International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

WORKER SAFETY HELMET and MINING TRACKING

H.Lanith1, Adepu Mounika2, Arika Vijaya Bhaskar Reddy3

Cheelasani Pavankumar4, Gudla Manohar5 under the humble guidance of Mr. Mohit KumarGoel, School of Electronics and Electrical Engineering, Lovely Professional University, Punjab, India. ***

Abstract Mining provides work to millions of population, but the working conditions of theminingpeoplearevery poor. The workers travel deep into the mine andstay till evening in the place where the oxygen levels are low. Large explosives are used everywhere which complicates the workers duty both physically and mentally. IOT has a great importance with varying applications drawing attention to its construction [1]. To the contrary side the main objective of this research is to make the workers safe for mining industry applications which would be monitored by the system on the grounds of hazardous events such as temperature, humidity, gas. Once, there is a hazardous situation the workers press the panic button and the people on the other side would nowthat there might be some danger in the mine and thus the people are saved.

Key Words: micro controller, temperature sensor, LCD display, mining, wireless network, panic button.

1. INTRODUCTION

Mininghasbecomeanecessarytasktotheextractionaswellascreationofvariousgoods,infrastructureandmanyservices whichenhances the quality of life. As a result,amining trackingandasafetyhelmetisproposedbyourteamtothemining industryusingAtmegamicrocontrollerbasedcircuit.ThismakesuseofRFcircuit[2].RFstandsforradiosignalsandparticularly thesesignalsarebeingusedforthisprojectastheycanonlysustainandsuittheconditionsofaminingsite.Blynkapplicationisused togetthenotificationsandcloudisalsoprovidedbythesameplatform.Thenotificationisreceivedtothetargetedmobilephone orawebpage.However,theutilizationofheavymachineryandthemethodsperformedduringexcavationsresultinrisksinall typesofmining[3].TheChasnalaminingdisasterthattookplacenearDhanbadintheIndianstateofJharkhandalmostkilled372 miners.Thiswasconsideredasoneoftheworstdisastersintheminingindustry.Once,apersonentersthemine,theywouldnot beawareofexternalenvironmentalconditionsthattakesplaceinsideandoutsidethemineandthiswouldresultindiscovering suchdevicesforthesafetyofthemineworkers.

LITERATURE REVIEW

Theadvancementsinthetechnologymadethedetectionofminesmuchmorepractical.Thewell beingofcoalminers hadmoderatelythekeyelementoftheworld.Accordingtostatistics,intherecentyears,thereweremanymineaccidents occurred.InsomecountrieslikeChina,weobservethattheproductionlevelisupto35%buttheaccidentcasesaccountupto 80%oftheworld[4].Thiscausesagreatdamagetotheeconomyandhumanlives.Thus,preventionshouldbetakentoavoid dangersinmines.Mostofthedisastersinminesoccurduetotheenvironmentalconditions.Asminesareverydeeperintothe earth,thedangeroussituationsintheexploitedareaswouldnotcomeintolimelight.

Layinglargecablesthroughtheminewouldnotbeaneasytaskandmayconsumemuchtime.Therefore,minemonitoring systemscomesintoexistenceandtheyplayavitalroleincaringfortheminingworkers.

The implementation of mine monitoring systems are made with the use of wireless sensor networks becomes importantanditisanecessarytaskbecauseitusesmoderntechnologyandgetsridofthelimitationscausedbythetraditional approaches.Trackingwithhumanstakesmuchtimeandconstitutesmanyconsequences.Thelocationoftheminermaybe withintheminebutwecouldnotfindhisexactlocation.Itmayrarelyhappenthattheminerwouldgotoadifferentplace forgetfullywithoutanyintimation[5].Thus,toovercomesuchsituationswirelessnetworkshavecomeintousage.Wireless SensorNetworksareanessentialsourceforanydevicemakingatpresent.WSNisbasicallyacollectionofdatausingnowires. AWSNisaninfrastructurewhichhasnowiredconnectionsandhasonlylessnumberofwiresinanadhocmannerused physicallyinsystematicenvironmentalconditions.Thisminiaturesensorsareabitexpensiveincontrasttotheoldsensors whichwereoriginallyinuseandaremoreadvanced.

•Layingofcablesisnotrequiredandiseasytoinstall,reducesthemachineryandcostofthemonitoringsystem.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2827

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

•Theconcentratednodesmakesurethatthedataistransferredwithgreatprecisionandoptimaldatatransmission whichisfurthersuitableformine’senvironment.

SYSTEM OVERVIEW:

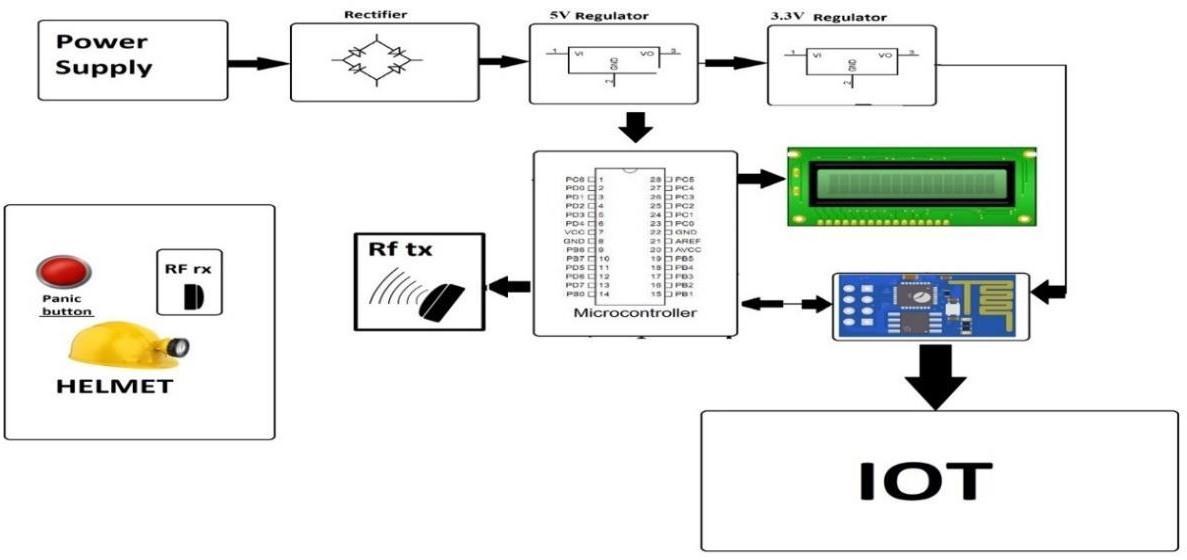

TheworkerswouldbeallowedonlywhentheRFIDtagisscanned.OncetheRFIDtagisscanned,theauthorizedworkergets theaccesstoenterthemine.Theywouldenterthemineandcompletetheirworkandthentheywouldaskforexitentry[6].Then theywouldbepermittedtocomeoutofthemine.Thisseemstobehappyasthereisnohazardoussituationinthemine.

Whatiftherewouldbeahazardoussituation?Here,oursystemcomeintousage.Theworker’shelmethasapanicbuttonwhichis technicallyanRFtransmitterandpassesRFsignalsandcommunicateswiththeRFreceiveratthebasestation[7].RFstandsfor radiosignalsandparticularlyRFsignalsarebeenusedforthisprojectastheycanonlysustainandsuittheconditionsofamining site.Blynkapplicationisusedtogetthenotificationsandcloudisalsoprovidedbythesameplatform.Whenthepanicbuttonis activated,thesignalistransmitted fromthetransmittertothereceiverandthenitreceivesthesignalandthendisplaysan emergencynotificationontheLCDdisplayofthemonitoringsystem.TheonboardcontrollerisconnectedtoanIOTboard,whichis oursystem’snodeMCU.ItsendsanSMSalerttotheprogrammedpersonanddisplaysanemergencytext.Whentheworkis completedandtheworkerusesthebutton,theLCDdisplaysamessage“WORKISDONEPICKUPREQUEST”,butwhenthereisa hazardoussituationandtheworkerusesthebutton,wewillhearabuzzersoundandtherewouldbeamessageontheLCDdisplay like“WORKERSAREATDANGER”.Therefore,theworkersaretrackedbasedonwhichminetheyaresenttoonthebasisofRFID tags.Thus,theperson’ssafetyisensuredonaconditionthathewearsthehelmet[8] Thehelmetisbeenlinkedandprocessedviaa rfbasedtrackingsystemwhichinthecoordinationwiththetrackerrfsystems

Reader basedtrackingsystemsmerelydetectwhenatagandareaderarewithinRFrangeofeachother.Whenatagisrecognized byareader,theminer’spositionbecomesassociatedwiththelocationofthefixedcomponent(tagorreader)[9].Theresolutionor distancewithinwhichtheminerislocatedisdeterminedbythespacingbetweenfixedpositioncomponents.InthiswayanRFIDtag isscanned[10]

Intheexistingsystem,mininghelmetensurestheprotection,butbeingawareoftheconditionsoftheenvironmentsuchashigh humidityandtemperature,theworkersmaysometimestakeoffthehelmetwhichcauseshighinjuriestothepersonunderany hazardoussituations[11].Inothercaseswhereminedoesnothaveproperfacilities,itisimpossibletohaveaseamlessconversation betweenthe

EXISTING SYSTEMS:

Manysystemsarebeingusedforthetransmissionofdatainsidethemines.Thesedatatransmissionsystems includeGSM,GPS,RFID,Zigbeeetc.Suchapproachesarebeingestablishedtomaintainthedatatransferthroughthemines[12] Allthesesystemsarebetterinitswaybutitworksmoreefficientlywhenintegratedwithothertechniques.Eachofthesehaveits ownlimitations.

GPS:GPSisabbreviatedasGlobalPositioningSystemandisthemostprevalentcommunicationsystem.Itisasatellite communicationsystem[13].Itisusedforlargecoverageareacommunication,butitcouldnotbeefficientforunderground mines.GPSdonotneedausertotransmitthedata.Itoperatesindependentlywithoutanyinternetortelephone[14].Such technologyhelpsustofindthelocationofaperson.Itismostlyusedinmilitary,civilandcommercializedservicesalloverthe world.ThegovernmentofUScreatedasystemandmaintainsitandmakesitaccessiblefortheusers [15].Withthehelpof satellites,GPShelpsustoknowthefastnessofthemotionoftheobjectanditsdirectionofmotionandtheheightittravelsetc.

GSM:GlobalSystemforMobileCommunicationcanbeusedforwidecoverageareabutwhenusedforundergroundmines, thesewouldbedelayincommunicationandthisleadstobeadisaster[16].GSMisacceptedallovertheglobeforstandarddigital cellular communications systems. It uses TDMA and provides speech and message services along with roaming services. RoamingisthecapacityofusingourGSMmobilenumberinotherGSMnetwork[17].GSMmanagesthecustomersandthedevice inmanyways.Mobilenumbers,customersandequipmentidentifiersaresomeoftheknownones.

RFID:Thismechanismisverymuchbettertolocatetheundergroundminers.Itdoesnotneedthelineofsighttotransmitor receivedata.Thissystemishighlysophisticatedbuthasalimitation.RFIDtagconsistsoftwocomponentsnamelyreaderandtag [18].Readerisasystemwhichconsistsofoneormoreantennasanditemitsradiowavesandthenreceivessignalsbackfrom RFIDtags.ThereaderofRFIDisconnectedtonetworkandismovableorfixed.Itmakesuseofradiowavestosendthesignals thatenablesthetag.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

BLOCK DIAGRAM

FLOW

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

COMPARISON TABLE:

Table1:ComparisonofProposedandExistingSystems

S.NO EXISTING SYSTEMS

1. No sensors were used back then inmining industries.

PROPOSEDSYSTEM

IRsensors arebeenusedin theminingindustries atpresent

2. No microcontrollers were used in thepastin miningindustries. Now,awidevarietyofmicrocontrollershavebeen usedwiththeadvancementsinthetechnology.

3. The worker might have used a helmetfor safety but it was not integrated witha panic button.

Theworkerhelmetisequippedwithapanicbutton rightnow.

4. Wirelessnetworkwasnotusedbackthen. Wirelessnetworkisbeingusedrightnowwiththe advancementintechnology.

5. Existinghelmetswerejustthebasichelmets. These helmets are the smart helmets which ensuresthesafetyoftheworker.

CONCLUSION

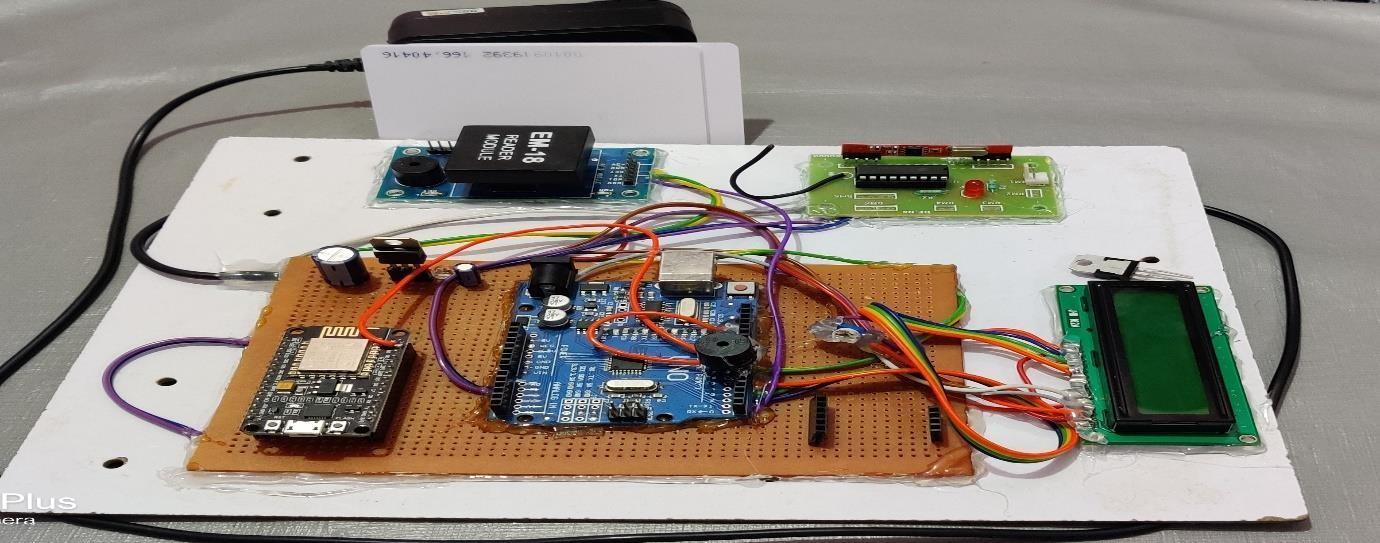

Tofinallyconclude,asmarthelmethasbeendesignedinordertohelptheworkerfromthedangeroussituationsif any.Thissystemprovidesusaclearandpoint to pointperspectiveoftheundergroundminesystemandprovidesreliable communicationusingIOT.Hence,itwouldbebeneficialtotheminerspresentinsidethemineandensuresthesafetyofthe workers. FIGURE1

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

FIGURE2. REFERENCES 1. ijarcce.com/wp content/uploads/2021/06/IJARCCE.2021.10579. 2. irjet.net/archives/V7/i4/IRJET V7I41051. 3. ijisrt.com/wp content/uploads/2017/04/A SMART HELMET FOR IMPROVING SAFETY IN MINING INDUSTRY. 4. geeksforgeeks.org/wirelesssensornetwork

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

16. ijtra.com/view/iot based smart helmet for accident detection.

17. researchgate.net/publication/340261013_Iot_Based_Smart_Helmet_for_Mining_Industry_Application

18. google.com/search?sxsrf=APq WBuCHs203iHua4pc8ZJxKk2SAhVnmA:1650897915457&q =Smart+helmet+for+coal miners+using+ Zigbee + technology&sa = X&ved= 2ahUKEwjrtb7 ua_3AhWimFYBHR_ xC2IQ1QJ6BAgXEAE&biw=1396&bih=649&dpr=1.38

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |