International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net

p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net

p-ISSN: 2395-0072

Department of Mechanical Engineering (Trinity Institute of Technology and Research, RGPV Bhopal) (Kokta Bypass Rd, Near Hindustan Petrol Pump, Patel Nagar, Bhopal, Madhya Pradesh 462021) ***

Abstract - The present research works aims examine the flow and thermal non-uniformity in a circular micro channel (CMC). A concept of variable size approach is employed to mitigate flow and thermal non uniformity in rectangular CMC. The heat dissipation requirement of an electronic chip of processor is deliberated in the present study. It is found that proposed design improves flow rate and heat dissipation with increase in diameter. It is found that increasing in diameter, the heat dissipation rate increase.

Keywords – Micro-channel; electronic devices; flow rate; chip cooling

Therapidgrowthofhigh densitypowerelectronic,with theincreasedminiaturizationofmicroelectronicdevicesand processing speed, thermal issues are more and more affecting overall electronic packaging and system capabilities. Problems related to heat dissipation of microelectronic devices have brought need of supplementary research and development. Microelectronic device performance and reliability are known to increase when effective temperatures are kept below 40°C [1]. Keepingthetemperatureconditionsinfocus,duringlasttwo decades research on cooling of electronic devices has increased multi fold. Earlier, heat removal from electronic devices was done by using forced air convection. With the increase in power and speed of electronic devices, the amount of heat to be removed has increased. This requires enhancementinheattransfercoefficient[2]. Owingtoupper limits of achievable heat transfer coefficient, the other modes, namelypool boiling andflow boilingusing dielectric fluids began to receive attention for microelectronic device cooling. The methodology can be adopted in system integrationefficiently.

D. B. Tuckerman et al (1981) has been investigated, convection heat transfer coefficient 'h' between substrate and coolant is considered to be the primary impediment to achieving low thermal resistance. Cooling viscosity determines the use of high aspect ratio channels to maximize the minimum practical channel width and surface area, which inspires the thermal support based on these ideas, new very compact water for silicon Cooled Integral HeatIllCircuithasbeendesignedandtested.

GregorySwiftetal(1985)hasseenthattheconstruction of a highly compact cross flow heat exchanger is done by kiln grazing, simultaneously stacking hundreds of stainless steel sheets and water flowing through a heat exchanger Measurement of heat transfer between liquid propylene. Exchangers are in excellent agreement with calculations basedongeometryandfluidproperties.

Ian Papautsky et al (2001) summarized in the field of experimental research endeavor on the microscale single phase internal fluid flow and the issue related to the examination of the flow of microscale has been discussed. Micro channel surface roughness appears to increase, it seems to intensify with higher surface roughness. Laminar friction appears to be 20% higher than theoretical predictionsforsupportedwaterflowunresttransition,ithas beendetailedthattherayisnotreliable.Itwasreportedthat the surface of the micro channel appears to increase roughness which is sharper with high surface roughness. Laminar friction appears to be nearly 20% more consistent than the theoretical prediction for the flow of water. No reliablerangeofrayshasbeendetailedforunresttransition. Some data showed that the disturbance is as low as the Micro Scale [Re =500]. At present, precise prediction of droplets of pressure in micro channels is not possible for non dropflows,sometimespressuredropscanbeestimated usingconventionaltheoryandcorrelations.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Dongliu et al (2002) experienced that the fluid flow in the micro channel have been both observational and scientific.Themicro channelswithhydraulicdiametersfrom 230 to 6500 on the Reynolds number from 244 to 974 dimensionswereused.Inthesemicro channels,thepressure is measured within the drop seat. The observational estimation of the pressure drop is in comparison to the scientific prediction. The result of the last but least mathematicalsimulationhasnotfulfilledtheagreementwith empirical measurements. The advancement of totally turbulentflowisturnedintomicro channels,intheshapeof less subtle channels that can have a critical effect on the improvement of unrest, which is recommended by the scale of Kolomorov length. In micro channels, due to flow visibility, due tocontamination, the beginningofunrest was qualitative. A great common assertion between the result of numericalsimulationandexperimentalmeasurements.

Wai Keat Kuan et al (2006) inspected, the experimental testsectionhassixparallelrectangularmicro channels,each of which has a cross sectional area of 1054 × 197 microns. The fluctuation effect on the boiling heat transfer flow in micro channelshasbeenseenastheworkingfluidofwater. Flowrestrictionswereintroducedontheinletofeachmicro channel to prevent flow restriction process and to avoid backflow phenomenon. Results are shown in comparison to unrestricted flow arrangement. The effect of flow inhibitors on heat transfer performance during boiling the flow in micro channels was studied. Flow blockers act as a physical pressure drop element (PDE) that is being studied. The result from the case without PDE is compared to 6.1% of PDE.Theheattransferresultisforthelargeflowof362.9kg /m2andfor144.4kg/m2and362.9kg/m2.Heattransfer performance increases to 144.4 kg / m2 by using a header with6.1PDEs.Usingheaderswith6.1%PDEhasreducedthe heattransferperformance.Inthecaseof6.1%,PDEdoesnot improve heat transfer performance for low mass flow rates. Theresultofheattransfersforalargeflowof362.9kg/m2 and 144.4 kg / m2. In the case of 362.9 kg / m2 using the headers,heat transferperformance hasimproved6.1% PDE and 6.1% PDE did not increase the heat transfer performanceforlowmassflowrates.

H. Y. Zhang et al (2009) have been seen that some parameters affect the microchannel, perhaps it is a new phenomenon of micro channels, namely as the vortex start and transition to turbulent flow for the rain old number, is less compared to the flow through conventionally shaped tubes. , Other aspects come from familiar events, which are generally neglected for flow and heat transfer through the tube with the flow, such as flow slip, Sticky wastage, and compressedflow.

Liang Gong et al (2011) performed parametric study of three dimensional laminar fluid flow and heat transfer attributesinmicro sized wavychannelsbyvariedtheheavy featureamplitude,wavelength,andaspectratiofordifferent ReynoldsNumbersbetween 50and150.Itwasfoundthata heatfluxof47w/cm2acceptedforachipsizeof1cm2found atthechannelcenterwithrespecttoflowdirection.BothNu and∆PincreasewithAandRe.

YanhuiHanetal(2012)studiedthatMicro ChannelHeat Exchanger (MCHX) has applied in heating, ventilation, air conditioning,andrefrigerationbecauseitisa moreeffective heat transfer rate and a more compact measure and lower cost. In this study, the qualities of micro channel heat transfersandfluiddynamicshavebeensummarizedandthe strategies of adjustment namely Geometry and thermodynamic execution and the preferences and impedimentsofMCHXwere examined.Itwasfoundthatthe micro channel heat exchanger has been executed more broadly in the refrigeration and air conditioning industry. Before designing the micro channel, pressure loss and heat transfer characteristics should be accurately estimated. In this manner, it is accepted that in the analysis of micro channel heat exchanger functioning in depth, optimize the heat transfer size and solve existing problems in fabricating andapplication.

AmirahM. Saharetal (2014)sawsingle phaseflow and conjugateheattransferinarectangularmicrochannel,which isalignedwithaglassplateinthecopperblockoftheheater, inwhichnumericalsimulationfluent14.5isused.Thewater used in this study fluid has been used and the hydraulic diameter of the rectangular channel is 0.561 mm and the length is 62 mm. Mathematical results have been validated using experimental data and existing traditional theory.The result showed that there was an important difference betweenthe3Dthinwallandthefullyconjugatedmodeland it demonstrated that the numerical plan was employed, which wascapable of providing a precise simulation of flow and heat transfer even in the microchannel. It was analyzed thatfourmodelsspecifically2D,3Dthinwall(oneside hot), 3D thin wall (three way hot) and 3D fully conjugated heat transfer models. Experimental and mathematical results show that the transition to laminar turbulence occurs again in 1600 2000. 3D thin wall model predicts exploratory value with the sensor of the 3D conjugate model. The divergence between empirical values and conjugate models may be due to the fact that the conjugate effect is not taken into consideration in the experimental data reduction process.Itwasfoundthatexploratoryandnumerical results showed that Re 1600 2000 transmitters of laminar in the turbulent. Experimental value with excellent agreement

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

comparedtothe3Dconjugatemodel in3 Dthin wall model prediction. The period between the conjugate model and exploratoryvaluesmay beduetothefactthattheconjugate effectisnottakenintoconsiderationintheexperimentaland datareductionprocess.

Ravindra Kumar et al (2014) observed that in spite of the fact that an exploratory investigation has been done on thevalidityofclassicalcorrelationsbasedontraditionalsize channels for the prediction of flow and heat transfer behavior of semi circular micro channels in single phase fluid flow. The experiments have been done with the disintegrating water cooling and Reynolds number 238 to 1250. Experimental results have shown that the results of the conventional theory were applicable to the flow of fully developed laminas for the range of our experiments. Classicalcorrelationswereevaluatedformicro channel,with the perception of continuous wall heat flux, the average Nassel number obtained for micro channel. It was investigatedtomakeanaccurateestimationofheattransfer rates and consider the effect of admission effect, conjugate effect, axial heat conduction, and boundary conditions. Empirical investigations have been done for the friction factorinthesingle stageliquidflowinside thesemi circular micro channels. The results of the experiment show the agreementwithtraditionalhydraulictheoryandseethatthe flowof fluid inside the microchannel fullydevelopsthe flow of laminar in the range of experiments (238 <Re <1250). It was found that experimental results have found that a good deal hasbeen reached with traditional hydraulictheory and ithasbeenobservedthattheflowinsidethemicro channels is the flow of the fully developed experiments (238 <Re <1250) it shows. The experimental value of the Nusselt number in the lower Reynolds number is slightly different from the correlations developed by SHAH & LONDON and Sieder Tate. It is observed near the estimated result by correlation developed by Sieder Tate and confirms that the flow is evolving together. The prediction of the result by numerical simulation for MCHS with a very thin substrate agrees well with experimental results and suggests that further analysis is needed to develop suitable new correlations for semi circular cross sectional MCHS. It is suggestedthatlowReynoldsnumberflowisbetter.

T.G. Karayiannis et al (2016) stated that due to the fast increment in the performance and commute of electronics and high power equipment, heavy heat flow values need to be successfully broken. The author has seen, the potential applicationofboilingflowinmicro channelstohighlightthe challengesinthermal managementfor eachapplication.The author presented exploratory investigate on the following fundamental factors the flow of flow in rectangular multi

channelsandsingletubestoexaminethedefinitionofmicro channel. Flow pattern and heat transfer mechanism fluctuation and their impact on reversal and heat transfer rates, impact of channel surface characteristics, noteworthy heatflowprediction.Thecorrelationforthepredictionofthe flow pattern transition and the heat transfer coefficient in small micro diameter tubes was developed recently. Flow boiling in a microchannel heat sink is very promising for manyapplicationssuchasthecomputerandITindustryhigh power semiconductor equipment. The average heat flow is predictedtoreach2 4.5MW/m2inacomputerchip,which contains local hot spots in the range of 12 45 MW / m2. In high power semiconductor devices, the heat flow can be 6.3 to 50 MW / m2 at the chip level. The instability of the flow and reversal is characterized by researchers rapidly developing bubbles. The authors suggest that channel surface characteristics, surface wettability, conjugated heat effects, and inlet sizes and outlet manifolds are important parameters that affect reversal and flow instability. Various heatandchannelfluxofchannelsurfacecharacteristicshave a significant impact on behavior on local heat transfer coefficients. Some studies analyze the effects of surface fluctuation on boiling the flow in the micro channels and examine the contradictory effects of the impending tilt. Correlationdesignswerecreatedtopredictheattransferand flow patterns in small micro diameter channels. There is an agreementamonganalystsontheFlowCriticalHeatFluxon mass flow effect, fluid properties, length ratio, and inlet subcooling. It was found that there is no common assertion on the criteria utilized for the definition of macro mini /mini/micro channels. Within the two stage flow, all physics based criteria were given the assignment of fluid properties and flow parameters, which depend on the conditionsoftherealparameters.Somestudiesanalyzedthe effect of melting the surface on boiling the flow in microchannels and saw the contraction effect on the provocativeurine.Acommonassertionbetweenresearchers on the effect of mass flux and fluid properties, critical heat flux over the flow of the diameter and inlet subcooling. Designs were developed to predict flow patterns and heat transferinsmallmicro diameterchannels.

HasanNihalZaidietal(2017)statedthatinthepresence of a transverse magnetic field and internal heating generation to the authors, the issue of fully developed free convection flow of electrostatic fluid in a tilted micro channelhasbeeninspectedandanexplanatoryarrangement has been found for velocity and temperature profile. The authors have considered the temperature jump and velocity slip on the microchannel wall and discussed the impact of diverse parameters with velocity and temperature profile along with the skin friction parameter and graphs on the

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Nusselt number. It was found that when the Knudsen number (Kn) increases the velocity of the particle growth, then the coefficient of heat generation and the interaction parameter (in) decreases with the increase of the Hartman number.

M.R. Ozdemir et al (2018)studied thata comprehensive reviewofsingleandtwo phasepressuredropcharacteristics andflow boilinginstabilityinmicro channelstoexcludeline discrepancies in the literature. Large scale flow effect, heat flow, exploratory conditions Channel geometric parameters (hydraulic diameter, aspect ratio) have been studied critically, including past and recent researchers. Two phase pressure drop in the micro scale has found similar properties with traditional scale channels and the flow boilinginstabilityhasaffectedtheperformanceofthesystem andinthisstudy,theunstableflowforthereliabledesignof themicroscopicheatboilingconditionshavebeenidentified Exchangers. It was said that for single phase pressure drop. There is a need to consider the loss of inlet and exhaust pressure, the single phase friction factor strongly depends onthecharacteristicsofthesurfaceofthechannel,duetothe transition size effect between the laminar turbulence in micro channelscanbethetraditionalchannel.

S.M. Chan et al (2018) imitated the impact of 10 micron transitional micro channel on the thermo hydraulic display for single phase flow in semi circular cross sectional surfaces, in which the position of the boundary for the temperature of the wall is consistent 350 k. It has been shownthatwiththeReynoldsnumber,deansbuyvortexand increase the heat transfer in the zone of spiral turn. The study proposed that a hydraulic diameter channel of 10 microns can improve heat transfer performance. Appropriatefor 10 diameterhydraulicdiameter channel for single phaseflowinspiraltransitionalmicro channel witha semi circularcross section.

TaoWangetal(2018)describedthatinthesingle phase microchannel heat sink (MCHS) temperature fluctuation, which uses the integrated temperature sensor with deionized water in the form of coolant. After the investigation, the result showed that the temperature fluctuation in temperature is not negligible. The motivation for fluctuations in temperature is based on both simulation and experimentation. It has been found that the effect of fluctuations in the inlet temperature is global, the temperature changes at different places at once and the impactofthegasbubbleislocalized,wherethetemperature changes are not synchronized at distinctive locations. The temperature gradient of the microchannel is linearly dependent on temperature fluctuations, where large

temperature gradient increases fluctuations in high temperaturesofMCHS.

The micro channel cooling technique appears to be a viable solution to high heat dissipation requirements of the micro electro mechanical system (MEMS) devices. The thermal design of these devices is a key issue that needs to keep the operating temperature at below the acceptable limit. Hence, the aim of the present work is to improve the thermal performance and reliability of these devices, by maintaining the operating temperature below the critical temperature say 85°C. The numerical study was conducted on single phase forced convection in micro channel using distilled water (DW) as a coolant. The set of numerical simulation was performed to measure the surface temperature of micro channel at fixed volume flow rates in the range of 10−25 ml/min. It is also design to improve the uniformity of temperature distribution on the surface of MEMS devices and improves the cooling efficacy of micro channelusingasDWasacoolant.

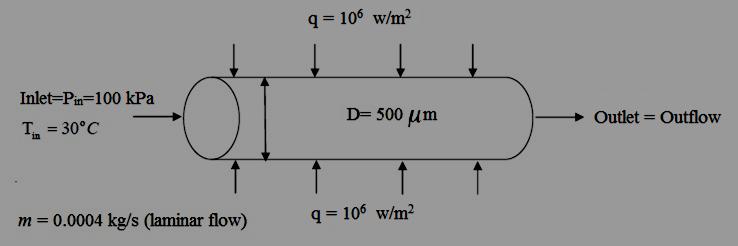

A circular micro channel’s computational domain is showedin3 dimensional(3D)infigure.Thegeometryexists of a pipe. A centre line and inlet and outlet boundaries, the diameterdandlengthlofthepipearespecifiedinfigure

Equationofcontinuity,momentumequation,andenergy equation (ANSYS Fluent 15.0) are included as single phase model equations. The continuity and momentum equations calculate the velocity vector. The energy equation calculates temperature distribution and the wall heat transfer coefficient. The equation for conservation of mass, or continuityequation,canbedepictedas:

The equation for conservation of mass, or continuity equation,canbewrittenasfollows:

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Equation (1) is the general form of the mass conservation equation, and is valid for both Incompressible andcompressibleflows.ThesourceZ_misthemassaddedto thecontinuousPhasefromthedispersedsecondphase(e.g., due tovaporization ofliquiddroplets) andanyuser defined sources.

Conservationofmomentuminaninertial(non accelerating) referenceframeisexplainedby: ⃗ ⃗⃗ ⃗ ⃗ (2)

Where p is the static pressure, is the stress tensor (described below), ⃗ and ⃗ are the gravitational body force and external body forces (e.g., that arise from interactionwiththedispersedphase),respectively. ⃗ alsocontainsothermodeldependentsourcetermssuchas porous mediaanduser definedsources.

Thestress isgivenby: ⃗ ⃗ (3)

Where µ is the molecular viscosity, I is the unit tensor, and the second term on the right Hand side is the effect of volumedilation.

EnergyequationissolvedbyANSYSFLUENTinthefollowing form: (⃗ ) ∑ ⃗ (̿̿̿̿̿ ⃗) (4)

WhereKeff istheeffectiveconductivity(K+Kt)where Kt isthe turbulent thermal conductivity, defined according to the turbulence model being used), and Jj is the diffusion flux of species J. The first three terms on the right hand side of equation represent energy transfer due to conduction, species diffusion, and viscous dissipation, respectively. sh includes the heat of chemical reaction, and any other volumetricheatsources. InEq.(4),

(5)

Wheresensibleenthalpyhisdefinedforidealgasesas ∑ (6) isthemassfractionofspecies j ∫ (7) isusedas298.15K.

Boundary condition applied in these numerical simulations aregivenbelow:

Anoslipboundarycondition

Inletpressure=100kpa,

inlettemperature=300c,

massflowrate=0.0004kg/s(laminar)

Heatflux=106w/m2.Outlet=outflow.

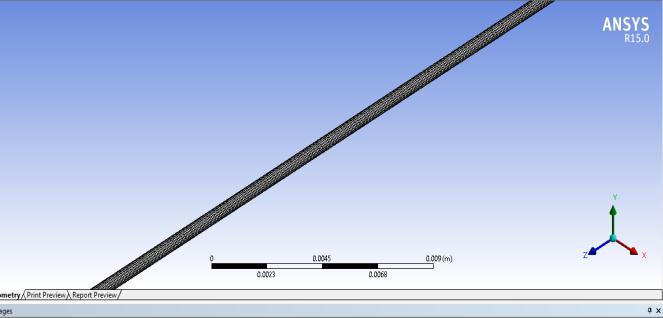

Meshing of geometry: structuredmeshingmethodhasdone in Ansys workbench was used for meshing the geometry 70125 nodes were generated. The 3D geometry of circular microchannelwithstructuredmeshshowninfigure.

Figure 3 shows that the variation in water temperature at centerlineinlaminarregimealongwithaxiallengthofmicro channelisgraduallyincreasingfrom303kupto333k.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

330.00

325.00

320.00

315.00

310.00

335.00 0.00 0.02 0.04 0.06 0.08 0.10 0.12

305.00

300.00

Temperature Length (m)

Figure3.Temperatureprofileatcenterlineinmicrochannel

Variation of the enthalpy along the axial length

Figure 4 Shows that enthalpy of water is gradually increasing along the axial length of micro channel .it is increasing from the point 20000 j kg 1 up to 140000. The enthalpy of water is showing of center line at laminar state withtheaxiallengthofmicrochannel.

140000.00

120000.00

100000.00

Figure5.Velocityprofileatcenterlineincircularmicro channel

Variation of the Reynolds number along the axial length

Figure 6 Shows that the Reynolds number of water is gradually increasing at laminar regime of axial length of micro channel's center line. It increases from 140 up to 250 thenitbecomesconstantalongwiththeaxiallengthofmicro channel.

80000.00

60000.00

40000.00

l=0.1 m d=500 ���� Pin=100 kPa m= 0.0004 Kg/s Tin= 300 C ∅ 106 w/m2 0.00

160000.00 0.00 0.05 0.10 0.15

Enthalpy Length (m)

20000.00

Static Enthalpy…

Figure4Enthalpyprofileatcenterlineincircularmicro channel

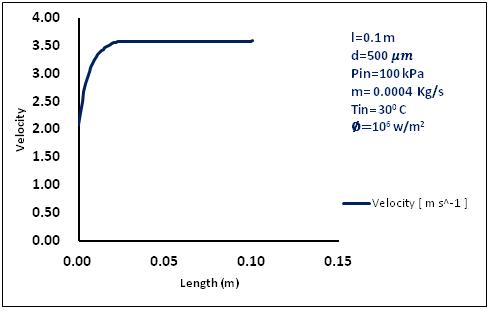

Variation of the velocity along the axial length

Figure 5 shows that velocity of water in laminar regime at center line in micro channel is increasing from 2.00 ms 1 up to 3.50 ms 1 then it becomes constant so it is showing initiallygetthefullydevelopedregion.

250.00

200.00

150.00

l=0.1 m d=500 ���� Pin=100 kPa m= 0.0004 Kg/s Tin= 300 C ∅ 106 w/m2 0.00

Reynolds number Length (m)

100.00

50.00

300.00 0.00 0.05 0.10 0.15

l=0.1 m d=500 ���� Pin=100 kPa m= 0.0004 Kg/s Tin= 300 C ∅ 106 w/m2

Cell Reynolds…

Figure6.Reynoldsnumberprofileatcenterlineincircular microchannel

Effect of different diameter on the enthalpy in circular micro channel

Figure7showsthatthevariationinenthalpyofwaterat center line in circular channel, with 500 micro diameter shows is increasing from 20000 up to 150000. It shows the 400 micro diameter is increasing from 20000 up to 120000 and this shows the 600 micro diameter is increasing from 20000 up to 100000. So, we find that the highest enthalpy 500 micro diameter then 400 micro diameters then 600

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

micro diameters of circular micro channel. It can be clearly seen that the enthalpy of the micro channel has been increasedwithinincreasinginthediameter.

velocity, that were commonly used, and proposed in this study,wereevaluated.Followingconclusionsweredrawn:

Temperatureislinearlyincreasedalongwithaxislength ofmicrochannel.

Velocity and Reynolds number is initially increased along with axis length of micro channel then it’s becomingconstant.

Thebulkenthalpyofthemicro channelisincreaseswith increasesinthediameter.

The average velocity of the micro channel is increases withdecreasesinthediameter.

7Effectofdiameterontheenthalpyprofileatcenter lineincircularmicrochannel

Figure 8 that velocity of water in laminar regime at center line in micro channel higher increasing in that 400 micro diameter 6 ms 1 then 500 micro diameter 3.6 ms 1 then600microdiameter2.62ms 1thenitbecomesconstant soitisshowinginitiallygetthefullydevelopedregion.Itcan be clearly seen that the velocity of the micro channel has beenincreasedwithinincreasinginthediameter.

[1] S.K.RAI,REVIEWOFRECENTAPPLICATIONSOFMICROCHANNELIN MEMS DEVICES, INTERNATIONAL JOURNAL OF APPLIED ENGINEERINGRESEARCH,13.9,64 69,(2018).

[2] S.K.RAIANDG.DUTTA,AREVIEWOFRECENTAPPLICATIONSOF SUPERCRITICAL FLUID IN NATURAL CIRCULATION LOOPS FOR NUCLEAR REACTOR INTERNATIONAL JOURNAL OF APPLIED ENGINEERINGRESEARCH,23,195 204(2018)

[3] H.K.GUPTA,S.KUMAR, AND T.SHEOREY,BOILINGFLOWHEAT TRANSFER IN MICROCHANNEL: EXPERIMENTAL AND NUMERICAL INVESTIGATION”,INPROCEEDINGSOFTHE23RDNATIONALHEAT AND MASS TRANSFER CONFERENCE AND 1ST INTERNATIONAL ISHMT ASTFE HEAT AND MASS TRANSFER CONFERENCE IHMTC 2015,1 8,TRIVENDRAM,INDIA,(2015)

[4] D.B. TUCKERMAN, R.F. PEASE, HIGH PERFORMANCE HEAT SINKING FOR VLSI, IEEE ELECTRON DEVICES LETT (1981) EDL2PP.126 129.

[5] P.S LEE, S.V GARIMELLA, D. LIU, INVESTIGATION OF HEAT TRANSFER IN RECTANGULAR MICROCHANNELS, INTERNATIONAL JOURNAL OF HEAT AND MASS TRANSFER, 48 (2005) 1688 1704.

Figure8velocityprofileatcenterlineincircularmicro channelwithdifferentdiameter

Theinfluencecharacteristicsandmechanismsofcircular micro channel were analyzed numerically. The numerical simulation has been performed in the ANSYS 15.0. Five indicators, including temperature, enthalpy, velocity, Reynoldsnumberandeffectofdiameterontheenthalpyand

[6] W.QU,I.MUDAWAR

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[8] H.A. MOHAMMED, P. GUNNASEGARAN, N.H SHAUIB, INFLUENCE OF CHANNEL SHAPE ON THE THERMAL AND HYDRAULIC PERFORMANCE OF MICROCHANNEL HEAT SINK, INTERNATIONAL COMMUNICATIONS IN HEAT AND MASS TRANSFER 38 (2011) 474 480.

[9] N. GHAZALI MOHD, O. J. TAEK, N. B. CHIEN, C. KWANG, R. AHMAD, COMPARIOSN OF THE OPTIMIZED THERMAL PERFORMANCE OF SQUARE AND CIRCULAR AMMONIA COOLED MICROCHANNEL HEAT SINK WITH GENETIC ALGORITHM, ENERGY CONVERSIONANDMANAGEMENT(2015).

[10] S.K.RAI,P.KUMAR,AND V.PANWAR,NUMERICALANALYSIS OF INFLUENCE OF GEOMETRY AND OPERATING PARAMETERS ON LEDINEGGANDDYNAMIC INSTABILITYON SUPERCRITICALWATER NATURAL CIRCULATION LOOP, NUCLEAR ENGINEERING AND DESIGN,369,110830(2020)

[11] S. K RAI, P. KUMAR, V. PANWAR, MATHEMATICAL AND NUMERICAL INVESTIGATION OF LEDINEGG FLOW EXCURSION AND DYNAMIC INSTABILITY OF NATURAL CIRCULATION LOOP AT SUPERCRITICAL CONDITION,ANNALS OF NUCLEAR ENERGY,155, 108129(2021)

[12] S.K. RAI, P. KUMAR AND V. PANWAR, NUMERICAL INVESTIGATION OF STEADY STATE CHARACTERISTICS AND STABILITY OF SUPERCRITICAL WATER NATURAL CIRCULATION LOOP OF A HEATER AND COOLER ARRANGEMENTS, NUCLEAR ENGINEERINGANDTECHNOLOGY,2022

[13] L.CHAI,S.A.TASSOU,EFFECTOFCROSS SECTIONGEOMETRY ONTHETHERMOHYDRAULICCHARACTERISTICSOFSUPERCRITICAL CO2 IN MINICHANNEL, ENERGY PROCEDIA 161 (2019) 446 453.

[14] S.E.GHASEMI,A.A.RANJBAR,M.J.HOSSEINI,EXPERIMENTAL AND NUMERICAL INVESTIGATION OF CIRCULAR MINICHANNEL HEAT SINKS WITH VARIOUS HYDRAULIC DIAMETER FOR ELECTRONIC COOLING APPLICATIONS, MICROELECTRONICS RELIABILITY73(2017)97 105.

[15] G.V. KEWALRAMANI, G. HEDAU, S.K. SAHA, A. AGRAWAL, EMPIRICALCORRELATIONOFLAMINARFORCEDCONVECTIVEFLOW IN TRAPEZOIDAL MICROCHANNEL BASED ON EXPERIMENTAL AND 3D NUMERICAL STUDY, INTERNATIONAL JOURNAL OF THERMAL SCIENCE142(2019)422 433.

[16] L.SU,Z.DUAN,B.HE,H.MA,G.DING,LAMINARFLOWAND HEAT TRANSFER IN THE ENTRANCE REGION OF ELLIPTICAL MINICHANNELS, INTERNATIONAL JOURNAL OF HEAT AND TRANSFER145(2019)118717.

[17] F.S MOGHANLOU, A.S. KHORRAMI, E. ESMAEILZADEH, H. AMINFAR, EXPERIMENTAL STUDY ON ELECTROHYDRODYNAMICALLY INDUCED HEAT TRANSFER ENHANCEMENT IN A MINICHANNEL, EXPERIMENTAL THERMAL ANDFLUIDSCIENCE59(2014)24 31.

[18] C.J. HO, P.C. CHANG, W.M. YAN, P. AMANI, THERMAL AND HYDRODYNAMIC CHARACTERISTICS OF DIVERGENT RECTANGULAR MINICHANNEL HEAT SINKS, INTERNATIONAL JOURNAL OF HEAT ANDMASSTRANSFER122(2018)264 274.

[19] S.G. KHANDLIKAR, SINGLE PHASE LIQUID FLOW IN MINICHANNELS AND MICROCHANNELS, ELSEVIER PUBLICATION, 2014.

[20] TUCKERMAN,D.B.,PEASE,R.F.:HIGHPERFORMANCEHEAT SINKING FOR VLSI, IEEE ELECTRONIC DEVICE LETTERS, EDL 2(1981).

[21] KANDLIKAR S.G.,COLIN S.,PELES Y.,GARIMELLA S.,PEASE R.F., BRANDNER J.J., TUCKERMAN, HEAT TRANSFER IN MICROCHANNEL2012 STATUS AND RESEARCH NEEDS,ASMEJ OF HEATTRANSFER,SEPT.,VOL.135,(2013).

[22] GAKU HAYASE, DEVELOPMENT OF MICRO CHANNEL HEAT EXCHANGER FOR RESIDENTIAL AIR CONDITIONERS, INTERNATIONAL REFRIGERATION AND AIR CONDITIONING CONFERENCE.PAPER1566.

[23] JAESEON LEE, ISSAM MUDAWAR, TWO PHASE FLOW IN HIGHHEAT FLUXMICRO CHANNELHEATSINKFORREFRIGERATION COOLING APPLICATIONS: PARTI PRESSURE DROP CHARACTERISTICS,ELSEVIER,INTERNATIONAL JOURNALOF HEAT ANDMASSTRANSFER48(2005)928 940.

[24] YANHUI HANA, YAN LIUA, MING LIAA,JIN HUANGA, A REVIEWOFDEVELOPMENTOFMICRO CHANNELHEATEXCHANGER APPLIED IN AIR CONDITIONING SYSTEM, ENERGY PROCEDIA 14 (2012)148 153

[25] AHMET SELIM DALKILIC MOHAMED M. AWAD, AND SOMCHAI WONGWISES, AIR SIDE PERFORMANCE OF A MICRO CHANNEL HEAT EXCHANGER IN WET SURFACE CONDITIONS, THERMALSCIENCE:YEAR 2017,VOL 21,NO 1A, PP 375 385

[26] HUIZE LI, PEGA HRNJAK, QUANTIFICATION OFLIQUID REFRIGERANT DISTRIBUTION IN PARALLEL FLOW MICROCHANNEL HEAT EXCHANGER USING INFRARED THERMOGRAPHY, APPLIED THERMALENGINEERING78(2015)410E418

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[27] KAMATA, KIM, FUJINO, 2012, PROCEEDINGS OF THE 2012 JSRAEANNUALCONFERENCE,SAPPORO,PP37 40

[28] E.S.CHO,J.W.CHOI,J.S.YOONANDM.S.KIM,“MODELING AND SIMULATION ON THE MASS FLOW DISTRIBUTION IN MICROCHANNEL HEAT SINKS WITH NON UNIFORM HEAT FLUX CONDITIONS,”INTERNATIONAL JOURNAL OFHEAT AND MASSTRANSFER,VOL.53,P.1341 1348,2010.

[29] Y. T.MU,L.CHEN,Y. L.HE AND W. Q.TAO,“NUMERICAL STUDYONTEMPERATUREUNIFORMITYINANOVELMINI CHANNEL HEAT SINK WITH DIFFERENT FLOW FIELD CONFIGURATIONS,”INTERNATIONALJOURNALOFHEATANDMASS TRANSFER,VOL.85,PP.147 157,2015.