International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

2

, Prof. Shweta S. Tikotkar3

1M.E.(Structures)Student, Department of Civil Engineering, G. H. Raisoni College of Engineering and Management, Ahmednagar 414008, Maharashtra, India.

2Vice Principal and Professor, Department of Civil Engineering, G. H. Raisoni College of Engineering and Management, Ahmednagar 414008, Maharashtra, India.

3 Assistant Professor, Department of Civil Engineering, G. H. Raisoni College of Engineering and Management, Ahmednagar 414008, Maharashtra, India. ***

Abstract This analysis explores the consequence of an experimental investigation for improving the shear capability of reinforced concrete (RC) T beams with shear inadequacies, strengthened with Basalt Fiber Reinforced Polymer (BFRP) sheets that are an economic and new relatively substitute for more expensive fibers widely used around strengthening of RC beams. A maximum of twenty two numbers of concrete T beams are analyzed as well as different sheet configurations as well as designs are analyzed to determine the effects of theirs along the shear capability of all the beams. One beam of the beams is viewed as control beam, while some other beams are strengthened with externally bonded BFRP sheets/strips. The experimental outcomes evidenced the usage of latest mechanical anchorage pattern containing laminated compositeplatesenhancestheshearcapabilityofthebeams considerablybystoppingthedebondingofBFRPsheets,such thetotalstrengthontheBFRPsheetsbecomeused.

Key Words: FRP Composites, Properties of FRP composites, Structural design, Repair of structures

Thetraditionaldesignapproachesonthemarketaresteel jacketing and concrete jacketing. The concrete jacketing createsthecurrentportionbigandthereforegetsbetterthe load hauling capacity of all the framework. Though the strategies have a few demerits including construction of completely new formworks, extra weight because of enlargement of aisle, higher set up cost etc. The steel jacketinghasfoundtobecomeagoodmethodtoimprovethe overallperformanceofcomponents,thoughthisprocesscalls for tough welding work within the area as well as have possible problem of corrosion that increases the cost of upkeep. Now a days, FRP composite substances are a fantasticchoicebeingutilizedasoutsidereinforcementdueto thehighspecificstiffnessoftheirsubstantialweight,higher tensile strength, light in weight, opposition to corrosion, excessivelongevityaswellassimplicityofsetup.

Concretebeamstendtobetheprimaryaspectinstructural engineeringthatarecreatedtotransportbothhorizontalalot becauseofseismicormaybeverticalgravityandwindloads. Like any other concrete elements, they are vulnerable for situations in which there is a rise within structural a lot. Typically, reinforced concrete (RC) beams fail within two ways: diagonal tension and flexure failure (shear) disappointment. Flexural disappointment is frequently desirable to shear malfunction while the former is ductile whilelatterisbrittle.Aductiledisasternotonlyenablesstress redistribution but also provides previous discover to occupants,whereasabrittlefailureissuddenandtherefore catastrophic. The utilization of outside FRP reinforcement might be categorized as: flexural as well as shear strengthening.

If the RC beam is deficient for shear, or perhaps when the shearcapacityofitisundertheflexuralcapacityrightafter flexuralstrengthening,shearstrengtheningmustbethought about. It is significantly crucial that you look at the shear capacity of RC beams that are suggested to become strengthened.

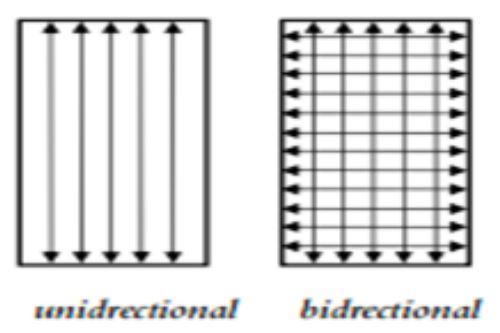

In order to boost the shear capacity of the beams, each compositesheetaswellasplatesmaybeconsumed,however theformeroneofthemismuchmoreappreciableduetothe flexiblenatureoftheirsaswellassimplicityofhandlingand application.DifferentFRPbondingsystemsmightbeutilized toenhancetheshearcapacityofRCbeams.Thesecontain(1) aspectbonding(bondedtowardsthesidesonthebeamsonly) (2)Ujacketing(bondedtothesidesaswellastensionfaceon thebeam)aswellas(3)wrapping(bondedaroundtheentire crosssegmentonthebeam).AsRCTsectionisconsidered themostpreferredformofgirdersandbeamsinbridgesand buildings,totalwrappingisnotanachievableoption.Fibers might be bidirectional orunidirectional asrevealedwithin figure1.3.Theutilizationoffiberswithin2instructionsmay clearly be favourable with value to shear opposition even though strengthening for turned around loading isn't

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

necessary, aside from not likely situation whereby one of manyfibrepathsisroughlyparalleltowardstheshearcracks.

To study the structural behaviour of reinforced concrete (RC) T beams under static loading condition. To study the structural behaviour of reinforced concrete (RC) T beams under static loadingcondition.

In order to look at the outcome of various details like quantity of layers, bonding surface, various fiberorientationetc.overtheshearcapacityonthe RCT beams.

In order to take a look at the outcome of an anchoragepatternovertheenhancementofshear capabilityontheRCT beams.

CorrosionResistance. Lightweight.

Easeofinstallation

LessFinishingandmaintenance.

Highfatigueresistance.

Ductility of FRP wrapped members improves extensively.

Theyareperfectforexternalapplication.

They are durable both environmentally and from servicepointofview.

They are available in various forms: sheets, plates, fabric,etc.

They are available in long lengths that eliminate joints.

Theycurewithin24hours.

Versatileinnature.

Mostoftheanalysisworksweremadeinvestigatingflexural as well as shear behaviour of RC rectangular beams strengthened with fiber reinforced polymer (FRP) composites. Till date absolutely no work has been found studyingtheshearbehaviourofRCTbeamsmakinguseof externally bonded Basalt fiber reinforced polymer (BFRP) composites.Asmallwork continuestobefoundaboutthe strengthening of RC Tbeams with no study and web openings has become reported on the strengthening of beamswithtransverseopeningbyusingBFRPcomposites.A lotofscientistsarefromtheviewpointwhichthepriordesign methods do not have detailed comprehension of the shear behaviourofRCTbeams.

1.6

In order to investigate the outcome of a new anchorage scheme over the shear capacity on the beam.

InordertoevaluatetheshearbehaviourofTsection RCbeamsbelowfixedloadingtimequality.

In order to look at the shear behaviour as well as modes of failure of RC shear deficient T beams externallystrengthenedwithbasaltfiberreinforced polymer(BFRP)sheets.

Inordertotakealookattheimpactofvarioustest detailsincludingfiberamountaswellasdistribution bonded surface area, quantity of layers, fiber orientationandalsoendanchorageprocessoverthe shear capacity of RC T beams strengthened with externallybondedBFRPcomposites.

Tocalculateanalyticallytheshearcapabilityonthe RCTbeams.

Twenty two reinforced concrete T beams are consideredinthisstudywithdimensionsasfollows:

Span= 1300mm Width of web= 150mm Depth of web= 125mm Depth of flange= 50mm Effective depth= 125mm The steel reinforcement in the beamsconsistsoftwonumbersofsixteenmmφand onenumberoftwelvemmφHYSDbarsastension reinforcement. 4 numbers of ten mm φ bars are providedashangerbars.

Thedepthandlengthofthebeamhavebeentaken as1300mmand175mm,respectivelybecauseofthe limitation of the loading system obtainable in the Structural Engineering laboratory, NIT Rourkela. ThebeamsareoverdesignedinflexureasperIndian code IS: 4562000to beable to guarantee a shear

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

failure.Theeffectoflengthparameter on theload carrying of beam has not been studied because of abovelimitation.

The beam specimens are made from the nominal mix of the concrete of grade M20 with mix proportionsasperIS:4562000.Formixingpurpose, the concrete mixer is used, and the water cement ratioisfixedat0.55.3numbersof150x150x150mm concretecubespecimens are cast along with each beamandcuredfortwenty eightdaystodecidethe compressivestrengthofconcrete.

The following component materials are used for fabricatingtheBFRPplate:

Orientation No. of layers

00 orientation

Ultimate Stress Ultimate Load Young’s Modulus (MPa) (N) (MPa)

2Layers 13.86 202 4588

4Layers 14.07 577 5561

6Layers 19.53 883 5607

8Layers 23.57 1010 6395 900 orientation

2Layers 328 5808 11920 4Layers 391 11870 12870 6Layers 421 22110 13130 8Layers 469 25480 13920

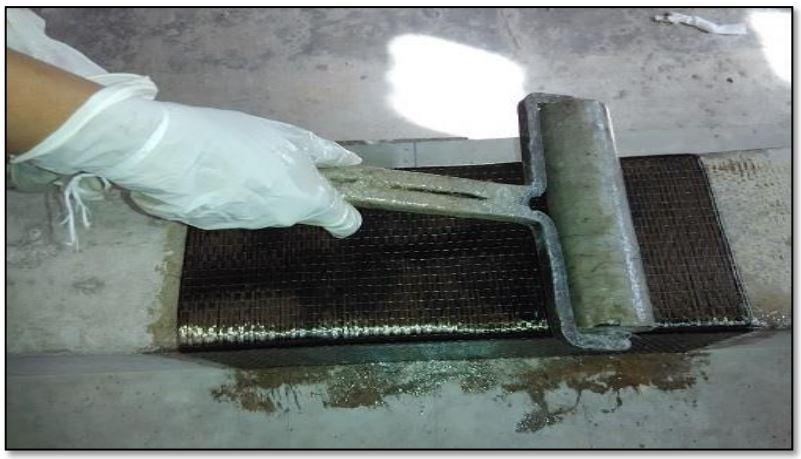

Oftheprocessofstrengthening,theFRPfabricsarebonded to the concrete surface using a good resin and hardener. First the bottom surface area of the beam is cleaned by removingallofthelooseparticles.Thenbymeansofcourse sandpaper,therequiredpartoftheconcretesurfaceismade uneven and most of the dirt and debris particles are removedwithanairblower.Theepoxyresinismixedand appliedonthenecessarypartoftheconcretesurfaceafter theplanningoftheconcretesurface.Theblendingisdonein a clear plastic container by taking 10 percent of hardener withrespecttothe epoxy resin andiscontinuedfor some timetogetauniformmixture.

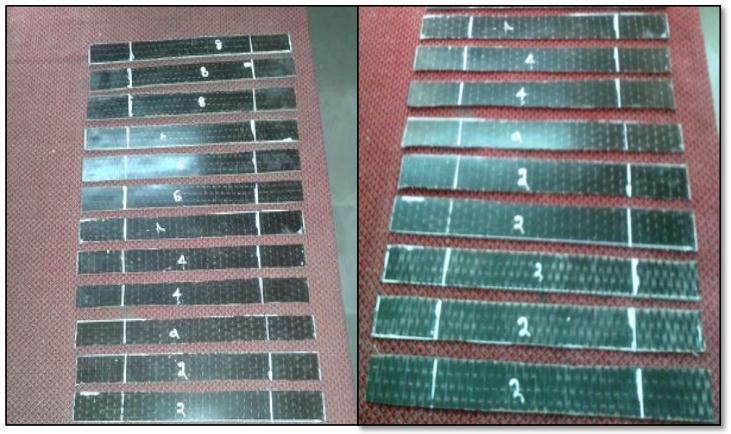

Theunidirectionaltensiletestisperformedtodeterminethe primarystress,ultimateload,andmodulusofelasticityofthe specimens. By using hex or diamond cutter saw the specimensarecutfromtheplatesandispolishedwiththe helpofpolishingmachine.

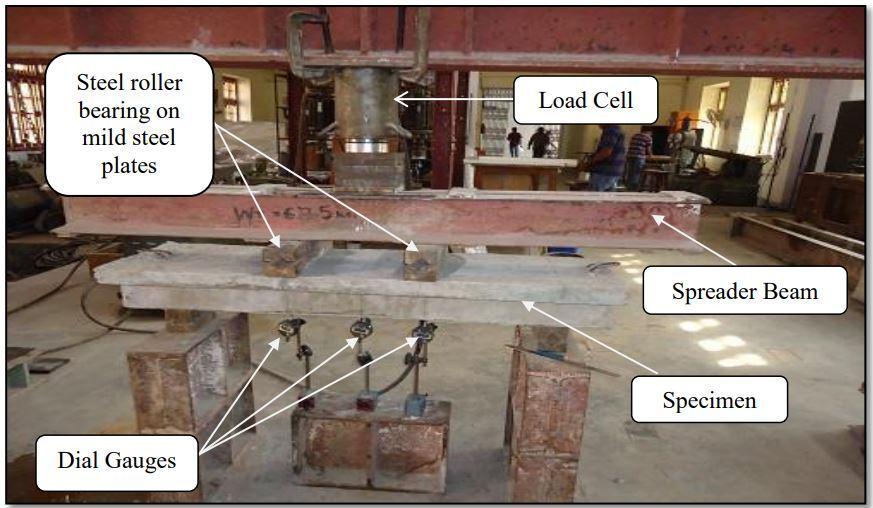

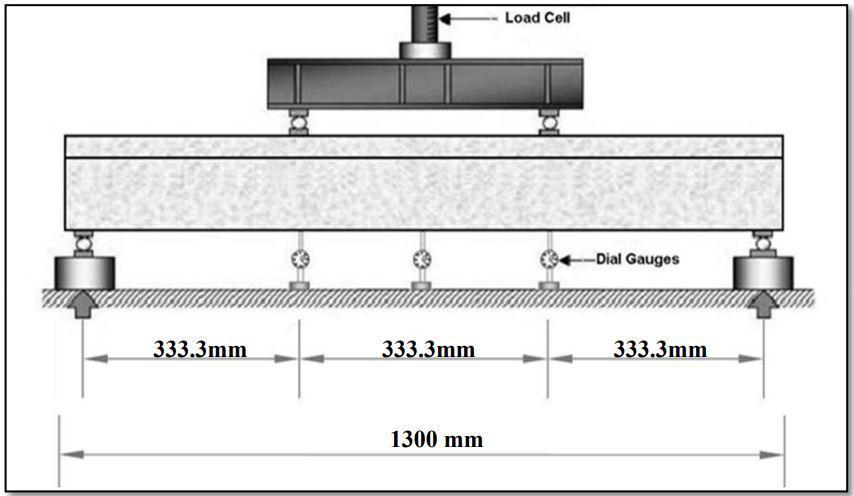

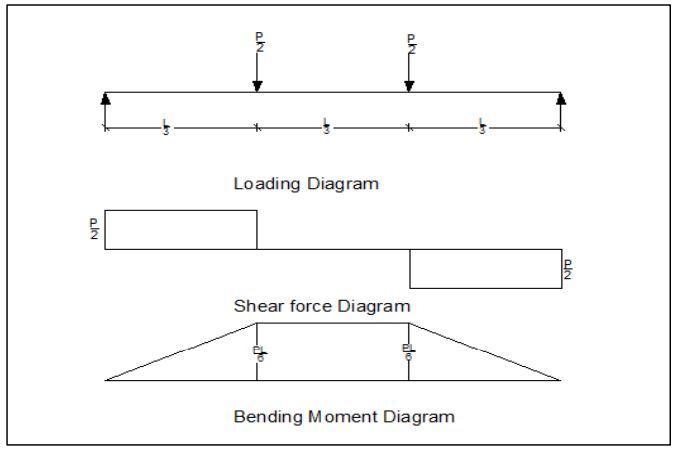

The arrangement of the 4 point static loading system is providedinFigure3.9.Theloadistransferredtoaspreader beambymeansofaloadcell.Thespreaderbeamisplaced abovethetestspecimenbymeansofsteelrollersplacedon steel plates bedded on cement to pay for an even levelled surface. The expected test loads should be carried by the loadingframeforallofthespecimenswithoutanydistortion. The beam specimen to be tested is placed on steel rollers placedbetween2steelplatesbearingleaving150mmfrom theendsofthespecimen.Therestofthe1000mmisdivided into3identicalpartsof333mmaspresentedintheFigure 3.9. The lines are drawn on the specimens to be tested at distances of L/3, L/2, & 2L/3 from the left support (L=1300mm).Thedeflectionofthespecimensisrecorded with the assistance of 3 dial gauges. 2 dial gauges are positionedunder2concentratedloads,i.e.,atL/3and2L/3 distancesaswellastheotherdialgaugeispositionedunder theCentreofthespecimen,i.e.,atL/2distancetomeasure thedeflections.

Fig8:Shearforceandbendingmomentdiagramforfour pointstaticloading.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

This analysis interprets the results obtained from the experimental investigation. The series A comprises of the shearstrengtheningoftheRCbeamswithTshapedcross sectionwithnotransverseopenings,thebehaviouroftheRC T beams with respect to initial crack load, ultimate load carrying capacity, crack pattern, deflection is studied throughoutthetestandtheirfailuremodesaredescribed. Except the control beams, all the beams are strengthened with different configurations of unidirectional BFRP sheets/strips. All the beams are made as shear deficient ones.

The twenty two numbersof RCT beamsaretestedunder four point static loading system and their cracking behaviourandmodesoffailurearereportedbelow.

Thefailureisfollowedbyadiagonalshearfailurewiththe increasing load and the beam failed at an ultimate load of 178kN.ThestrengtheningofbeamSB1withBFRPsheetsin 00orientationhavingUwrapscaused12.66%increasein shearcapacityoverthecontrolbeam

The beam failed by the debonding of BFRP sheets, the ultimatefailureisfollowedbyadiagonalshearfailurewith theincreasingloadandthebeamfailedatanultimateloadof 167kN.

ThefailureofthebeamSB3occurredatanultimateloadof 170kN, and the ultimate shear failure is because of the debondingoftheBFRPstripsfollowedbyawiderdiagonal shear crack. The strengthening of beam SB3 with BFRP U strips caused 7.59 % increase in shear capacity over the controlbeam.

The ultimate shear failure of the beam SB4 occurred as a result of the debonding of the BFRP strips followed by a widerdiagonalshearcrackatanultimateloadof163kN.The strengthening of beam SB4 with BFRP side strips caused 3.16%increaseinshearcapacityoverthecontrolbeam

5.

Thedebondingfailureisfollowedbyadiagonalshearfailure withtheincreasingloadandalsothebeamfinallyfailedatan ultimateloadof200kN.ThestrengtheningofbeamSB5with BFRPsheetsin900orientationhavingUwrapscaused26.58 %increaseinshearcapacityoverthecontrolbeam.

6.

Thedebondingfailureisfollowedbyadiagonalshearfailure withtheincreasingloadandalsothebeamfinallyfailedatan ultimate load of 175kN. The strengthening of beam SB6 caused10.76%increaseinshearcapacityoverthecontrol beam.

The failure of the beam SB7 occurred as a result of the debondingoftheBFRPstripsatanultimateloadof185kN followedbyawiderdiagonalshearcrack.Thestrengthening ofbeamSB7withBFRPUstripscaused17.09%increasein shearcapacityoverthecontrolbeam

The ultimate shear failure of the beam SB8 occurred as a result of the debonding of the BFRP strips followed by a widerdiagonalshearcrackatanultimateloadof166kN.The strengthening of beam SB8 with BFRP side strips caused 5.06%increaseinshearcapacityoverthecontrolbeam.

9.

The ultimate shear failure of the beam SB9 occurred as a result of the debonding of the BFRP strips followed by a widerdiagonalshearcrackatanultimateloadof192kN.The strengtheningofbeamSB9withBFRPUstripscaused21.52 %increaseinshearcapacityoverthecontrolbeam.

The ultimate failure of the beam SB10 is because of the tearingoftheBFRPsheetsbelowtheanchorageplateatan ultimate load of 219kN. The strengthening of beam SB10 with BFRP sheets in 900 orientation having U wraps with end anchorage system caused 38.61 % increase in shear capacityoverthecontrolbeam.

The failure of the beam SB11 occurred on account of the tearing of the BFRP sheets below the anchorage plate followedbyawiderdiagonalshearcrackatanultimateload of232kN.Anincreaseintheshearstrengthisobservedas comparedwithbeamSB10.ThestrengtheningofbeamSB11 with 4 layers of BFRP sheets in 900 orientation having U wrapswithendanchoragesystemcaused46.83%increase inshearcapacityoverthecontrolbeam.

The ultimate failure of the beam SB12 occurred at an ultimateloadof200kNbecauseofthetearingoftheBFRP strips followed by a wider diagonal shear crack in an equivalent region as in case of CB. The strengthening of beamSB12withBFRPUstripsin900orientation

2021, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Basedontheexperimentalinvestigationandanalyticalstudy ofshearstrengtheningofRCTbeamswithexternallybonded unidirectionalBFRPcomposites,thefollowingconclusions aredrawn:

shear capacity of RC beams with T shaped cross sectioncanbeincreasedsignificantlybyusingBFRP compositesasanexternalreinforcementThe The firstcracksinthestrengthenedbeamsareformedat agreaterloadcomparedtotheonesinthecontrol beams.

1 HariAkshayaEKR,Dr.D.ShobaRajkumar,Experimental Investigation on Behaviour of Reinforced Concrete Beams Retrofitted with Ferrocement, International Journal of InnovativeResearchinScience,TechnologyandEngineering (IJIRSET),Volumenine,Issuenine,September2020

2 NehalAshraf1,Prof.VikasChodankar2,AReviewon"FRP Composites as an alternative in Structural Engineering Design”, International Journal of Innovative Research in Science,TechnologyandEngineering(IJIRSET),Volumenine, Issuenine,September2020.

Strengthening with BFRP composites bonded to webs only are most prone to debonding with premature failure. The beam strengthened with BFRP sheets is found to have a lot more shear capacitycomparedtothebeamstrengthenedwith BFRPstripsstrengtheningofbeamsusingUwrap configuration is found to be better than the side wrap configuration. Among all the BFRP strip configurations(i.e.,horizontalstrips,verticalstrips and strips inclined at 450), the U strip with 450 fiber orientations is more effective Formation of crack gets delayed because of the use of BFRP sheetsaswellasbyintroductionofendanchorage.

3 Wenliang Hu, Yuan Li, Haoyun Yuan, Review of Experimental Studies on Application of FRP for Strengtheningof Bridge Structures,Advances inMaterials ScienceandArticleID8682163,Engineering,Volume2020, twenty onepages4MohmmadR.Irshidat,MohmmadH.Al Saleh(2017),flexuralstrengthrecoveryofHeat?Damaged RCbeamsusingcarbonnanotubesmodifiedCFRPIJIRSET.

4 Keertika Sharma, S. S. Kushwah, Aruna Rawat (2016), InternationalJournalofScientific&EngineeringResearch, Issue5,Volume7,May 2016.

The load carrying capacity of the strengthened beams can be found to be in excess of that of the control beams, thus the externally bonded BFRP compositesenhancetheloadcarryingcapacity.

FRPstrengtheningofRCTbeamsusingcarbonand aramidcomposites.

5 Swami P.S, Patil S.S, Kore Behavior of concrete deep beams with high strength reinforcement" by P.N 2015, IJIRSET.

6 D.N. Shinde, Pudale Yojana M, Nair Veena V (2014) [5] "Flexural behaviour of reinforced cement concrete beam wrappedwithGFRPsheet"InternationalJournalofResearch inTechnology,Vol.3andEngineering.

Strengthening of RC T beams using woven basalt fiber.

Strengthening of RC L section beams with FRP composites.

Strengthening of RC L section beams with transversewebopenings.

Effectoftransversewebopeningsofdifferentsize andshapeontheshear behaviourofRCL section beams.

Effectsofshearspantoeffectivedepthratioonthe shearcapacityofbeams.

Numerical modeling of RC T & L beams strengthenedwithFRPsheetswithendanchorage.

IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified