Study on the Thermal Properties of Mortars with Partial Cement Replacement by Barite and Ceramic Waste Powder

Sachin Soudagar, S. V. Joshi

Sachin Soudagar, S. V. Joshi

ABSTRACT: Buildings consume 40% more power to maintain good thermal comfort for users of the building. Several efforts are being made to reduce this energy. Hence different materials have been recommended to give good thermal comfort inside the building and also contributetolowertheCO2 emission.

In this study, strength and thermal properties of cement mortars with partial replacement of cement by ceramic wastepowderandbaritepowderarestudied.Thecement is replaced partially with varying dosages of ceramic wastepowderandbaritepowderi.e.,by10%,20%,30%, 40% and 50%. Compressive strength and thermal properties like thermal conductivity is found out by hot wire method and specific heat is found out by half open dynamic method. A MatLab code is developed based on cyclic admittance method to obtain thermal characteristics like decrement factor and time lag. Also thermal performance analysis of a building wall is done using COMSOL software wherein plastering material for wallisthecementmortarthatwasdevelopedwithpartial replacement of cement by ceramic waste powder and baritepowder.XRDtestisconductedtoknowthephases developedafterhydration.

Fromexperimentalinvestigationandanalysisinsoftware, CC20 mix has the lowest thermal conductivity of 0.177 W/m K and specific heat of 1009 J/Kg K. From MatLab code,itsdecrementfactorcameouttobe0.026andtime lag of 4.82 hours. From thermal performance analysis of building wall, CC20 as the plastering material showed best results by attaining a temperature of 26°C at the inner surface of the wall when the outer surface of the wallissubjectedtoatemperatureof34.2°C.

KEYWORDS: Barite, Ceramic Waste, Decrement factor, XRDtest,Mortar.

I. INTRODUCTION

Cement is the most widely used man made material inthe world. Itistheprimary component of the concrete mixture. Even though it occupies only 10 15 % of the total volume of the concrete mixture, it is the critical material structure that after reacting with water combines and binds together all the other constituents. Its huge popularity is due to its numerous advantages that it has like low cost, wide applicability and general

availability. But its popularity also carries with it huge risktoenvironment.Itnotonlycontributestothecarbon footprint but also due to its high thermal conductivity, it becomes inefficient in thermally insulating the building. Hencepartialorfullreplacementofcementisconsidered a sustainable solution toward decreasing the environmentalimpactofcementproductionandwillalso contributetosustainableconcrete

The production of cement involves the consumptionoflargequantitiesofrawmaterials,energy, andheat.Cementproductionalsoresultsinthereleaseof a large amount of solid waste materials and gaseous emissions.

There are numerous ways to reduce the environmental impact of concrete and conserve energy. Oneofthewaysistousethesupplementarycementitious material. Since production of cement is energy intensive and also contributes to carbon footprint , substituting it with other materials that are by products of industrial process can be a good option. The best known of such material is Fly ash. It is a residue of coal combustion which is an excellent cementitious material. It also improves certain properties of concrete such as durability.GroundGranulatedBlastFurnaceSlag(GGBFS) is another cementitious material that is a by product of steelindustry. Wecanrelyonrecycledmaterialsalsofor the substitution of cement or aggregates in the concrete mix.Indian ceramic production is 100 million ton per year. About 15 to 30% waste is generated in the ceramic industry from the total production which is not recycled in any format in the present day. They are dumping the wasteinnearbypitorvacantspaces.Thisleadstoserious environmentalanddustpollution.Astheceramicwasteis being piled up every day, pressure is build up on the ceramic industry to find a solution for its safe disposal. Thus employment of ceramic waste powder in various sectors of industry especially construction industry will help in protecting the surrounding. This will result in growthofeco friendlyconcrete.Inadditiontoprotecting the surrounding, it has many other advantages like reductionintheuseofotherrawmaterials,conservation ofenergyasitisareusedmaterial.

There are different types of Ceramic products like wall and floor tiles, brick and roof tiles, table and ornamental ware, refractory products , sanitary ware, etc,. Ceramic waste may come from two source. The first

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

source being the ceramic industry and this waste is classified as non hazardous. They can be waste from thermalprocessand wastefrommanufactureofceramic products, bricks, roof tiles. The second source of ceramic waste is from Construction and demolition activity. BariteisamineralcomposedofBariumSulphate.Itisthe main source of Barium. It gets name from Greek word "barys"whichmeansheavy.Thisisduetothehighatomic weight of barium. It has specific gravity of 4.5 which is extraordinary for a non metallic material. Because of its

highspecific gravity,itis widelyusedindifferentsectors ofindustry.Bariteofsize0 100micronsisbasicallyused in concrete. It is a clean, smooth , unresponsive and inexpensive naturally available material. It is non toxic and non reactive material. It can be one of the best alternativeforpartiallyreplacingcementinconcreteand cementmortar.

II. Methodology

III. Objective No. Statement of the Objective Method/ Methodology Resources Utilised

1

Literaturereview

Referringrelevant journalpapersand referencebooks

Journals/Books 2

Basicmaterial testing Laboratorytest proceduresandcode books

Rawmaterialslikecement, ceramicwastepowder, baritepowder,sand,water anddifferentequipments. 3

StudyofStrength, Thermalproperties andXRDtest

Compressivestrength test,Hotwiremethod forThermal conductivity,HalfOpen Dynamicmethodfor SpecificheatandXRD test

Labequipments, fabricatedequipments, XRDequipmentandmortar cubes 4

StudyofThermal characteristics

TocodeinMatLabto determineDecrement factorandTimelag

MatLabsoftware 5

Factorsaffecting Thermal characteristics

Heattransferanalysis forawallinCOMSOL

DensityandApparent porosity Mortarcubes 6 Thermal performance analysisofbuilding wall

COMSOLMultiphysicsPvt Ltdsoftware

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

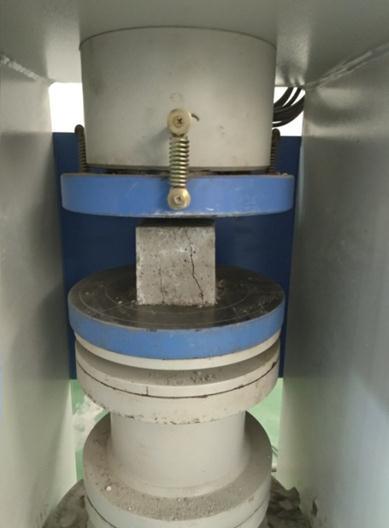

Compressive Strength Test ,Thermal Conductivity And Specific Heat Test:

Experimental setup for measuring thermal conductivity of mortar cubes

Experimental setup for measuring specific heat of mortar cubes

EFFECT OF DENSITY AND POROSITY ON THERMAL PROPERTIES OF MORTAR CUBESincrease in porosity will decrease the thermal conductivity.Toknowtheporosity,waterabsorptiontest was conducted wherein cubes after water curing of 7 days and28 days were usedfortesting.After7 days and 28 days of curing, the cubes are taken out and dried in room temperature for 24 hours. After 24 hours, they are weighed.Thisweightisnoteddownasdryweightofcube beforeimmersion.Theyarethenimmersedinwaterand kept for 48 hours. It is taken out after 48 hours. Any excess water is removed from the surface by wiping it with clean cloth. They are weighed and the weight is noted down as wet weight after immersion. The

measured water absorption percentage is expressed as the increase in weight as percentage of dry weight. The main aim here was to know percentage of voids present and that would be filled with water. This gives the porosityofthematerialbecausebyknowingtheincrease inmassofthesamplewegettoknow howmuchofvoids inthesampleareempty.

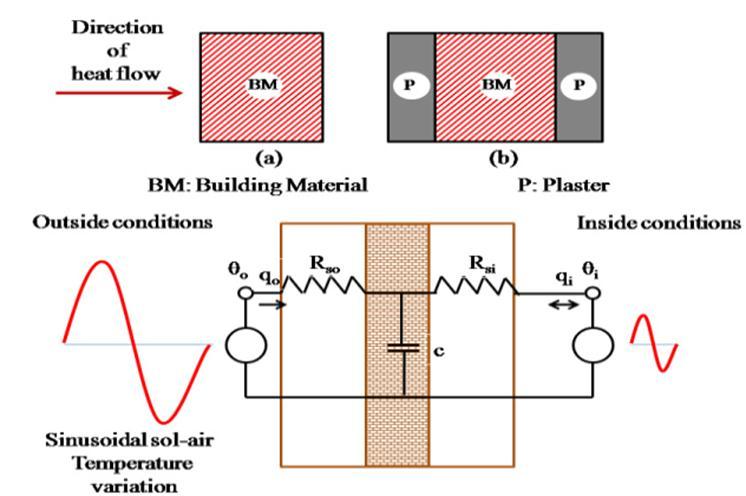

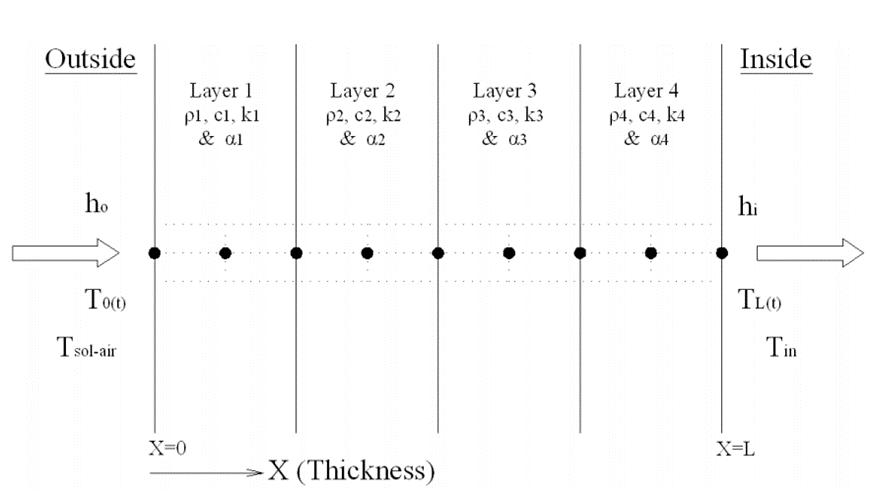

III. Thermal performance analysis of building wall

Forthepracticalapplicationofthematerial,wearegoing tocheck thethermal performanceof a wall.Thisisdone in COMSOL. COMSOL is a general purpose simulation software for modelling designs, devices and processes in all fields of engineering and scientific research. The heat transfer through the walls is assumed to be one dimensional. Some of the wall consists of many layers of different materials with different thickness and different thermalproperties

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

15mm on both the sides. Thickness of the wall being 230mm(includingplastering).

X Ray Diffraction Test (XRD):

To perform material characterization and identifying hydration phases in Cement mortar mix XRD test was conducted.Thistestisperformedforcementmortarwith partial replacement of cement by ceramic and barite which has shown optimum thermal conductivity and specificheattoprovidethermalcomfortofbuilding.

IV. Conclusions:

Thegeneralgoverningonedimensionaltransient heatconductionequationisasfollows,

Where,kisthermalconductivity,ρisthedensity and cp is the specific heat of the building materials. Two boundaryconditionandoneinitialconditionisnecessary to be specified. Convective boundary condition on both insideandoutsidesurfaceofthewallarepresent(C,etal., 2013). Theboundaryconditionatinsidesurfaceisgiven by,

where, hi is the inside surface heat transfer coefficient , for still air its value is 9.36 Wm 2K 1 which is asperIndianstandard3792 1978.

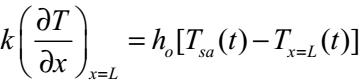

The boundary condition at the outside surface is writtenas,

From the experimental investigation and analysis in software,followingconclusionsaremadewhencementis partially replaced by ceramic waste powder and barite powderincementmortar:

Compressivestrengthdecreaseswithincreasein the percentage of replacement of cement by ceramicwastepowderandbaritepowder.

CC20hastheleastthermalconductivityof0.177 W/m Kwhichis60%lesserthanRMthatshows thermalconductivityof0.449W/m K.

CB20 shows the highest specific heat of 1313.733 J/Kg K which is 15 % more than the specificheatofRM(i.e.,1143.698J/Kg K).

The thermal conductivities of cement mortar with partial replacement of cement by barite powder increased from 7 days to 28 days because of the increase in density. More denser is the material , more is the thermal conductivity.

where, ho is the outside surface convective heat transfercoefficient.Itisgivenbytheformula, ho = 18.63 V0.605 in Wm 2K 1 ( for windwardsurface)

where,V=0.25vforv>2m/s or0.50vforv< 2m/s

Tx=0 is the wall inside surface temperature,

Tx=L is the wall outside surface temperature and T sol(t) isthesol airtemperature(sol airtemperature)

COMSOL works on various formulas and concepts that are related to the analysis. Above formulas are applicable for thermal analysis of the wall. The study isTime dependentanditisanalysedunderheattransfers in solids. A brick wall is considered with plastering of

Thermal conductivities of cement mortar with partial replacementofcementbyceramicwaste powder decreased from 7 days to 28 days even thoughthedensityhasincreasedfrom7daysto 28 days. The possible reason for decrease in thermalconductivityisincreaseinporosity.

Porosity of cement mortar made with partial replacement of cement by ceramic waste powder has increased from 7 days to 28 days. Hence,thereisdecreaseinthermalconductivity forcement ceramicmortarcubes.

CC20 showed lowest decrement factor of 0.026 and highest time lag of 4.582 hours among all othercementmortarmixes.

By thermal performance analysis of the wall, wall made with CC20 as the plastering material decreased the inside surface temperature of the

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

wall to 26°C when outside temperature was 34.2°Candroomtemperaturewas25°C

XRD analysis shows that that peak value of portlandite has decreased with the increase in percentageofreplacementofcementbyceramic wastepowder.Thesameisobservedwithpeaks of CSH which is primarily responsible for strength of cement based materials. This accounts for decrease in strength of cement mortar with the increase in percentage replacement of cement by ceramic waste powder.

Demirboga, R., 2007. Thermal conductivity and compressive strength of concrete incorporation with mineral admixtures. Building and Environment, Elsevier, Volume42,pp.2467 2471.

Demirboga, R. & Gul, R., 2003. The effects of expanded perlite aggregate, silica fume and fly ash on the thermal conductivity of lightweight concrete. Cement and ConcreteResearch,Volume33,pp.723 727.

XRD shows most of the components that were formedafterhydrationhas alumina inone form ortheother.

Future Directions:

• To improve the strength of mortar mixes without altering the thermal characteristics of themixes

• A complete building can be modelled and its thermalperformanceanalysiscanbedone

• Change in the microstructure of the cement mortar can be studied to justify the reasons for change in thermal conductivity when cement is partiallyreplacedbyceramicwastepowderand baritepowder.

REFERENCES

Abdul hamead,A.A.,Othman,F.M.&Hmeed,N.A.,2018. Theeffectofnanoflyashonpropertiesofcementmortar. AIPconferenceproceedings.

Anwar,A.,Ahmad,S.,Husain,S.M.A.&Ahmad,S.A.,2015. Replacement Of Cement By Marble Dust And Ceramic Waste InConcrete For Sustainable Development. InternationalJournalofInnovativeScience,Engineering& Technology,2(6),pp.496 503.

Bentz, D. et al., 2011. Thermal properties of high volume flyashmortarsandconcretes.JournalofBuildingPhysics, Volume3.

Bumanis, G., Bajare, D. & Korjakins, A., 2013. Mechanical and Thermal Properties of Lightweight Concrete Made. Journalofsustainablearchitectureandcivilengineering.

C, B. N., Mani, M. & V, V. R. B., 2013. THERMAL PERFORMANCEOFTHEBUILDINGWALLS.Italy,s.n.

Eswar, S., Reddy, V. K. S. & Mary, J. A., 2017. Ceramic Waste:EffectiveReplacementofCementForEstablishing Sustainable Concrete. International Journal of Advanced Research in Basic Engineering Sciences and Technology , Volume3.

fathipour,R.&Hadidi,A.,2017.Analyticalsolutionforthe studyoftimelaganddecrementfactor forbuilding walls inclimateofIran.Energy.

Franco, A., 2007. An apparatus for the routine measurement of thermal conductivity of materials for building application based on a transient hot wire method.AppliedThermalengineering,p.2495 2504.

Ismai, N. et al., 2017. strength, water absorption and thermal comfort of mortar bricks containing crushed ceramicwaste.JurnalTeknologi(Sciences&Engineering), 79(7),pp.167 173.

Kannan,D.M.,Aboubakr,S.H.,El Dieb,A.S.&Taha,M.M. R., 2017. High performance concrete incorporating ceramic waste powder as large partial replacement of Portlandcement.ConstructionandBuildingMaterials,pp. 35 41.

Meenakshi, P., 2017. Partial Replacement of Cement by Barites and Lime Powder in Concrete. International JournalofChemTechResearch,10(3),pp.143 148.

Meyer,C.,2005.ConcreteasaGreenBuildingMaterial.

Pan, J., Zou, R. & Jin, F., 2016. Experimental Study on Specific Heat of Concrete at High Temperatures and Its InfluenceonThermalEnergyStorage.

R, A. & Kumar, A., 2017. Experimental Study on Replacement of Cement with Ceramic Tile Powder. International Journal for Research in Applied Science & Engineering,5(10),pp.1814 1818.

Saidani, K., Ajam, L. & Ouezdou, M. B., 2015. Barite powder as sand substitution in concrete: Effect on some mechanical properties. Construction and Building Materials,pp.287 295.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Shaik, S., Gorantla, K. & Setty, A. B. T. P., 2016. Investigation of Building Walls Exposed to Periodic Heat Transfer Conditions for Green and Energy Efficient BuildingConstruction.s.l.,Elsevier.

Sinha,D.A.,2014.Thermal propertiesofconcrete. Indian JournalofResearch,3(2). Xu, Y. & Chung, D., 1999. Effect of sand addition on the specificheatandthermalconductivityofcement. Cement andConcreteResearch,Volume30,pp.59 61.

E. Irassar, V. Rahhal, A. Tironi, M. Trezza, Z. Pavlík, M. Pavlíková, M. Jerman, R. Cerny´ , Utilization of ceramic wastes as pozzolanic materials, in: Technical Proc. of the 2014 NSTI Nanotechnology Conference and Expo, NSTI Nanotech2014,vol.3,2014,pp.230 233

K.Lu shu,S.Man qing,S.Xing Sheng,L.Yun xiu,Research on several physico mechanical properties of lightweight aggregateconcrete,Int.J.LightweightConcr.2(4)(1980) 185 191.