International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1PG Student, Department of Civil Engineering, Bheema Institute of Technology and Science, Alur Road, Adoni 518301, Kurnool (Dist.), Andhra Pradesh, India.

2Associate Professor, Department of Civil Engineering, Bheema Institute of Technology and Science, Alur Road, Adoni 518301, Kurnool (Dist.), Andhra Pradesh, India. ***

Abstract The cost of building supplies today has an impact on every structure's economy. It is a key element influencing environmental housing systems all over the world. Sand will be utilized as the fine aggregate in concrete, along with traditional materials like gravel. While Robo sand (Stone dust) will be used to full replace the natural sand in concrete, GGBS is used as partial replacement of cement in concrete. In this study, M30 grade of concrete with a combinationofGGBS as partial replacement in the proportion of 0%, 10%, 20%, 30% , 40% and 50% will be replaced and Robo sand (stone dust) as fine aggregate with a full 100% replacement of natural sand, sample specimens are prepared and will be tested for workability, displaying the comparative results with conventional M30 grade concrete as well as the compressive strength, split tensile strength and flexural strength for 7, 14, and 28 days, respectively. With the help of this project's inquiry, concrete may become high dense while using robo sand and it gets excellent workability with GGBS as well as carbon content as heat of hydration will gets reduced.

Key Words: compressive strength, tensile strength and flexural strength. GGBS (Ground Granulated Blast Furnace Slag), Robo sand (M sand).

Man'sthreefundamentalrequirementsareforfood,clothes, andshelter.Allofaperson'sfundamentalneedsaredirectly or indirectly relevant to civil engineers. Humankind has made significant advancements in the way that shelter is built. Man, first lived in huts, which through time transformed into load bearing homes. The rising cost of building construction materials is a major worry in this built environment. The price of construction supplies is increasing daily. Aggregates, cement, and water are the mostoftenusedcompositematerialsinconcrete,whichis used by people all over the world. The growth of infrastructurearoundtheworldhasboostedtheneedfor constructionmaterials.Productionisanticipatedtoriseto more than billion tons per year. The demand for its components, including aggregates, cement, water, and admixtures,hasincreasedbecausetotherapid growthof infrastructure development and building activities worldwide.

Themajorityofresearchersarenowconcentratingonuse of the waste materials in concrete according to their properties. Concrete can be partially replaced by fly ash, ricehusk,slag,andsludgefromthetreatmentofhomeand industrialwastewater.Inadditiontothewastematerials already mentioned, research suggests that Ground GranulatedBlastFurnaceSlagwastefromsteelindustrycan alsobeusedascementitiousmaterialinconcrete.

Robosand,alsoreferredtoasquarrydust,isaproductof crushedstonequarries.Thechallengeofpreservingnatural sandcanbesolvedbyusingrobosand,andseveralstates have already outlawed the use of river sand for building. Accordingtosources,Robosandiswidelyusedthroughout theworld,andallprojectsworldwideinsistonutilizingitin placeofnaturalsand.

The primary goal of this project is to investigate the qualitiesofconcreteutilizingGranulatedBlastFurnaceSlag (GBS),whichisusedinplaceofnaturalsandandcementin percentages of 0, 10, 20, 30, 40, and 50%. This study focusedontheworkability,compressivestrength,andsplit tensile strength of concrete made with M30 grade mix. Therefore,theconcretemadefromGGBSandrobosandis thesubjectofthisthesis.

Dr.ChandrashekarA,PramodK,andChaithraHL(2015). Basedontheirexperimentalexamination,itwasdiscovered that the amount of GGBS in concrete increased with workability. As the proportion of quarry sand rises, it furtherfalls.Maximumcompressiveandflexuralstrength wasachievedwhen40%GGBSwasusedtoreplacecement. Maximum split tensile strength is attained when sand is replacedwith40%QSand50%GGBSinthecement.

C. S. Mallikarjuna and Dr. D. V. Prasada Rao (2016). Accordingtotheirtestresults,using40%GGBSand50% Quarry Dust leads in an increase of 18% in Compressive Strengthat28days.Atareplacementrateof40%GGBSand 50% quarry dust, split tensile strength increases by a maximum of 23.5 percent when compared to control concrete.At40%and50%substitutionsofcementandfine aggregate with GGBS and quarry dust, respectively, the

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

greatest percentage gain of 29% in flexural strength compared to control concrete is achieved. The Water Absorption has the lowest value with a replacement percentage of 40% cement with GGBS and 50% fine aggregatewithQuarryDust.Finally,itisfascinatingtosee that different test variations in test results followed the similartrend.

Nidhi Gupta and Yogesh Soni (2016). Based on their experimental examination, it was discovered that when GGBS in concrete grows, so does workability. As the proportionofquarrysandrises,itfurtherfalls.Maximum flexuralstrengthwasattainedwhen40%GGBSwasusedto replacecement.Maximumflexuralstrengthwasattainedby replacinghalfthecementwithGGBSandhalfthesandwith QS.

Rahul(2016)Tosolvetheissueofdisposingofsolidwaste, theconcreteindustryiscontinuallylookingforadditional cementitiousmaterial.Amongthesolidwastesproducedby industry are rice husk ash, quarry sand, and ground granulated blast furnace slag (GGBS), to name a few. An economicallyviablesolutiontothisdilemmaisthepartial substitutionofcementwithGGBSandRHAandnaturalsand (NS) with Quarry sand. This study is conducted in two phases.Ihaveafirstphase.Analysisandcomparisonofthe resultswiththenominalmixwillbedoneafterthestrength propertiesoftheconcretemixareexaminedfor7days,14 days,and28daysofcuring.Thesecharacteristicsinclude compressivestrengthandsplittensilestrength.

Ananthi Arunachalam (2018). Based on her findings, relevant inferences can be drawn about the workability, strength, durability, and other properties of concrete. Natural sand is replaced with manufacturing sand, and cement is partially replaced with 20 percent GGBS in concreteoftheM25,M30,andM40classes.Overall,ithas been found that artificial sand is the strongest and most durablealternativetonaturalsand.AfterusingGGBSand M sand, the concrete's compressive strength rose. At the seventh day, the M30 grade concrete reaches a higher startingstrengththantheM25andM40gradeconcretes. The M30 grade of concrete is discovered to be more effectivefromthecomparisonresultsofthethreeclassesof concrete.

T.VenkatDasandS.K.Sirajuddin(2019).Theycametothe conclusionfromtheirinquirythatthetestresultsshowed anincreaseof10%,12%,and15%inCompressivestrength, spilttensilestrength,andFlexuralstrengthattainedat40% GGBS and 50% QD replacements of cement and fine aggregate,respectively.Finally,wedrawtheconclusionthat substituting 40% GGBS for cement and 50% QD for fine aggregatewillresultinmixeswithgreaterstrengthsthan thecontrolmix.

SajidullaJamkhandi,MalleshM.,andNandeeshM.(2019).In theirinvestigation,themeangoalstrengthforconcreteof

grade M25 is attained by partially substituting GGBS for cementandfineaggregateforrobosand.Accordingtothe results of this experimental study, the ideal replacement ratioforM25gradeconcretemixis20%GGBSreplacement for cement and 25% Robo sand replacement for fine aggregate, which results in a 61 percent increase in compressive strength over conventional concrete results andtheM25Mixtargetstrength.Experimentalresearchhas shown to be a more effective method of getting rid of industrial waste and byproducts like ground granulated blast furnace slag and Robo sand. We can reduce environmentalwasteandimproveeconomicsbyreinforcing concretewithreadilyaccessibleGGBSandRobosand.

We had collected the cement from nearest store and using Ultra techOrdinaryPortlandcement53gradeinthis projectresearch.

Table 1: Test results on Cement

S.NO. Particulars

Test results

1 Specificgravityofcement 3.15

2 Consistencyofcement 30%

3

Initial&FinalSettingof cement 45min.&9hrs.40 min.

4 Fineness 6.5%

Well graded crushed stone powder passing through 4.75 mmwasusedasfineaggregate.Priortomixing,thestone dustwasairdriedandsievedtoremoveanyimpurities.We are testing stone dust for its ability to absorb water, its specificgravity,anditsfinenessmodulus.

Fig 1: Robo sand

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Table 2 Test results of Fine Aggregate

S.NO. Particulars Result

1 Specificgravity 2.69 2 WaterAbsorption 2.4% 3 Finenessmodulus 2.77

Thetypicalcoarsematerialusedforthisprojectiscrushed granite with a maximum particle size of 20 mm. We are testingcoarseaggregate for itsabilitytoabsorbwater as wellasitsspecificgravityandfinenessmodulus.

4. High chloride ingress resistance, lowering the risk of reinforcingcorrosion

5.Highresiliencetochemicalandsulphateattack

6.Considerableenvironmentaladvantages.

Themethodwhichisusedtomixdesignintheresearchis ISrecommendations(i.e.,asperIS:10262 2019)ofalltest resultsoffreshandhardenedpropertiesofconcrete.

Choosingthe right mixgrade,designing itusingthe right procedure,creatingtestbatches,anddeterminingthefinal mixratios.

• Calculating the total amount of concrete needed to completethejob.

• Calculating how much cement, stone dust, coarse aggregate,andGGBSwillbeneededtocompletethejob.

•Testingthepropertiesof GGBS,cement,stonedust,and coarseaggregate.

IndianStandardmethodisusedforfindingthepropertiesof materialstomixgrade.

Table 4: Combination of Replacement of GGBS & Robo sand

Fig 2: Crushed coarse aggregate (20 mm)

Table 3: Test results on Coarse Aggregate

S.NO. Particulars Result

1 SpecificGravity 2.75 2 WaterAbsorption 0.5%

ThemajoruseofGGBSisinreadymixedconcrete,andit is utilized in a third of all UK “ready mix” deliveries. Specifiers are well aware of the technical benefits, which GGBSimpartstoconcrete,including:

1. Better workability, which facilitates placement and compaction

2.Alowerriseinearlyagetemperature,whichlowersthe chanceofthermalcrackinginhugepours.

3. Reducing the possibility of harmful internal reactions suchASR

S.NO. Particulars %GGBS+%RS Cement GGBS RS CA 1 0%+100% 505 0 605.12 1120.4 2 10%+100% 454.5 50.5 605.12 1120.4 3 20%+100% 4.4 101 605.12 1120.4 4 30%+100% 353.5 151.5 605.12 1120.4 5 40%+100% 303 202 605.12 1120.4 6 50%+100% 252.5 252.5 605.12 1120.4

The analysis of workability, compressive strength, split tensilestrength,andflexural strengthofconcrete ofM30 grade mix concrete for 7, 14, and 28 days with the

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

replacementofGGBSascementitiousmaterialby0%,10%, 20%, 30%, 40%, and 50% respectively, and natural sand withRobosandisshowninthetablesandgraphsbelow.

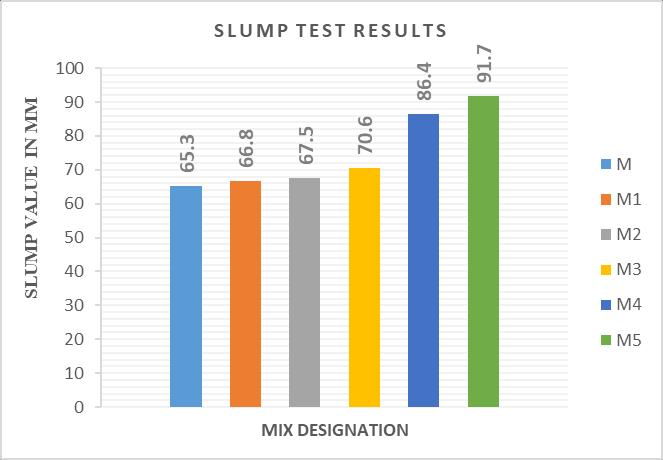

Chart -1:Slumptestvalues

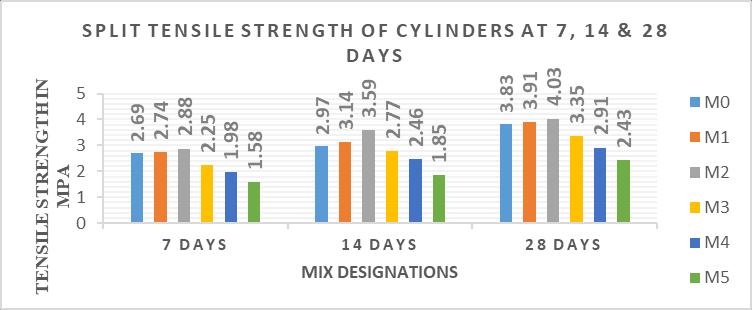

Chart -2: Compressive strength test values

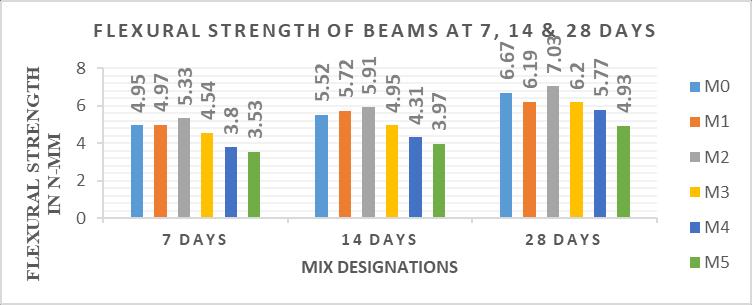

Chart -4: Flexural strength test values

On the basis of results obtained by this experimentalinvestigationofM30gradeconcrete,following conclusionsareshownbelow:

1. Theworkabilityofthefreshconcreteisexcellentwith granulated blast furnace slag by replacement of cement. The slump values increase with increasing percentageofslaginthemixmaximumvalueoccursat M5

2. The compressive strength of hardened concrete is almostaboveM30gradeat7daysand14daysofmixes M0,M1,M2andM3andbelow30N/mm2formixesM4 andM5.After28daysthemaximumstrengthoccursat mixM2thatis20%ofslagwith100%ofrobosand.

3. Further,thestrengthgetsreducesgraduallyforother mixes M3, M4 and M5. Therefore, the best mix for producingconcreteisM2.Anditisabovethevalueof targetmeanstrengthi.e.,38.25N/mm2 .

4. And also, if further wants to decrease the cement contentwithacceptanceofstrengththemixesM3and M4canalsobeusedformakingM30gradeconcrete.

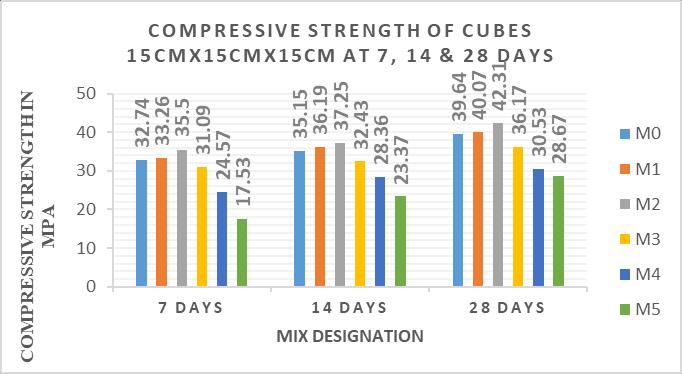

5. The tensile strength of concrete increases when compared to conventional concrete mix M0 with adding mineral admixture. And the strength gets gradually increases from 7 days to 28 days for the mixesM1toM3withincreaseofslagandfurtheritgets reducesforthemixesM4andM5.

Chart 3: Split tensile strength test values

6. Fromthecodeguidelinestherequiredtensilestrength ofconcretefromtheempiricalformulais3.83N/mm3 Aspertheconcernedstrengthconsideredthemixfor tensilestrengthofconcreteispreferrableM0,M1and M2.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

7. Andtheremainingmixesareneglectedi.e.,M4andM5. Themaximumtensilestrengthofconcretewillgetfor themixM2i.e.,4.03N/mm2 whichisgreaterthanthe required.

8. The flexural strength of concrete is increase with gradualincreaseinaddingadmixtureinthemixtureof concreteproportions.Thestrengthgetsincreasesfrom 7daysto28daysforthemixesM0,M1andM2.The maximumflexuralstrengthoccursforthemixM2when comparedtoM0andM2.

9. And further the flexural strength gets reduces graduallyforthemixesM3,M4andM5from7daysto 28days.

10. Therefore, from the investigation point of view the partial replacement of cement by granulated blast furnaceslagwithrobosandisgivingexcellentresults whencomparedtoconventionalconcrete.

11. Andalso,bytheuseGGBSintheconcretewithpartial replacement of cement decreases the cement production and also it helps the reduce the large carbonemissiongasesintheenvironmentfromcement industries.

12. So,itisenvironmentaleco friendlyandgoodadvantage inthecaseofcostofproductioncostandalsostrength pointsofviewandgoodworkabilityproperties.

1. Chaithra H L, Pramod K, Dr. Chandrashekar A (2015).“Anexperimentalstudyonpartialreplacement ofcementbyGGBSandnaturalsandbyquarrysandin concrete” International Journal of Engineering Research&Technology(IJERT) ISSN:2278 0181 Vol. 4Issue05,May 2015.

2. Dr.D.V.PrasadaRao,C.S.Mallikarjuna(2016).“An experimentalinvestigationonpropertiesofconcrete bypartialreplacementofcementwithGGBSandfine aggregatewithquarrydust” InternationalJournalof Science and Research (IJSR) ISSN (Online): 2319 7064 IndexCopernicusvalue(2016):79.57.

3. YogeshSoniandNidhiGupta(2016).“Experimental investigationonworkabilityofconcretewithpartial replacement of cement by ground granulated blast furnaceandsandbyquarrydust” IJARIE ISSN(O) 22395 4396.

4. Rahul(2016).“Experimentalinvestigationonpartial replacement of cement by GGBS & RHA and natural sand by quarry sand in concrete” International JournalofEngineeringResearch&technology(IJERT) ISSN:2278 0181.

5. ArunachalamAnanthi(2018).ResearchGate.IJSEA (2018)1 6.

6. S.K. Sirajuddin and T. Venkat Das (2019). “Experimentalinvestigationonpropertiesofconcrete bypartialreplacementofcementwithGGBSandfine aggregatewithquarrydust” InternationalJournalof Recent Technology and Engineering (IJRTE) ISSN:2277 3878,volume 7,Issue 6C2,April2019.

7. MalleshM,SajidullaJamkhandi,NandeeshM(2019). “Experimentalstudyonpartialreplacementofcement by GGBS and fine aggregate by Robo sand for M25 Grade concrete” International Research Journal of EngineeringandTechnology(IRJET) e ISSN:2395 0056 Volume:06Issue:08/Aug2019.

IS CODES:

8. IS:456 2000 PlainandReinforcedConcrete Code ofpractice.

9. IS:10262 2019 Concrete Mix Proportioning Guidelines.

10. IS:383 2016 CoarseandFineAggregateforConcrete Specifications

TEXT BOOKS:

11. Textbook of “Concrete Technology: Theory and Practice”byM.S.Shetty.S.Chand&companyprivate Ltd.,NewDelhi.

12. Textbook of “Concrete Technology: Theory and Practice”byM.L.Gambhir.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified