International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

K.VARSHASRI. 1 , A.KALPANA2 A.ANIL3 B.BABY4

1,P.G Student , Annamacharya Institute of Technology and Sciences ,Tirupati,India 2,3,4Assitant Professor , Annamacharya Institute of Technology and Sciences ,Tirupati,India ***

Abstract Environmental contamination is the world's most serious concern today. The manufacture of Portland cement, in particular, results in the emission of pollutants such as CO2, resulting in environmental contamination in the construction industry. By increasing the use of by products from industries in our construction industry, we can lessen the polluting effect on the environment. Geopolymer brick is an innovation in the brick business that is mostly made from industrial by products such as fly ash and GGBS, resulting in lower pollution levels. Experiments on Geopolymer bricks manufactured with fly ash and GGBS as source materials and river sand as fine aggregates, and a solution of sodium hydroxide (NaOH) and sodium silicate (Na2SiO3) as an activator were carried out in this study. For all of the mixtures, the molarity of sodium hydroxide was kept constant at 1M, and the ratio of sodium silicate to sodium hydroxide solution was varied between 1, 0.5and 2. The dimensions of the brick examples are 230mm x 110mm x 70mm. The test specimens were put through their paces in terms of compressive strength, water absorption, and efflorescence. After 3 and 7 days of ambient room temperature curing, the compressive strength and weight of geopolymer bricks were determined. At all ages, the weight and compressive strength of bricks as the ratio of SSS to SHS was increased, and the strength of geopolymer bricks is imparted by sodium silicate solution. By The study's purpose was to reduce or reuse industrial wastes to protect the environment, as well as to increase low cost bricks for the construction industry's long term growth.

Key Words: CLASS-F FLYASH,GGBS(Ground Granulated Blast Slag),Sodium Silicate Solutions(SSS), Sodium Hydroxide Pellets (SHP)Wemustreplaceflyashwiththeotherbinderswhichhave no negative environmental impact to manufacture environmentallyfriendlybricks Thermalpowerplantscan be used as binders to assist relieve the problem. The new geopolymerbricktechniqueisapossibletechniqueinthis area. Geopolymer technology can reduce CO2 emissions fromtheflyashandGGBSsectors,whichcouldhelptoavert global warming. Additionally, proper industrial waste disposalcancontributetothereductionofrubbishdischarge intotheatmosphere.

Inorganicgeopolymers,suchaszealots,arealumina silicate (Si O Al) based ceramic materials. When an alkaline

activated solution combines with silica and alumina minerals, a tri polymeric long chain with an amorphous coordinatecovalentnetworkisproduced.Polymerresearch encompasses all aspects of chemistry, engineering, and polymer science. The two types of polymers are organic (carbon based)andinorganicpolymers(Ex.Silicon based). The three types of organic polymers include natural polymers(rubber,cellulose,etc.),chemicallymanufactured polymers (textile fibers, plastics, films, etc.), and natural biopolymers(biology,medicine,etc.).Thetermgeopolymer referstothegeologicallyproducedrawmaterialsusedinthe fabricationofsilicon basedpolymers.

Class F fly ash contains a lot of silica and alumina. The massiveconcentrationofsilicaandaluminainflyash(class F) combines with alkali activated sodium hydroxide and sodium silicate pre mixed solution when used to create bricks.Thischemical activityproducesa gel thatactsasa binder,eliminatingtheneedforcementinthebrick making process.

STUDY ON THE BEHAVIOR OF GEOPOLYMER BRICKS UNDER DIFFERENT CURING TEMPERATURES AND ALKALINESOLUTIONCONCENTRATIONS.

Issue:07Nov2020

Authors: .S.Sasikumar, Dr. M. Natarajan, Dr. N. Balasundaram,Dr.V.Karthik

Geopolymer bricks could be a viable alternative to traditionalclaybricks.GPBspecimensmadewithClassFfly ashhadgreaterpowerratingsthanthosemadewithClassC flyash.Itwaspreviouslydeterminedthatthebestresultsare obtainedusinga10Malkalinesolutionanda600Cwarmair oven curing temperature. Beyond 10M, the strength attribute has no greater effects than alternative concentrationsandraisestheGPBcharge.ThepowerofGPB mixesgrowsasthecuringtemperaturerises,however,900C does,notyieldworkableresults.

EXPERIMENTAL STUDY ON THE BEHAVIOUR OF GEOPOLYMERBRICKSIssue:02Feb2018

Authors:PavithraN,DivyaG,SuganthiM,OmprakashS.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

The goal of this paper is to learn more about the sturdinessandstrengthofbricksmadeusingtypeF flyash,slag,metakaolin,andquarrydust.

Slag(tenpercent)andquarrydust(35percentto30 percent,60percentto40percent)arereplacedwith up to 20% white metakaolin and chemical compoundsinthisprocess(sodiumhydroxideand sodiumsilicate).

Incontrasttotypicalclaybricksandflyashbricks, geopolymerbrickscanbemadeusinglowcalcium flyashandmolaritiesthatprovideenoughstrength.

It is clear from the statement that using 15% metakaolinprovideshighercompressiveenergyon theseventhdayofcheckingout,i.e.10.11N/mm2 .

Andtheresultsofcompressivestrengthatthe14and28th daysindicatethatthemostenergyofcompressivestrength is found at 15% of metakaolin. 15.405 N/mm2 and 23.66 N/mm2,respectively.

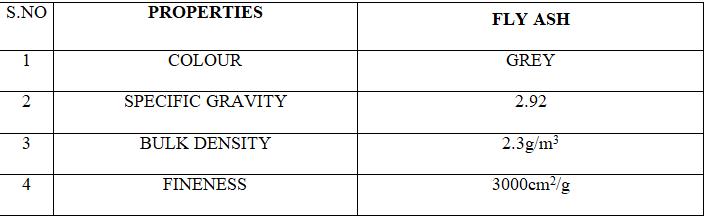

Fly ash is a thin grey powder made up primarily of spherical, glassy particles that is a byproduct of coal fired power plants. Mineral impurities in coal (clay, feldspar, quartz,andshale)fuseinsuspensionduringburningandare carried out of the combustion chamber with the exhaust gases. The fused material cools and hardens as it rises, formingsphericalglassyparticlesknownasflyash.ClassFfly ashwasusedinthisprojectbecauseithasself cementingand pozzolanicqualities.Thechemicalandmineralelementsoffly ashdetermineitscolor.Thcolorenceoflimecontentmaterial within the fly ash imparts tan and mild hues, whilst the presenceofironcontentmaterialimpartsabrownishshade.

Groundgranulatedblastfurnaceslag(GGBS)isabyproduct ofironproductionthatincreasestheworkability,strength, anddurabilityofconcretewhenaddedtoit.Thissubstance ismadebyheatingironore,limestone,andcoketoaround 1500degreesCelsius.Inablastfurnace,theprocessofGGBS does not form directly. Molten iron and molten slag are byproductsofironproduction.Themoltenslagcomprises silicaandalumina,aswellasoxidesinsmallamounts.

Aftercooling,theslagisgranulated.Itispermittedtopass throughhigh pressurewatertoaccomplishthis.Thiscauses theparticlestoquench,resultingingranuleswithadiameter oflessthan5mm.Itisthendriedandprocessedintoafine powder in a spinning ball mill, resulting in ground granulatedblastfurnaceslag. Fig No 3.2: GGBS

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

3.4

Ratio(Flyash/GGB S)%

MOLARITY RATIO (SODIUM SILICATE/SODIUM HYDROXIDE)

95:5 1 0.5 90:10 1 0.5 80:20 1 0.5 95:5 1 1 90:10 1 1 80:20 1 1 95:5 1 2 90:10 1 2 80:20 1 2

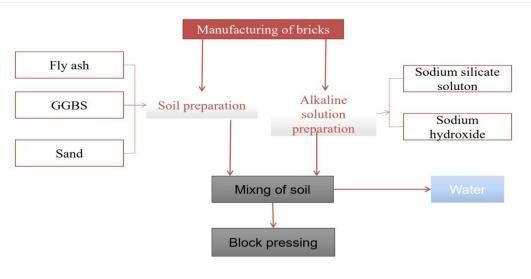

In this process, Rangan’s method was governed for manufacturingbricks.Thealkalinesolution,onedaybefore mixingthematerialsalkalinesolutionhastobedonewith sodium silicate solution and sodium hydroxide solution which work as an activator in geopolymer bricks manufacturing. After one day of alkaline solution preparation,soilpreparationhastobepreparedbydifferent proportionsofflyashandGGBSlike95 5%,90 10%,and 80 20%.Herethealkalinesolutionisaddedtothesoilmix. Afterthemixing,applygreasetothemoldsandthenfilled withthemixturewithpropercompactiontoremoveairgaps. Here230mmx110mmx70mmsizeofmoldsareused.

As per IS 3495 ( Part 1): 1992 Compressive strength is a material'sorastructure'sabilitytosustainpushingforces thataredirectedaxially.Brickswithdimensionsof230mm x110mmx70mmwerecast,andspecimensweretestedfor compressivestrengthafterthreedays.Theloadisappliedto thebricks,andwherethefailureoccursisnotedasfailure load.Thespecimensarethenplacedinacompressiontesting machine.

The formula is used to calculate compressive strength. Fck=Pc/A

WherePc=loadatfailureinNA=loadedareaofbrickinmm2

Geopolymerbrickwasplacedattypicalroomtemperature duringthecuringprocess.Aftercastingforaboutoneday,the bricksaretakenoutofthemoldandleftinthechamberfor threedays.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Table No:4.1

Unit weight (kg/m3)

Compressi vetestfor 3 days (N/mm2)

Compr essive testfor 7 days (N/mm 2)

Ratio (Flyash/GG B S)%

MOLAR ITY

RATIO (SODIUM SILICATE /SODIUM HYDROXIDE)

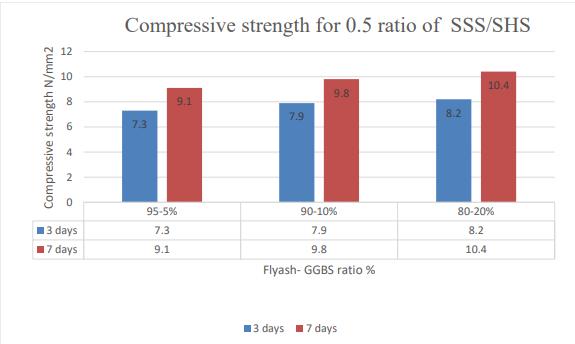

1000 7.3 9.1 95:5 1 0.5

1000 7.9 9.8 90:10 1 0.5

1000 8.2 10.4 80:20 1 0.5

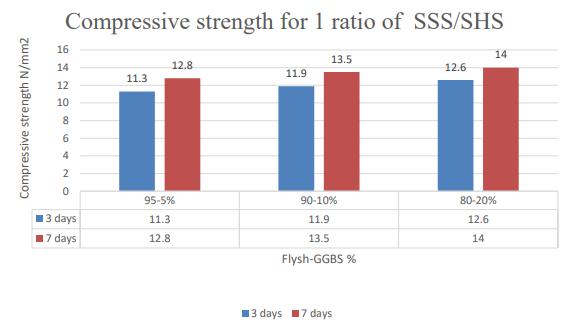

1000 11.3 12.8 95:5 1 1

1000 11.9 13.5 90:10 1 1

1000 12.6 14 80:20 1 1

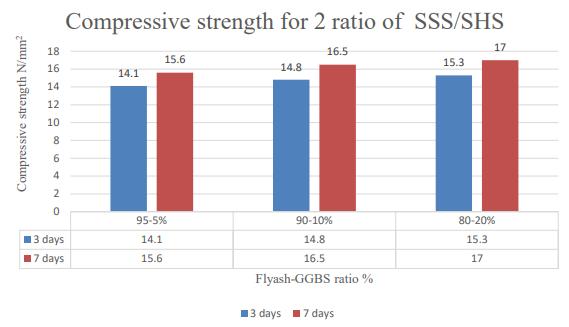

1000 14.1 15.6 95:5 1 2

1000 14.8 16.5 90:10 1 2

1000 15.3 17 80:20 1 2

Graph No 4.3: Compression strength for 2 ratio of SSS/SHS

Here the increase in the percentage of Flyash to GGBS (95 5,90 10 and 80 20%) willincreasethestrengthofthebricks

Also, the increase in the ratio of SSS/SHs willincreasethestrength.

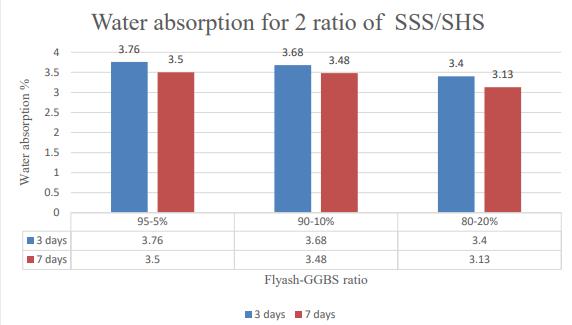

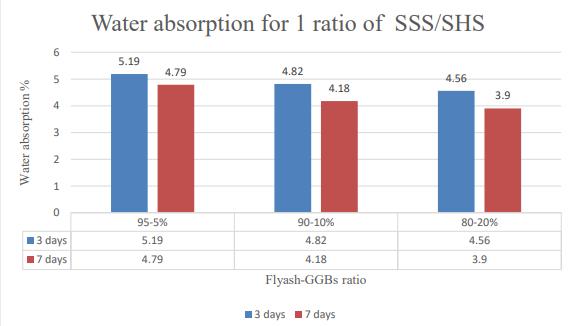

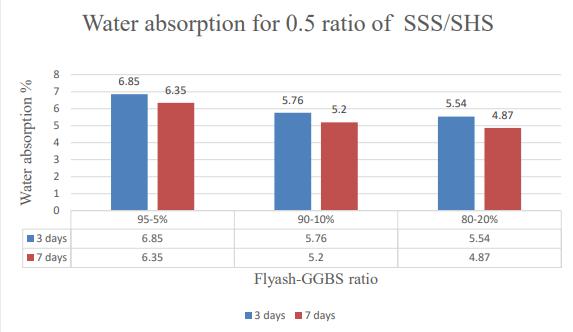

AsperIS3495(Part2):1992 Submergethespecimenin fresh and clean water for 24 hours at room temperature once it has completely dried. After 24 hours, take the specimen out of the water, wipe off the water with a dry cloth,andweighthespecimen. Weighthespecimenthree minutes after it has been taken out of the water.The following formula could be used to calculate the mass of waterthathasbeenabsorbedafter24hoursofimmersionin coldwater:(M2 M1/M1)x100

Graph No 4.1 : Compression strength for 0.5 ratio of SSS/SHS

Fig 4.2 Water absorption

Graph No 4.2: Compression strength for 1 ratio of SSS/SHS

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

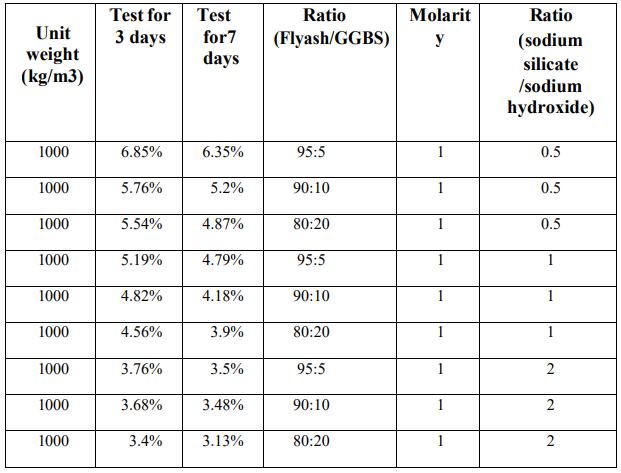

Table No:4.2

Graph No 4.4: Water absorption for ratio 0.5 of SSS/SHS

Heretheobservationshowsthatthewaterabsorptionisless than7%forallsampleswithdifferentpercentagesofflyash to GGBS (95 5, 90 10 & 80 20%) and different ratios of SSS/SHS(0.5,1&2)

The increase in the percentage of Flyash to GGBS (95 5,90 10and80 20%)willincreasethestrength of the bricks Also, the increase in the ratio of SSS/SHswillincreasethestrength.

According to IS 3495(part 1):1976, bricks' compressive strength must not be less than 7.5N/mm2 .

Theresultsofthisstudy'sobservationsindicatethat thecompressivestrengthfortheratio1ofSSS/SHS isofasufficientlyhighquality

Water absorption is less than 7% for all samples withdifferentpercentagesofflyashto GGBS(95 5, 90 10&80 20%)anddifferentratiosofSSS/SHS( 0.5,1&2).

ByincreasingtheratioofSSS/SHS&thepercentage of Flyash to GGBS the percentage of water absorption is decreasing, which increases the durabilitypropertiesofbricks.

• C.A. Hendriks1, “Emission Reduction of GreenhouseGasesfromtheCementIndustry” Greenhouse gas control technologies conferencepaper.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

• ErnstWorerell. Lynn Price, et al. “CO2 emission from the global cement industry”, Annual review of energy and the environment.Vol26:p 303 329.

• D.M.J.Sumajouw, D. Hardjito, S. Wallah, and B.V.Rangan,“.BehaviorofGeopolymerBrick ColumnsunderEqualLoadEccentricities”.

• NALloydandBVRanganCurtinUniversity of Technology, “Geopolymer Brick with Fly Ash”.

• B.VijayaRangan,DjwantoroHardjito,Steenie E.Wallah,andDodyM.J.Sumajouw,“Studies on fly ash based geopolymer brick”, Geopolymer:greenchemistryandsustainable developmentsolutions.

• Davidovits,J.(1988b).GeopolymerChemistry and Properties. Paper presented at the Geopolymer’88,FirstEuropeanConference onSoftMineralurgy,Compiegne,France.

• Warner, R. F., Rangan, B. V., Hall, A. S., &Faulkes, K. A. (1998).BrickStructures. Melbourne:Longman.

• Xu, H., & Deventer, J. S. J. V. (1999). The Geopolymerisation of NaturalAlumino Silicates.PaperpresentedattheGeopolymere ’99 International Conference,Saint Quentin, France.

• C.Banupriya,Sharonjohn,R.Suresh,E.Divya and P.Vinitha(2016). “This learn about in mostcasestargetedonuseofquarryduston changed with river sand for making geopolymerbricksandpaverblocks.”