

Nischal C N is an undergraduate student pursuing Mechanical Engineering at Vellore Institute of Technology,India.Heisfascinated byAutomobiledomain.

Vedant Rasal is an undergraduate student pursuing Mechanical Engineering at Vellore Institute of Technology,India.Heisinterested inmanufacturingdomain.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified