International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Department of Mechanical Engineering (Trinity Institute of Technology and Research, RGPV Bhopal) (Kokta Bypass Rd, Near Hindustan Petrol Pump, Patel Nagar, Bhopal, Madhya Pradesh 462021) ***

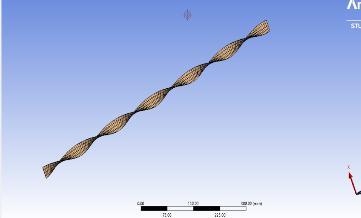

Abstract - A well-planned heat exchanger works on enhancing the effectiveness of the heat exchanger. In this study, the shell and tube type heat exchanger has been considered under the CFD modelling and the twisted tape insert has been attached within its flowing channel for creating turbulence to improve the rate of heat transfer without using any external source of energy. In addition, the nanofluid has been added as a coolant for enhancing the coefficient of heat transfer with zero input. This passive method of heat transfer has resulted in improved heat transfer characteristics of the studied heat exchanger.

Keywords Shell and Tube Heat Exchanger; Twisted Tape Insert; Nanofluid; Thermal analysis.

Heat exchanger is a mechanical device that reuses the heatenergy presentinthe workingfluid. The shell and tube are a versatile heat exchanger due to its flexibility in design and is commonly used in many industries for cooling of turbine and compressor, oil industries, for refrigeration and air conditioner etc. It consists of many numbers of tubes enclosed inside a shell. The twisted tape inserts have been utilizing by the worldwide researchers for increasing the rate of heat transfer as a passive technique. These inserts could be of many shapes such as elliptical, square and triangular etc. There are some embossing operations also whichareusedtocreate discontinuitiesforproducing more turbulence in the flowing fluid stream. Today, successive utilizationofvariousmetal nanoparticlesinventuresis self evident. One of the utilizations of these particles is in heat move science. The utilization of nanoparticles with high warm limit could bring about an addition of warm conductivityofthenanofluid.

TheAluminum Oxide(Al2O3)with waterasa basefluid is used inside the shell side for improvement in rate of heat transferduetoitscumulativecontributioninhigherthermal

conductivity. Double distilled water is used to prepare the nanofluidandSodiumDodecylSulphateisusedassurfactant toincreasethestabilityofthenano fluid.Thehotfluidflows inside the tube side and the cold fluid i.e., water with nano particles concentration, flows through shell side. The shell sideflowratehasbeenvariedfrom1lpmto5lpmandtube sideflowratehasbeenkept constantas1lpm.Theanalysis hasbeendoneforallthecasestofindthemosteffectiveone. The outlet temperature of the tube and shell side and effectivenessofheatexchangerhasalsobeencalculatedand presentedgraphicallyinthisresearchwork.

Sahaetal.[1]examinedtheintensitymoveofstreamand strain drop qualities inside a round tube with wound tape components, tentatively. Chun et al. [2] concentrated on the impact of nanofluid on the intensity move inside a twofold line heat exchanger in laminar stream, tentatively. They sortedoutthat,thelevelofvolumepartofnanoparticlesand calculation of particles is the major figure heat move improvement.DateandSaha[3]examineddevelopedstream inside a cylinder with long wound tape and sorted out that, bydiminishingcontortedbreadthandmakingmorecourses, hugethermohydraulicexecutioncanbegotten.Wenetal.[4] researchedthenanofluidinsideacylinder,tentatively.That's what they proclaimed, by expanding the volume part of nanoparticles, the hydrodynamics entrance length diminishes, and the warm entry length upgrades. Sharma et al. [5] concentrated on a round tube with wound tape and showed that water Al2O3 nanofluid upgrades the intensity move with the expansion of Reynolds number and nanoparticle focus. Murugesan et al. [6] examined the contactvariableofatwofoldlineheatexchangerwithsquare bent tapes and straightforward turned tape with water as a functioning liquid, tentatively. They reasoned that the upsides of Nusselt number and erosion calculate tubes with square curved tapes are higher than the cylinder (without bent tapes) and cylinders with essentially contorted tapes. Jaisankar et al. [7] concentrated on the intensity move, grinding component, and warm execution of a sun powered water radiator with wound tapes with various turned

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

proportions, tentatively. They sorted out that the intensity move coefficient in tubes with contorted tapes (from left to right) is superior to the cylinder (without turned tapes). Salman et al. [8] concentrated on heat move of rotational stream by utilizing CFD reproduction and showed that the increment of intensity move and grating variable in the cylinder with two way thick tape has an immediate relationship with the decrease of curved proportion and shear profundity. The presence of a bent tape tube causes the improvement of intensity move and Nusselt number, which is because of the making of vortices destructing the limitlayer.Salmanetal.[9]exploredtheintensitymoveand gratingelementofnanofluidstreaminsidearoundtubewith curved tapes by utilizing CFD technique. They showed that intensity move and contact factor upgrade with the expansionofturnsanddecreaseofshearprofundityoftapes. Jafaryar et al. [10] concentrated on the intensity move upgrade inside a contorted tape tube with an elective pivot and uncovered that, by expanding the turned point, temperature slope (because of the improvement of optional stream) upgrades, however pressure diminishes. They additionally sorted out that, by expanding the curved point, the Nusselt number improves. Tusar et al. [11] researched the stream and intensity move characteristics through a cylinder with curved tape embeds, mathematically. Liang et al. [12] analyzed the impact of the middle tightened wavy tape embed on the warm execution of laminar stream in a line. Abolarin et al. [13] researched the intensity move qualitiesinaroundaboutcylinderwithwoundtape.Wanget al. [14] played out a mathematical reproduction to examine the intensity move performance in the round tube with the vortex generator. Yang et al. [15] completed a mathematical recreation on the shell side of a shell and cylinder heat exchanger. They proposed the ideal calculation of bent taps to accomplish the most elevated warm water driven execution.

Furthermore, Geete et al. [16] worked on a shell spiral heat exchanger, the performance of constructed heat exchanger at different flow rates and inlet temperatures of hot and cold fluids, shows the highest achievable effectiveness of 0.988. Gupta et al. [17] reviewed the forced convection heat transfer characteristics with different nanofluids based on experimental investigations with constant heat flux, constant wall temperature boundary conditions and in heat exchangers is presented. Nanofluids demonstrateanimprovedheattransfercoefficientcompared to its base fluid. Further it increases significantly with increasing concentration of nanoparticles as well as Reynolds number. Gupta et al. [18] observed that energy saving is the major challenge for people now these days becauseofthedepletingfossilsfuelsdaybyday.Shell&tube heat exchanger is used in many industrial applications such

asrenewableenergy,aviationindustry,automobileindustry, oil, and gas industry and many more for energy conversion atreducedcost without any environmental effects.Liu et al. [19] experimental investigation results shows that nanofluids with low concentration of Cu, CuO, or carbon nanotube (CNT) have considerably higher thermal conductivity than identical base liquids. Moorthy & Srinivas [20] findings of the anticorrosive properties and enhanced heat transfer properties of carboxylated water based nanofluids. The stability of nanofluid is greater with carboxylated water rather than normal water. Qi et al. [21] analyzesflowandheattransfercharacteristicsofTiO2 water nanofluids with different nanoparticle mass fractions in a spirally fluted tube and a smooth tube are experimentally investigatedatdifferentReynoldsnumbers.TheeffectsofpH valuesanddosesofdispersantagentonthestabilityofTiO2 water nanofluids are discussed. It is found that there is a larger increase in heat transfer and a smaller increase in frictional resistance coefficients for turbulent flow than that for laminar flow of TiO2 water nanofluids in the spirally fluted tube. Teng et al. [22] analyze the characteristics of alumina (Al2O3)/water nanofluid to determine the feasibility of its application in an air cooled heat exchanger for heat dissipation for PEMFC or electronic chip cooling. Experimental results show that the nanofluid has a higher heat exchange capacity than water, and a higher concentrationofnanoparticlesprovidesanevenbetterratio of the heat exchanger. W. He et al. [23] investigated the effectsofthenanofluidandtwistedtapeontheheattransfer characteristics of the heat exchanger and suggested to use variations in the concentration of the nanofluids and nano particles.

ThisarticleisfocusedonCFDanalysisofthedoublepipe heat exchanger with twisted tape insert by using Al2O3 as nanofluid particle with water as a base fluid In [22], the researcherhasanalyzedthecharacteristicsof(Al2O3)/water nanofluid for its feasibility to use in heat exchanger. It has been observed that very few work has been done by using the(Al2O3)/waternanofluidwithtwistedtapeinsert.There can be variation of nanofluid concentration along with the use of twisted tape insert. Under the CFD analysis the meshing creates the complexity due to finite element analysis and it becomes difficult to compute the results and while doing variation on meshing can also alter the results. Here this research work can be carried out to do the CFD experimentation for twisted tape insert. Furthermore, the shell and tube heat exchanger can be considered for this research and can check either its versatility is useful for the nanofluid with twisted tape insert or not. And also, the pressure drop needs to be examined so that it can be found

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

that in what cost of pressure drop, the supposed methodology gives better performance without using any externalsourceofenergyinput.

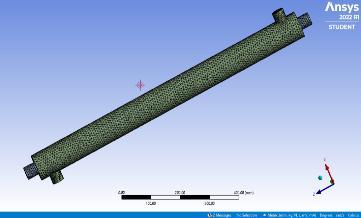

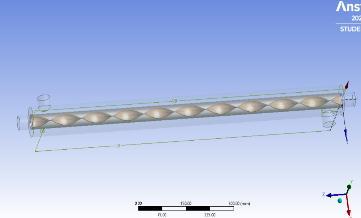

The geometry of the heat exchanger modeled on ANSYS Workbench2020withthedimensionsasbelow.

Lengthoftestsection 1000mm

Shellside 84mm

IDandODofcoldandhotfluid 40mm

TubeOD 42mm

TubeID 40mm

Numberofturnsoftwistedtapeinsert 4

Nanofluidused Al2O3

The materials used are aluminum and graphene. The shell and tube are made up of aluminum The tube side is filledwithhotfluidandtheshellsideisfilledwithcoldfluid.

Essential overseeing conditions like force condition, energy condition, and the progression condition are utilized in the CFD examination of shell and cylinder type heat exchangers. PRESTO plan is utilized in the coupling of tension and speed under SIMPLEC calculation. For mathematical discretization of the relative multitude of conditions, the upwindplan ofsecond requestis being used inlightofmoreprecisionthanthefirst requestupwindplan. Assembly rules for the various boundaries are unique. For congruity condition, 1.0e 05 is utilized, for speeds this way and that 1.0e 05 is utilized, for energy condition 1.0e 08 is utilized and for k and e 1.0e 05 is utilized. To arrive at the combinationesteemquick,theunwindingesteemallottedto pressureis0.3whilekand ∈are0.7andtemperatureis0.9. Massstream channel is utilized for delta of thecold and hot liquid and tension outlet is utilized for the power source of thetwoliquids.

Thehotliquid'smassstreamrateis1lpm,2lpm,3lpm, 4lpmand5lpmyetthemassstreamrateissavedsteadyfor the chilly liquid, which is 1 lpm. The temperature of cold liquiddeltais300kwhilehotliquidchannelis353k.

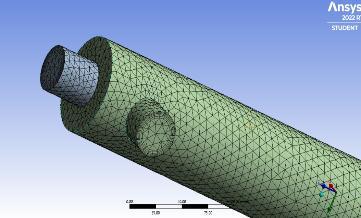

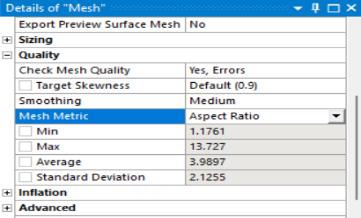

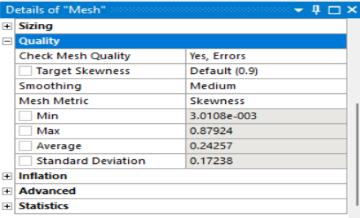

After model development of the intensity exchanger, fitting is to be finished on the model. Fitting is the method involved with disseminating surfaces into little regions. These little regions are dissected independently to track down the last arrangement. Cross section ought to be fine, and the nature of the lattice is checked by perspective proportionandskewness.Viewpointproportionoughttobe under600andskewnessoughttobeunder0.9.

The calculation has coincided with a component size of 10 mm. Expansion is given on both internal and external liquid independently to think about of no slip condition and laminar sub layer in the limit layer. Coincided math and the expansionaredisplayedinFig.1.Theprimarylayerthickness isdeterminedfromthewally+addingmachine.Thenaming of both channel and outlet of cold and hot liquid is finished for the counter progression of liquid. Limit conditions are applied on the arrangement page of Ansys 2020. Energy conditions are kept on and stream is thought to be fierce. A violent model of k epsilon is utilized. Materials properties are added for graphene and Al2O3 nanofluid. The hot liquid iswater,andthechillyliquidisnanofluid.Thematerialofthe shellandcylinderisaluminum,andthelayerofthecylinder sideisgraphene.Themassstreampaceofcoldliquidiskept fixed i.e., 1 lpm, and the mass progression of hot liquid is fluctuatedfrom1to5lpm.Emphasisisfinishedtilltheunion is reached. Every one of the information has been determined from post examination. Heat motion, the temperature of the wall and liquid, pressure drop, skin grinding coefficient, surface Nusselt number, and powerful Prandtl number are determined. Convective intensity move coefficient is determined from the standard condition of intensity move i.e., q = hdT. The liquid temperature, wall temperatureandintensitytransitionaretakenat10distinct areas each at 0.1 m. Then, at that point, a normal of the multitude of information to work out the convective intensitymovecoefficientistaken

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

strategy.And,alsofornanofluidwithouttwistedtapeinsert, theheatfluxincreasesfrom3596.57to5852.59W/m2 .

Figure2 Modelofheatexchangerwithtwistedtapeandits meshing

As shown in the figure 5, we can observe that the convective heat transfer coefficient for cold fluid that is nanofluid with twisted tape is higher for STHX followed by nanofluid and water only. The twisted tape creates turbulence in cold fluid causing to increase the convective heat transfer coefficient of nanofluid. The convective heat transfer coefficient increases from 1070.16 to 1533.01 W/m2K,and531.67to1412.48W/m2Kand379.72to700.04 W/m2Kforwaterwithoutnanofluid.

Heat Flux (Cold) With nanofluid

Heat Flux (Cold) W/o nanofluid

Heat Flux (Cold) With nanofluid and twisted plate

Heat Flux (Hot) With nanofluid Heat Flux (Hot) W/o nanofluid

Heat Flux (Hot) With nanofluid and twisted tape

Figure3 Qualityofthemesh

Terminologyused

Atvolumefraction=0.6

Nanofluiddensity(ρnf): ρnf =2727.28 kg/m3

Nanofluidspecificheat(Cpnf): Cpnf =1389.02J/kg K

Nanofluidviscosity(μnf): μnf =0.0025075kg/m s

Nanofluidthermalconductivity(Knf): Knf =5.13W/m K

Performanceanalysisofthedesignedshellandtubetype heat exchanger with twisted tape insert along with Al2O3 nanofluidisasfollows:

Heat flux is showing improvement for both nanofluid and nanofluid with twisted tape insert. Heat flux for the coolant on shell side that is, nanofluid with twisted tape insert increases from 5994.98 to 10,361.31 W/m2, which is very close to the values of hot fluid on tube side which is showing the effectiveness of the developed model and

VOLUME FLOW RATE (LPM)

Figure4 Heatfluxofhotandcoldfluid

Convective heat transfer coefficient (Cold) With nanofluid Convective heat transfer coefficient (Cold) W/o nanofluid Convective heat transfer coefficient With nanofluid and twisted plate

VOLUME FLOW RATE (LPM)

Figure5.Growthinconvectiveheattransfercoefficientof coolanti.e.,nanofluidwithandwithouttwistedtapeinsert andhotwater.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Pressure drop variation has been presented graphically in the figure 6, from which, it can be observed that the pressure drop is increasing with flow rate and also it is higher for the case of nanofluid than the water (without nanofluid) and again it becomes higher in the case of nanofluid with twisted tape. That means there is strong increasein rate ofheat transfer byusing twistedtapeinsert along with nanofluid and increasing the thermal efficiency but with the cost of pressure drop. But, if we observe, it clearly showed that the rate of heat transfer is increasing with the much bigger margin than the increase in pressure drop rate. So, it can be said that the overall efficiency of the heat exchanger has been improved with greater margin by usingthetwistedtapeinsertalongwiththenanofluid.

Convective heat transfer coefficient for cold fluid using nanofluidwithtwistedtapeinsertatflowrateof5lpmgives the highest value of 1533.01 W/m2K, while ranging from 1070.16W/m2K.

The change in velocities at the inlet and outlet for both the fluid is negligible. There is a maximum increase of 1.2 percentageinvelocities.Thisshowsthelossesinthepipeare considerable.

The Nusselt number (Nu) obtained through the calculations has been presented in the figure 7. It is to be noticedthattheNusseltnumberishighestincasewhencold fluid is nanofluid with the twisted tape insert followed by nanofluid and simple water for all the flow rates. Whereas with increasing the flow rate, the Nusselt number is also increasingcontinuouslyforalltheflowrates.Thisisshowing thatourdevelopedstrategyissuccessfulforimprovementof the rate of heat transfer of the heat exchanger by using this passivemethod.

Thenanofluidgiveshigherheatfluxwiththeincreasein the difference in mass flow rate of hot and cold fluid, whereas the combine effect of twisted tape insert and nanofluid gives a higher convective heat transfer coefficient forcoldfluid.

Thecombinedeffectoftwistedtapeinsertandnanofluid increasesthepressuredroponthecoldsidewithincreasein mass flow rate but the Nusselt number has been improved by greater margin with a little cost of pressure drop which can be minimized by using the suitable percentage of concentration of the nanofluid with cold fluid that is water. Above resultsindicates that with low pressure drop in shell sidenanofluidgiveshigherheatflux.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

PIPEHEATEXCHANGERSYSTEM,”KOREANJ.CHEM.ENG.,VOL.25, NO.5,PP.966 971,2008,DOI:10.1007/S11814 008 0156 5

[3] A. W. DATE AND S. K. SAHA, “NUMERICAL PREDICTION OF LAMINARFLOWANDHEATTRANSFERCHARACTERISTICSINATUBE FITTED WITH REGULARLY SPACED TWISTED TAPE ELEMENTS,” INT J.HEAT FLUID FLOW, VOL 11, NO 4, PP 346 354,1990, DOI:HTTPS://DOIORG/10.1016/0142 727X(90)90058 J

[4] D. WEN AND Y. DING, “EXPERIMENTAL INVESTIGATION INTO CONVECTIVE HEAT TRANSFER OF NANOFLUIDS AT THE ENTRANCE REGION UNDER LAMINAR FLOW CONDITIONS,”INT J.HEAT MASS TRANSF., VOL 47, NO 24, PP 5181 5188, 2004, DOI: HTTPS://DOIORG/10.1016/JIJHEATMASSTRANSFER.2004.07.0 12

[5] K.VSHARMA,L.S.SUNDAR, AND P.K.SARMA,“ESTIMATION OF HEAT TRANSFER COEFFICIENT AND FRICTION FACTOR IN THE TRANSITION FLOW WITH LOW VOLUME CONCENTRATION OF AL2O3 NANOFLUID FLOWING IN A CIRCULAR TUBE AND WITH TWISTEDTAPEINSERT,”INT.COMMUN.HEATMASSTRANSF.,VOL. 36, NO. 5, PP. 503 507, 2009, DOI:

HTTPS://DOIORG/10.1016/JICHEATMASSTRANSFER.2009.02. 011

[6] P. MURUGESAN, K. MAYILSAMY, AND S. SURESH, “TURBULENT HEAT TRANSFER AND PRESSURE DROP IN TUBE FITTED WITH SQUARE CUT TWISTED TAPE,” CHINESE J. CHEM ENG., VOL 18, NO 4, PP 609 617, 2010, DOI:

HTTPS://DOIORG/10.1016/S1004 9541(10)60264 9

[7] S. JAISANKAR, T. K. RADHAKRISHNAN, K. N. SHEEBA, AND S. SURESH,“EXPERIMENTALINVESTIGATIONOFHEATTRANSFERAND FRICTION FACTOR CHARACTERISTICS OF THERMOSYPHON SOLAR WATER HEATER SYSTEM FITTED WITH SPACER AT THE TRAILING EDGE OF LEFT RIGHT TWISTED TAPES,” ENERGY CONVERS. MANAG., VOL. 50, NO. 10, PP. 2638 2649, 2009, DOI: HTTPS://DOIORG/10.1016/JENCONMAN.2009.06.019

[8] S. D. SALMAN, A. A. H. KADHUM, M. S. TAKRIFF, AND A. B. MOHAMAD, “CFD ANALYSIS OF HEAT TRANSFER AND FRICTION FACTOR CHARACTERISTICS IN A CIRCULAR TUBE FITTED WITH QUADRANT CUT TWISTED TAPE INSERTS,” MATH PROBL ENG., VOL 2013,P 273764,2013,DOI:10.1155/2013/273764.

[9] S. D. SALMAN, A. A. H. KADHUM, M. S. TAKRIFF, AND A. B. MOHAMAD, “HEAT TRANSFER ENHANCEMENT OF LAMINAR NANOFLUIDS FLOW IN A CIRCULAR TUBE FITTED WITH PARABOLIC CUT TWISTED TAPE INSERTS,” SCI WORLD J., VOL 2014,P 543231,2014,DOI:10.1155/2014/543231.

[10] M.JAFARYAR,M.SHEIKHOLESLAMI,ANDZ.LI,“CUO WATER NANOFLUID FLOW AND HEAT TRANSFER IN A HEAT EXCHANGER TUBE WITH TWISTED TAPE TURBULATOR,” POWDER TECHNOL., VOL 336, PP 131 143, 2018, DOI: HTTPS://DOIORG/10.1016/JPOWTEC.2018.05.057

[11] M. TUSAR, A. NOMAN, M. ISLAM, P. YARLAGADDA, AND B. SALAM, “CFD STUDY OF HEAT TRANSFER ENHANCEMENT AND FLUID FLOW CHARACTERISTICS OF TURBULENT FLOW THROUGH TUBE WITH TWISTED TAPE INSERTS,” ENERGY PROCEDIA, VOL 160, PP. 715 722, 2019,DOI: HTTPS://DOI.ORG/10.1016/J.EGYPRO.2019.02.188.

[12] Y. LIANG, P. LIU, N. ZHENG, F. SHAN, Z. LIU, AND W. LIU, “NUMERICAL INVESTIGATION OF HEAT TRANSFER AND FLOW CHARACTERISTICS OF LAMINAR FLOW IN A TUBE WITH CENTER TAPEREDWAVY TAPEINSERT,”APPL.THERM.ENG.,VOL.148,PP. 557 567, 2019, DOI: HTTPS://DOIORG/10.1016/JAPPLTHERMALENG.2018.11.090

[13] S. M. ABOLARIN, M. EVERTS, AND J. P. MEYER, “HEAT TRANSFER AND PRESSURE DROP CHARACTERISTICS OF ALTERNATING CLOCKWISE AND COUNTER CLOCKWISE TWISTED TAPEINSERTSINTHETRANSITIONALFLOWREGIME,”INT J.HEAT MASS TRANSF., VOL 133, PP 203 217, 2019, DOI: HTTPS://DOIORG/10.1016/JIJHEATMASSTRANSFER.2018.12.1 07.

[14] Y.WANG,P.LIU,F.SHAN,Z.LIU, AND W.LIU,“EFFECT OF LONGITUDINAL VORTEX GENERATOR ON THE HEAT TRANSFER ENHANCEMENT OF A CIRCULAR TUBE,”APPL THERM ENG., VOL 148, PP. 1018 1028, 2019, DOI: HTTPS://DOI.ORG/10.1016/J.APPLTHERMALENG.2018.11.080.

[15] D. YANG, T. S. KHAN, E. AL HAJRI, Z. H. AYUB, AND A. H. AYUB, “GEOMETRIC OPTIMIZATION OF SHELL AND TUBE HEAT EXCHANGER WITH INTERSTITIAL TWISTED TAPES OUTSIDE THE TUBES APPLYING CFD TECHNIQUES,” APPL. THERM. ENG., VOL. 152, PP 559 572, 2019, DOI: HTTPS://DOIORG/10.1016/JAPPLTHERMALENG.2019.01.113

[16] A. GEETE, A.BHATTACHARJEE,A. PATWA, AND K. PANDEY, “ENTROPY, EXERGY AND ENTRANSY ANALYSES ON FABRICATED SHELLANDSPIRALTUBEHEATEXCHANGER,”J.INST ENG SER C, VOL 102,NO 4,PP 897 908,2021

[17] M. GUPTA, N. ARORA, R. KUMAR, S. KUMAR, AND N. DILBAGHI, “A COMPREHENSIVE REVIEW OF EXPERIMENTAL INVESTIGATIONS OF FORCED CONVECTIVE HEAT TRANSFER CHARACTERISTICS FOR VARIOUS NANOFLUIDS,” INT J. MECH MATER ENG.,VOL 9,NO 1,PP 1 21,2014.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[18] S. K. GUPTA, S. GUPTA, AND R. SINGH, “A COMPREHENSIVE REVIEWOFENERGYSAVINGINSHELL&TUBEHEATEXCHANGERBY UTILIZATION OF NANOFLUIDS,” MATER TODAY PROC., VOL 50, PP 1818 1826, 2022, DOI: HTTPS://DOIORG/10.1016/JMATPR.2021.09.212

[19] M. LIU, M. C. LIN, AND C. WANG, “ENHANCEMENTS OF THERMAL CONDUCTIVITIES WITH CU, CUO, AND CARBON NANOTUBE NANOFLUIDS AND APPLICATION OF MWNT/WATER NANOFLUID ON A WATER CHILLER SYSTEM,” NANOSCALE RES LETT.,VOL.6,NO.1,PP.1 13,2011.

[20] C. V. MOORTHY AND V. SRINIVAS, “CORROSION AND HEAT TRANSFER CHARACTERISTICS OF WATER DISPERSED WITH CARBOXYLATE ADDITIVES AND MULTI WALLED CARBON NANO TUBES,”J.INST ENG SER C,VOL 97,NO 4,PP 569 577,2016.

[21] C.QI,C.LI, AND G.WANG,“EXPERIMENTAL STUDY ON THE FLOW AND HEAT TRANSFER CHARACTERISTICS OF TIO2 WATER NANOFLUIDS IN A SPIRALLY FLUTED TUBE,” NANOSCALE RES LETT., VOL 12, NO 1, P 516, 2017, DOI: 10.1186/S11671 017 2284 5.

[22] T. P. TENG, Y. H. HUNG, T. C. TENG, AND J. H. CHEN, “PERFORMANCE EVALUATION ON AN AIR COOLED HEAT EXCHANGER FOR ALUMINA NANOFLUID UNDER LAMINAR FLOW,” NANOSCALERES.LETT.,VOL.6,NO.1,PP.1 11,2011.

[23] W. HE, D. TOGHRAIE, A. LOTFIPOUR, F. POURFATTAH, A. KARIMIPOUR, AND M. AFRAND, “EFFECT OF TWISTED TAPE INSERTS AND NANOFLUID ON FLOW FIELD AND HEAT TRANSFER CHARACTERISTICS IN A TUBE,” INT. COMMUN. HEAT MASS TRANSF., VOL. 110, P. 104440, 2020, DOI: HTTPS://DOIORG/10.1016/JICHEATMASSTRANSFER.2019.104 440.