International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

T B DAYANANDA1 , MANJUNATH N2, THARUN M T3, VEERABHADRASWAMY R4, YASHWANTH KUMAR V M5 .

1Associate professor. Department of EEE, Dr. AIT, Bengaluru Karnataka 560056,India 2,3,4,5 Students, Department of EEE, Dr. AIT, Bengaluru Karnataka 560056,India ***

ABSTRACT: At present, industries are rapidly shifting towards automation. Today’s industrial automations mostly based on programmable controllers and robots. In order to do the tedious work and to serve the mankind, automation is developed in industries. DC motor plays an important role in various industries hence we selected it. This project present a system to provide protection, control and monitoring the condition of DC motor. Here Arduino Uno and various sensors like current, voltage, speed and temperature sensors are used. Real time values of various parameters like current, voltage, temperature and speed can be monitored in ThingSpeak mobile app. By continuous monitoring, the motor can be protected against fault like short circuits, overloading, overheating etc. hence machine performance is improved.

Keywords: IoT, Arduino Uno, Node MCU, DC motor, LCD, Fault, etc.

Nowadaysthereisadvancementintechnologies,inordertoreducethemanpowerinindustries,theindustriesareshifted towardsautomation.DCmotorsareusedinvariousindustriesbecauseoftheirsmallsizeandhighenergyoutput.Themanual controlofmotorindifferentareasofanindustryfortheswitchONorOFFistimeconsumingandinconvenienthereaneffortis madetocontrolautomatically.Protectionormaintenanceisalsoveryimportantaspectforthesmoothoperationofmotorinan industry.ThemonitoringofseveralParametersofmotorlikevoltage,current,temperatureandspeedetc.byhumanisvery time consuming process. These problems are studied and developed a remote project as solution called IOT BASED ELECTRICALMOTORCONTROLANDMONITORING.Inthispaper,acosteffectiveprotectionandcontrolsystemhasbeen developedforDCmotorswhichcanbeusedinpractice.

Inthemotorprotectionscheme,therespectivesensorsprovideaccurateandprecisionintimationSoastoprotect themotor underabnormalconditionlikeprotectionagainstoverheating,overcurrentandvoltagefluctuations.

Realtimevaluesofseveralparameterslikevoltage,current,temperatureandspeedaresensedbysensorsanduploadedtothe ThingSpeakapplicationusingNodeMCUwhichgivesusfeatureofrealtimemonitoringofmotorfrommobiledevice.The valuesarecomparedwithdefaultvaluestodeterminetheconditionofthemotor.

Inthisproject,wehaveinterfacedvarioussensorswiththeArduinoUno,NodeMCUandthemotortocollectdataofthevarious parameterslikevoltage,current,temperatureandspeedtoknowtheconditionofthemotorandalsogiveprotectionagainst overvoltage,undervoltage,overloadandthermaloverloadingbyprovidingprogramforthat,soifthemotorcrossesthe predefinedvalueofcurrent,voltageandtemperaturebysomefaultitwillgetautomaticallyturnoffandthealarmgivessignal ontheapplication.Alsowecanturnon/offmotorbybuttonplacedintheapplication.Blockdiagram,andresultsarediscussed below.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

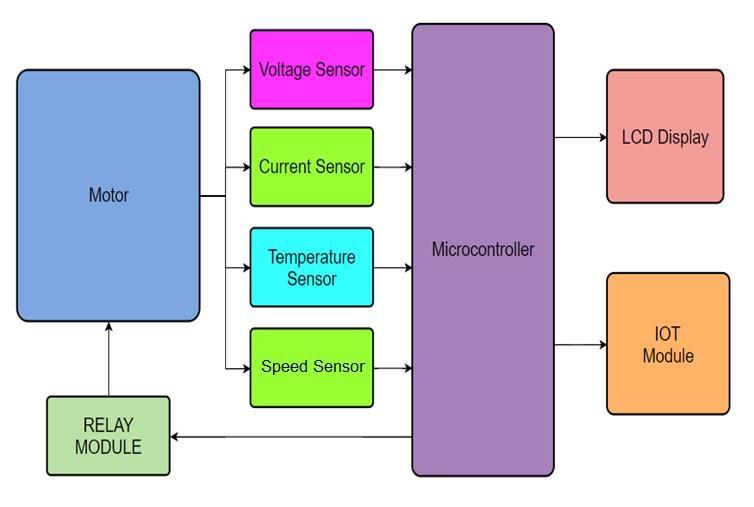

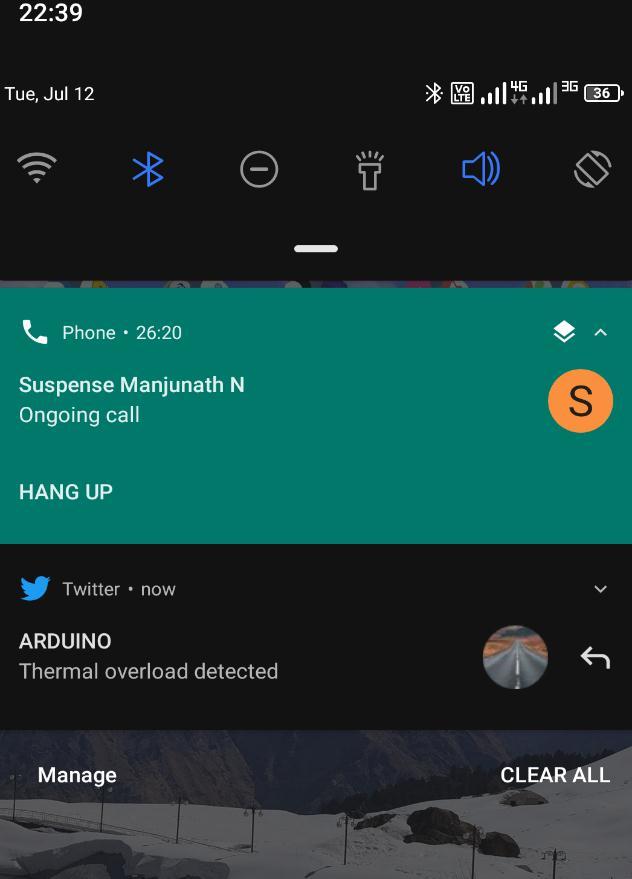

Inthisprojectwork,thevoltagesensorisusedtoreadthevoltagevalue.Thecurrentsensorisusedtoreadthecurrentvalue, temperaturesensorisusedtomeasurethetemperatureoftheDCmotor.Thespeedsensorisusedtomonitorthespeedofthe motor.ThesignalfromtheabovementionedsensorsisprocessedbytheArduinounowiththepredefinedvalues.TheNode MCUisusedtotransmittherealtimedatatoanapplicationforremotemonitoring.IfthevaluesofanyparametersoftheDC motor is not within the predefined value then specific abnormality will be triggered and the motor will shut down automatically.LCDdisplayisusedtodisplaytheparametersofthemotoronthespotandusingNodeMCUtheabnormality conditionisnotifiedtothelinkedmobiledevices.

RemotemonitoringisdoneusingNodeMCUwhichhasinbuiltWi Fi.WhichisinterfacedwithArduinoUnoforsensordata whichcanbeusedtolinktoThingsSpeakmobileapplication.Bythiswayrealtimemonitoringcanbeachieved.

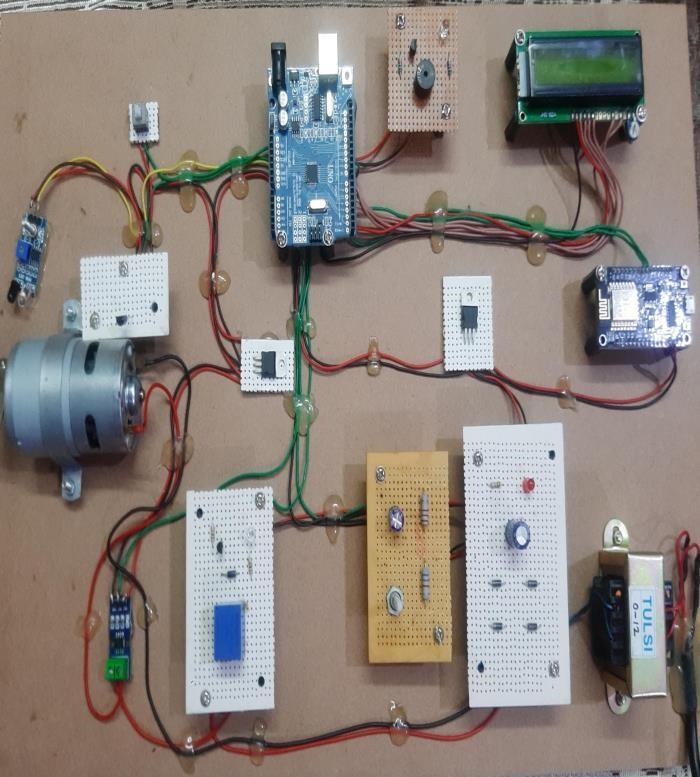

Fig 2: Hardware Model

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

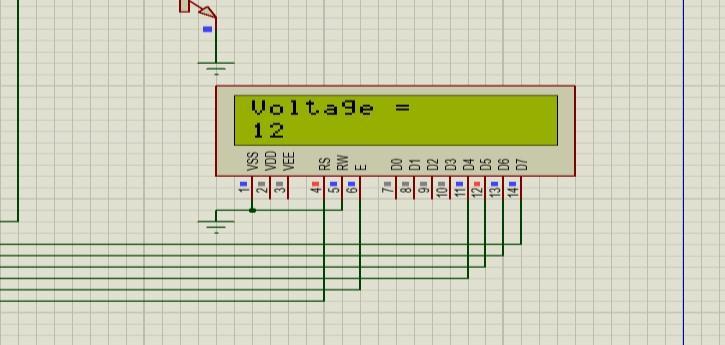

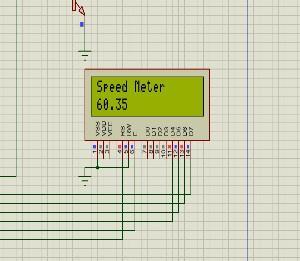

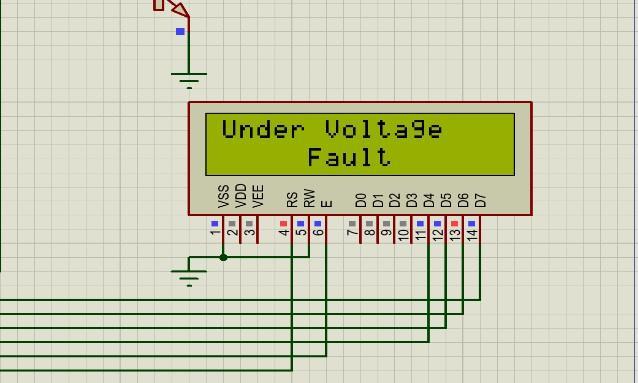

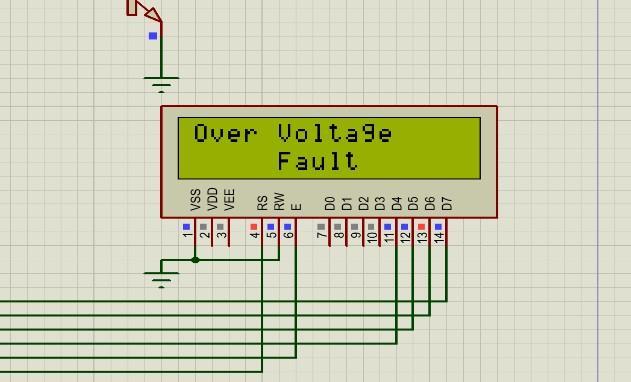

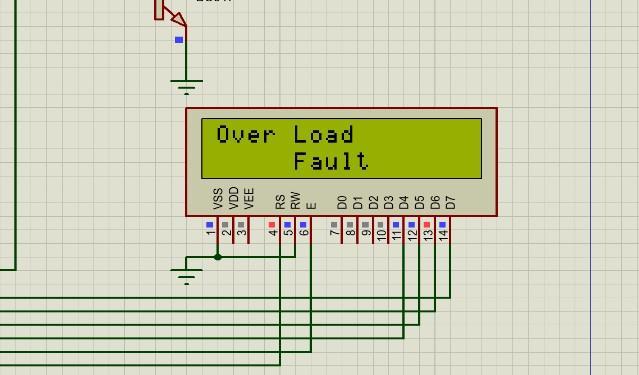

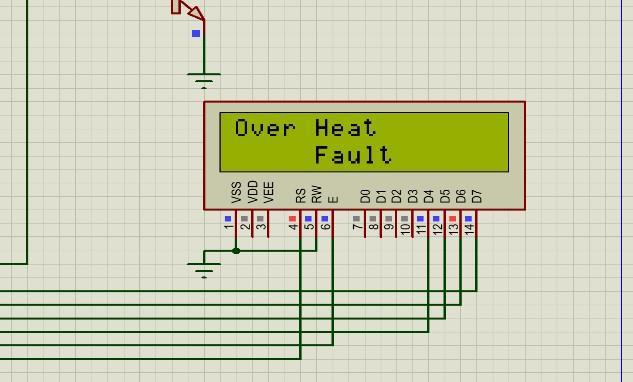

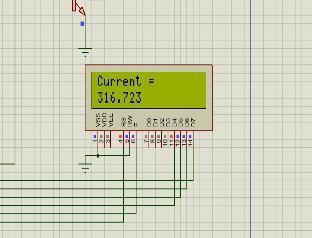

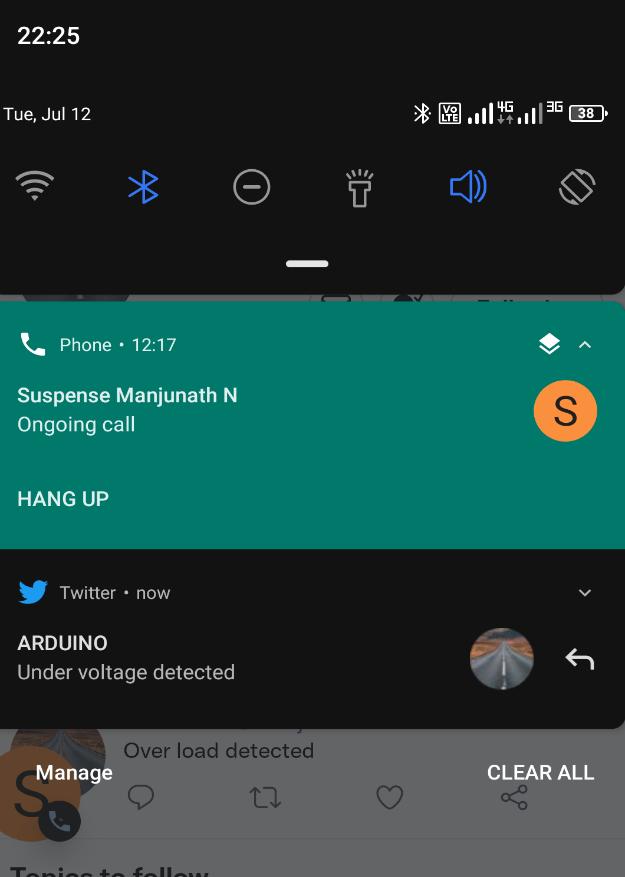

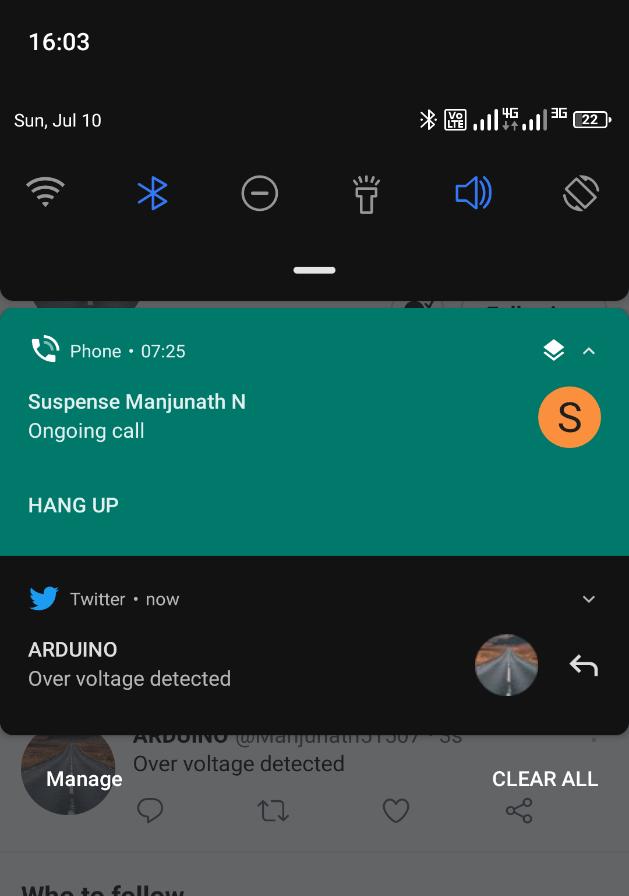

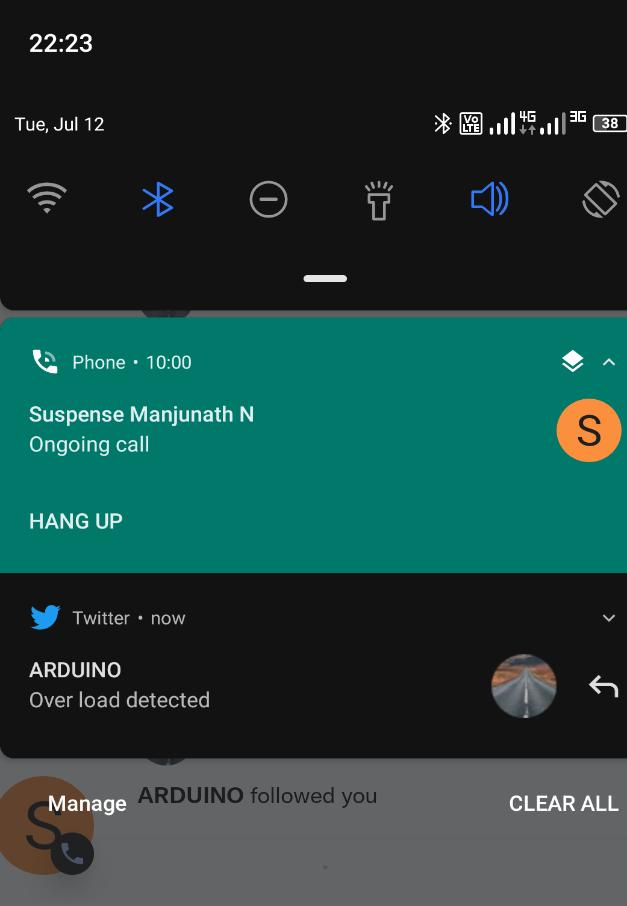

Inthisprojectthe predefinedvaluesofvariousparameters were,ifcurrentexceeds1900mAthenoverloadconditionis triggered, if voltage exceeds 14V then over voltage condition is triggered, if voltage goes below 11V then under voltage condition is triggered, if temperature exceeds 35°c then thermal overload condition is triggered. Speed sensor is used to monitorthespeedofthemotor.InallthesecasesthealarmistriggeredtheconditionofmotorisdisplayedusingLCDdisplay. Andtheparametersofthemotorarealsomonitoredusingmobileapplication.

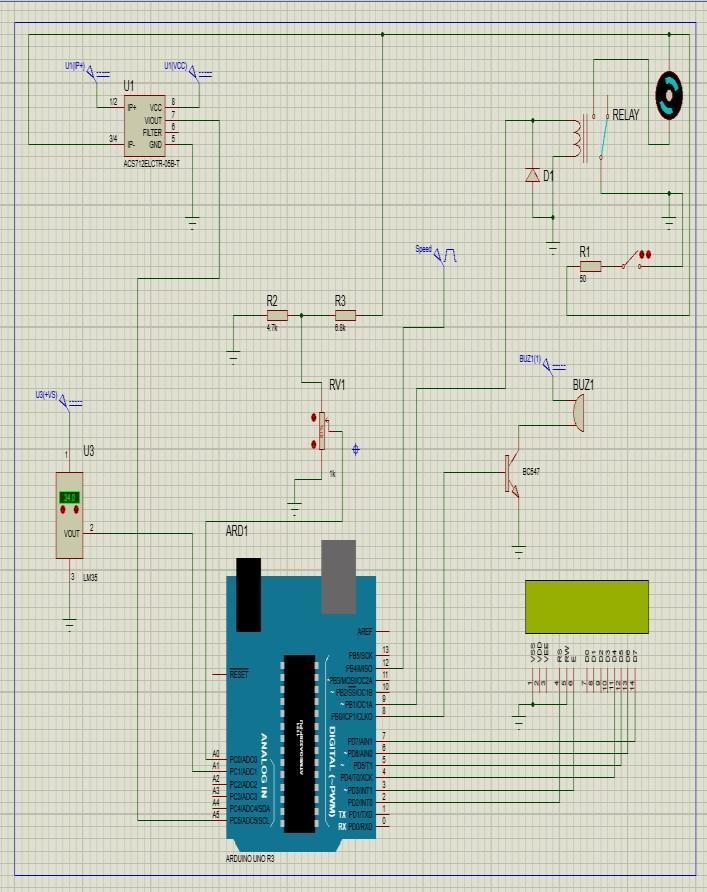

Fig 3: Simulation Setup

ThisisthesimulationsetupwehavedoneintheProteussoftware.Andwehavesetthepredefinedvaluesto

1 Above35Cthermaloverloadfault. 2 Above12Vovervoltagefault. 3 Below9Vundervoltagefault. 4 Above400mAoverloadfault

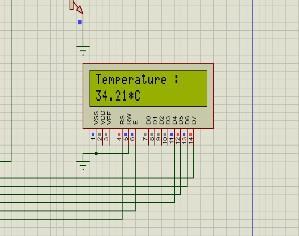

Fig 4: Temperature reading is displayed

Fig 5: Voltage reading is displayed

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Fig 6: Current reading is displayed

Fig 7: Speed (RPM) reading is displayed

Fig 8: Over heat fault is displayed

Fig 9: Under voltage fault is displayed

Fig 10: Over voltage fault is displayed

Fig 11: Over load fault is displayed

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Inthisproject,asystemintroducedthatcanprotect,controlandmonitoraDCmotorthroughmobileapplicationusingArduino UnoandNodeMCU.Variousparameterslikecurrent,voltagetemperatureandspeedandtheirreal timevaluescanobserved on the screen. Protection against the overload, overvoltage, under voltage and overheating is achieved. Also we have successfullycompletedsimulationpartofthisproject.

[1] S.U.PRABHA,S.PAVITHRA,International ResearchJournalofEngineeringand Technology(IRJET)e ISSN:2395 0056 Volume:07Issue:03,April 2020.

[2] JYOTHIBGADADE,BE.StudentDept.of ElectricalEng.,S.BPatilcollegeof engineering,Maharashtra,India, (IRJET V5I5666)eISSN:2395 0056,May 2018.

[3] PREETHI.R,DHIVYA.N,Knowledgeinstituteoftechnology,Kakapalayam,Salem,(IRJET V2I6189)e ISSN:2395 0056, September 2015.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |