International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Abstract Concrete is a crucial component of manydifferent forms of construction, includingmulti storyhighrisebuildings to the flooring of huts. One of themost versatileheterogeneous materials is concrete. Civil engineering has reached the pinnacle of technology with the introduction of concrete. When strength, durability, impermeability,fireresistance,and abrasion resistance are needed, it is the material of choice. Reinforced concrete is susceptible to degradation inanumber of locations where rigorous applications reduce durability. As a result, researchers from all around the world are workingto create a new material to solve this issue. The global development of major building facilities and machinery boosted the consumption of materials. Due of this situation, additional materials are being used to enhance the quality. One such material that is incorporated as a partial replacement of cement is Ground Granulated Blast Furnace Slag .Inclusion of GGBFS as a partial replacement of cement solves many challenges coming in the construction industry .firstly it improves the strength parameters of concrete, also it also reduces the consumption of cement at the same time, subsequently reducing the emission of carbon dioxide in the preparation of cement thus minimizing environmental problems related to cement industry. The present experimental work is performed on M35 Grade concrete. Firstly, concrete mixes is prepared by using OrdinaryPortland cement( OPC 53) as a referral concrete mix and then blended concrete mixes is prepared by partial replacementof cement using GGBFS in range of 10%, 20%, 30%, 40% by the weight of cement. The optimum percentage of using GGBFS with cement in the concrete mixes is determined. The blended concrete mix is investigated for Abrasion resistance , workability of freshly prepared concrete mixes, compressive strength, split tensile strength and flexural strength.

Key Words: workability, Abrasion, GGBFS, Compressive strength, Split tensile strength, flexural strength, Durability, workability, Ordinary Portland cement.

The mix design of concrete plays a significant role in the preparationofconcreteandprovidesastandarddesignfor enhanced performance and better durability of concrete. Currentlythedevelopmentofconcreteisdependentonthe

applicationofindustrialwastagessuchasGGBFSthatisused asapozzolanicadmixtureimprovingtheconcretestrength, responsibleforimprovedworkability,lowheatofhydration andadaptabilityinwiderareasofconstruction.Atthesame time,itsapplicationalsoprovides a sustainablemethodof concrete preparation as its reduces the consumption of cementtherebyreducingGreenhousegasesemission,thus minimizingenvironmentalissues..Raoetal.[1]reportedthat onincreasingtheGGBFScontent,thesurfaceabrasionwas increasedbyupto50%for28and90days.Ashwinitbhosale [2] reported that on replacement of cement with 40% of GGBFS, the 7 days compressive strength is increased by 6.09% as compared to referral concrete. Awasare and nagendra[3] reported that the optimum percentage of replacing cement with GGBFS is 30% at which there is maximumincrementincompressiveandflexuralstrengthin concrete as compared to referral concrete mixes.. Gahlot ,Sankla et al.[4] reported that the compressive strength considerablyincreasedtill20%replacementofcementby GGBFS in M30 and M35 grade of concrete. Kamaldeep et al.[5]reportedthatonthereplacementofcementby45% GGBFS,the7and28daysstrengthofconcretewashighest among other replacement level.M rajaram et al.[6] investigated that on replacement of GGBFS at 35% replacementlevel,the flexural strength increased by 54% with respect to nominal concrete strength. V.santa rao et al.[7] reported that on replacement of cement at 40% replacement level with 20%GGBFS and 20% Fly ash increased the compressive, split and flexural strength by 4%,17%and 22% respectively .Karri,rama rao, et al.[8] reported that the strength parameters shows maximum valuesat40%replacementofcementbyGGBFSinM20and M40grade concrete. Ozbay et al.[9] studied that on 40% substitutionofcementwithGGBFS,thereis20%increment in abrasion resistance of concrete. Sharma et al.[10] reportedthatonreplacementof25%and20%cementby GGBFS, compressive strength is increased by 14.4% and flexural strength is increased by 40.26% with respect to conventionalconcretemixes.Thisexperimentalinvestigation is performed to study the effect of including GGBFS (as a partial replacement of cement) in fresh and mechanical properties of concrete, mainly for abrasion resistance. Referral concrete mixes prepared from OPC and blended

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

concrete mixes are prepared from using GGBFS partially replacingcement.Theconcretemixesarecastedandtested at 7 and 28 days for Compressive strength, Split tensile strength,flexuralstrengthat28days.Workabilityoffreshly preparedconcretemixesisalsodetermined.Theoptimum percentageofusingGGBFSwithcementisdeterminedand thenatoptimumpercentageofGGBFS,70.6mm cubesare casted for both referral and blended concrete mixes for determiningtheabrasionresistanceofconcretemixes.

ConventionalConcretemixes(Referralconcretemixes) is preparedby usingOrdinaryPortlandCement(OPC)ofgrade 53as abindingmaterial,coarseaggregate,fineaggregate, water, super plasticizer. GGBFS is used as a partial replacement of cement in the preparation of blended concretemixes.

OPCof brand BIRLAUTTAMofGrade53isusedfor this study. The cement test results are: normal consistency = 28 %; initial setting time = 115 minutes;finalsettingtime=235minutes;specific gravity=3.10;CS=45.25MPa(28days).Thesetest valuesareinaccordancewith theprovisionsofIS: 12269 1987 [11]. The chemical compositions of OPCisshowninTable1asprovidedbysuppliers.

Natural Fine aggregate of rounded shape is used and the surface texture of fine aggregates used is smooth.(conformsto

zoneII,IS:383 1970[12]) It’sbulkdensityis1680 kg/m3 and specific gravity is 2.65 The Fineness Modulus of Fine aggregate was 2.45.The water absorptionoffineaggregateis1.1%.

The Coarse aggregates of size 10 mm and 20 mm having Specific gravities = 2.67 and 2.75 respectively;waterabsorptions=0.21%and0.30% respectively were used and satisfied IS 383 1970 [12]. The surface texture of coarse aggregates is rough.The bulk density of10 mm and20mmsize aggregatewere1600kg/m3 and1640kg/m3 &its finenessmodulusvalues forthecoarseaggregates of size 10 mm and 20 mm was 6.25 and 7.07 individually

GGBFS,a pozzolanicadmixture ofoffwhite color having specific gravity 2.82. Moisture content is 0.23%. it is procured from jindal steel & power limited,hisar,harayana.

A Superplasticizer, Sika ViscoCrete having density approximately1.08kg/l.wasused

Inthisstudy,M35gradeconcretemixesarepreparedusing OPC 53 Grade using IS 10262 2019 [13] with required proportions:Totalcementbindercontent=362Kg/m3,Fine Aggregate = 696 Kg/m3 , Coarse Aggregate =1261 Kg/m3 , super plasticizer = 1.16 litre/m3 and w/c = 0.42. The experimentalworkwascarriedonreferralconcreteofM35 grademixconcrete. Initially ConcretemixesofgradeM35 were madeusingOPC53 aloneasControlcubeand then replacingcementbyweight10%,20%,30%and 40% with GGBFS . The mechanical parameters of concrete mixes examined are Workability of freshly prepared concrete, Compressive Strength at 7 and 28 days, Split Tensile Strength at 28 days, Flexural Strength at 28 days and Abrasion Resistance at 28 days .Cubes of 150 mm were castedtodetermineCompressiveStrengthattheageof7and 28days.Inthesamemannercylindersofdiameter100mm andheight200mm.iscastedtodeterminetheSplitTensile Strength.Beamsof 700mm×150mm×150mmarecastedto determineFlexuralStrength.Thespecimenwastestedafter curingthemin tapwaterfor7and28days.TheCompressive Strength of concrete cubes was determined using compressiontestingmachine(capacity2000KN)asperthe provisionscontainedinIS:516 1959[14].Todeterminethe FlexuralStrength,Threepointloadmethod oftestingwasdoneafter28dayscuringaspertheprovisions containedinIS:516 1959[14].SplitTensileStrength was determinedaspertheprovisionsofIS:5816 1999[15]Final mixproportionsforM35gradeconcreteareshowninTable 2.TheoptimumpercentageofusingGGBFS(optimization) usedasapartialreplacementofcementistobedetermined. AftertheoptimizationofGGBFSwithCement,theAbrasion resistance of blended Concrete mixes at that optimum percentageisdeterminedusingtileabrasionmachineasper theprovisionofIS1706 1972.[16]

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

OPC (%) GGBFS (%)

SiliconDioxide 20.1 36.4

CalciumOxide 62.0 34.12

AluminumOxide 5.3 10.39

IronOxide 4.3 0.69

MagnesiumOxide 2.7 10.26

PotassiumOxide 0.9 0.97

SodiumOxide 0.2 0.35

Lossofignition 3.12 1.64

Design mix Quantity per M3

W/Cratio 0.42

OPC 362kg/m3

Workability 100mm CoarseAggregate 1261 kg/m3 FineAggregate 696kg/m3 Water 152 Litres

Superplasticizer 1.16Litre/m3

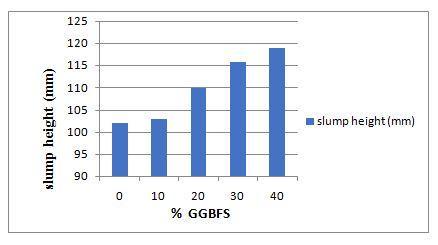

TheeffectofincludingGGBFS onworkabilityofconcreteis giveninFig4.1inwhichslump heightIs increasedupto40% replacementlevel.ThisisduetotheadditionoffinerGGBFS particles which causes the water demand decreased and improvingcohesivenessofconcretemixes.

4.2 Hardened Mechanical Properties of GGBFS blended

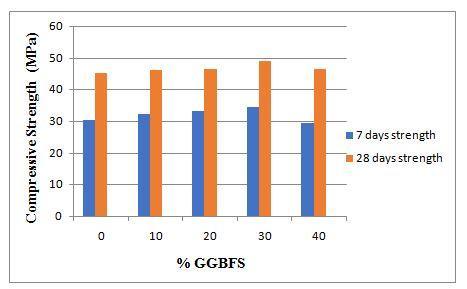

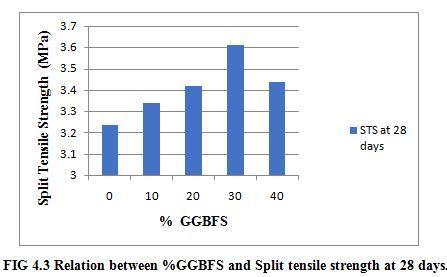

CompressivestrengthofGGBFSblended concreteat7and 28 days is listed in table 3, Compressive strength , Split TensileStrength andFlexuralStrength at28daysaregiven inTable 4.ThesubstitutionofOPCwithGGBFS isdoneat 0%,10%,20%,30%and40%.ItisclearfromtheTablethat the Compressive Strength increases with the addition of GGBFStill30%andlaterdecreasesconsiderablyatfurther replacement level. It is alsoobserved from this Table that incrementinCompressiveStrengthis13.32%and8.17% at 7 and 28 days respectively with respect to the referral concrete. Split Tensile Strength and Flexural Strength of concreteattheageof28daysarealsogiveninTable 4.

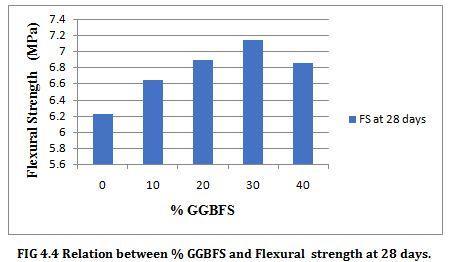

ItisevidentfromthisTablethatSplitTensileStrength and FlexuralStrength increasesupto30%replacementofOPC withGGBFS inconcreteandafterfurtheradditionofGGBFS at 40% replacement of cement, the respective strength decreases However, strength is higher at all replacement levels ascomparedtothatof referralconcrete.Percentage increasein SplitTensileStrength andFlexuralStrength is foundtobe11.41%and14.60%respectively higherwith respecttoreferralconcretemix at28days.

Table 3 Compressive strength at 7 and 28 days at various % of GGBFS

Fig. 4.1 Slump Vs % of GGBFS in concrete

% GGBFS Compressive strength at 7 days (MPa)

Compressive Strength at 28 days (MPa) 0 30.31 45.25 10 32.12 46.10 20 33.15 46.57 30 34.35 48.95 40 29.50 46.53

FIG 4.2 Relation between % GGBFS and Compressive Strength of concrete at 7 and 28 days

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Table 4

Compressive Strength, Split Tensile Strength & Flexural Strength of 28 Days at various % of GGBFS

% GGBFS Compressive strength at 28 days (MPa)

Split Tensile Strength at 28 days (MPa)

Flexural Strength at 28 days (MPa) 0 45.25 3.24 6.23 10 46.10 3.34 6.65 20 46.57 3.42 6.89 30 48.95 3.61 7.14 40 46.53 3.44 6.86

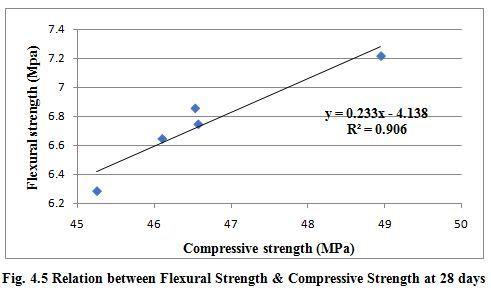

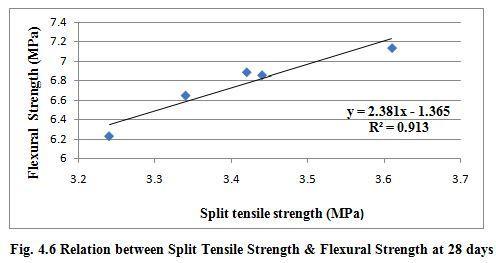

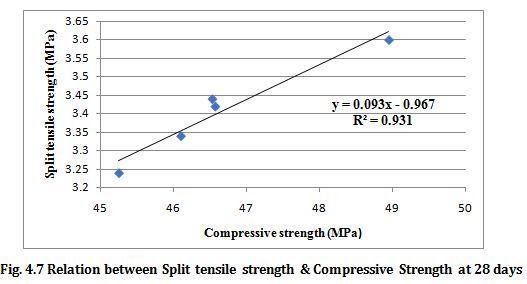

RelationbetweenFlexuralStrength &CompressiveStrength, Split Tensile Strength & Flexural Strength , Compressive Strength & Split Tensile Strength of GGBFS blended concretemixesdeveloped&plottedandaregiveninFigs4.5 -4.7.Regressioncoefficient, R2 valuesamongthedifferent strength parameter is found 0.906, 0.913 and 0.931 respectively. The high values of correlation coefficient indicatesthatthereisastrongrelationshipwitheachofthe strengthproperties(compressive,flexuralandsplittensile strength).

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Table 5 : Relation between No. Of revolutions, loss in weight (gms) and Depth of wear(mm) in concrete mixes

No. Of Revolutio n

Referral concrete GGBFS blended concrete (30% replacement of GGBFS)

Loss in depth (mm)

Loss in weight (gms)

Loss in depth (mm)

Loss in weight (gms)

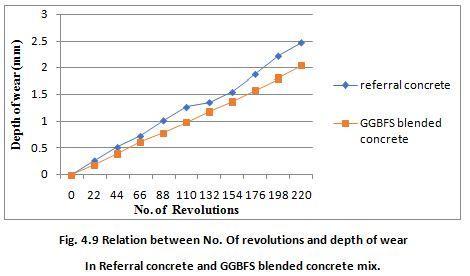

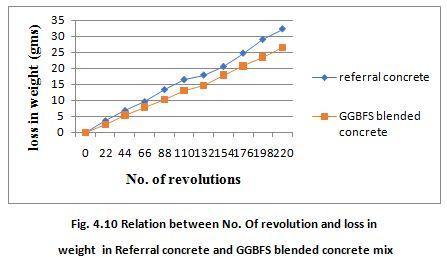

Abrasion resistance test is determined using tile abrasion machine as per IS code :1706 1972.for each samples of concrete mixes( referral and GGBFS blended concrete mixes), cubes of 70.6mm were casted and subjected to grinding path of abrasion machine after 28 days curing. Depthofcubesismeasuredat5points(fouratcornersand one at the center).weight of cubes and loss in depth of cubes(depthofwear) ismeasuredbeforeabrasiontestand recordedafterevery22setsofrevolutions.Thisprocessis repeatedtill220revolutions shownintable5. Theextent ofabrasionwasdeterminedfromthedifferenceinvaluesof thicknessmeasuredbeforeandaftertheabrasiontest.

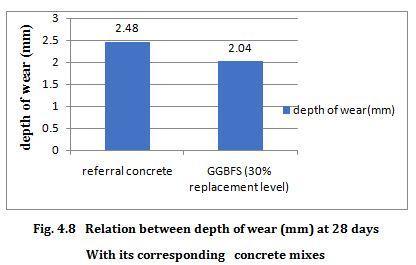

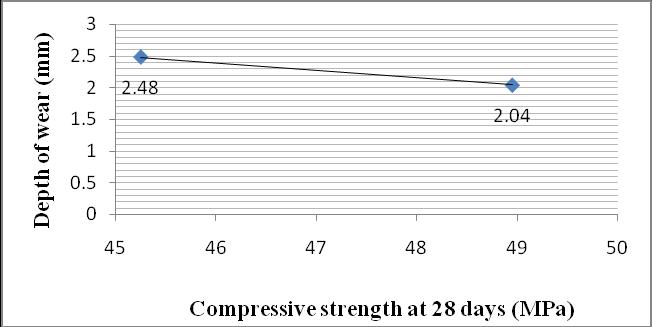

The variation of depth of wear (mm) increases with the no.of revolutions and decreases with age of curing. The depth of wear and loss in weight of cubes in referral concretemixes is2.48mmand32.24gms.Relationbetween

No. Of revolution and depth of wear at 0% and 30% replacementofGGBFSisshowninfig.4.9.Relationbetween No. Of revolution and loss in weight at 0% and 30% replacement of GGBFS is shown in fig.4.10. On the replacementofOPCwith 30%GGBFS,thedepthofwearis decreasedto2.04mmandlossinweightisalsodecreasedat 26.35gms.Thusthereisenhancementinabrasionresistance in GGBFS blended concrete mixes with respect to referral concretemixesasthedepthofwear andlossinweight Is decreasedinGGBFSblendedconcretemixesAsshowninfig 4.8

0 0.00 0.00 0.00 0.00 22 0.27 3.61 0.18 2.34 44 0.52 6.80 0.40 5.39 66 0.73 9.57 0.61 7.89 88 1.02 13.34 0.78 10.14 110 1.27 16.46 0.98 13.09 132 1.36 17.88 1.19 14.65 154 1.55 20.53 1.38 17.80 176 1.89 24.68 1.59 20.62 198 2.23 28.96 1.81 23.40 220 2.48 32.24 2.04 26.35

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Thereisa relationbetweenthecompressivestrengthand abrasionresistance(depthofwear)asshowninfig.4.11.itis evidentfromthefig.4.11 thatabrasionresistanceisclosely relatedwithitscompressivestrengthasthe Thedepthof wear decreaseswithincrementincompressivestrengthof concrete mixes. The depth of wear has decreased from 2.48mm (Referral concrete, CS = 45.25 MPa ) to 2.04 mm (GGBFS blended concrete mix, CS = 48.95 MPa ) (30% replacementofOPCwith GGBFS)ishigherascomparedto referralconcretemixes.

Workability (slump height) of concrete mixes after the replacementofcementwithGGBFSisincreasedconsiderably atallreplacementlevels.Theoptimumpercentagelevelof replacing cement with GGBFS is found to be at 30% .CompressiveStrength ofGGBFS blendedconcretemixesat 30%replacement ofcement isincreasedby13.32%and 8.17%ascomparedto referral concreteat7and28 days respectively.SplitTensileStrength andFlexuralStrength of GGBFS blended concrete mix is increased by 11.41% and 14.60 % at 28 days with respect to referral concrete mix. Regression coefficient (value of R2 ) is determined among strength properties ie. Flexural Strength & Compressive Strength, Flexural Strength & split tensile strength and CompressiveStrength &SplitTensileStrength andis0.906, 0.913 and 0.931 respectively. Increment in regression coefficient,R2valuesof blendedconcretemixesisincreased by the addition of GGBFS. Abrasion resistance of concrete mixat30%replacementofcementwithGGBFS isincreased asdepthofwearhasdecreasedconsiderablyfrom2.48mm (in referral concrete) to 2.04 mm ( in GGBFS blended concrete mix). On the optimization of GGBFS (at 30%) in concrete mixes, the depth of wear is reduced upto 17.74 %.Thus Abrasion resistance is higher in GGBFS blended concretemixeswithrespecttoreferralconcrete.Abrasion resistance of concrete is strongly correlated with % of GGBFScontentusedanditscompressivestrength.

[1] Rao, S.K., Sravana, P. and Rao, T.C., 2016. Abrasion ResistanceandmechanicalpropertiesofRollerCompacted Concrete with GGBS. Construction and Building Materials, 114,pp.925-933

[2] Ashwini T Bhosale, Ground Granulated Blast Furnace Slag Concrete, International Journal for Research in EngineeringApplication&Management(IJREAM),

ISSN:2454-9150Vol-02,Issue10,Jan2017

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[3]VinayakAwasare, Prof.M.V.Nagendra,ANALYSISOF STRENGTH CHARACTERISTICS OF GGBS CONCRETE, InternationalJournalofAdvancedEngineeringTechnology, E ISSN0976 3945

[4]Praveen KumarGahlot, SureshsinghSankhla,Krishan KumarSaini UseofGGBSasPartialReplacementofCement in Concrete While using Master REHO Build 823PQ International Journal of Engineering and Advanced Technology (IJEAT) ISSN: 2249 8958 (Online), Volume 9 Issue 3,February2020

[5]M .G. Kamaldeep, K. Shyam Chamberlin Experimental StudyonPerformanceofConcretebyusingCombinationof FlyashandGgbsasBlendedMaterial, InternationalJournal ofRecentTechnologyandEngineering(IJRTE)ISSN:2277 3878,Volume 7,Issue 6C2,April2019

[6] M.Rajaram ,A.Ravichandran, A.Muthadhi , Studies on OptimumUsageofGGBSinConcreteVolume2,Issue5,May 2017 International Journal of Innovative Science and ResearchTechnology

ISSNNo: 2456 2165

[7] V. Santa Rao, G. Lakshmana, K. Bhanuji Rao, G. Himala Kumari. Effect of strength parameters in concrete using doubleblending flyashandGGBFS, InternationalJournalFor Technological Research In Engineering Volume 5, Issue 6, February 2018 ISSN (Online): 2347 4718

[8]SantoshKumarKarri,G.V.RamaRao,P.MarkandeyaRaju ,Strength and Durability Studies on GGBS Concrete, SSRG International Journal of Civil Engineering (SSRG IJCE) volume 2 Issue 10 October 2015

[9]ErdoganOzbay, MohamedLachemi,UmurKorkutSevim, Compressive strength, abrasion resistance and energy absorption capacity of rubberized concretes with and without slag , Materials and Structures (2011) 44:1297 1307DOI10.1617/s11527 010 9701

[10] Balram Sharma, S. D. Thanvi Influence of Microfine GGBS on Concrete of Grade M35 & M40 Made with Pozzolana Cement, International Journal of Engineering Research&Technology(IJERT)ISSN:2278-0181

IJERTV5IS100252Vol.5Issue10,October-2016

[11]IS: 12269-1987.: Specification for 53 grade Ordinary Portland Cement. Bureau of Indian Standards,New Delhi, India

[12]IS:383-1970.:SpecificationforCoarse&Fineaggregate from Natural Sources for Concrete, Bureau of Indian Standards,NewDelhi,India

[13]IS:10262-2019.Code ofPracticeforMixDesign,Bureau of Indian Standards, New Delhi, India.

[14]IS:516-1959:MethodsofTestsforStrengthofConcrete, Bureau of Indian Standards, New Delhi India

[15]IS: 5816-1999 Splitting Tensile Strength of ConcreteMethodofTest,BureauofIndianStandards,NewDelhi,India

[16]IS:1706-1972Methodfordeterminationofresistanceto wear by abrasion of Concrete- Method of Test, Bureau of IndianStandards,NewDelhi,India