International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1Undergraduate student at PDEU, Gujarat, India ***

Abstract Numerous manufacturing firms in India experience a variety of issues, including long cycle times, a high number of rejections, unfulfilled orders, degraded quality, inadequate safety assurance, etc. Japanese lean production tools such as KAIZEN,5S and Kanban aid in achieving continual improvement in the workplace. Applyingtheseresultsintheremovalorreductionofvarious wastes in a sector of the economy improves the organization’s overall effectiveness. Assembly time reduction has appeared as an essential thing of improvementtoproduceacomponentofhigh quality inthe least time possible with maximum resource utilisation. The following study was carried out at a CNC manufacturing company

Key Words: Time Study, KAIZEN, Assembly process, Bolt Tray

A sheet metal assembly of a single CNC machine took 6 hourstocompleteatthecompany.Thesimpletaskwasto achieve the same quality of final assembly in the least possibletimebyoptimizingtheprocess.Variousindustrial engineering concepts were applied to achieve the aforementioned. The concepts are explained in brief below:

1. Kaizen: It is a Japanese term for "improvement" or "change for the better," and it refers to a way of thinking or doing things that are centered on always improving business, engineering, and manufacturing processes. Kaizen strives to reduce waste by enhancingstandardizedtasksandprocedures.

2. Cycle Time: It is described as the actual amount of timeneededtoperformaseriesoftasks(onecycle).

3. Time Study: Time study is a structured technique of directlyobservingandmeasuringhumanworkwitha timing device to determine the time required for a qualifiedworkertocompletetheworkatasetlevelof performance.

Itadherestothefundamentaltechniqueofsystematic workmeasurementof:

Work analysis into simple, clearly observable componentsorfactors

Measurement ofindividualcomponents

Synthesis of those measurements to arrive at a timefortheentirejob

4. 5S: The term 5S is a housekeeping philosophy about maintaining order and cleanliness in the work area. ThefiveSsare:

Sort: Sorting involves clearing the workspace of anyextraneousobjectsanddiscardingthem.

Straighten: The remaining tables, tools, parts, documents, and workbenches need to be sorted now that the mess has been removed. Keep everythingatrightangleswhilestraighteningasa generalruleofthumb.

Scrub/Shine: The meaning of the third S is rather obvious. To help it look like a showroom, the work area should be thoroughly cleaned. The operators will feel proud of keeping the workplace tidy and orderly, and you'll discover thatthey'll wanttocontinuedoing so.Cleaningis beneficial for appearance as well as accident and injuryprevention.

Standardize: Writtencriteriashouldbecreatedto track the 5S program's development and compliance. As previously indicated, keep colors andidentificationsuniformandstraight

Sustain: Justdevelopingtheabovegivensystemis not enough. A company needs to maintain it, as humans we are naturally resistant to change, so anemployeeshouldbeappointedwhoseestothe maintenanceofthesystem.

5S improves employee morale, makes a fantastic first impression on consumers, and keeps the operation running smoothly with continual accountability and faithintheprogramme.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

5. Kanban: It is a method for defining, administering, and enhancing knowledge delivery services. It aids in visualizing tasks, increasing productivity, and always improving. Kanban boards represent work, allowing employees to maximize work delivery across various teamsandhandleeventhe mostcomplicatedprojects inasingleenvironment.

The sheet metal assembly of a typical 800mm bed size model consist of 52 pieces and 150+ nut bolts of various types. The complete process of putting together a whole bodytakes2workersabout6hours(360mins)

As for the bolt arrangement they were using a big trolley inwhichallthetoolswerekept.Theissue withthetrolley was that it could not be taken inside the sheet metal assembly.

The Old assembly process consisted of no standard operatingprocedureandthewholeassemblywasdoneby the workers according to their convenience and availabilityofequipmentandmaterial.

Timing for each activity was found using time study. To measurethetimeandrecordthedurationofanactivity,a continuous stopwatch was used. This eliminates the requirement for subtractions and enables the element times to be entered directly on the time study sheet. The time spent by each operator on the task, which they completedoveranumberofcycles,wasrecorded.

Thetimestudydatacanbefoundbelow:

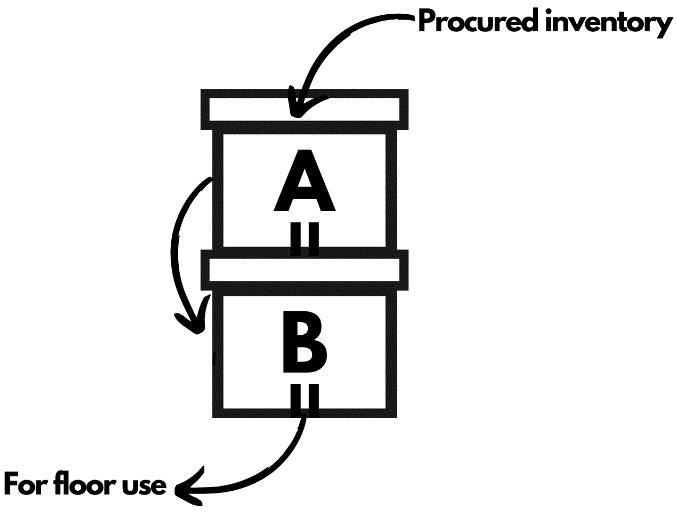

The company has been using two bin Kanban system to solve their inventory needs. The general working of the systemisasfollows:The2 binsystem,toputitsimply,isa method of managing inventory that employs two actual bins, typically for small but essential parts (such as fasteners and components). It is a straightforward pull systeminwhichcontainerscontainthepieces

The system is merely based on giving employees two plastic storage bins filled with inventory, which they can use to fill orders or supply supplies to various departments. The number of products put in the bins will dependonhowquicklytheyareutilizedindividually

Theemployeestakewhattheyneedfromonebinuntilitis empty,atwhichpointtheyswitchtothesecondbinwhile simultaneously placing an order to restock the first bin with what they need. The first bin must be replenished with a predetermined quantity of goods, so there is little chanceofrunningoutofsupplies(whichcouldslowdown production)

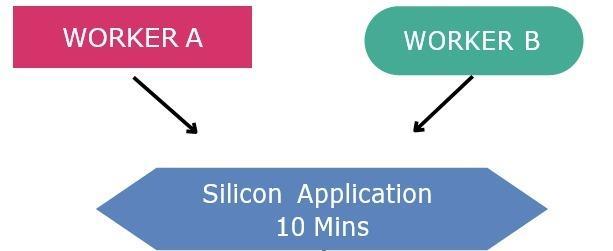

Introduction of a standard operating procedure for the workers with the inclusion of diversions for equipment and material shortages was experimented by us. The proposed process led to equal distribution of work over the workers. This led to better resource utilization. And a custom made magnetic bolt tray was also introduced. All this made an improvement in the sheet metal assembly time.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Assembly Task

Estimated Time Worker A Worker B

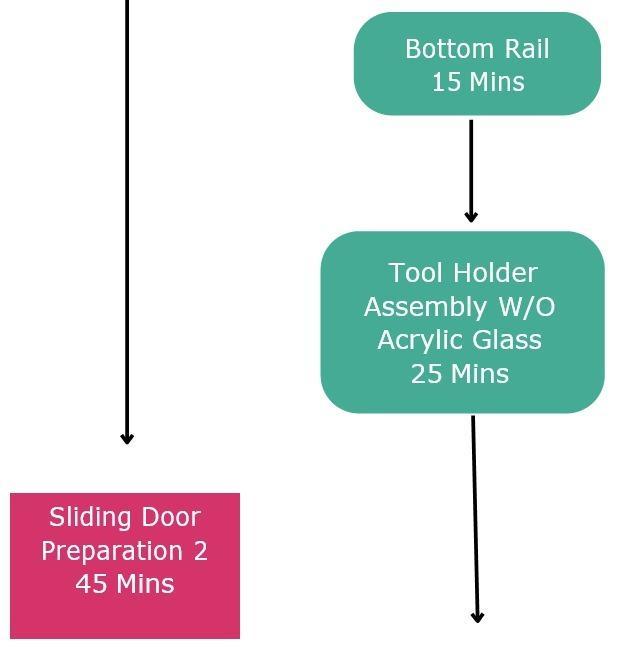

SiliconApplication 10 Assembly of Right and LeftJointofSheetMetal 20 TopCoverJoint 10 TopGuideBar 20 Sliding Door Preparation(1) 45 BottomCover 10 BottomRail 15 Tool Holder Door Assembly W/O Acrylic Glass 25

Sliding Door Preparation(2) 45 Window Assembly W/O AcrylicGlass 40

LEDLightMounting 15 ToolHolderRackFitting 15 3MTape 15

Name Plates and Black Plates 35 Acrylic Mounting for All Windows 30 JSLPlate 10 Brackets 15

Door Mounting and DoorAlignment 35 StoppersMounting 20

Total Time 280 min 280 min

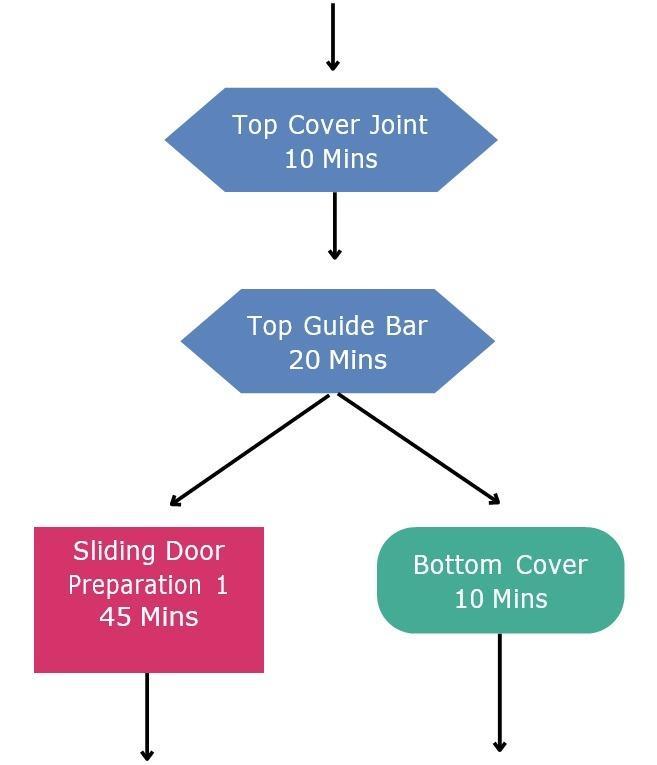

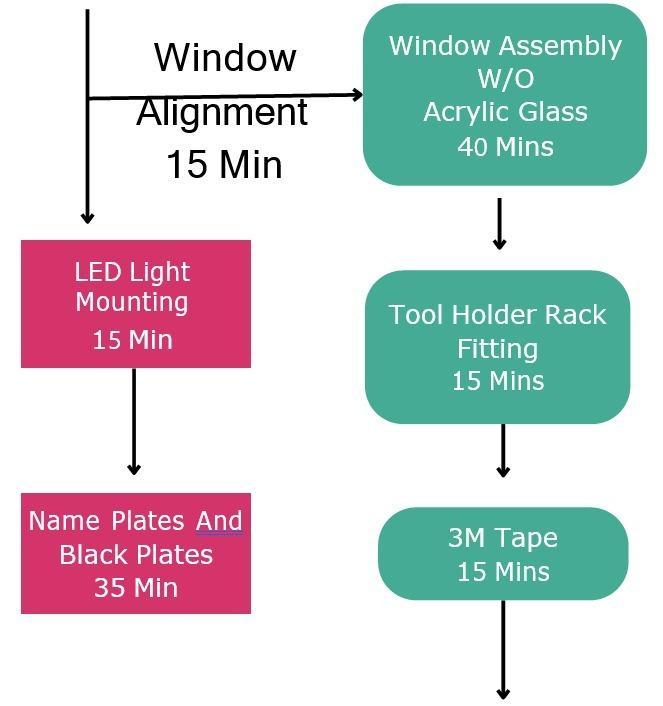

Theflowchartcanbeinterpretedasfollows:

Taskofthe2workershavebeendividedin3blocks,Redis forworkerA,GreenisforworkerBandBlueiswherethey both work together. The task has been written with the estimated time it takes a worker to complete it. The time foreachtaskwasrecodedfromthetimestudiesconducted aboveandtheiraveragetimewastaken.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Theexceltablecanbeinterpretedasfollows: Each row contains a task, it’s approximate completion time and the green color indicates work allocation to the worker. The table was used during the application of the flow chart to cross check the results and write observations. The observations are further discussed in conclusion.

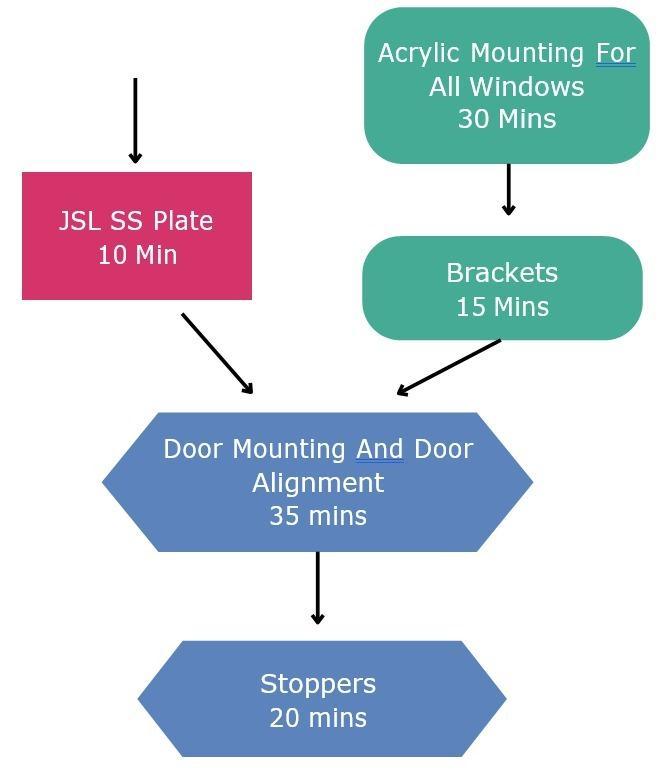

assembly uses very few nuts so no slots for nuts was Software)therenderedimagescanbefoundbelow

provided.The tray was firstmade in Fusion 360(CAD

Worker A Worker B

Itcanbededucedfromtheabovetableandflowchartthat there is equal time based work allocation between both theworkers. In case of equipment shortages, the workers were providedwithatablebeforehand,whichcontainsthetask whichcanbeperformedinsuchconditions.

The tray used upcycled acrylic sheets from the window pane. Acrylic was drilled as per the design. A right angle bracketfromtheheadstockassemblyoftheCNCwasused toholdtheacrylicandthemagnettogether.Weusedanoff the shelf magnet with the carrying capacity of approximately2kgs.

We designed and built 2 magnetic bolt trays, one for the rightandotherforleftsideoftheassembly.Eachtrayhad exact number and size of slots as the required bolts. The

This tray created the following improvements: The workers now did not have to remember the number and sizesofboltsfortheassembly,aswhentheyarrangedthe tray with the bolts it is made sure that they have just the required bolts. The magnetic support of the tray made it very versatile as it can be attached on any section of the sheetmetalassembly.Duetowhichtherewasareduction intheworker’shandandfeetmovement.

It was observed that implementation of KAIZEN and the optimizationofastandardizedoperatingprocedureinthe assemblyledtoa20%increaseinproductivity.Therewas a reduction in the lead time without making new resourcesavailable.

Aftertheimplementationoftheabove mentionedprocess flowchartandthemagneticboltholder tray weobserved

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

theprocessandhavecomeupwithfollowingissueswhich canbeimprovedfurther:

1. Unexpected inconveniences caused due to different skilllevelofdifferentworkersandtheirexperience.

2. Improvement in tray deign to accommodate nuts and button bolts. Also, custom magnet to support the addedweightwillbeneeded.

3. A time study should be performed to segregate tasks in value and non value adding tasks. This will further decreasetheprojectedleadoftheassembly.

[1] Ortiz, C. A. (2006). Kaizen Assembly: Designing, Constructing, and Managing a Lean Assembly Line (1st ed.).CRCPress.

[2] Tejas Rathod et al. A CASE STUDY ON APPLICATION OF KAIZEN IN INDUSTRY, International Research Journal of Engineering and Technology (IRJET), June 2019.

[3] Jain, Ashish. (2015). The Kaizen Philosophy for Industries:AReviewPaper.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal