International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1Assistant Professor, Applied Mechanics and Structural Engineering Department, Faculty of technology and Engineering, M.S. University of Baroda, Vadodara.

2 Associate Professor, Applied Mechanics and Structural Engineering Department, Faculty of technology and Engineering, M.S. University of Baroda, Vadodara. ***

Abstract The aspect of the durability of the concrete was not afforded as much attention as compressive strength. Consequently, many structures have shown signs of deteriorationearlier thantheirexpectedservicelife,whichhas resulted into needforrepair andrehabilitation, oftenat great cost. Durability of concrete is related to the material performance and environment and cannot be thought of as being an inherent property of the concrete. Compressive strength of concrete can not guarantee durability. It is imperative to quantify durability performance of concrete to evaluate service life prediction of reinforced concrete structures. Durability indices for medium strength concrete containing OPC, silica fume and fly ash in binary and ternary blendingare evaluatedbytestingthespecimensat28days,56 days and 90 days. Oxygen permeability, water sorptivity and chloride conductivity tests are conducted to evaluate effectiveness of mineral admixtures in enhancing various transport mechanisms. It is observed that macroscopic pore structure of the concrete material plays an important role in durability of the concrete instead of compressive strength. Results show that blending of silica fume and fly ash as a part replacement ofOPCimprovises durabilityperformancewhich helps toelongateservicelifeofreinforcedstructuresinmarine environment.

Key Words: Silica Fume, Fly Ash, Sorptivity, Chloride Conductivity,OxygenAirPermeability

Concrete is one of the most important and widely used constructionmaterials.Itisamaterialcomposedmainlyof cement, aggregate and water. Chemical and mineral admixturesareusedassupplementarymaterialstoenhance performance. Concrete may consider to be a durable material if properly proportioned, executed in fresh state, cured, and maintained impervious. Reinforced concrete structuresareexpectedtobemaintenance freeduringtheir serviceliveswhensuchconcreteisused.However,thereare numerousexamplesofprematuredeteriorationofmodern structures.

Adurableconcreteisonethatperformssatisfactorilyinthe workingenvironmentunderanticipatedexposureconditions during its service life. One of the main characteristics influencingthedurabilityofconcreteisitspermeabilityto the ingress of water, oxygen, carbon dioxide, chloride, sulphate,andotherpotentiallydeleterioussubstances.

Inthelastdecade,onlystrengthofconcretewasconsidered in the concrete mix proportioning procedure assuming strengthofconcretegoverningallotherdesirableproperties ofconcreteincludingdurability.Itisnotentirelytruethat the stronger concrete is always a durable concrete. In addition to strength of concrete another factors, such as environmental condition (exposure condition), transport mechanisms that involve the ingress of ions or molecules from surrounding liquids and gases into and through the materialsarealsoimportantconsiderationfordurability[1].

Differentcountrieshavedifferentapproachesinaddressing theissueofreinforcedconcretedurability.Thetraditional prescriptive approach adopted by India specifies limiting values for certain material properties (w/c ratio, cement type,coveretc.)dependingonenvironmentalconditionsand expected service life of the structure without adequately addressing other issues of the concrete qualitatively [2]. Suchlimitingvaluesmaybeout datedastheywereframed based on experience after which significant changes have beenoccurredwiththematerialsusedinmodernconcrete. Whilethedesignmayplacerestrictionsonvaluesforcertain properties, there is often no way of verifying that the construction practices have adhered to these values establishedbyprescriptiveapproachsincetheyaredifficult tomeasure.

South African approach has gained credit for following a more performance based approach rather than the traditionalprescriptivewhichprovidesarationalmethodto design for durability [3]. The desired acceptable performance criteria of the structure are defined, and the concreteisspecifiedanddesignedaccordinglytomeetthese criteria.TheDurabilityIndices(DI)approachprovidestools tohelpdefinetheperformancecriteria[4].Itsuggestsuseof threetests,namelytheOxygenPermeabilityIndex(OPI)test, Chloride Conductivity Index (CCI) test and the Water Sorptivity Index (WSI) test, to characterise and quantify

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

different mechanisms of deterioration [5]. This approach addresses permeation, migration, and absorption type transportmechanismsthroughconcrete.

This paper aims to address effectiveness of mineral admixtureinthreegradesofmediumstrengthconcreteon allthesethreetransportmechanismsbyevaluatingindices withthehelpofwhichdurabilityofconcreteisdetermined.

53gradeOPCconformingtoIS:12269 1987[6],Silicafume conforming to IS 15388:2003 [7] and processed siliceous pulverizedflyashconformingtoIS3812(Part1):2013[8] areusedaspartreplacementofcementinconcrete.Dosageof SuperplasticizerconformingtoIS9103:1999[9]iskeptas 0.8to1%byweightofcementforworkabilitypurpose.

Total9typesofmixesweredesignedasperIS10262:2019 [10]. (1) M30: OPC (2) M40: OPC (3) M50: OPC (4) M30: OPC+10%SF(5)M40:OPC+10%SF(6)M50:OPC+10%SF (7)M30:OPC+20%FA+8%SF(8)M40:OPC+20%FA+8%SF (9)M50:OPC+20%FA+8%SF.

Total170numbersofcubespecimensof150mmx150mmx 150mmwereprepared.Coresamplesof3inchesdiameter wereextractedfromeachcubespecimenandthreeslicesof 30mmthicknesswerecutfromeachcoretoproducethree samplesforeachtest.Thesesamplesweretestedafter28th , 56th and90th dayforoxygenpermeability,watersorptivity andchlorideconductivitytest.

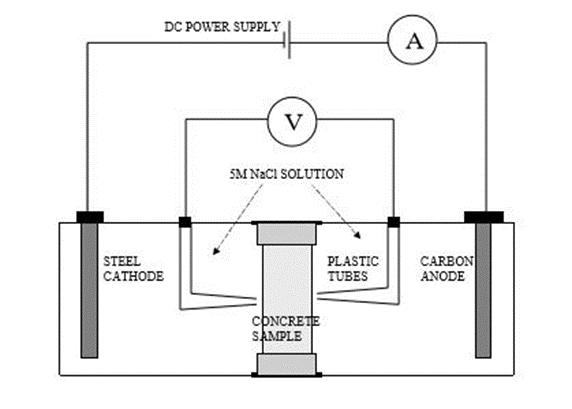

When fluid moves through the pore structure due to externally applied pressure, this phenomenon defined as permeation.Thepermeabilityoftheconcretedependsonthe microstructureoftheconcrete,environmentalcondition,and permeating fluid. Ballim developed a falling head permeameter that allowed simple measurement of oven driedconcreteexposedtooxygenunderpressure.Figure1 shows the experimental test set up for the oxygen permeabilitytest.Concretecoresamplesareinitiallydriedin ovenat50ºCfollowedbyexposingto100±5kPapressure. Darcy coefficient of permeability is determined using a logarithmic transformation from the slope of the pressure decaycurve.Oxygenpermeabilityindex(OPI)iscalculatedas the negative logarithm of the Darcy coefficient of permeability. Concrete with oxygen permeability index values above 10 may be considered to have excellent impermeabilitycharacteristicswhilstvaluesfrom9.5to10 indicategoodimpermeabilityandbelow9.5itisconsidered poorimpermeability.

Sorptivity is defined as a measure of the capacity of the medium to absorb or adsorb liquid by capillarity action. Sidesofthespecimenarecoatedwiththeepoxymaterialto ensurethatabsorptiontakesplaceinonedirectiononly.A linear relationship is observed when the mass of water absorbed is plotted against the square root of time. The sorptivity,Softheconcreteisdeterminedfromtheslopeof thestraightlineproduced.Sorptivityvaluebetween10and 15isconsideredaspoorconcrete,6to10:goodconcreteand below5:excellentconcrete.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Diffusionistheprocesswherefluidsorionsmovethrougha porousmaterialundertheactionofaconcentrationgradient. Diffusionoccursinpartiallyorfullysaturatedconcreteandis the dominant internal transport mechanism in marine environment. Diffusion rates depend upon temperature, saturation level of concrete, type of diffusant, chemical interactions and inherent diffusibility of the material [11]. Chlorideconductivitytestingforwhichtestsetupisshownin Fig.3hasbeenfoundtobesensitivetochangesinconcrete microstructurecausedbyw/cratio,initialcuring,andtypeof binder. The type ofcementitious material hasa significant effect on chloride conductivity. If the chloride value falls below 0.75 mS/cm, it is considered to have an excellent chlorideresistance.Ifitfallsbetween0.75and1.5,ithasgood chlorideresistanceandabove1.5,itisconsideredtobepoor chlorideresistance.

tobenotedthatcompressivestrengthofconcreteremains almostsameonplain,binary,andternaryblendedconcrete, whereasdurabilityperformanceisimprovisedmuchwhen pozzolanic materials are used which is attributed to improvisedporestructure,eliminationofdelayedettringite formation,pozzolanicreactivity,increased denseness,and enhancedworkabilityetc.Impermeabilityofconcreteisthe secret behind durable performance of concrete which is obtainedusingmineraladmixture.

Fig 3:TestsetupforChlorideConductivityTest

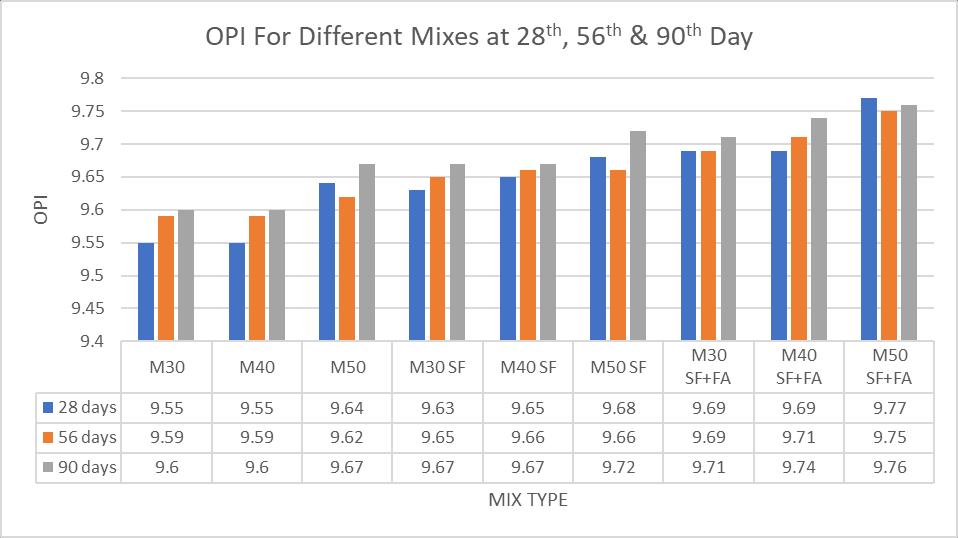

Testresultsofoxygenpermeabilitytestfor28th,56thand90th days are indicated in Fig. 4. It is found that Oxygen PermeabilityIndex(OPI)almostremainssameatdifferent ages.Therefore,thisindexshall beevaluatedon28th days whichisrepresentingforremainingperiodaswell.Thereis no much enhancement of value of OPI after 28 days. Test resultsarerangingfrom9.55to9.77forallthemixeswhich fallinthecategoryofgoodresistanceagainstpermeability. OPIvalueisfoundtobetheminimuminconcreteproduced withOPCforeachgradewhichindicatesthatuseofOPCmay notbesuggestedfordurabilitypointofview.Asthegradeof concreteincreases,OPIvaluealsoincreases. Highestvalues ofOPIarefoundtobeinternaryblendedconcreteineach grade. Therefore, ternary blended concrete proves to the bestfordurableperformance.Binaryblendedconcretei.e., OPC+SFindicateOPIlessthanternaryblendedconcrete.Itis

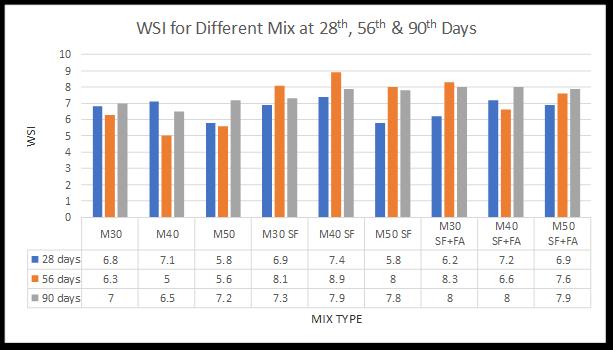

Fig. 5 reveals that test results for 28th day’s exhibit satisfactoryWaterSorptivityIndex(WSI)indexalmostfor allthemixesmaybebecauseofsaturationofcapillarypores bywater.WSIindexisfoundtobethemaximumat59days foralmostallmixes.Effectofadditionofmineraladmixtures hasnotbeenprovedtobeefficientinreductionofWSIindex. Itcanbesaidthatmineraladmixturesdonotplayanyrolein absorptionphenomenon.

Fig 5 WaterSorptivityIndexforDifferentConcreteMixes

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

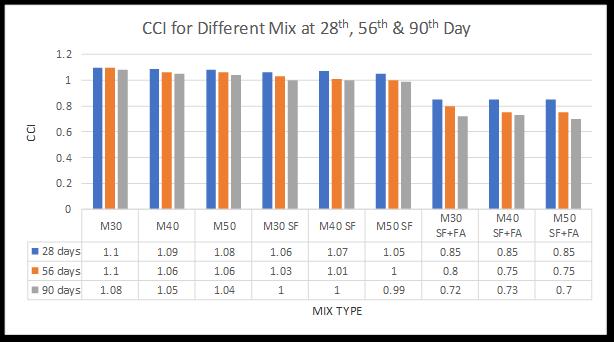

Fig.6revealsthatChlorideConductivityIndex(CCI)value decreases with the age of concrete. However, CCI value indicatesgoodperformanceofallthemixesat28th days.As the grade of concrete increases, CCI index decreases marginally, therefore, imperviousness is enhanced by increasingcompressivestrengthofconcrete.CCIindexgoes onimprovingwhenmineraladmixturesareusedinbinary andternarymixesofallgradesofconcrete.Diffusionprocess is affected by addition of mineral admixtures in concrete. Ternaryblendedconcretemixesexhibitexcellentchloride diffusion resistance being value less than 0.75 at 90 days. Blendofsilicafumeandflyashisconsideredtobethemost effectiveresistanceagainstchloridediffusion.

under exposure of marine environment which enhances durabilityofconcretetothelargeextent.

[1] S.Omar,B.Al Amoudi,A.WalidAl Kutti,S.Ahmad,M. Maslehuddin,Correlationbetweencompressivestrength and certain durability indices of plain and blended cement concretes, Cement & Concrete Composites, 3, 672 676,2009.

[2] Indian standard for plain and reinforced concrete, IS 456:2000,BureauofIndianStandards,NewDelhi.

[3] M.G.Alexander,J.R.Mackechnie,Y.Ballim,Guidetothe use of durability indexes for achieving durability in concretestructures,ResearchMonograph,Universityof CapeTown,SA.1999.

[4] S. G. Cheriyan, B. S. Dhanya, M. Santhanam, Durability indicesforconcreteswithdifferentdosagesofmineral admixtures,TheIndianConcreteJournal,March2014.

[5] H. Beushausen, M. G. Alexander, The South African durability index tests in an international comparison, Journal of the South African Institution of Civil Engineering,50(1),20 26,2008.

[6] IS 12269:2013 Ordinary Portland Cement, 53 Grade Specification

[7] IS15388:2003 SilicaFume Specification

OPIvalueincreasesmarginallywithincreaseincompressive strengthofconcreteaswellasincreaseinage.Additionof mineral admixtures enhances permeation process in concreteasitisimprovisedinbinaryandternaryblended concrete.CombinationofflyashandsilicafumewithOPCin concrete results into the maximum enhancement of OPI value.

WSIvalueincreaseswithageofconcretemaybebecauseof drying the capillary pores. Water sorption property improveswithincreaseingradeofconcretebeingdenseand impervious due lower water/cement ratio. Addition of mineraladmixturesdoesnotaffectpermeationprocessdue towhichbinaryandternary blended mixesdonotexhibit betterperformanceascomparedtoOPCconcrete.

Chloride conductivity of concrete is a resistance against diffusivity. Ternary blended concrete mixes with combination of fly ash and silica fume exhibit excellent chloride diffusion resistance. Therefore, this kind of combinationofmineraladmixturesinconcreteistobeused

[8] IS3812(Part1):2013 PulverisedFuelAsh Specification for use as Pozzolana in Cement, Cement Mortar and Concrete

[9] IS9103(1999):Specificationsforconcreteadmixtures

[10] Concretemixproportioning guidelines,IS10262:2019, BureauofIndianStandards,NewDelhi.

[11] L. Tang, H. E. Sorensen, Prediction of the nordic test methodsformeasuringthechloridediffusion/migration coefficientsofconcrete,MaterialsandStructures,34(8), 479 485,2001.

Rajdeep R. Parmar B.E. (Civil) M.E. (StructuralEngineering),isworkingasa temporary assistant professor in Applied Mechanics Department of FacultyofTechnologyandEngineering, The M. S. University of Baroda, Vadodara,(Gujarat),India.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Dr. J. D. Rathod is working as an Associate Professor in Applied Mechanics Department of Faculty of TechnologyandEngineering,TheM.S. University of Baroda, Vadodara, (Gujarat),India.HereceivedhisPh.Din 2009fromthesameuniversity.Hisarea of interest is on development of Engineered Cementitious Composites andConcreteTechnology.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |