International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

2

1PG Scholar, Dept. of Civil Engineering, Malabar College of Engineering

2Professor, Dept. of Civil Engineering, Malabar College of Engineering ***

Abstract Metal chips are generated during the cutting, milling and turning process as a side effect of manufacturing elements. These wastes represent about 3 5% by weight of metal casting. This project is aimed to study the effect caused on water bodies nearby the metal industries in Kulapully, a small town in Palakkad district. As a solution to minimize the waste generation, this metal chips can be used asreplacement of aggregates or steel fibres in concrete. The sample required for the study were collected from both borewell and openwell. The metal chips that are directly released into the environment may also pollute water sources and soil. Therefore the metal waste is added as a replacement of aggregates in concrete. The water samples collected and water quality tests such as determination of pH, Total Dissolved Solids, Total Dissolved Iron content, Biochemical Oxygen Demand, Chemical Oxygen Demand, Total Hardness, Chlorides, Alkalinity, Flouride, Nitrate, Manganese, Sulphate, Sulphide and Turbidity was tested in a nearbylaboratory.The results of the groundwater quality of the present study are compared and discussed with the highest desirable limits. It was observed that the iron content and total hardness was higher than the desirable limit. While comparing the two sources of water it can be concluded that water sample collected from borewell shows a higher variation in thevalues as compared to sample collected from open well.

Key Words: Metalchips,Aggregates, TotalDissolvedSolids, BiochemicalOxygenDemand,ChemicalOxygenDemand.

Drinking water is a very important need of the people to maintainthehydrationofthehumanbody.Becauseofscanty rainfallandmanyfoldusesofwater(drinking,irrigationand industrialpurposes),groundwatertablehasdecreased.All overtheworld,waterhasbeencontaminatedregularlydue tomanmadeandnaturalsources.Mostofthehouseholdsuse domesticsandfilterstotreatgroundwaterbeforedrinking, to remove iron and odors. These simple sand filters also remove iron content and hardness, with an average reduction rate of 80%. The existence of trace metals in aquatic environments often led to serious concerns about theirinfluenceonplantandanimallife.

The site selected for the present study is surrounded by many small scale metal industries. The widespread use of

steelproductsintheindustryresultsinenergyconsumption , CO2 emission and production of steel waste in various amounts and size .Some steel waste is recycled. Due to contaminationofthechipsurfacewithoilsorothercoolants duringthemachiningprocess,thestorageofthiswastehasa negative impact on the environment, and its cleaning generatesadditionalcosts.Inaddition,thegeneratedchips can have different properties due to different types of materialsbeingprocessed.Inliteratureitcanbefoundthat metal chips used in concrete mix are classified by other scientistsasareplacementforaggregateorsteelfibers.

Theaimofthestudyistoevaluatethepropertiesof drinkingwatersamplecollectedfrombothborewell and open well from the nearby areas of the metal industries.

Thepresenceofdifferentcontaminantsarestudied byconductinglaboratoryexperiments.

Theobtainedvaluesarecomparedwiththestandard values.

Contaminationcausedduetothemetalexposurecan bereducedtoacertainamountbyinstallingfilters.

Theotherwaysuggestedistoreusemetalwastein cementconcrete.

AnitaSinghetal[1]conductedastudyonwastewaterfrom Dinapursewagetreatmentplantusedforirrigatingvegetable plotsatVaranasicity.Theyquantifiedtheconcentrationsof heavymetals,viz.Cd,Cr,Cu,Ni,PbandZninsoil,vegetables and the waste water used for irrigation. The waste water used for irrigation had the highest concentration of Zn followedbyPb,Cr,Ni,CuandCd.,Heavymetalconcentrations varied among the test vegetables, which reflect the differences in their uptake capabilities and their further translocation to edible portion of the plants. Percent contribution to daily intake rate of Cu, Ni, Pb and Cr was higher by fruit vegetables, whereas that of Cd and Zn was higher by leafy vegetables. They made a conclusion that waste water treatment technology should involve steps to remove heavy metals causing risk to human health.Arjun

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Lakshman et al [2] collected a total of 382 groundwater samples from 58 villages and analyzed for HMs and Sr by inductivelycoupledplasmamassspectrometer.Theaverage concentrationsofHMsandSrinwaterwasintheorderof strontium(Sr)>arsenic(As)>chromium(Cr)>lead(Pb)> mercury(Hg)>cadmium(Cd).Outof58villages,21,37,35, 35,35and39villageshadCr,As,Cd,Hg,PbandSrhigher (WHO limit) than their respectively permissible levels. G.Murali,C.M.VivekVardhan[3]conductedan experimental study influence of addition of waste materials like lathe waste,softdrinkbottlecaps,emptywastetins,wastesteel powderfromworkshopatadosageof1%oftotalweightof concrete as fibres. The lathe waste, empty tins, soft drink bottlecapsweredeformedintotherectangularstripsof3mm widthand10mmlength.Thatconcreteblocksincorporated with steel powder increased its compressive strength by 41.25%andtensilestrengthby40.81%.Softdrinkbottlecaps reinforcedblocksexhibitedanincreaseinflexuralstrengthof concrete by 25.88%. Better split tensile strength was achieved with the addition of the steel powder waste in concrete. The strength has increased upto 40.87% when compared to that of the conventional concrete specimen MarcinMałeketal[4]studiedtheeffectofaddingsteelchips without pre cleaning on the properties of concreteSteel wastewasaddedasareplacementforfineaggregateinthe amountsof5%,10%and15%ofthecementweight,which correspondwith1.1%,2.2%and3.3%massofallingredients and 0.33%, 0.66% and 0.99% volume of concrete mix, respectively.Theslumpcone,aircontent,pHvalue,density, compressive strength, tensile strength, tensile splitting strength, elastic modulus, Poisson’s ratio and thermal parameters were tested. It was observed that with the addition of lathe waste, the density decreased, but mechanicalpropertiesincreased.Noeffectwasobservedon thermalconductivity.ManpreetKauretal[5]dealswiththe assessment of the risk exposure related to heavy metal contentsingroundwaterand soil samples totwo different age groups via three different transits, i.e., ingestion, inhalationanddermal.Theconcentrationsofheavymetals (Zn,Cd,Cu,PbandCr)weremeasuredinthevillagesoflower Himalayas of Reasi district by using microwave plasma atomic emission spectrometer. All the mean values of the concentration. of heavy metals in water and soil samples werefoundtobelessthanthevaluesprescribedbyvarious agencies.Allthemetalconcentrationinthesoilsampleswere foundtobelowcontaminatedandthecorrespondingvalueof pollutionloadindexcalculatedlessthanunity.

Water samples were collected from different household wells near to Technocraft industrial estate at kulapully. Watersamplewascollectedfrom3borewellsand3open wells.Atadistanceof1kmwithinthearea.500mlsamples werecollectedinplasticbottles.Reuseoflathewasteisdone bycollectingofwastesedimentsandgranulesareaddedto concreteandtestsare done.Basedonthetestresults,itcan

be concluded that the metal chips released into the environmentmaycausepollutiontothewatersourcesand hence it can be utilized in concrete. Literature study was doneontheavailabledataonuseofmetalchipsinconcrete. Metal chips were collected from Lakshmi industries kulapully.Mixdesignfordifferentproportionsofconcrete wasdecidedandtestswereperformedtoobtainthestrength and properties of different mixes. Based on the literature survey and optimum quantities of bottle caps and steel powder,thecombinationswereadopted.

The samples collected were stored in plastic bottles and following water qualitytestswere done in Environmental Engineering laboratory of Jyothi Engineering College, Cheruthuruthy, Thrissur. The tests done were pH, Total Dissolved Solids (TDS), Total hardness and Iron content, other tests conducted are COD, BOD turbidity, alkalinity, chloride, fluoride, nitrate, manganese, sulphate etc. The obtainedresultsarecomparedwithIS105002012.

Basedonthetestresults,itcanbeconcludedthatthemetal chipsreleasedintotheenvironmentmaycausepollutionto thewatersourcesandhenceitcanbeutilizedinconcrete. Literature study was done on the available data on use of metal chips in concrete. Metal chips were collected from Lakshmi industries kulapully. Mix design for different proportions of concrete was decided and tests were performedtoobtainthestrengthandpropertiesofdifferent mixes.

Therawmaterialsusedinconcretemixarecement,coarse aggregate,fineaggregateandwaterinrequiredproportions. Thecolourofcementshouldbeuniformlygreenishgrey.And whenhandisthrustedinto a bag ofcementitshouldfeel cool.Crushedstonesofsizemorethan4.76mmareknownas coarseaggregate.Coarseaggregateofsizeupto80mmare

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

usedinbuildingandroadconstruction.Specificgravity,void ratio,porositycalculationandsieveanalysiswereperformed on coarse aggregate sample. Specific gravity of the taken sampleofcoarseaggregate is3.06,void ratio 0.257%and porosity0.44%.Maximumsizeofaggregatesusedinthetest was20mm.M sandisusedasanalternativeforriversand. Manufactured sand is an alternative for river sand. lathe wasteof10%ofcementisused.Thesteelwastesareinshape ofthincoiledfibersofsize3mmwidthand5cmlength.

M30 grade concrete was prepared by doing mix design calculations.Theproportionsofmaterialsusedis obtained aftermixdesignprocedureandareasfollows:

Quantityofcement= 10.54kg Fineaggregate = 23.3Kg Coarseaggregate =37.01Kg

Water =4.98litre

The ratio of cement: coarse aggregate: fine aggregate is 1.00:2.26:3.30

The casting is done in cast ion cubes of standard dimension of 150mm×150mm×150mm from Material Testing Laboratory of Al Ameen Engineering College, Kulapully.Thecastedconcretecubeswerecuredinwater tank,demouldedandslumptestandcompressiontestwas done.

Table -1: WatersamplecollectedfromBorewell

Sl. No Parameter Unit Accept able limit

Permissibl elimit Observe dvalue

1 Turbidity NTU 1 5 2.4 2 pH No unit 6.5 8.5 No relaxation 6.3 3 TDS mg/l 500 2000 241 4 Alkalinity mg/l 200 600 50 5 Total hardness mg/l 200 600 525 6 Chloride mg/l 250 1000 11.03

7 Fluoride mg/l 1 1.5 Nil

8 Nitrate mg/l 45 No relaxation Nil

9 Iron mg/l 0.3 No relaxation 0.91

10 Manganese mg/l 0.1 0.3 Nil

11 Sulphate mg/l 200 400 5.6

12 Sulphide mg/l 0.05 No relaxation Nil

13 COD mg/l Nil

14 BOD mg/l nil

Table 2: Watersamplecollectedfromopenwell

Sl. No Parameter Unit Accept able limit

Permissibl elimit Observe dvalue

1 Turbidity NTU 1 5 1.5

2 pH No unit 6.5 8.5 No relaxation 6.9

3 TDS mg/l 500 2000 38

4 Alkalinity mg/l 200 600 80

5 Total hardness mg/l 200 600 320

6 Chloride mg/l 250 1000 2.75

7 Fluoride mg/l 1 1.5 Nil

8 Nitrate mg/l 45 No relaxation Nil

9 Iron mg/l 0.3 No relaxation 0.82

10 Manganese mg/l 0.1 0.3 Nil 11 Sulphate mg/l 200 400 6 12 Sulphide mg/l 0.05 No relaxation Nil

13 COD mg/l Nil 14 BOD mg/l nil

• From(Table1)incaseofborewell,turbidity,total hardness and iron content are more than the acceptablelimit.

• In case ofopen well (Table 2 ) total hardnessand ironcontentshowsahighervalueascomparedto theacceptablevalue.

• Whilecomparingthetwosourcesofwateritcanbe concluded that water sample collected from borewellshowsahighervariationinthevaluesas comparedtosamplecollectedfromopenwell.

• The yellow stains seen on wash basins and water closetsareanevidenceforthepresenceofdissolved solids and iron content in the water sample. Similarly the water mark that appears on vehicle glassesarealsoanevidenceforthescenario.

Aftertestingthecompressionstrengththeresultswere takenandcomparedwithstrengthofnormalconcrete.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

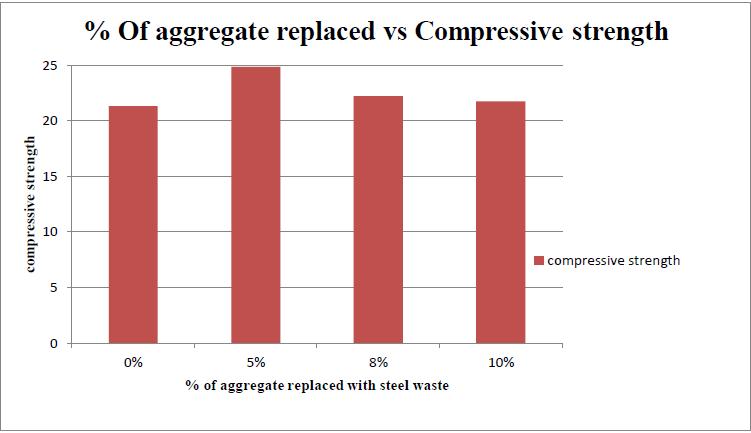

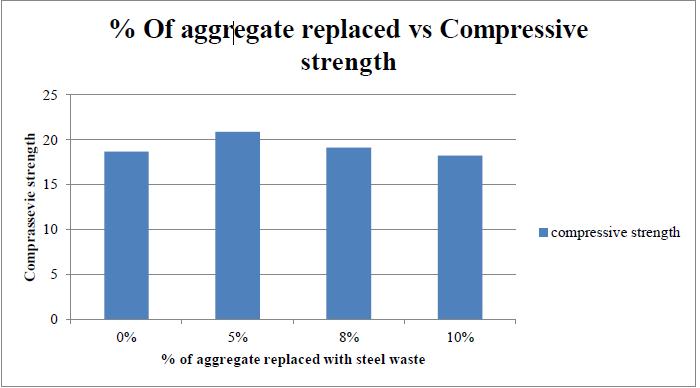

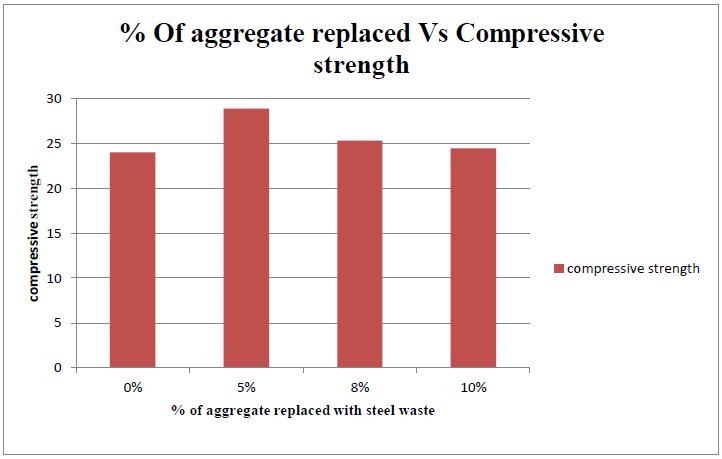

Theresultsweretakenafter7,14,28days.Theresultsare shownintableanditsgraphicalrepresentation.

Table -3: Compressivestrengthofconcreteafter7days

Concretemix Load(kN) Strength(N/ mm2)

Conventional concrete(0%) 420 18.66 Replacementof aggregatewith 5%

470 20.88

Replacementof aggregatewith 8%

410 18.22

430 19.11 Replacementof aggregatewith 10%

Chart 2:GraphicalrepresentationofCompressive strengthafter14days

Table -5: Compressivestrengthofconcreteafter28days

Concretemix Load(kN) Strength(N/ mm2)

Chart -1:GraphicalrepresentationofCompressive strengthafter7days

Table -4: Compressivestrengthofconcreteafter14days

Concretemix Load(kN) Strength(N/ mm2)

Conventional concrete(0%) 480 21.33

Replacementof aggregate5% 560 24.88

Replacementof aggregate8% 500 22.22

Replacementof aggregate10% 490 21.77

Conventional concrete(0%) 540 24.00 Replacementof aggregatewith 5%

Replacementof aggregatewith 8%

Replacementof aggregatewith 10%

650 28.88

570 25.33

550 24.44

Incaseofborewell,turbidity,totalhardnessandironcontent are more thanthe acceptablelimit. The observed value of totalhardnessofthewatersamplecollectedfromborewellis 525mg/lwhereastheacceptablelimitis200mg/l.Similarly ironcontentofthatsampleis0.91mg/lwhichismorethat theacceptablelimitof0.3mg/l.Similarlytheobservedvalue of total hardness of the water sample collected from openwell is 300 mg/l whereas the acceptable limit is 200 mg/l.Similarlyironcontentofthatsampleis0.8mg/lwhich ismorethantheacceptablelimitof0.3mg/l.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

properties of concrete. Utilization of excessive amount of metalchipswillreducethestrengthofconcrete.

[1] AnitaSingh,RajeshKumarSharma,MadhoolikaAgrawal And Fiona M. Marshall, (2010), “Risk assessment of heavymetaltoxicitythroughcontaminatedvegetables from waste water irrigated area of Varanasi, India”, InternationalSocietyforTropicalEcology,pp375 387.

Chart -3:GraphicalrepresentationofCompressive strengthafter28days

Soinordertominimizethedisposalofsteelwasteintoopen environment and there by its leachate to groundwater sources we can effectively use them as replacement for aggregateinconcrete.Compressivestrengthwastestedat7 and14daysbyreplacingaggregatewith5%,8%and10%of steelwaste.The7dayand14daytestshows5%asoptimum value as it gives higher value of compressive strength comparedto8%and10%. 7daycompressivestrengthis maximumwith5%replacementofaggregatewhichis20.88 N/mm2 14daycompressivestrengthismaximumwith5% replacement of aggregate which is 24.88 N/mm2 28 day compressivestrengthismaximumwith5%replacementof aggregatewhichis28.88N/mm2

On the basis of test data it can be inferred that the metal wasteproducedfromthemetalindustriescausepollutionto the water bodies and hence makes it unfit for drinking purpose.Theexcessironcontentinthewatergivesbadtaste to water and also creates marks and stains on ceramics, vehicle surface and tiles. The solution to overcome the effects of excess iron content and hardness of water is to installfiltersinhouses.Butitisanexpensivemethod.Soas analternative,themetalchipscanbeusedasreplacementof aggregates or steel fibres in concrete. This project is an experimental study of using steel waste in concrete. M30 designmixischosen.Metalchipsareusedasareplacement forcoarseaggregatewithvaryingpercentagessuchas0%, 5%,8%,10%.Theworkabilityandcompressiontestswere carriedout.Fromtheobtainedresultsitshowsaverylow workability. Compressive strength for 5% have more strength than other . 8% have strength more than conventional concretebutlessthanthat of5%.10% have compressive strength near to conventional concrete. By usingoptimumpercentageofMetalchipscanimprovethe

[2] Arjun Lakshman Khandare, Vakdevi Validandi, AnanthanRajendran,TotejaGurudayalSingh,Longvah Thingnganing,SrinivasuKurella,RajuNagaraju,Srinivas Dheeravath.Nagaraju Vaddi,SrinivasuluKommuand Yadaiah Maddela., (2020). “Health risk assessment of heavy metals and strontium in groundwater used for drinkingandcookingin58villagesofPrakasamdistrict, AndhraPradesh,India”,EnvironmentGeochemHealth, pp1 27.

[3] G.MuraliandC.M.VivekVardhan(2020),“Experimental investigationonfibrereinforcedconcreteusingwaste materials”,Internationaljournalofadvancedscientific researchandtechnology,vol2,278 283.

[4] ManpreetKaur.AjayKumar.RohitMehra.Inderpreet Kaur,(2019),“Quantitativeassessmentofexposureof heavymetalsingroundwaterandsoilonhumanhealth in Reasi district, Jammu and Kashmir”, Environment GeochemHealth,pp1 18.

[5] Marcin Małek , Marta Kadela, Michał Terpiłowski, TomaszSzewczyk,WaldemarŁasicaandPawełMuzolf, (2021), “Effect of Metal LatheWaste Addition on the Mechanical and Thermal Properties of Concrete”, Materials,pp1 19.