International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Barani M1 , Rakul P R2 , Mohammed Thoufeek3, Dr. M.A. Vinayagmoothi4

1 2 3 Student, Dept. of Mechanical Engineering, Kumaraguru College of Technology, Tamil Nadu, India 4Assistant Professor, Dept. of Mechanical Engineering, Kumaraguru college of Technology, Tamil Nadu, India ***

Abstract The Steering system is one of the vital subsystems of a vehicle which provides directional control and stability. In this project we are designing a steering system for an All Terrain Vehicle. An All Terrain Vehicle (ATV) is a vehicle that can travel on all different terrains. As a result, the steering system is designed for the worst case scenario, providing maximum directional control, pure rolling motion to the wheel, and the minimum possible turning radius. The main aim of this paper is to design a efficient steering system for an ATV.

Key Words: ATV,SteeringSystem,Ackermanngeometry,RackandPinion,Design

Thesteeringsystemisasetofassembledcomponentsthatguidesthevehicletofollowadesiredcoursebasedonthedriver's input.Thegoalofthesteeringsystemistoprovidedirectionalcontrolforthevehicle,toreducesteeringeffortandofferproper roadresponsetothedriver.

TheAckermansteeringsystemisdesignedusingafour barlinkagemechanisminwhichseverallinkagesmoverelativeto oneanotheranddirectthevehicleinaspecificdirection.Thissystemisusefulinsharpcornerssinceitreducessteeringeffort andfacilitatesmaneuverability.

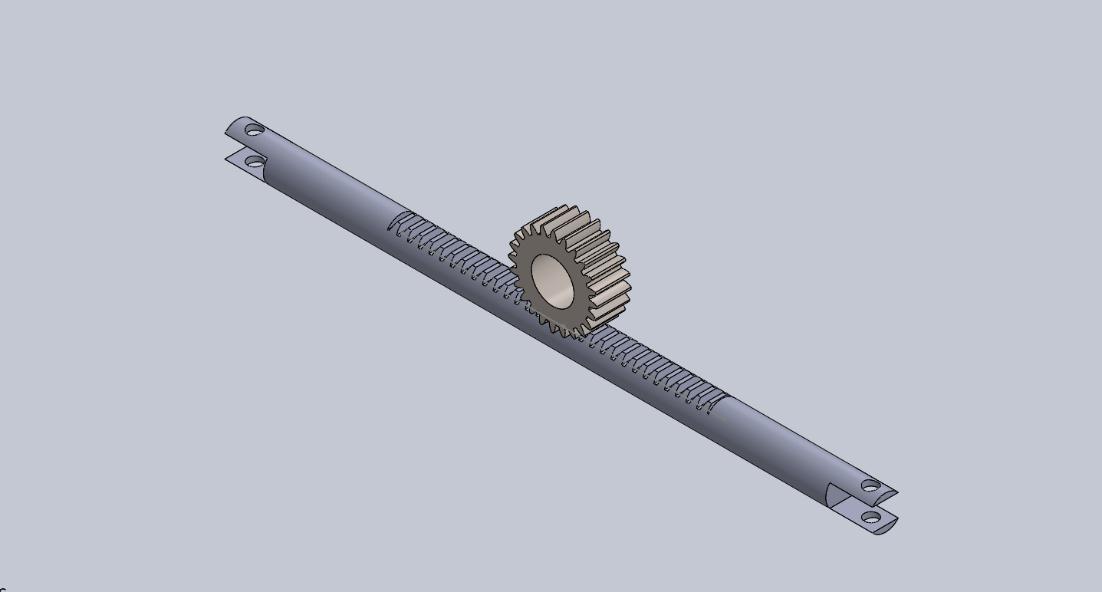

Incomparisontoothersteeringmechanisms,therackandpinionmechanismisidealduetotheobviousbenefitsofsimple design,easeofmanufacturing,significantlyreducedspacerequirements,andcost effectiveness.

Thepinionofarackandpinionsystemmesheswiththepinion,whichisfastenedtotheendofthesteeringshaft.The pinionisrotatedbyrotatingthesteeringwheel.Themovementofrackisresponsibleforturningofwheelsthroughsteering linkages.

Thefollowingliteraturesurveygivesapreviewglimpseofourworkinthisresearchrelatedtodesignofsteeringsystemin anATV.

Mohan poojari et al. [1]: Designeda2 DTurningradiusmechanismbyusingCatiaV5R21consideringtheacquiredbasic parameterracklengthsteeringarmlengthandotherparametersarechangedtoobtaindifferentturningradiusandAckermann percentagevalues.

William F. Milliken and Douglas L. Milliken [2]: InthebookofRaceCarVehicledynamicsItisshownthatifthewheel steersautomaticallywhenitturnsoverabumpordrooporwhenthevehiclerollsinaturnthevehiclewilltravelinapaththat driverdidnotselect.Soitisgoodtokeepzerobumpsteer.

Akshay Pawar and Suraj Zambare [3]: WheelbaseandTrackWidtharedecidedconsideringthesuspensiongeometry, handlingandstabilityofthevehicle.Kingpinoffsetwasdecidedbyconsideringthewheelassemblyandcastorangleselectedso thatitgivesstraightlinestabilityandoptimumself returningactionforbetterhandling.Positionofrackischosenbyconsidering pedalpositionandtoavoidsignificantamountsofbumpsteer.

Shylaen S Keshwani and A. M. Surendra Kumar [4]: TomakecalculationsimpleraC Programwascodedwhichcalculates varioussteeringvaluesneededsuchasAckermannangle,TieRodLength,SteeringRatioetc.Thisprogramwassimulatedunder differentAckermannangle,anditwasinferredthatwhentheAckermannangleincreasestheouterwheelturnslesser,which givesthebettersteeringresponse,andinputvariabilityincreaseshenceitgivessmoothdriving.

Nitish Malik et al [5]: Increasedthediameterofsteeringwheeltoreducethesteeringeffortbecausethedrivereffortto rotatethesteerhasbeenincreaseduponreducingthesteeringgearratio.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Amit Kumar Shakya et al. [6]: TominimizethebumpsteertierodmustbeparalleltoSuspensionA Armssothatduring bumptheInstantaneouscenterofthetierodmeetstheinstantaneouscenteroftheA Armsatinfinity.Inthismanner,thearc travelledbythetierodsandthearmswereequidistanttoeachotherduringsuspensiontravel,andnoforcewasgeneratedalong theracktoproducebumpsteer.

Kshitij N Sable et al. [7]: Thecalculatedvalueswerevalidatedusinglotussharksoftwaretochecktheproperfunctioningof suspensionsystemsandthenthedesigningofcomponentsweredoneinCADSoftwareCATIAV5R21.Allthecomponentsare analysedtotherealworldusingFiniteElementAnalysis

Prashant L Agrawal et al. [8]: Itwasmentionedthatthelengthofthesteeringrackisdirectlyproportionaltotheangleof thesteeringwheelandinverselyproportionaltotheaverage turningradiusofthevehicle.

Sandeep Chaudhary et al. [9]: Whileavehicletakingaturntheouterwheeltravelsmoredistancethantheinnerwheeli.e., innerwheelmakeshigheranglethantheouterwheel.SoHigherthesteeringanglesmallerwillbetheturningradius.

Element C Si Mn P S Cr Mo Ni

Content (%) 0.10 0.20 0.10 0.35 0.50 1.00 0.040 (Max) 0.040 (Max) 0.75 1.25 0.08 0.15 1.00 1.50

Table 1: ChemicalCompositionofEN 353

Mechanical Properties Density (gm/cm³)

Young’s Modulus (Gpa)

Poisson’s Ratio Yield Strength (Mpa)

Compression strength (Mpa)

Ultimate Tensile strength (Mpa)

Value 8.08 190 0.26 440 550 550

Table 2: MechanicalPropertiesofEN 353

SinceEN353hasgoodductilityandfatiguestrengthweuseitforrackandpinion.

Steeringsystemshouldbedesignedinsuchamannersothat Itshouldbeaccurateandeasytohandle, Steeringeffortshouldbeminimum, Roadshocksshouldnotbetransferredtodriverand

Itshouldprovidepurerollingmotiontowheel

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

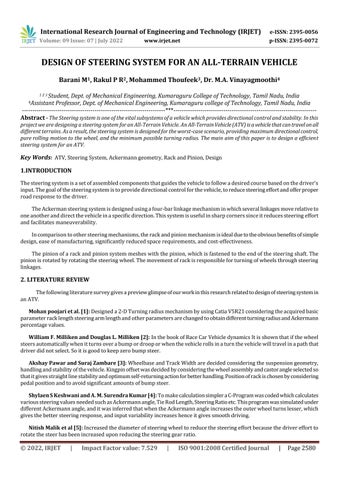

Fig -1:DesignMethodology

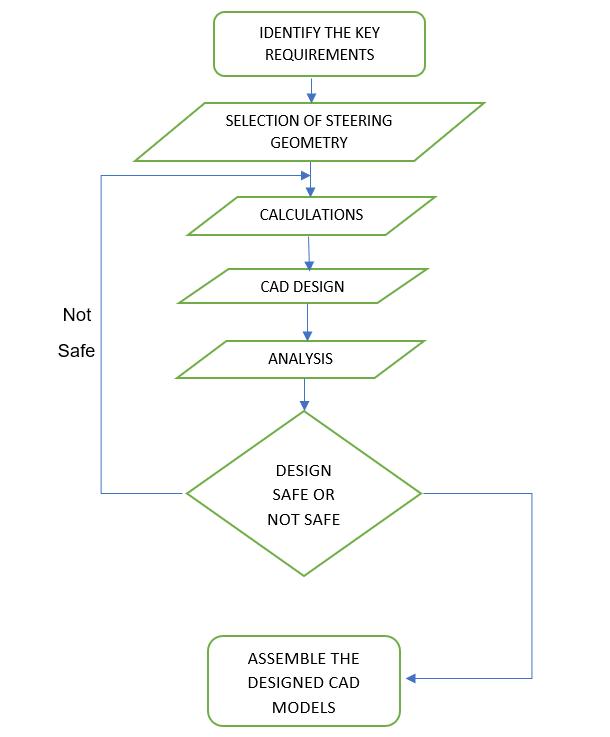

Tractionisanimportantfactorinoff roadracingascomparedtospeed.WechooseAckermannsteeringgeometrysinceitgives highstabilityatlowerspeed.Becauseoftheterrain,thisgeometryissuitableforBAJAvehicleswithaspeedlimitof60kmph.

Fig 2:SchematicDiagramofAckermannSteering[3]

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

AccordingtotheAckermannprinciple,theextendedaxesofthesteeringarmshouldmeetatthecentreoftherearaxle. Whenavehicleisturning,theconditionofperfectrollingisreachedwhentheextendedaxisofthefrontwheelsandthe rearaxismeetatapoint.Thispointiscalledinstantaneouscentreofthevehicle.Theinnerwheeldeflectsmorethanthe outerwheelwhileavehicletravelsalongacurvedpathtopreventskiddingwhilecornering

TrackWidth(mm) 1219.2

Wheelbase(mm) 1320.8

LocktoLock 1.25

InnerWheelAngle (Deg.) 48

Distancebetween KingpinCenter Center (mm)

1122.68

GroundClearance(in) 12

Table 3: InitialParametersforsteeringdesigncalculations

Ackermann angle

tanα=kingpin kingpincentredistance/2x(Wheelbase)

α=tan 1 (1122.68/2x52x25.4)

α=23.03°θ

Maxinnerwheelangle,Assume,θ=48°

ByAckermanncondition

Cot(Φ) cot(θ)=Trackwidth/wheelbase

(Φ)=28.74°So=29°(Maxouterwheelangle)

TurningRadiusoffrontinnerwheel,Ri=wheelbase/Sin(θ) (Trackwidth K.k)/2

TurningRadiusoffrontouterwheel,Ro=Wheelbase/Sin(θ) (Trackwidth k.K)/2

Ri=1729.50mm,Ro=2698.59mm

Turning Radius (Vehicle)

R=(Ri+Ro)/2=2.2m

Ackermann percentage

Ackerman%=Si/Ackermanx100

Ackerman=tan 1 (Wheelbase/(tan(Φ)*Trackwidth))

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Ackermanpercentage=101%(>100%)oversteer (Assumelocktolocktobe1.25revolution)

Locktolock=SteeringWheelangle/360°

Steeringwheelangle=1.25x360°=450°

Thesteeringwheelmustberotatedabout450°

SteeringRatio=steeringwheelangle(Fulllockononeside)/Innerwheelangle =225/48°=5

Steeringratio=5:1

Rack travel

Steeringratio=steeringwheeltravel(fullrotation)/Racktravel

5=(2*π*(5*25.4)*540)/360/Racktravel

∴Racktravel=188.435mm(full)

Ononeside,racktravel=94.2mm

∴Diameterofsteeringwheel

Steeringratio=steeringwheelcircumference/pinioncircumferences(or)

Radiusofsteeringwheel/Radiusofpinion

5=5*25.4/r

r=24mm

d=48mm(pinion)

No of teeth in pinion

Assumemodule=2*m=D/T∴T=D/m=48/2=24

Gearratio=540°/360°=1.25

Gearratio=Numberofteethinrack/Numberofteethinpinion1.25=N/18

Noofteethinrack=30

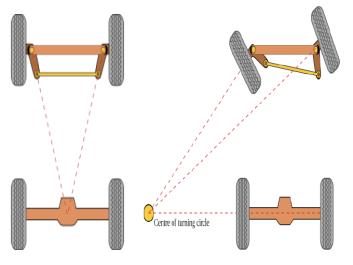

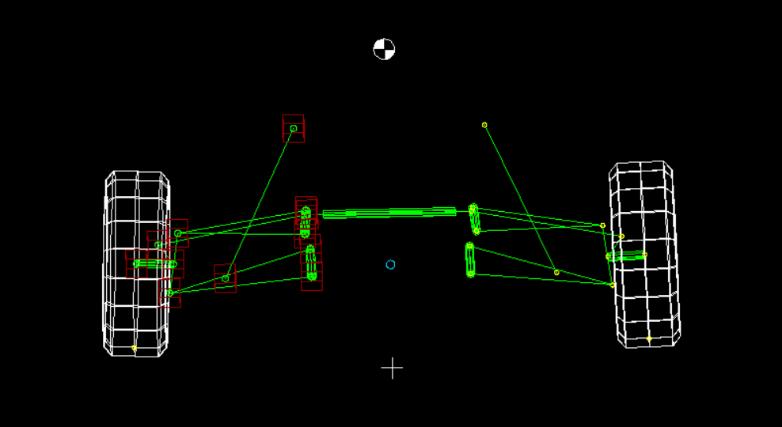

ImporttheCalculatedvaluesinLotussharksoftwaretocheckthesuspensioncharacter.

Aftergettingthesystemaimsclear,thesteeringiterationsweredoneinLotusSharksoftware.Someofthepredetermined parametersarelistedintheabovetable.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Fig 3:LotussharkInterface

Fig 4:WheelTravelinBumandDroop

AfterseveraliterationsinLotussharksoftwarefinalparametersfordesigningthesteeringsystemwerementionedbelow PARAMETERS

DIMENSIONS

STEERINGMECHANISM RACKANDPINION

ACKERMANNANGLE 23.03 STEERINGARMLENGTH 90mm INNERWHEELLOCKANGLE 48Deg OUTERWHEELLOCKANGLE 29Deg STEERINGRATIO 5:1

ACKERMANNPERCENTAGE 101%

TYPEOFSTEERING Oversteering

STEERINGARMLENGTH 91mm

Table 4: Final

SinceAckermannPercentagegreaterthan100%ThetypeofsteeringwillbeOversteering.Oversteerisatendencyforcarsto turnsharperthanthedriverintended,helpingthetiresgripsharpcorners.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

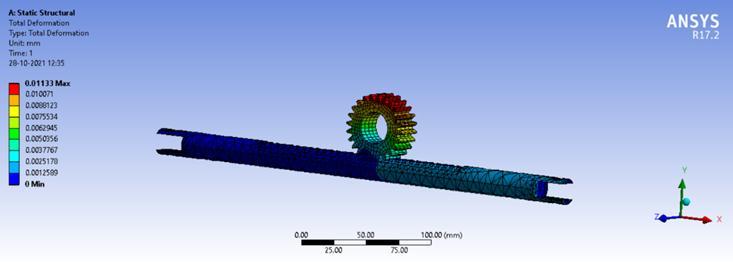

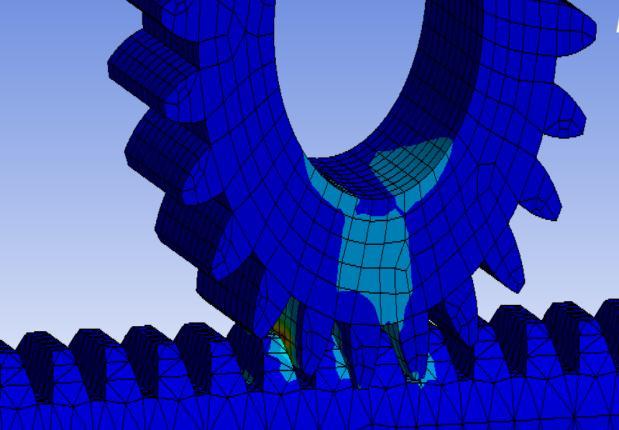

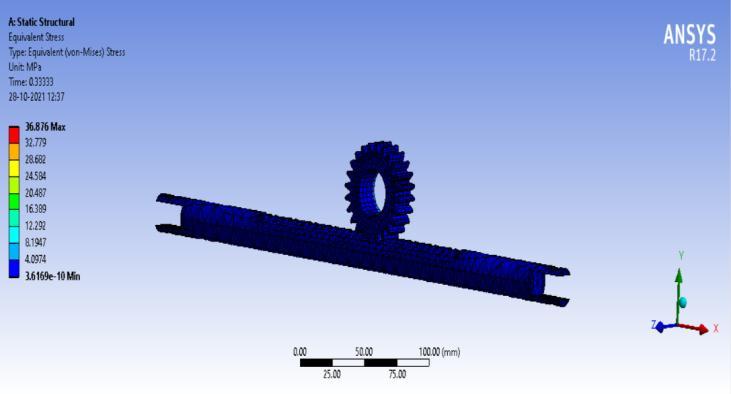

RackPinion

MAXIMUMDEFORMATION=0.01133mm

MAXIMUMSTRESS=36.876Mpa

Factorofsafety=8.1

ThedesignisSafe

Fig 8:AssemblingofCADModels

ThesteeringsystemplaysanimportantroleintheoverallperformanceofAllterrainvehicles.Thisresearchpaperconcluded bypresentingacompletedesignmethodologyaswellasresultingoptimaldesignsthatcanbemanufacturedforthegivenreal timecondition.Itcanbeusedinoff roadingvehicles.Thefollowingconclusionsareobserved:

Thesteeringhasbeendesignedtoproduceminimumturningradiusof2.2mwith101percentage.Asteeringratioof5:1is achievedalongwithlowsteeringeffort

[1] M.Poojari,B.S.Shreyas,R.Muddaiah,A.Raj,andB.S.Babu,“Design,analysisofsteeringsystemandfront suspensionforanElectricAll Terrainvehicle,”in Materials Today: Proceedings,2021,vol.46,pp.2848 2857.doi: 10.1016/j.matpr.2021.03.102.

[2] “WillamF.MillikenandDouglasF.MillikenRaceDynamicsVehicleDynamics”.

[3] Akshaypawar,andSurajZambare,“DesignofSteeringSystemforAllTerrainVehicle,”2018.

[4] S.S.KeshwaniandA.M.SurendraKumar,“REVERSEENGINEERINGOFSTEERINGSYSTEMWITHDEVELOPED EQUATIONFORSTEERANGLE,”2012.

[5] MalikN,AgarwalPandRajputA,“DesignandPerformanceOptimizationoftheSteeringSystemofavehicle,” Trans Stellar, 2017.[Online].Available:www.tjprc.org

[6] V.Saini,S.Kumar,A.KumarShakya,andH.Mishra,“DesignMethodologyofSteeringSystemforAll Terrain Vehicles,” International Research Journal of Engineering and Technology,2017,[Online].Available:www.irjet.net

[7] M.Kshitij et al.,“Design&AnalysisoftheSteeringSystemforAll TerrainVehicle,”2019.[Online].Available: www.ijsrd.com

[8] H.H.KumarB,C.Byrappa,andA.Professor,“ModelingFiniteElementAnalysisAndWeightOptimizationSteering Arm,”2012.[Online].Available:www.ijedr.org

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[9] P.L.Agrawal,S.S.Patel,andS.R.Parmar,“DesignandSimulationofManualRackandPinionSteeringSystem,”vol. 2,2016,[Online].Available:www.ijsart.com

[10] S.Chaudhary,G.K.Kantak,P.Sharma,andH.Mathur,“DesignAnalysisandFabricationofM BAJAATV2020,”2020. [Online].Available:www.erpublication.org

Barani M

HeispursuingthirdyearBachelor MechanicalinKumaraguruCollege ofTechnology,Coimbatoreandhe is captain of Electrical Baja Team E BLITZfortheyear2022 2023

Rakul P R

HeispursuingthirdyearBachelor MechanicalinKumaraguruCollege ofTechnology,Coimbatore

Mohammed Thoufeek M

HeispursuingthirdyearBachelor MechanicalinKumaraguruCollege ofTechnology,Coimbatore

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal