International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

DESIGN AND ANALYSIS OF COUNTER FLOW VORTEX TUBE

Abstract Vortex tube is a mechanical device, without any moving parts. It separates the compressed air stream in to a low temperature flow and a high temperature flow, such separation of flow in two regions low side and high side is knownasthetemperatureorenergyseparationeffect.Vortex tube has many applications, for example, electronic systems cooling, machining processes cooling, in aviation and environmental chambers. This paper presents the design, analysis and modifications of parametric design based on parameters and data found in the literature. This paper describes the experimental study of the temperature separation phenomenon in a vortex tube. Effects of (1) using insulation on tube, (2) the cold and hot orifice diameter, (3) tube length, (4) using different material, and (5) Surface roughness on the temperature reduction of the tube were experimentally investigated.

Key Words: Vortex Tube, design, analysis, temperature, energyseparationeffect

1. INTRODUCTION

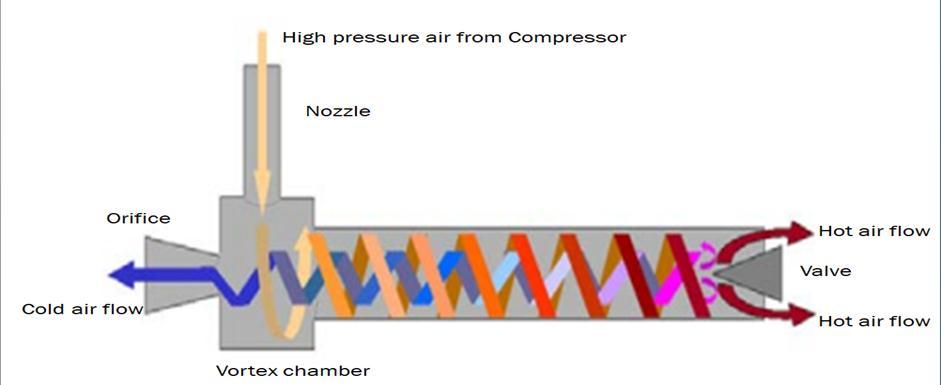

TheVortexTube(VT)isadevicethatgeneratescoldandhot air from compressed air. It was invented by Georges J. Ranque in 1933[1]. The German engineer Rudolf Hilsch suggestedtheworkingvortextubedesignin1947[2].Itisa simple device having low cost, with no moving parts, no electricityandthereisapossibilitytoadjustthetemperature [3,4].Themaindrawbacksareitslowthermalefficiency,the noiseandtheavailabilityofcompressedair.VortexTubeis commonlyusedinaviation,space/miningsuitscooling,spot cooling,whencompressedairisavailable,likecuttingtools ofCNCmachines,laboratoryequipment,etc.Compressedair issentthroughthetangentialinletnozzlesothatthevortex motioncanbecreatedinsidethetube,fig.1.

2. WORKING PRINCIPAL

Compressed air is passed through the nozzle as shown in previous image. Then air expands through the nozzle and acquireshighvelocityandswirlmotioniscreatedinvortex chamber Thenduetoitsdesign,theairmovestowardsthe partlyclosedvalveend.Asitreachesthevalve,theKinetic Energy is converted into the pressure energy and state of stagnationisreached.Butthestagnationpressureishigheras comparedtothepressureatleftside;thereforethereversal inflowtakesplace.Duringthisprocess,heatistransferred fromreversedstreamtoforwardstream.Therefore,reversed airstreamgetscooledbelowtheinlettemperatureoftheair, whileforwardairstream getsheatedup.Thecoldstream escapes through the back side orifice, while hot stream is passedthroughtheopeningofthevalve.Bycontrollingthe openingandclosingofthevalve,thequantityoftheairand itstemperaturecanbevaried.[3]

3. LITERATURE REVIEW

TheVortexTubecanbeusedinatemperaturecontrolwork andisveryeffectiveandeconomicalwherethecompressed airisreadilyavailable[1] Thereisnobetteradvantageof thiswherethecharacteristicslikelowweight,combination of cooler and heater are desired and the compressed air which is the only main cost present with it Refrigeration playsamajorroleindevelopingthecountries,generallyitis preferred for food preservation, also for providing the comfortable environment especially it is used for air conditioning. It plays a vital role in storage of ice, blood,

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

medicines, preservation of photographic films, archaeologicaldocumentsetc.byusingFreonorR134aR 11 toR 50asarefrigerant,whicharethemainsourcesofthe ozonelayer depletion. After a very longtime an extensive research is carried out for an alternative refrigeration system.Thevortextubeisfoundtobeanexcellentsolution oralternatesolutionforrefrigerationsystem.[2]Thevortex tubeperformancemainlydependsonfollowing parameters, firstlyairorworkingparameterssuchasinletpressureof compressedair andsecondlytubeorgeometricparameters suchaslengthofhotsidetube,coldorificediameter,number ofnozzles,diameterofnozzle,valveangleandalsomaterial ofvortextubeaffectsCoefficientofPerformance(COP).[3,4] UVKongreetal analyzedthevortextubemodelinAnsys software. In their work, the design and transient thermal analysisweredonebyusingansys.Ansysgivesmuchbetter approximationofexperimentaldatatomodelingdata.Also different materials were tested for their utility for vortex tube manufacturing sustainable for further future development.[3]MVDudheetalexperimentedresultsofthe energy separation in vortex tubes for different nozzle diameters keeping the rest geometrical parameters constant. It is experimentally manifested that the nozzle diameter greatly affects the separation performance and efficiency.Themostimportantpointrevealedinthispaperis thatthereisanoptimumnozzlediameterthatgivesthebest performanceofvortextube.Anexperimentalinvestigation has been performed to realize the thorough behavior of a vortextubecoolingsystem.Thecounterflowvortextubehas beendesigned,manufacturedandtested.[4]

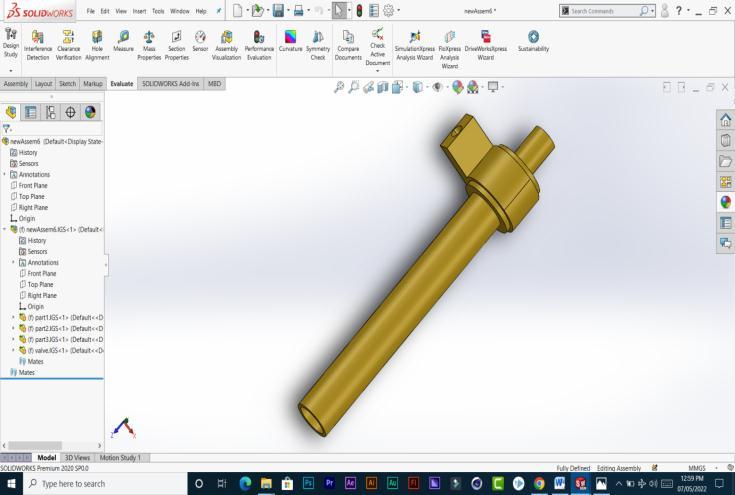

4. DESIGN

3D partsaredesignedinCADSoftware.WeusedSolidworks Premium2020becauseitisthemostpopularCADsoftware right now which gives better results than other CAD software.

Followingdimensionsareused

Hottubelength 100mm

Hottubeouterandinnerdiameter 15mmand12mm respectively

Generatordiameterinnerandouter 20mmand25mm

Nozzlediameter 5mm Coldtubediameter 10mm

Valvediameter 10mm Fulllength 134mm

Afterthemodelingofeachpart,theyweretransferredto theassemblywindowandallthepartswereassembled.

Fig 2: AssembledmodelinSolidworks

5. ANALYSIS IN ASNSYS

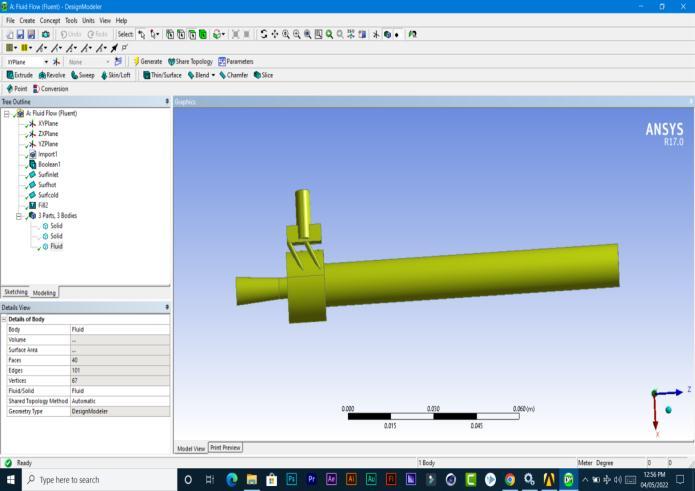

After the assembly of model it was exported in IGS(Initial graphicsexchangespecification)fileformat.Itwasdoneto importitinotherCAD/CAEsoftwares.ThentheIGSfilewas imported in Ansys workbench software. We used Ansys workbench17.0version.

ForthisweusedFluentflowanalysissystem.

5.1 EXTRACTED FLUID DOMAIN

Afterourgeometryimportedindesignmodellerwindow,we usedFillcavitymethod,Afterthefillcavitymethod,wegot our fluid body. The following picture(Fig.3) is the fluid domainofourgeometry.

Fig 3: Extractedfluiddomainmodel

5.2 MESHING

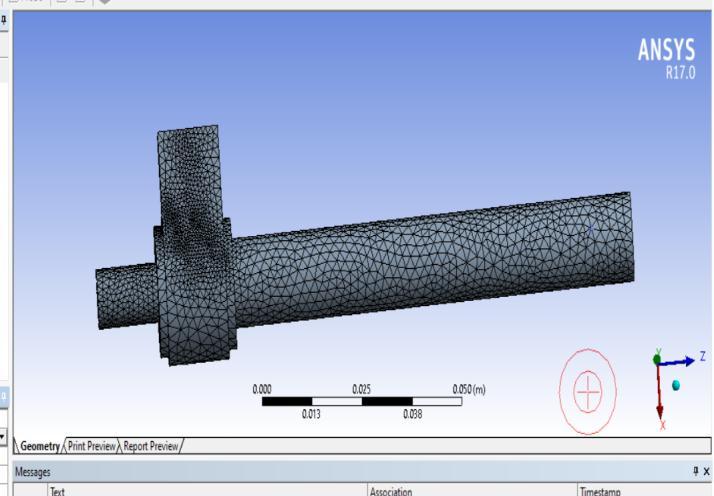

Then we updated the geometry and moved into Meshing window.Weusedtetrahedronmeshingmethod.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

6. RESULT

Fig 4: Meshingmodel

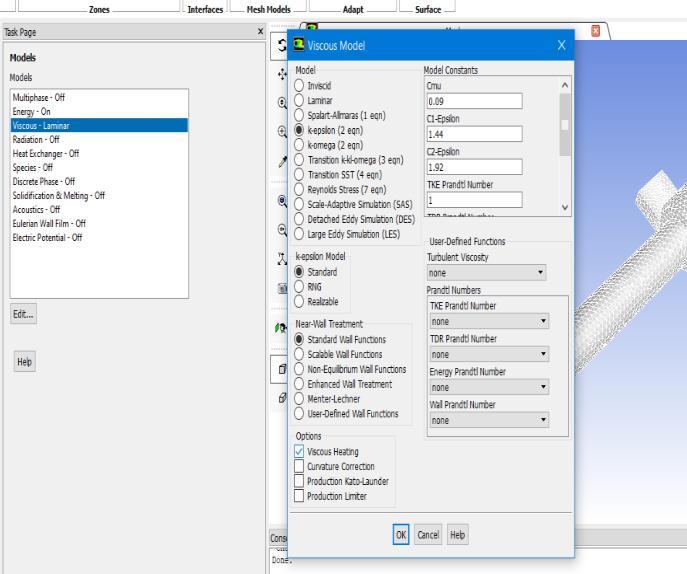

5.3 FLUENT SOLVER

Afterthesuccessfulmeshingweupdatedourgeometryand moved into Fluent Solver window. Then we checked the Energy equation for temperature measurements Weareusingturbulentflow,that’swhyweusedK epsilon modelandcheckedviscousheatingforpropervortexflowas showninFig.5

Fig 5: SetupinFluentSolver

BOUNDARY CONDITIONS

6.1

STEEL MATERIAL WITH ORIGINAL DIMENSIONS

Cellzoneconditionsandboundaryconditionswereapplied asshownprevious..

MaxTemperatureobtained 316k MinTemperatureobtained 280k

Fig 6: Result1(Steelmaterial)

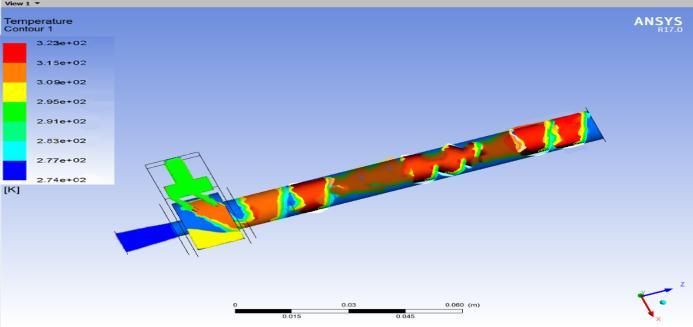

STEEL MATERIAL AND LENGTH INCREASED BY 40mm

6.2

Nowthelengthisincreasedby40mm,thereforethehot tubelengthwhichwaspreviously100mm,nowbecame 140mm.

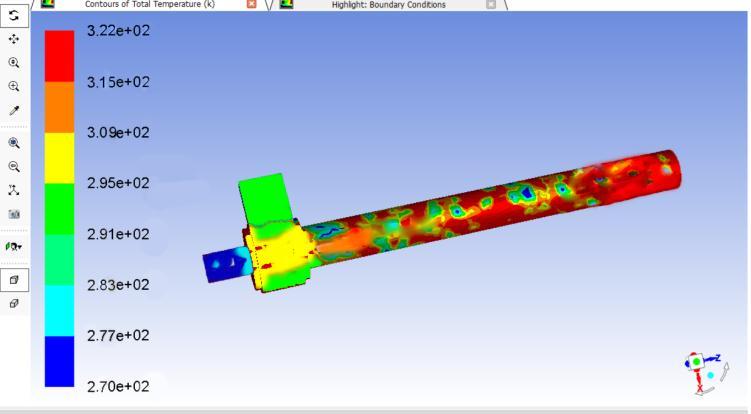

MaxTemperatureobtained 322k MinTemperatureobtained 270k

Fig 7: Result2(Lengthincreased)

6.3 COPPER MATERIAL WITH ORIGINAL DIMENSIONS

Nowcoppermaterialwasdefinedwhenapplyingcellzone conditions.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

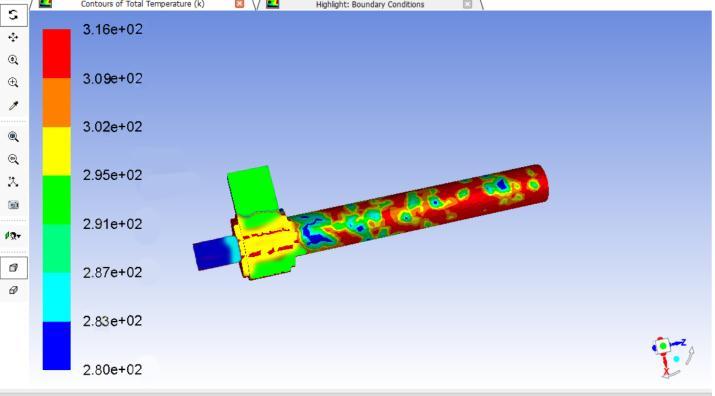

MaxTemperatureobtained 320k MinTemperatureobtained 270k

Fig 8: Result3(Coppermaterial)

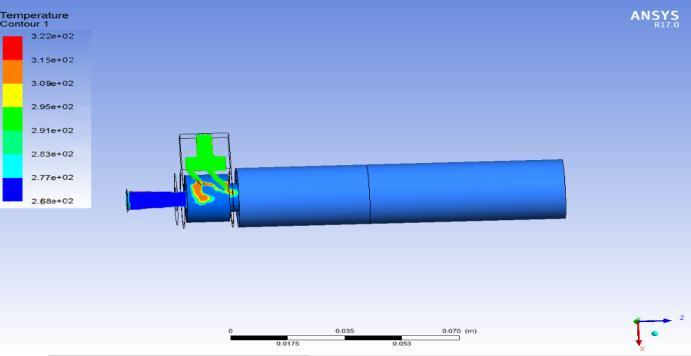

6.4 GLASS WOOL INSULATION

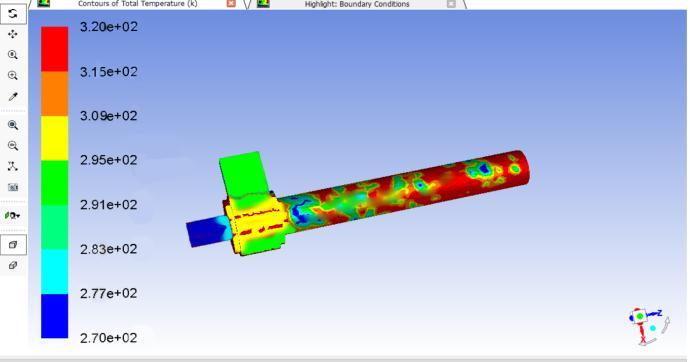

Glasswoolinsulationof8mmthicknessused.

MaxTemperatureobtained 322k MinTemperatureobtained 268k

Fig 9: Result4(Insulation)

6.5 SURFACE ROUGHNESS WITH ORIGINAL DIMENSIONS

Surfaceroughnessof0.1RA(roughnessaverage)defined insidethetubeinnersection.

MaxTemperatureobtained 323k MinTemperatureobtained 274k

Fig -10: Result5(Surfaceroughness)

7. CONCLUSION

Inourworkwefoundthatpressureisdirectlyproportional to the efficiency. Higher the pressure, higher is the difference of hot flow and cold flow. We have used 4 bar pressure in all the experiments. Generally 2 to 7 bar of compressedairisusedbasedonthedesignofthetube.Some high grade industrial vortex tube can even sustain the pressureof12to15bar.

Fromtheaboveexperiment,wehavediscoveredthat coppergivesbetterresultcomparedtosteelduetocopper conductivityishigherthansteel.

Effect of tube length is also directly proportional to efficiency but it is limited to some degree, as larger tube lengthresultsinmoistairattheendofoutlets.

Effect of insulation is as expected, insulation decrease temperature drop from tube wall to surroundings and efficiencyobtainedisbetter.

Some value of roughness inside the tube gave better resultascomparedtosmoothsurfacefinish.Thereasonis thatheattransferincreasesduetotheeffectofincreasein thecontactarea.

If more than one inlets are used, then the resulting efficiencyachieved will behigher asmoreamount ofhigh pressurizedairentersintothechamber.

Nozzle diameter should be balanced to achieve proper tangential motion. Generally small diameter is always desirabletoavoidpressurelossbutalsonottoosmallwhich hindersthepropertangentialflow.

ACKNOWLEDGEMENT

I owe a great thanks to many people who helped and supported me during this research Words will be always inadequatetoexpressmyprofoundsenseofgratitudetomy project coordinator Mr. Santosh Kansal for his unfailing supportandinvaluablesuggestionsateverypointoftime. Last but not the least I would like to express a sense of gratitudeandlovetomybelovedparentsandmyfriendsfor theirmanualsupport,strengthandhelpforeverything.

REFERENCES

[1]PramodBajarangVhankade,“DesignandManufacturing of Vortex Tube “ ,International Journal of Science and Research(IJSR)ISSN(Online):2319 7064 2015

[2] Nitin V Galwade, Prof. Tushar Koli, Prof. Sayyad L.B, “Design and Fabrication of Vortex Tube“ International JournalofScientific&EngineeringResearchVolume9,Issue 3,56ISSN2229 5518 March 2018

[3] U. V. Kongre, M. D. Kurve, P. R Angaitkar, S. R. Ade, “Design and analysis of vortex tube refrigeration”, International Research Journal of Engineering and Technology(IRJET)e ISSN:2395 0056Volume:05Issue:04 |www.irjet.netp ISSN:2395 0072,IRJET Apr 2018

[4]U.V.Kongre,M.V.Dudhe,A.N.Petkar,V.S.Kamble,S.M. Kamble , “Investigation of vortex tube refrigeration with novel material “ , © IJCRT | Volume 6 | ISSN: 2320 2882 2018

[5]DhruvManilawala,SauravKoul,KiranMarudwar,Keval Oswal,“Design,ManufacturingandTestingofVortexTube”, InternationalJournalofFutureGenerationCommunication andNetworkingVol.13,No.2s,(2020)

[6] Mustafa Abdulhussain “A review on the vortex tube geometricalaffectingparameters”JournalofMechanicaland EnergyEngineering,Vol.4(44),No.1,2020

[7]F.P.Branco,E.D.Buchelt,F.M.Barbosa,B.P.Rosa,andD. J. Laporte “Design And Study Of Dimensional Parameters Influence On Vortex Tube Behavior”Universidade Católica DomBoscoDepartamentodeEngenhariaMecânicaBairro JardimSeminárioCP.79117 900,CampoGrande,MS,Brasil

[8]UpendraBeheraa,P.J.Paula ,S.Kasthurirenganb,R. Karunanithi b , S.N. Ram b , K. Dinesh b , S. Jacob “CFD analysisandexperimentalinvestigationstowardsoptimizing theparametersofRanque Hilschvortextube“Department of Aerospace Engineering, Indian Institute of Science, Bangalore560012,India

[9] Penka Zlateva. Krystin Yordanov, diyan M. Dimitrov “Numerical simulation of temperature separation phenomena inside vortex tube” technical university of Varna,Dep.HeatEngineering,Bulgaria,2014

[10] Wasan Naksanee, Rathassak Prommas ” An Experimental Investigation to Reduce the Temperature of Hot Air by means of a Vortex Tubefed with Low Inlet Air Pressure and a Specific Snail Nozzle Geometry Article in International Journal of Engine” International JournalofEngineeringandTechnology·June2018

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |