International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1,2,3UG scholars Department of Mechanical Engineering, Viswajyothi College of Engineering and Technology, Vazhakulam, Kerala, India 4 Assistant professor, Department of Mechanical Engineering Viswajyothi College of Engineering and Technology, Vazhakulam, Kerala, India ***

Abstract - Wind energy is transformed into electrical energy by wind turbines for distribution. Propeller like blades turn when the wind blows, capturing wind energy to drive the generator and produce power. Horizontal axis turbines and vertical axis turbines are the two main types of wind turbines on the market. The power output of small wind turbines is 10 kW, whereas the power output of large scale wind turbines ranges from 5000 to 8000 kW. It is crucial to realize that wind turbines cannot function in either excessively high or excessively low wind conditions. Only 59.3% of the kinetic energy is transformed into electricity output utilizing wind turbines, which is below the Betz limit. The cubic power of velocity directly relates to the wind power generated by a wind turbine. Therefore, a small increase in velocity might result in a significant increase in power production. In shrouded wind turbines, this idea is applied. The pressure gradient produced by a diffuser shroud increases the speed of the approaching wind. Additionally, because of the growing sophistication of engineering and technology, the rotor size of a wind turbine grows in direct proportion to its swept area. In this project, we create a shrouded wind turbine with which we run several tests with various specs and blade counts. It aids in comprehension of the various outputs and efficiencies offered by a wind turbine. The output of a wind turbine increases as its efficiency rises. and contributes to boosting energy production.

Keywords: vertically inclined winds, Betz limit, shroud, nozzle, diffuser.

Inordertogenerate,transmit,andintegratewindturbines into the power system, electrical engineering is used in conjunction with a variety of multidisciplinary and broad technological disciplines, including aerodynamics, mechanics,structuredynamics,andmeteorology.Themost promisinganddependablekindofrenewableenergytodayis wind turbine technology, which has improved over time. Since the early 1980s, the transition from small wind turbines with a few kilowatts to the multimegawatt wind turbinesoftodayhashappenedquitequickly.Windturbines transformwind'skineticenergyintousefulelectricalenergy. Propeller likebladesturnwhenthewindblows,capturing wind energy to drive the generator and produce power.

Therearetwomaintypesofwindturbinesonthemarket: horizontal axis turbines and turbines with vertical axes. Large scalewindturbinescanproducepowerupto5000 8000 kW, whereas small wind turbines have production capabilityof10 20kW.

To ascertain whether the wind flows are adequate for generating power, the location for placing wind turbines mustalsobeadequatelyexamined.Asuitablewindturbine system for the location is also found with the aid of the evaluation.Thequalityofthewindresourcesattheareaof installation considerably affects the efficiency of wind energy,whichcanreachmorethan40%ifthelocationofthe wind energy system is correctly chosen. It is crucial to realizethatwindturbinescannotfunctionineithertoohigh ortoolowwindconditions.

Windpowerisinverselycorrelatedwithwindspeedcubed. The output power of a wind turbine can be significantly improvedifwecanharnessthefluiddynamicssurrounding astructuretoincreasethewindspeed,specificallyifwecan catch and concentrate the wind energy locally. When comparedtoanopenturbinewitharotorofanequivalent size,ashroudinashroudedwindturbineservestoenhance thevelocityoftheairtravellingthroughtherotorplane.

Asthesizeofthewindturbineincreases,itscostrisesandits failureraterisesinconventionalwindturbines.Additionally, those enormous wind turbines cause social issues like increased noise (aerodynamic noise) as a result of the turbines,anincreaseintheriskofbirdstrikes,deterioration ofthesurroundingsceneryasaresultoftheturbines'sizeor theirsharpblades,andmore.Asaresult,itischallengingfor thelocalpopulationtoacceptsuchenormouswindturbines, which makes it challenging to build such wind turbines. Scaling of blades has limitations, as several recent investigationshaveshown.

Inthispaper,wedevelopashroudedwindturbinewhichis used to perform different tests according to different specifications and number of blades. It helps in understandingthedifferentoutputsandefficienciesinthe givenspecifications.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

•Tofindoutthemostoptimumarrangementinashrouded windturbine.

•To study the difference between the performance of conventional horizontal axis wind turbines and shrouded windturbines.

•To study the changes in different output parameters of a shroudedwindturbineatdifferentwindspeeds.

•Tounderstandthedifferencebetweenusageofthreebladed andfivebladedrotorsinhorizontalaxiswindturbines.

•Thisturbinewillbecapableofproducingmorepowerthan conventionalhorizontalaxiswindturbines.

•A clear cut image of the most optimum geometrical arrangementtoproduceelectricityefficientlyinashrouded windturbineisobtained.

•Increaseinthevolumeofsweptwindbytheuseofnozzle anddiffuser.

•Can be used as wind guidance system for larger wind turbines.

When one comprehends how the speed influences the power,thesignificanceofcorrectwindspeeddatabecomes apparent.Takeintoaccountadiscofarea"A"withairmass "dm"movingthroughit.Themasswilltraveladistanceof'U dt'intimedt,resultingintheformationofacylinderwitha volume of 'A x U x dt' and a mass of ‘dm = A x ρ x U x dt’, where"denotestheairdensity.Thetemporalrateofchange in kinetic energy, or the power contained in the moving mass,isgivenbyP=d(KE)/dt=d(½xmU²)/dt=½xU² dm/dt=½xAxρU³.

Asaresult,powerisinverselyrelatedtowindspeedcubed. The wind speed must be precisely known because any inaccuracyinthepowercalculationisamplified.

Independent of the design of a wind turbine operating in open flow, Betz's law identifies the maximum power that may be obtained from the wind. For all Newtonian fluids, including wind, Betz's law is applicable. The wind speed would decrease to zero if all of the energy from wind movementviaaturbinewerecollectedasuseableenergy.A blockage would prevent any additional fresh wind from entering ifthewindstoppedblowingattheturbine'sexit.

Theremustbesomewindmovement,howeverslight,onthe opposite side with some wind speed greater than zero in order to maintain the wind going through the turbine. AccordingtoBetz'slaw,asanarea'sairflowincreasesandas energyislostduringenergyextractionfromaturbine,wind speed drops, requiring airflow to be distributed across a largerregion.Geometrythereforerestrictsturbineefficiency toamaximumof59.3%.

The Betz limit is based on an open disk actuator. More energycan beobtainedifa diffuserisemployedtogather morewindandrouteitthroughtheturbine,butthelimitstill appliestothecross sectionoftheoverallstructure.

TheBetzLimitisthemostenergythatcanbeextractedfrom a fluid moving at a specific speed using an infinitely thin rotor.

TheBetzLimitisthemostenergythatcanbeextractedfrom a fluid moving at a specific speed using an infinitely thin rotor.

1. The rotor is ideal, without a hub, and has an infinite number of blades that are completely free of drag. Any ensuingdragwouldonlymakethisidealvaluesmaller.

2.Axialflowentersandexitstherotor.Inordertocreatea solutionforthiscontrol volumeanalysis,thecontrolvolume mustincludeallincomingandoutgoingflow;otherwise,the conservationequationswouldbebroken.

3. There is no compression of the flow. There is no heat transfer,andthedensitydoesnotchange.

4.Thediscorrotorissubjectedtoauniformthrust.

Thetheorybehindrevealedthatadiffuser shapedstructure canacceleratethewindattheentranceofthebody.Usinga nozzlewillreducethepressureandincreasethevelocityof airintakeandcutstheblades.Astheairleavesthroughthe diffuserthepressureisincreasedreducingthevelocity.Since the change in pressure is continuous a smooth flow of air occurs.

Thefabricationworkbeganwiththeproductionoftwotype ofblades;5 bladeand3 blade,madeofPVC.Thentheywere bolted onto a bearing housing made of cylinder pipe of diameter50mmandabearingof internaldiameter16mm (SKF6202)wasfixedintothecylindricalpipe,asshownin fig1.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

For power generation a standard bicycle dynamo of head diameter of 20mm is used. The typical electrical output producedfromabicycledynamois12volts.Dynamoshave traditionally been used to power lights with alternating current (AC). There have been sufficient advancements in battery technology, LED light technology, and charging technologyaswehavemovedintoaworldofcommunication andbecomemoreefficient.Thebicycledynamowascoupled to a wheel of diameter 100mm for speed addition to the dynamoasshowninfig2.Aspeedratioof5:1isachievedon thedynamo.

Theshroudwasclippedontotheouterperiphericalringof thearrangementtocompletethe fabrication work.A bulb wasconnectedtothedynamousingaregulatorIC(IC7305) in series with two resistors in parallel (630 ohm) to the dynamo. The completed fabrication of shrouded wind turbineproducinganoutputusingdynamoisshowninfig3.

SpecificationsOftheFabricatedWindTurbine:

Throatdiameter =710mm

Lengthoftheblades =310mm

Rotordiameter =705mm

TowerHeight =1210mm

Nozzleinletdiameter =760mm

Diffuseroutletdiameter =850mm

Bearinghousingdiameter =50mm

Dynamorotatingridged knobdiameter =20mm

Additionwheeldiameter =100mm

L/DRatio, L/D =0.44

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Thevarioustestsareconductedwiththeuseofwindtunnel atconstantwindspeed.Aconstantwindspeedisobtained bysettingaconstantvalueforrpmofthewindtunnel.After settingaconstantwindspeedthedifferentparameterslike variation in output voltage, variation in rpm of the rotor shaft, cut in wind speed, etc. are recorded for different arrangementoftheblades,nozzleanddiffuser.Twosetsof windspeedsareused 6.3m/sand5.1m/s.

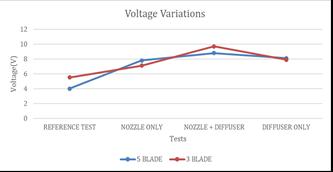

The wind speed is set to a constant value of 6.3m/s by settingthewindtunnelto625rpmandthevoltagevariations of the 3 blade and 5 blade arrangement are recorded by using a multimeter for the below shown geometrical parameters.

Table 1 below shows the values obtained in volts(V) for differentgeometricalparameters.

Table -1: Voltagevariationsat6.3m/s

TESTS 5 BLADE 3 BLADE REFERENCE TEST 4.0V 5.5V

NOZZLE ONLY 7.8V 7.1V NOZZLE+ DIFFUSER 8.8V 9.7V

DIFFUSER ONLY 6.9V 6.1V

Achartisplottedshowingthevoltagevariationsat6.3m/s asshowninchart1below:

withnozzle.Thediffuseralonearrangementcanonlyreduce the pressure but the pressure reduction can only happen withtheuseofnozzle.Butwiththehelpofbothnozzleand diffuser the pressure reduction and addition can happen simultaneously in both nozzle and diffuser arrangement (shroud).Thevaluehassignificantlyincreasedwiththeuse of shroud to approximately from 4V to 10V. Shroud arrangement offers higher output and load carrying capability.Withtheincreaseinoutputgivesmorepower.

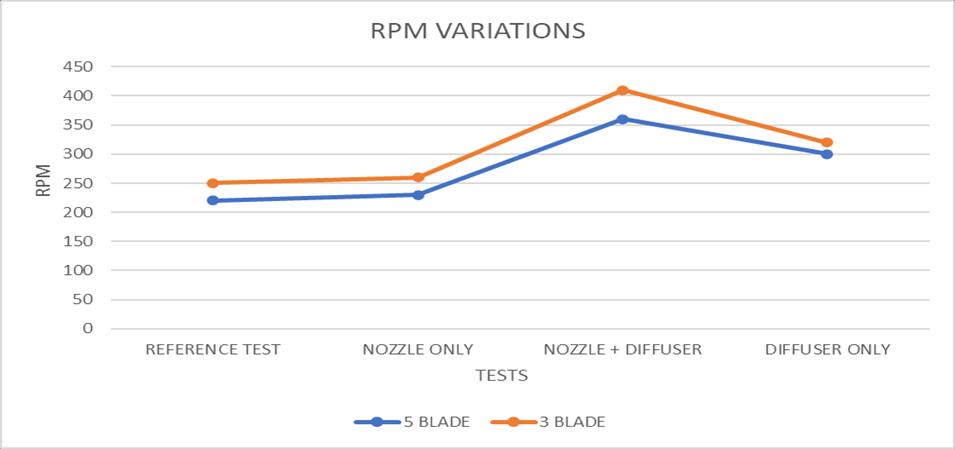

The wind speed is set to a constant value of 6.3m/s by settingthewindtunnelto625rpmandtherpmvariationsof the3 bladeand5 bladearrangementarerecordedbyusing atachometerforthebelowshowngeometricalparameters.

Table2belowshowsthevaluesobtainedinrevolutionsper minute(rpm)fordifferentparameters.

Table 2: RPMvariationsat6.3m/s

TESTS 5 BLADE 3 BLADE REFERENCE TEST 220rpm 250rpm

NOZZLE ONLY 230rpm 260rpm NOZZLE+ DIFFUSER 360rpm 410rpm DIFFUSER ONLY 300rpm 320rpm

Achartshowingthevariationsofrpmat6.3m/sisshownin chart2above.

Herethereferencetestorthetestwithouttheadditionany nozzleordiffuserhastheleastoutput.Withtheadditionof nozzle,amarginalincreaseinvoltageoutputisseen.Diffuser alonehaslesseroutputthannozzlealonesincetheintakeof airislessinthebeginning.Theintakeofwindisincreased

Chart 2: RPMvariationgraphat6.3m/s

Here the reference test has the least output. With the additionofnozzle,amarginalincreaseinrpmoutputisseen. Diffuseralonehaslesseroutputthannozzlealonesincethe intakeofairislessinthebeginning.Theintakeofwind is increasedwithnozzle.Thediffuseralonearrangementcan onlyreducethepressurebutthepressurereductioncanonly

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

happen with the use of nozzle. But with the help of both nozzleanddiffuserthepressurereductionandadditioncan happen simultaneously in both nozzle and diffuser arrangement(shroud).Thevaluehassignificantlyincreased withtheuseofshroudtoapproximatelyfrom220 rpm to 410rpm.Shroudarrangementoffershigheroutputandload carryingcapability.Withtheincreaseinoutputgivesmore power.

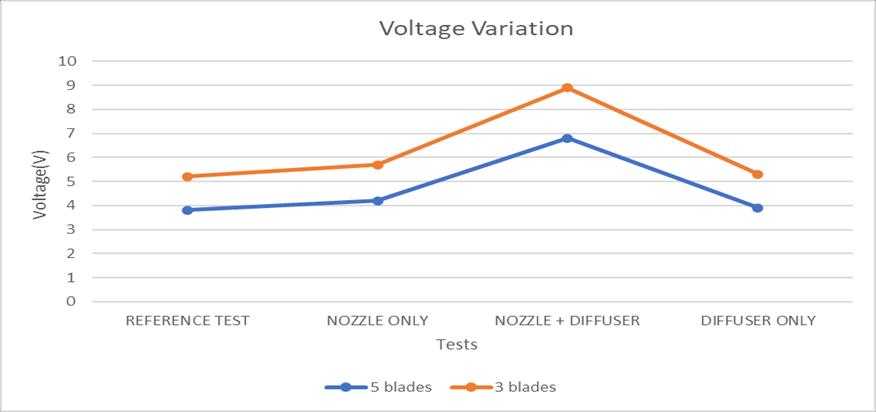

The wind speed is set to a constant value of 5.1m/s by settingthewindtunnelto555rpmandthevoltagevariations of the 3 blade and 5 blade arrangement are recorded by using a multimeter for the below shown geometrical parameters.

Table 3 below shows the values obtained in volts(V) for differentparameters.

Table 3: Voltagevariationsat5.1m/s

TESTS 5 BLADE 3 BLADE REFERENCE TEST 3.8V 5.2V

NOZZLE ONLY 4.2V 5.7V NOZZLE+ DIFFUSER 6.8V 8.9V DIFFUSER ONLY 3.9V 5.3V

Achartshowingthevoltagevariationsat5.1m/sasshownin chart3below:

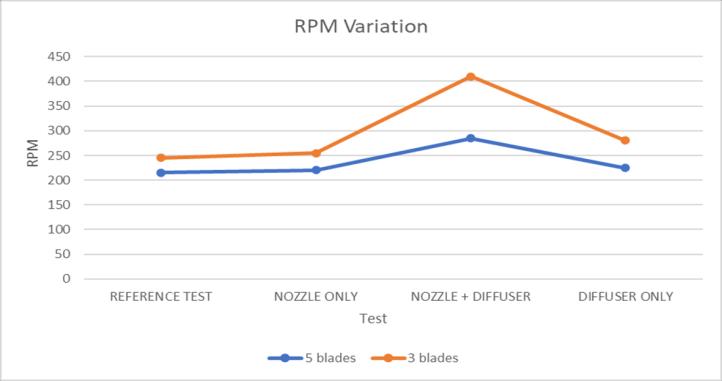

Table4belowshowsthevaluesobtainedinrevolutionsper minute(rpm)fordifferentparameters.

Table 4: RPMvariationsat5.1m/s

TESTS 5 BLADE 3 BLADE REFERENCE TEST 215 245

NOZZLE ONLY 220 255 NOZZLE+ DIFFUSER 285 410 DIFFUSER ONLY 225 280

Achartisplottedshowingtherpmvariationsat5.1m/sas showninchart4below:

Chart 3: Voltagevariationgraphat5.1m/s

The wind speed is set to a constant value of 5.1m/s by settingthewindtunnelto555rpmandtherpmvariationsof the3 bladeand5 bladearrangementarerecordedbyusing atachometerforthebelowshowngeometricalparameters.

Chart 4: RPMvariationgraphat5.1m/s o CUT INWINDSPEED

Referencetest 4.2m/s

Nozzleonly 3.6m/s

Diffuseronly 3.8m/s

Nozzle+ Diffuser 3.0m/s

To increase the output of the HAWTs we proposed the designofshroudintothesystem.Bydoingsowewereable toincreasetheoutputby2 3times.Sincethisprojectuseda cycle dynamo the varying output was limited. The output waslimitedto12Vmaximum.Although,therangeofoutput waslimited,theincreaseinvoltageandrpmweresignificant. Theoutputvariedfrom4Vto10Vandtherpmfrom215 410 rpm. Among the various arrangements we used the nozzle and diffuser arrangement was the best suited to producethebestresult.Itgaveanoutputvoltageof9.7Vand 410rpm. Wind turbines with nozzle diffusers can

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page266

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

significantlyimproverotorperformance.Thisisbecausethe windturbineinsidethediffuserisdrawntomoremassflow byalow pressureareacreatedbyastrongvortexformation behindthebroaddiffuser.Theabilityofcreatingapressure differenceproducesanoutputthatfarexceedsthenormal HAWTs. Even for a slight variation in applied wind load a significantoutputcanbeproduced.Improvedresearchwill befruitfulinutilizingtheunlimitedresourcesthatarefree and bountiful in nature. Since the usage of fossil fuels are veryhigh,developmentsinwindenergyproductioncanbe veryresourceful

[1] Ohya, Y. and Karasudani, T., 2010. A shrouded wind turbine generating high output power with wind lens technology. Energies, 3(4),pp.634 649

[2] Pambudi,N.A.,Febriyanto,R.,Wibowo,K.M.,Setyawan, N.D., Wardani, N.S., Saw, L.H. and Rudiyanto, B., 2019. Theperformanceofshroudedwindturbineatlowwind speedcondition. Energy Procedia, 158,pp.260 265

[3] Alquraishi,B.A.,Asmuin,N.Z.,Mohd,S.,AbdAl Wahid, W.A. and Mohammed, A.N., 2019. Review on Diffuser AugmentedWindTurbine(DAWT). International Journal of Integrated Engineering, 11

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal