International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1Karthik J Iyer, 2Jaydipkumar K Valaki, 3Arpitkumar R Hathila, 4Akil H Jariya

1,2,3Undergraduate Student, Production Engineering Department at Birla Vishvakarma Mahavidyalaya (BVM) Engineering College, Vallabh Vidyanagar, Anand Dist., Gujarat, India 4Assistant Professor,DepartmentofProductionEngineering, Birla Vishvakarma Mahavidyalaya (BVM) Engineering College, Vallabh Vidyanagar, Anand Dist., Gujarat, India ***

Abstract This study has been done for the productivity improvement of a motor manufacturing company. Data collection was done by which it was analysed that the reduction of time in certain operations can be done and performingcertainsetofoperationssimultaneouslycanover all reduce the cycle time of the assembly of the motors. Increase in production rate about 65 units/shift is observed.

Key Words: Productivity Improvement, Production Rate, CycleTime,ParetoChart

Timestudyisthebaselineforanyprocess.Withoutthetime study, one can never know whether the process have possibility of any improvement in its performance or the processhaveimprovedcomparedtotheprevious.Oneofthe important objectives of the time study is to analyse the activitiesforperformingajobwiththeviewtoeliminateor toreduceunnecessaryorrepetitiveoperations.Bywhichthe human effort can be minimized. Time study also helps in evaluating the performance for the development of individual or group strategies for achieving the above average performance and the evaluation of workstation’s productivity

Datacollectionisoneoftheimportantpartsofanystudy. Since data gives us the existing scenario ofwhat exactlyis happeningoroccurring.Datacollectionplaysavitalrolefor anyoftheproject.Foranyimprovementtobedone,onemust collecttheexistingdatasothataftertheimprovement,the proposed data or the implemented data can be compared withtheexistingdata.

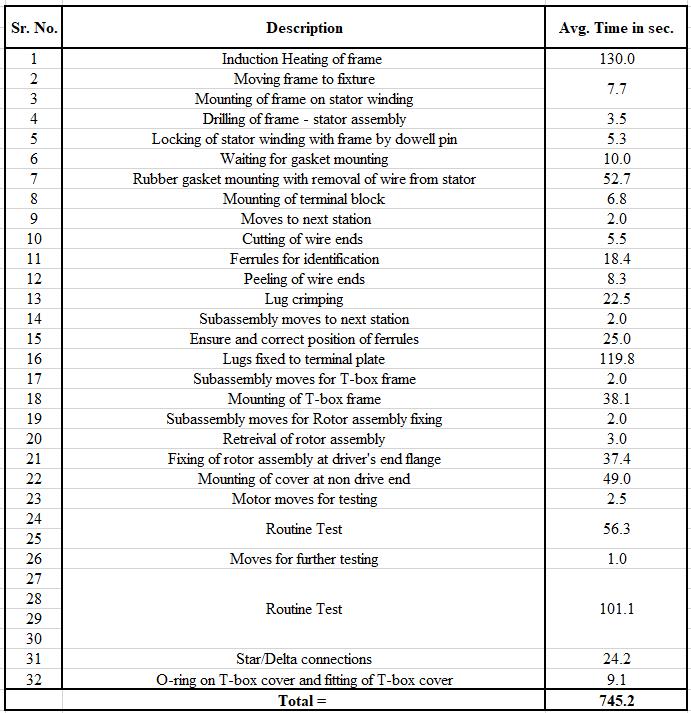

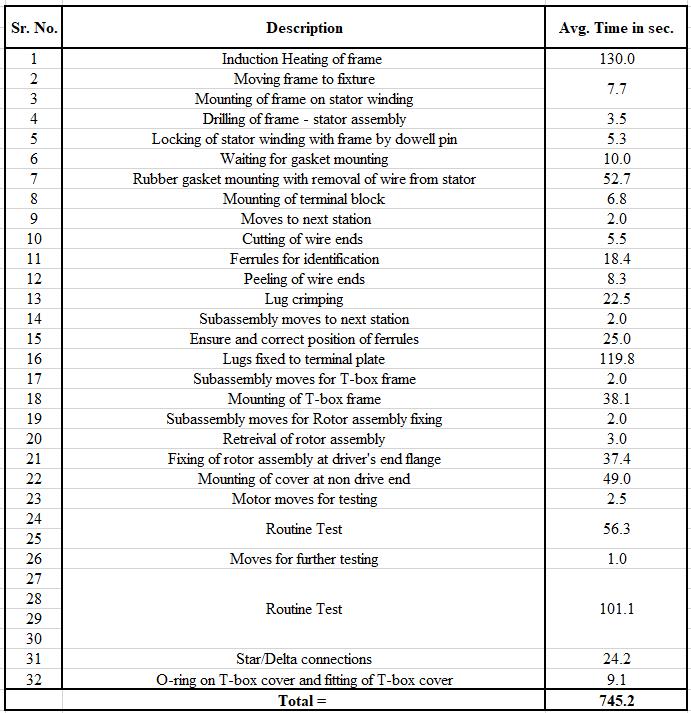

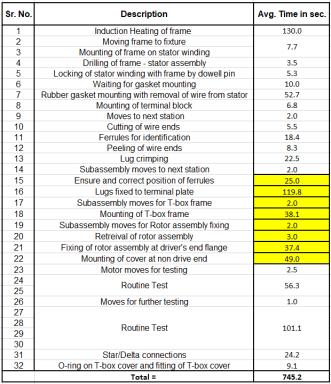

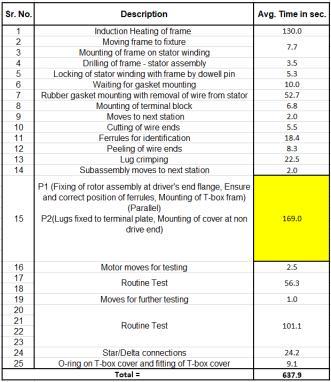

Currenttimestudyoftheassemblylineoftheinduction motorwasrecordedandtheaverageoftenreadingswere taken.

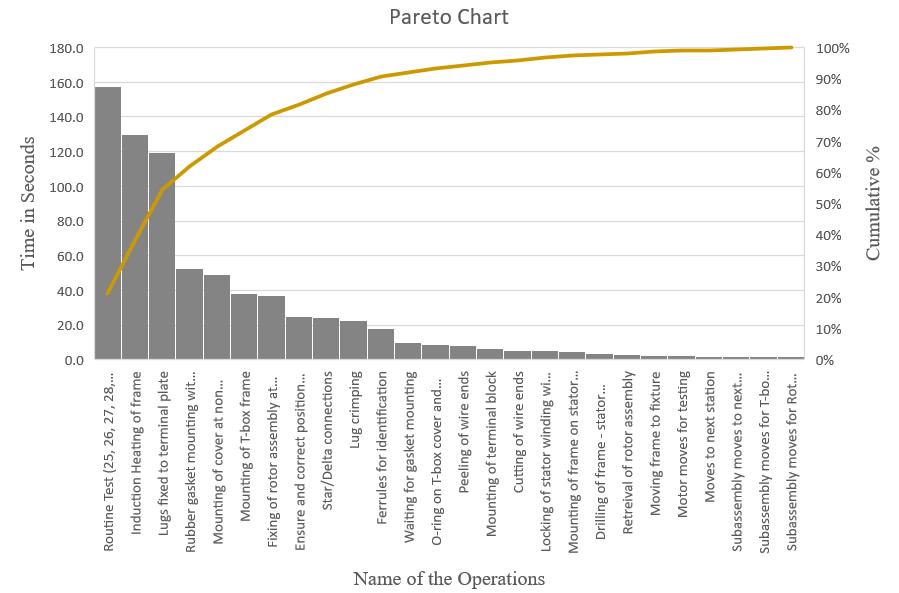

Bytheparetoanalysisofthecurrentassemblyprocesswe canknowthemosttime consumingstepintheassemblyand possibility of the improvement in any of the step is taken care. Then after, performing of certain assembly steps simultaneously in the assembly was suggested by which, reduction in cycle time was observed. So, by the implementationofnewtestingmachineandifthesuggested method for performing certain operations simultaneously wasimplementedthentheoverallcycletimeisreducedand increaseintheproductionratewillbeobserved.

Principle [4] TheParetoprinciplestatesthatformany outcomes,roughly80%ofconsequencescomefrom20%of causes.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

The main motive of the pareto chart is to bring out the largest(important)oneamongtheavailabledata.Mostlythis tool is used in the quality management for any of the industry to find out the most occurred defect among the occurrenceofthedefect.So,bythearrangementofthedata indescendingorderaspertheimportancepriority,onecan identify the most targeted data (20% Causes) that can resolvethe80%consequences.Wehavethecollecteddata (Table 1)inwhich,byarrangingthevaluesofAveragetime insecondscolumnindescendingorder,wewillgetthemost time consumingoperationsfromthat.So,workingonthose operationswillreducethetimeconsumptionintheassembly process.Descriptionnumber24,25,26,27,28,29and30are the combined operation which is the routine testing operation.Andpracticallytheimprovementofdescription number1(InductionHeating)wasnotpossibleasthetime takenfortheinductionheatingoftheframewasconstant.

Aspertheprincipleoftheparetoanalysis,weproceededfor theimprovementofassemblyline.Firstly,wefocusedonthe routinetestingmachineasitwasthemosttime consuming operationamongalltheoperations.Thenafterwefocusedon otheroperationsandwefoundoutthatcertainoperations canbesimultaneouslyperformedbyproperarrangementof theworkers.Byapplyingtheparetoprincipleforourcase,we proceededfortheimprovementoftheassemblylineofthe motors which positively increase the productivity of the assemblyline.

Fromthetimestudytable,weobservedthatthebottleneck operationwasinthelastfewsteps(i.e.,Timetakenfortesting operation). Description number 24, 25, 27, 28, 29 and 30 consistsoftestingoperations.24 IRTest(InsulationTest) ,25 HV Test (High Voltage) ,27 Resistance test ,28 Reduced Voltage test, 29 No load test, 30 LockedRotor test.Andallthesetestsaredoneintestingmachinewhichis denotedas‘RoutineTest’.Fromthetimestudytable,Number (24, 25) = 56.3 sec. and Number (27, 28, 29, 30) = 101.1 seconds. Therefore, the total time taken for the above mentioned will be: Number (24, 25, 27, 28, 29, 30) = (56.3+101.1) =157.4 sec. Now, 157.4 sec. is the greatest amongallthetimingsinthetable.Hence,thebottle neckof theassemblyisidentified.

Aftertheidentificationofthebottle neckintheassemblyline, itwasfoundthattheavailabilityoftheimprovedtechnology isfeasibleandcompanytookfurtheractionsforthesameand implementedthenewmachinewhichtherebytakesabout90 sec.fortestingasinglemotor.

By analysis, we came to know that there are certain operations which can be performed parallelly (simultaneously)bywhichtherewillbereductioninthecycle timeoftheassemblyline.Butbeforeproceedingwewillfirst understand the operations in detail which can be done parallelly.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

15

16

18

21

22

Ensureandcorrectpositionof ferrules.Theferrulesare positionedtotheendofthe wire,nearcrimpedlug(Top side)andnowalltheselugs insertedonthebolt.

Lugsarescrewedtothe terminalplate.Thecrimped lugsarefittedbynut,washer andboltbythehelpof pneumaticgun

MountingofT boxframe.The frameofterminalboxisfixed onthetopsideofthemotor withthehelpofbolt,nutand washer.

Fixingofrotorassemblyat driver'sendflange.Retrievalof rotorassemblyiscarriedout thenitisfixedtothedriveside ofthemotor.

Mountingofcoveratnondrive endFixingofendcoverofthe motoratmotor'snon drive end.

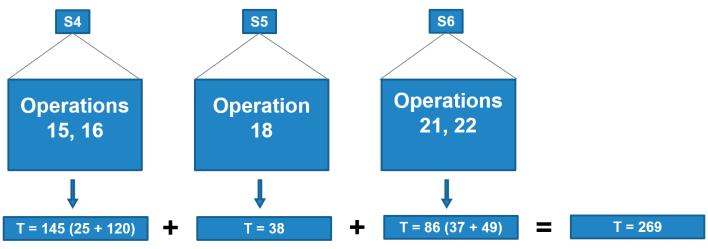

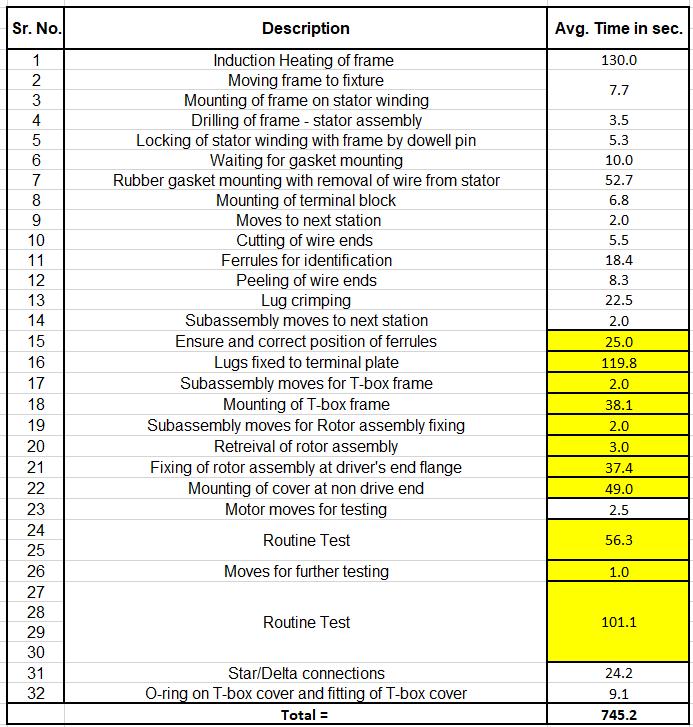

Abovementionedoperationnumbersanditsfunctioningis nowunderstood.Now,forthementionedoperations,thetime takenforperformingthesameareasfollows:

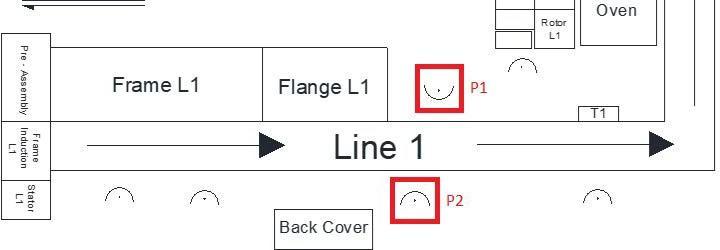

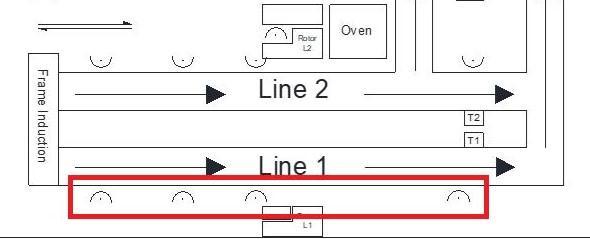

Theabovediscussedoperations(i.e.,operationnumber15, 16, 18, 21 and 22) are here carried out in sequence. After analyzingthesequenceofoperations,wecametoknowthat theabovediscussedoperationscanbecarriedoutparallelly in systematic way. The below figure conveys that the operationscanbeperformedparallellybyschedulingthemin systematic manner. As it is observed that the difference between the above and below figure is that, one of the membersofline 1willbearrangedontheoppositesideof theline 1(Asshowninbelowfigure)

S (4,5,6) = Stations and T = Time taken for the respective station in seconds For the imagination purpose, we have shownbytheblockdiagram(Fig 1)includingtheoperation number andthe respective time taken forperformingthat operation. We can see that the total time taken for performing the mentioned operations is 269seconds. And these operations are performed in series in the existing layout.Regardingthelayoutandthepositionoftheworkers, wewillbediscussingfurtherwiththeappropriatedrawing. Forunderstandingtheproposedmethodologyofperforming thesetofoperationsparallellyandsimultaneouslywewill first understand the existing layout and line up of the workers.Allthementionedoperationsaredoneinsingleline (i.e., One after one operation is carried out in sequence in singlelineasshowninthebelowfigure)

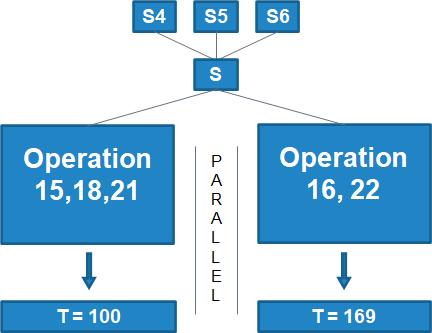

The following operations will be carried out as scheduled belowtoindividualperson[i.e.,ForPerson1(P1)andPerson 2 (P2) as indicated by red coloured box]. For person, the followingoperationswillbecarriedout.P1 Operation(15, 18, 21), P2 Operation (16, 22). For the understanding purpose, we assume that the operation number 15 (i.e., Ensureandcorrectpositionofferrules)isalreadyfinishedfor onemotor.Now,thismotorwillproceedtotheperson(P1 andP2)intheinductionassemblyline.

The following operations will be carried out in the listed manner:

P2willstartoperationnumber16(i.e.,Lugsscrewedtothe terminal plate) simultaneously P1 will start operation number21(Fixingofrotorassemblyatdriver'sendflange). Operationnumber16willconsume120sec.andoperation21 willconsume37sec.Therefore,P1willbefreeforabout = (120 37)=83seconds.Inthistime,P1willperformoperation number15forthenextmotorwhichwillconsumeabout25 sec.Therefore,thetimeremainingforP1willbe=(83 25) =58 seconds. Now, for the remaining time, person P1 can perform auxiliary tasks like, installing necessary stickers,

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Helping the other by tightening the nut with the help of pneumaticgun.After120sec.,P1andP2willcompletetheir operations and will be proceeding with next operation discussed below, P1 will perform operation number 18 (MountingofT boxframe)simultaneouslyP2willperform operationnumber22(Mountingofcoveratnondriveend).

The block diagram for the proposed methodology is as follows:

Existing cycle time is 745.2 seconds and if the proposed arrangementisappliedthenthenewcycletimewillbe637.9 seconds.The%Reductionincycletimewillbe=[((745.2 637.9))/745.2]×100=14.4%

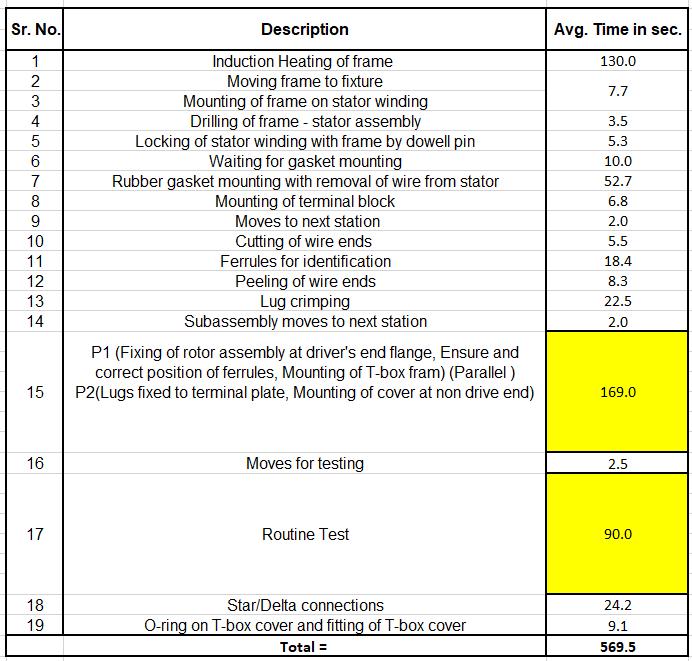

The testing machine is implemented and if the proposed arrangement of performing certain set of operations parallelly (simultaneously) is also implemented then the resultwillbe:

Fromtheblockdiagramwecanseethatthemaximumtime willbethestationtime(i.e.,169sec.).T=Timetakenforthe respectivestationinseconds.Byimplementingtheproposed method,thetimesavedwillbe,

Hence,thetotaltimesavedpermotorwillbe100seconds. The existing time taken is 745.2 seconds as seen in below table

Intheexistingmethodthecycletimeis745.2seconds.So, aftertheimplementationofboththediscussedthenewcycle timewillbe569.5(Table 5)

Therefore, the % reduction in the cycle time will be = [((745.2 569.5))/745.2]×100=23.57%

Currently approximately 200 units are made per shift (25200seconds)by6persons.

Therefore,forthenewcycletimeof569.5secondstheunits madewillbe=(25200/569.5)=44.24(units)⁄person

Since,AssemblyLineiscarriedoutby6persons,theunits madewillbe=(44.24×6)=265units⁄shift

Hence, by implementing both the discussed, the total number of extra units made will be = (265 200) = 65 units⁄shift

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Therefore,theproductivityimprovementwillbe=(65/200) ×100=32.5%

Table 5: CycleTimeafterimplementation

[6] https://www.dissertationhelp.co.in/our process/importance of data collection/

[1] Nikhil Verma, Pulkit Trivedi, Vivek Agnihotri, Productivity Improvement in Assembly Line of an Automobile, IOSR Journal of Mechanical and Civil Engineering (IOSR JMCE), Volume 12, Issue 4 Ver. III (Jul. Aug. 2015), PP 01 06M. Young, The Technical Writer’sHandbook.MillValley,CA:UniversityScience, 1989.

[2] Abdul TalibBon, SitiNorAini,Samsudin,Productivity ImprovementinAssemblyLinebyReductionCycleTime using Time Study at Automotive Manufacturer, Proceedings of the International Conference on Industrial Engineering and Operations Management Bandung,Indonesia,March6 8,2018K.

[3] Productivity Improvement in Machining Industry by using Time Study and Method Study Techniques, International Research Journal of Engineering and Technology(IRJET),Volume:07Issue:07,JULY2020

[4] Productivity improvement by work and time study technique for earth energy glass manufacturing company,4thWorldConferenceonBusiness,Economics andManagement,WCBEM

[5] https://en.wikipedia.org/wiki/Pareto_principle

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page