International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Pakhare S.R.1 , S. M. Zubair 2

1PG Student ,Dept of Civil Engineering ,Deogiri Institute of Engineering and Management Studies, Aurangabad, 2Assistant professor Dept of civil Engineering ,Deogiri Institute of Engineering and Management Studies, Aurangabad ***

ABSTRACT Since few decades, it was normal practice to replace some of the cement with pozollanic materials in order to improve the qualities of concrete. These compounds are referred to as supplemental cementing materials since they have the same pozzolanic and binding qualities as cement. Silica is well known for its usage in constriction as silica fume, but as nano particles become more prevalent in the construction sector, the impact of nano silica on concrete characteristics is also being investigated. This review paper summarizes the research that has been done on the effects of silica fume and nano silica colloidal form on the fresh and mechanical properties of concrete. This review work included a study of the fresh qualities of concrete, such as workability, bleeding and segregation, and setting time. This paper also evaluated the literature on the effects of silica on mechanical parameters such as compressive strength, flexural strength, and split tensile strength.

Keywords: Nano material, Silica, Compressive strength, Flexuralstrength

In recent years, high strength and high performance concrete has become more popular around the world, mandating a decrease in the water/binder ratio and an increase in the binder content. [3,4] However, when attempting to create high strength and high performance concrete, both economic and environmental considerations must be taken into account. As a result, other Supplementary Cementing Materials (SCMs) are currently employed in concrete to partially replace the Portland cement component. In modern concrete technology, active pozzolanic admixtures such as silica fume(SF)andmetakaolinareusedasSCMstoachievehigh performance qualities. Nano scale pozzolans aid in the creation of more dense micro structural packing and a more impervious cement matrix. [10] In recent years, therehasbeena growinginterestintheuseof nano silica in concrete. [1]According to studies, nano particles have an ultrafine size, which causes them to have unique physical and chemical properties that are distinct from those of regular materials. According to the number of

dimensions, the author has classified nano particles into four primary groupings that are not limited to the nanoscalerange:(i)Quantumdotsandfullerenesarezero dimensional (0 D) materials. (ii) Nanotubes, nanowires, and nanorods are examples of one dimensional (1 D) materials. (iii)Graphene and nanosheets are two dimensional (2 D) materials. (iv) Nano porous materials, which are three dimensional (3 D). [7]Silica is one of the SCMs that comes in a variety of forms, including silica fume,colloidalsilica,andnano silica.Silicahasavarietyof effectsonthestrengthandcharacteristicsofconcreteinits many forms. The impact of silica fume on concrete strength has yet to be properly quantified. [9]The use of active pozzolanic admixtures, dense microstructure packingofparticles,andalowwater/cementratioarethe most common techniques to obtain high performance features in concrete. The most common and effective pozzolanic additive is silica fume (amorphous SiO2). The particle sizes of silica fume (SF) range from 20 to 500 nanometers.[10]Althoughthereisalotofinfoaboutsilica fume concrete in the literature, much of the research focuses on compressive strength, and technical data on tensile strength is few. [9]Although several studies have looked at the influence of nano silica on cement mortars, this research has focused on nano silica engineering in order to achieve significant outcomes. The authors used a simple and quick sol gel approach to make silica nanoparticles.The impact ofcalcinationandsurfactant on the size and shape of nano silica was studied. Different dosages of produced silica nanoparticles were added to cement mortars, and the effects on compressive and flexural strengths were investigated. [7]Colloidal silica (CS)isatermusedtodescribetinyparticlesmadeupofan amorphous SiO2 corewitha hydroxylatedsurfacethatare insolubleinwater.Theparticles'sizescanrangefrom1to 500 nm, making them tiny enough to stay suspended in a fluid medium without settling.The nanometer sized CS particleshavealargespecificsurfacearea,makingthema highly reactive siliceous material. However, it is still unknown whether the faster hydration of cement in the presenceofnano silica isrelatedtoitschemical reactivity during dissolution (pozzolanic activity) or a high level of surface activity. [6]According to the study, nano silica

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

comes in two forms: compressed dry grains and colloidal solution. Dry nano silica necessitates a particular preparation method prior to mixing to ensure that the nano particles are well dispersed in the mixing water, or other liquid admixtures, and are evenly distributed throughout the concrete mixture. Colloidal nano silica, on theotherhand,isaready to useversionofnano silicathat is generated as a suspension stabilized by a dispersive agent. [11]When compared to typical grain size materials with the same chemical composition, nanoscale particles can have dramatically better characteristics. As a result, industriesmaybeabletore engineermanyexistingitems and build new and creative products that perform at previouslyunimaginablelevels.[6]Itshouldbeunderlined that nano silica isa muchmore expensive admixture than silica fume; therefore replacing SF with nano silica is not cost effective. A more efficient technique to achieve some favorablesecondaryeffectsistoutilizenano silicainsmall amounts.[10]Theeffectofdifferenttypesofcolloidalsilica on the characteristics of concrete is briefly examined in thisarticle.

There are several types of cement, including OPC, PPC, rapidhardeningcement,lowheatcement,andso on, with OPC and PPC being the most popular. The most frequent typeofcement utilizedinstudiesisOPC,whichstandsfor ordinary Portland cement. Irish Cement Ltd provided the ordinary Portland cement (PC) used in this investigation. The cement had a specific gravity of 3.15 g/cm3 and was grade 42.5. [2]Low thermal conductivity characterizes lightweight concrete.As a result, slow hydration cement should be utilized in mix designs to prevent thermal microcracking caused by heat evolution during cement hydration. As a result, CEM III/A 42.5 N slag cement was used. [5]Ordinary Portland Cement was employed, which has a 28 day compressive strength of 54 MPa. [9]This investigation employed a type I Portland cement with a Blainefinenessof385m2/kg.[11]

Table1. Chemicalcompositionandphysicalpropertiesof cementitiousmaterials[6]

Constituents

Content(%)

SiO2 16.51

CaO 62.15

MgO 1.05

K2O 0.50

SO3 3.53

Na2O 0.09 Cl 0.03

Specificgravity 3.02 SpecificSurfaceArea(m2/g) 0.318

A typical concrete mixture contains 10% to 15% cement, 60%to75%aggregate,and15%to20%water.Asaresult, aggregate is the most significant component of concrete. As a reason, the aggregate must be carefully graded. Sand with particle sizes ranging from 1.18 mm to 5 mm, a specific gravity of 2.60 g/cm3 2.78 g/cm3, and fineness modulesof2.5to3wereemployed.Waterabsorptionwas measured in the range of 0.2 percent to 0.8 percent. [2,6,8,9,12]The coarse aggregate utilized was well graded natural gravel with particle sizes ranging from 10 to 25 mm, a specific gravity of 2.77 g/cm3 2.78 g/cm3, and finenessmodulesof6.95.Waterabsorptionwasmeasured in the range of 0.6 percent to 0.9 percent. [2,8,10,12] For theexperimentwithlight weightconcreteasalightweight aggregate, Liaver expanded glass with varied fractions (0.5 1,1 2,and2 4mm)wasemployed.[5]

In concrete, water plays a crucial function. Water aids the hydration of cement, resulting in the cement's binding properties.Theportablewater hada pH rangeof 6to 7.5. Different research used a wide variety of water cement ratios, ranging from 0.26 to 0.45 and higher up to 0.80. [ 3,6 9,11] In some research, varying dosages (0.1 to 3.5 percent) of admixture super plasticizers are used to achieveaconsistentworkabilitylevel.[2,3,9,10,12]

The effect of silica on various qualities of concrete has been studied in literature. The silica utilized in this approach was either solid or liquid. Silica fume is solid silica, and colloidal silica or nano silica is liquid silica.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

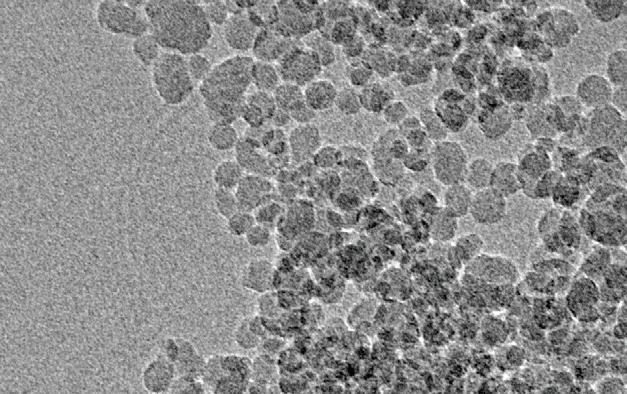

Colloidalsilicaisasuspensioninaliquidphasecontaining tiny amorphous, nonporous, and generally spherical silica particles. It's characterized as a concentrated stable dispersion made up of discrete and dense amorphous silica SiO2 particles with uniform particle sizes ranging from 5 to 100 nm with a high specific area. These suspensions have a solid concentration of 30%. [6]The colloidal silica sol utilized had a solid content of 15% by weight.The particle size was5nm, witha specific surface areaof500m2/g. [2]

Fig. 1 Transmissionelectronmicrograph(TEM)ofnano SiO2 [6]

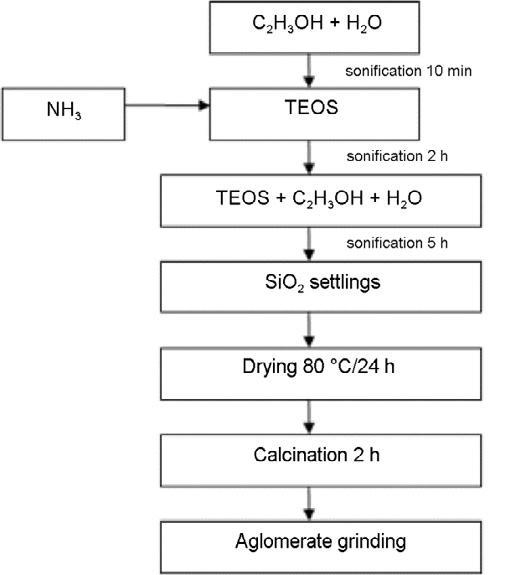

Fig. 2 Schematicprocedureofsilicanano particles preparation[7]

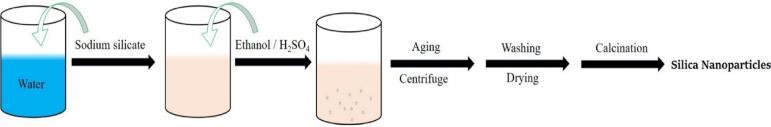

Fig. 3 GenadyShakhmenkoetal.UsedSol Gelmethodfor synthesizingSiO2 nano particle[10]

P. Sikora et al. used silica fume to replace cement in light weight concrete and compared the results to colloidal silica replaced concrete. [5]Instead of using nanoSiO2 powder,colloidalnanoSiO2 (CNS)wasemployedtoensure auniformdispersionofnanoSiO2 inthecementpaste.The sol gel process was utilized to manufacture sodium stabilizedCNSwithanaverageparticlesizeof10nm(CNS 10).[11]Thenano silicausedwasinthecolloidalformofa 50 percent SiO2 aqueous solution. The nano silica had a meanparticlesizeof35nm,aspecificgravityof1.36,anda pH of 9.5, respectively. [12]The research suggests that in the majority of cases, silica fume replacement is greater, ranging from 5% to 30%. [3,8,9]The nano silica replacement, on the other hand, was in a smaller proportion,rangingfrom1%to15%.[2,5 7,10 12]

The fresh qualities of concrete, such as workability, bleedingandsegregation,andsettingtime,areallaffected by silica in any form. Because of the large increase in viscosity caused by adding Nano Silica to the mix, a smalleramountofstabilizer (ornoneatall)isrequired to prevent bleeding and segregation.[5]After observing a decrease in workability when adding silica fume to concrete, M. Mazloom et al. discovered that mixes containing higher silica fume content required larger

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

super plasticizer dosages. [3]According to Mounir Ltifi et al., the setting of fresh pastes was marginally accelerated as the nano SiO2 content increased, but the gap between the initial and final time decreased as the NS content was increased. [6]Behnam Behnia also affirms that by adding 4% silica nanoparticles to the cement paste, the sample's curingtimewasreducedto220minutesfrom250minutes forthe0%silicasample.[7]

The impact of silica on concrete's compressive strength is quantifiable. Several investigations have been conducted on the effect of silica on concrete compressive strength at various curing ages of 7, 14, 28, and 90 days. M. Aly discovered that when colloidal silica was substituted by waste glass, the compressive strength rose by 31 percent at a 3 percent colloidal silica replacement percentage. [2]M. Mazloom discovered that at the age of 28 days, the strength of concrete containing 15% silica fume was around 21% higher than that of control concrete, with a minimalincreaseafter90days.Thisdemonstratesthatthe addition of silica fume to concrete mostly impacts the concrete's short term strength. [3]P. Sikora investigated the effect of nano silica on light weight concrete, discovering a significant increase in flexural and compressive strengths after 28 days of curing in both LW and ULWA concretes when cement was replaced by NS. [5]The addition of nano SiO2 to cement mortars improves their strength properties, according to the author. As the nano SiO2 content in the mortars increased from 3% to 10%, the strength of the mortars increased. They also stated that increasing the amount of nano SiO2 in the mix must be followed by changes in the water dosage to guarantee that specimens do not suffer from excessive self desiccationandcracking.[6]

Compressive strength silica fume addition

20

15

10

5

0

25 7 14 28 90 % c h a n g e

Curing age in days

Chart-1 PercentagechangeinCompressivestrengthof concreteincorporatingsilicafume[3]

Compressive strength nano silica addition 1% 2% 3% 4% 5% 10% 15%

Curing age in days

Chart 2 PercentagechangeinCompressivestrengthof concreteincorporatingnano silica[7]

Both the 6 percent and 12 percent SF concrete mixtures demonstrated an increase in compressive strengths when compared to ordinary concrete, according to J.M.R. Dotto et al. [8]S. Bhanja and B. Sengupta discovered that at 15 percent silica fume replacement, the maximum compressive strength was attained at 28 days curing age, howeverthatincreasingthesilicafumepercentagecaused slightly reduced compressive strength. [9]According to Genady Shakhmenko et al., the sol gel nano silica has no noticeable effect on long term compressive strength. [10]According to A.M. Said et al., adding nano silica to the

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

mix boosted the strength by up to 6% at all curing ages. The compressive strength of mixtures containing 30 percent Class F fly ash and nano silica was significantly improvedat28days.[12]

As well as compressive strength, silica has an effect on flexural and tensile strength. According to M. Aly et al., colloidal silica can boost the flexural strength of concrete byupto55percent.[2]P.Sikoraetal.studiedtheeffectof silica fume and nano silica on light and ultra light weight concrete and observed that the silica fume dose had no effect on the flexural strength of LW and ULW concrete. Nano silica, on the other hand, has a favorable and visible impact on both LW and ULW concrete's flexural strength. [8]Incorporating 4% silica nano particles into the mix resultedinoptimalflexuralstrengthof22.61percentfor3 days, 10.12 percent for 7 days, and 17.20 percent for 28 days,accordingtoBehnam Behnia.These findingssuggest that nano silica aids in the development of flexural strength in concrete at an early age. He also notes that increasingthesilicadosagereducestheflexuralstrengthof concreteslightly.[7]

strength nano silica addition

flextural strength silica fume addition at different w/c ratio 0.26 0.30 0.34 0.38 0.42

silica fume (%)

Chart-4 PercentagechangeinFlexuralstrengthof concreteincorporatingsilicafume[9]

S. Bhanja and B. Sengupta further confirm that increasing thedosageofsilicafumereplacementreducestheincrease insplit tensilestrength. In terms of percentages, 15%and 20% silica fume replacement improve split tensile strength by 25% and 25.7 %, respectively; however 25% silica fume replacement only improves split tensile strength by 19.3 percent. However, flexural strength increasessignificantlywith largersilica fumereplacement percentages.[9]

Thischapterpresentsanoverviewofstudiesontheimpact of silica on concrete mechanical properties. The following arethefindingsoftheliteraturereview:

Curing age in days

Chart 3 PercentagechangeinFlexuralstrengthof concreteincorporatingnano silica[7]

•Nano silicaimprovestheconcrete'sfreshcharacteristics. The use of a little amount of nano silica reduces bleeding andsegregation.

• Adding colloidal silica to concrete reduces its workability, necessitating the addition of a substantial amountofsuper plasticizertokeeptheconcreteworkable.

•Thesameisapplicablefor silica fume:asthepercentage of silica fume added increases, the demand for super plasticizerincreasestokeeptheconcreteworkable.

•Due to the presence of silica, the setting time of concrete isaccelerated.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

•Up to a specific dosage, silica improves the compressive strength of concrete at various curing ages, but further silica replacement causes no appreciable increase in compressivestrength.

• After adding silica to concrete, the split tensile and flexural strengths respond similarly to the compressive strength. The silica replacement exhibits a substantial increase in flexural and split tensile strength at a given dosage.

According to the literature, silica has a significant impact on the characteristics of concrete, indicating that it is a viable alternative for usage as a supplemental cementing element. The usage of silica fume is now common in the construction sector, but colloidal silica will be more effective in the future, both environmentally and economically.

1.D.Kongetal.,Influenceofnano silicaagglomerationon microstructure and properties of the hardened cement based materials, Construction and Building Materials, 37, (2012),707 715.

2. M. Aly et al. , Effect of colloidal nano silica on the mechanical and physical behavior of waste glass cement mortar,MaterialsandDesign,33,(2012),127 135.

3. M. Mazloom et al. , Effect of silica fume on mechanical properties of high strength concrete, Cement & Concrete Composites,26,(2004),347 357.

4. S. M. Zubair et al. , Experimental Investigation on Effect ofMineralAdmixturesonHighPerformanceConcretewith various W/B ratios, International Journal of Research in EngineeringandTechnology,(2015),eISSN:2319 1163

5. P. Sikora et al. , Evaluating the effects of nanosilica on the material properties of lightweight and ultra lightweight concrete using image based approaches, ConstructionandBuildingMaterials,264,(2020),120241

6. Mounir Ltifi et al. , Experimental study of the effect of additionofnano silicaonthebehaviorofcementmortars, ProcediaEngineering,10,(2011),900 905.

7. Behnam Behnia et al. , High performance cement mortars based composites with colloidal nano silica: Synthesis, characterization and mechanical properties, ArabianJournalofChemistry,14,(2021),103338.

8. J.M.R. Dotto et al. , Influence of silica fume addition on concretes physical properties and on corrosion behaviour ofreinforcementbars,Cement&ConcreteComposites,26, (2004),31 39.

9. S. Bhanja, B. Sengupta , Influence of silica fume on the tensile strength of concrete, Cement and Concrete Research,35,(2005),743 747.

10. Genady Shakhmenko et al., Influence of Sol Gel Nanosilica on Hardening Processes and Physically Mechanical Properties of Cement Paste, Procedia Engineering,57,(2013),1013 1021.

11.P.Houetal.,ModificationeffectsofcolloidalnanoSiO2 oncementhydrationanditsgelproperty,Composites:Part B45,(2013),440 448.

12.A.M. Said et al. , Properties of concrete incorporating nano silica, Construction and Building Materials, 36, (2012),838 844.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2550