1

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Abstract Metal spinning is forming of ductile materials into seamless axisymmetric components by combination of rotational motion and force. Metal spinning can be used to cost effectively produce a small number of parts out of expensive materials or large quantities of components of low cost materials such as aluminum reflectors. In manual spinning, a circular blank of flat sheet is pressed against a rotating mandrel using a rigid tool. The tool is moved manually over the mandrel to form the component. It is reported that during deformation the work piece stretches in the radial direction and compresses circumferentially aiming to keep the original wall thickness constant. The surfacefinish of spun component is usually of sufficient quality that no additional machining is required after spinning. The surface finish of spun component is typical of 1.5 micron order. In this work on conventional metal spinningofAI2024metalbythree different rollers namely single roller, double roller,anddouble radii roller are used to obtain cylindrical profile components. The surface roughness of finished product is measured by Talysurf which are formed at three different speeds on three different thickness of sheets. The present study is to explore adaptivity of non contact measurement of roughnessbyusing Image Processing. The studyrevealsthattheImageProcessing method can be adopted with considerable error. The surface roughness has significant in functional applications of spun parts.

Key Words: Cylindrical profile, Image processing, Roller tool, Surface roughness, Thickness of sheet

Spinningisaseverecoldworkingoperationwhereinawell definedanddirectionalgrainflowpatterisproducedwhich make tensile and yield strength increases and ductility decreases.Themagnitudeofthisdependsonanamountof wall thickness reduction and on susceptibility of metal to workhardening.Theinitialpositionandpathofrolleristhe key parameters in cone spinning. In majority of cases the shape. Dimensional accuracy and surface finish of spun parts,thestabilityoftoolforcesintheprocessarethemost usefulcriteriainspinningprocessdesignandproduction.[1]

Forconventionalspinningprocess,itinvolvesmanyrandom processparameterssuchasvariationofmaterialflowstress, initial thickness, profile of roller path, geometry of roller,

rollerfeedrateandfrictionalconditionbetweenworkpiece and tool:[2] The Authors reported that the relative stress patterns are identical trend for various thickness of the sheets. According to Hayama low mandrel speed, smaller diameter of roller and low viscosity lubricant give low surfacefinish[3].Rollernoseradiusalsohasthesignificant effect on dimensional accuracy, the larger nose radius resulted in uniform thickness and low surface roughness. SandeepKambojetal.,concludedthatthevariationinfeed ratio has a considerable effect on tool forces, spinnability andsurfacefinish[4].Ahighfeedratioresultsintohigher forming force and lower feed ratio results in excessive materialflowintheoutwarddirectionwhichresultsabetter surface finish without the failure of the material. The researchers concluded that the surface morphologies in cylindricalpatharemoreuniformcomparedtoradiusR10 surface. Also reported that the surface roughness in the radiusR10regionishighercomparedcylindricalparts.The process of conventional spinning is investigated by many researchers, and it is still highly depending on spinner experiences.J.MAllwoodmentionedthespinningprocessis used to produce components in symmetrical in axial direction,thesecomponentsareusedbyseveralindustries likeautomobile,aerospace,energygenerationplantsetc.[5] Surfaceroughnessplaysakeyroleindeterminingthequality ofcomponents,thecomponentsusedbyaerospaceindustry should have high surface finished so that stress failures reduce,productionandmanufacturingsectorsalsopreferto have higher surface finish especially for moving parts in engine so that the efficiency improves [6]. To develop a furtherunderstandingoftheprocess,theexperimentationis carriedtoevaluatethesurfaceroughnessbyvaryingroller geometry. Image processing methodology is adopted to measuretheroughnessofthecylindricalpartswithhelpof MATLAB software. In image processing method the cylindricalspecimenpicturesaretakeninadigitalcamera, thenitspictureistransformedintobinaryformtomeasure theroughnessvalueofthecylindricalpart.

The experiment is carried out on Engine Lathe to obtain cylindrical profile. For an aluminium alloy 2024 which is

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

extensivelyusedinaerospaceandhouseholdutensils.The chemicalcompositionoftheworkpieceistabulatedintable 1

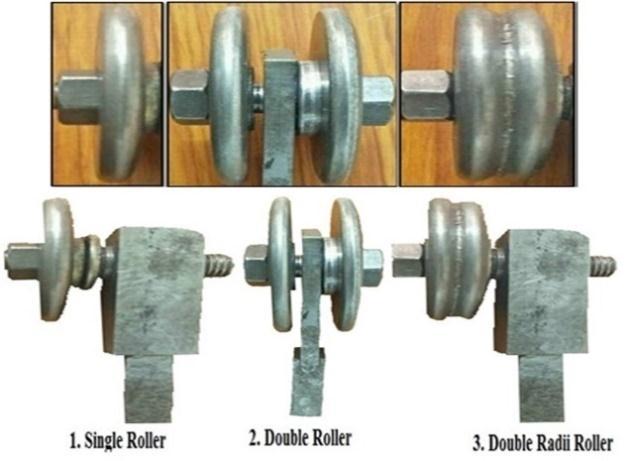

Rollerisusedtoapplyforceagainstthesheetmetal,toform thecomponentasperrequirement.Daksheshproposedasin order to get good surface finish one need to maintain the speedofMandelhighandshoulduselargerdiameterroller. Roller radius determines the dimensional accuracy, with largernoiseradiusgivesuniformthicknesswhilespinning operation.[7]. The geometry of tools used for experimentationaresingleroller,doublerolleranddouble radiiroller.Thetypesofrollerisillustratedinfigure(1)and chemicalcompositionoftherolleristabulatedintable2

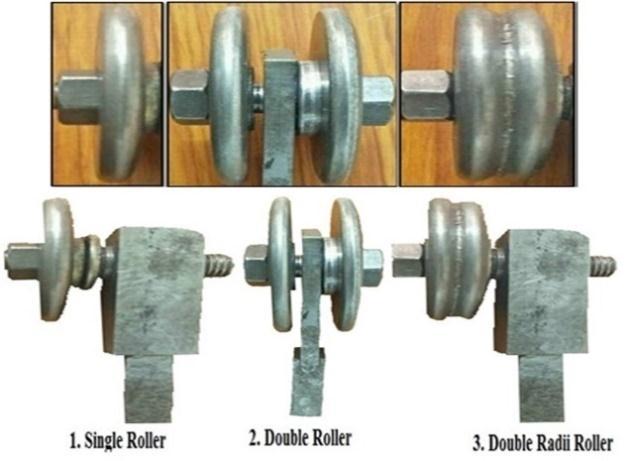

Mandrel determines the shape of final workpiece. In this experimentweusecylindricalMandel.Thediameter(d)of mandrel is taken as 50mm, the blank size (S) is taken as 85mm×85mmasreference.Theheight(h)iscalculatedby theequation1,themandrel2 ddesignisillustratedinthe figure(2) (1)

Table 1:Thechemicalcompositionofthespecimen

Figure 1:TypeofRollers

Figure 2:Mandrel2 dsketch

Table 2:Thechemicalcompositionofroller

Constituent member C Mn Si S P Percentage 0.35 0.40 0.60 1.00 0.10 0.40 0.50 0.50

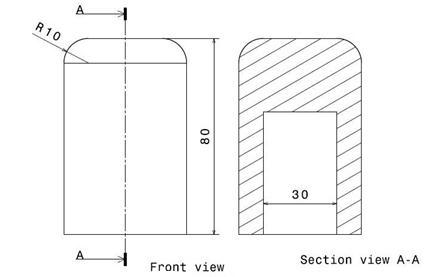

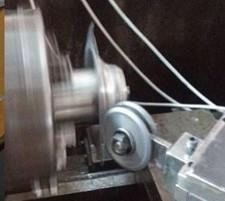

Thefollowing inputsettingswere used inan independent experimentonacylindricalcomponentusingtheTaguchiL9 array:1mmsheetthickness,133rpmmandrelspeed,anda singlerollerspinningtoolByadjustingthespeedbetween 133 and 207 rpm, the sheet thickness between 1 and 1.5 mm, and with three distinct roller types Single roller, Doubleroller,andDoubleradiiroller theviablespacefor thespinningparameterswasidentified.Threelevelsofthe parameterswerechosenforthespinningparameterdesign. Surface roughness is the output parameter taken into considerationforstudy.Table3displaysthenumerousinput variablesutilized in the experimentand designmatrix for experimentationasperTaguchiisillustratedintable4.Fig.3 and Fig. 4 show the experimental setup and spur components. Using the Mitutoyo Surftest indicator, the surfaceroughnessiscalculated,andthevaluesareshownin Table5forvariousexperimentaltrials.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Table 3:Metalspinningfactorsandlevels

Factors Units Testlevels Level1 Level2 Level3 Speed Rpm 133 150 207 Thickness ofsheet Mm 1 1.2 1.5 Roller type Single roller Double roller Doble radii roller

Table 4:Designmatrixforexperimentation

Experimentno 1 2 3 4 5 6 7 8 9 Speed 1 1 1 2 2 2 3 3 3 SheetThickness 1 2 3 1 2 3 1 2 3 Rollertype 1 2 3 2 3 1 3 1 2 Figure 3:Experimentalsetup Figure 4: SpecimenComponents

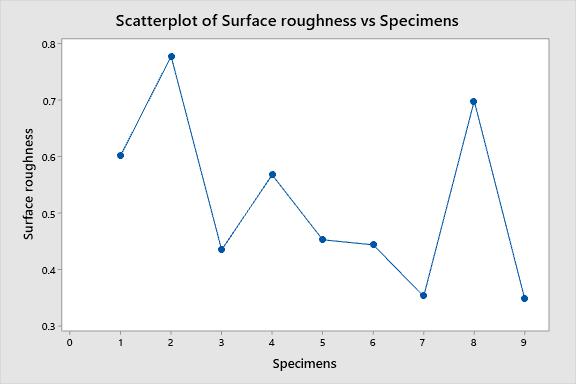

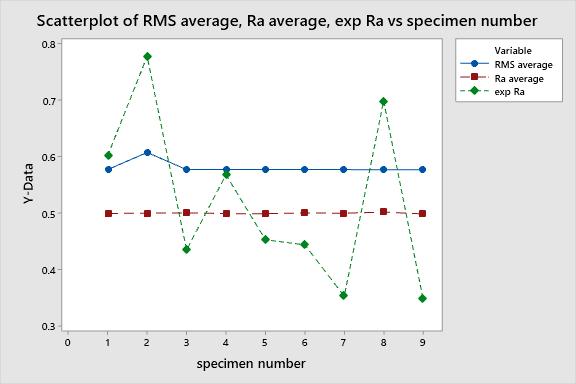

Thestandarddeviation,whichisdeterminedtogiveasense oftheprecisionofthedata,iscalculatedandisfoundtobe 0.14µmfromtakingvaluesoftable5.Figure5illustratesthe specimen'spatternofsurfaceroughness.Experimentaldata showanaverageroughnessof0.52µm.

Figure 5: Graphofexperimentalsurfaceroughnessvalues

Table 5:ExperimentalResult

S.No Speed Thickness Roller Type Surface Roughness S(rpm) T(mm) R SR(µm) 1 133 1 1 0.602 2 133 1.2 2 0.778 3 133 1.5 3 0.435 4 150 1 2 0.568 5 150 1.2 3 0.453 6 150 1.5 1 0.444 7 207 1 3 0.353 8 207 1.2 1 0.699 9 207 1.5 2 0.348

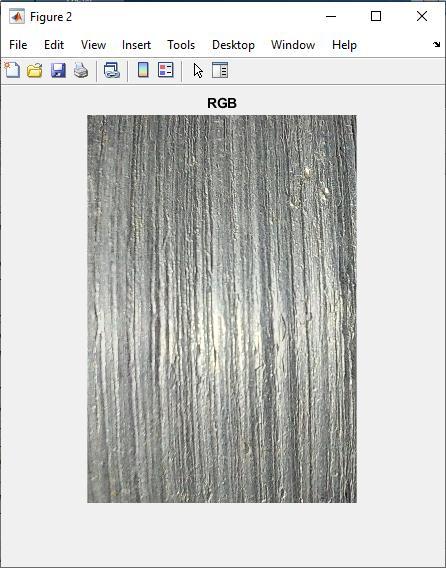

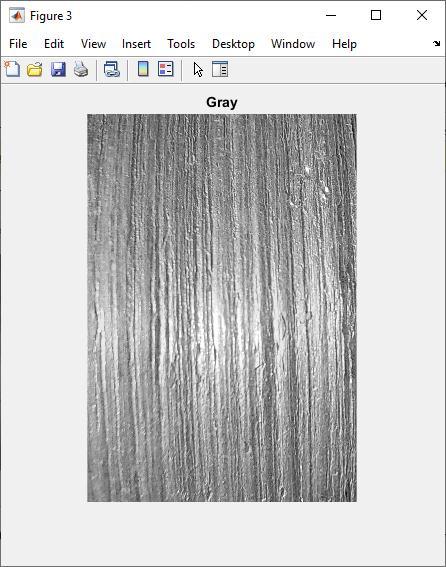

Priortoimageprocessing,cylindricalspecimenphotographs are obtained with a digital camera that is positioned 90 degrees from the specimen. All of the specimens are separated into eight equal pieces, each of which is photographed using a digital camera. All additional specimens are photographed using the same camera and lightingsource.Then,MATLABisusedtoprocesstheimages for the purpose of assessing surface roughness. The followingaretheimageprocessingmethodologies 1. ConvertingRGBimageintograyimage

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Thergb2grayfunctionisusedtoconvertatruecolorimage to a grayscale image. By removing the hue and saturation datawhilekeepingthebrightness.Figure(6)andfigure(7) indicatescolorimageandgrayscaleimageofthespecimen1 at00 .

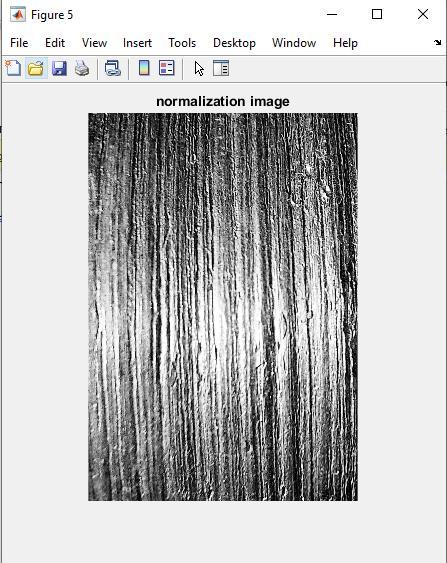

h(x,y)isnormalizedmatrixfortheimagematrix,k(x,y)is image matrix, min(k) is minimum value of image matrix and max(k) is maximum value of image matrix. Figure(8)representsnormalizedimageofspecimen1at

Figure 7:Grayimage

Image normalization plays a key role in reducing the disturbances due to light source. Image normalization reduces lighting variation. Image normalization of gray image is done by usingequation(2)

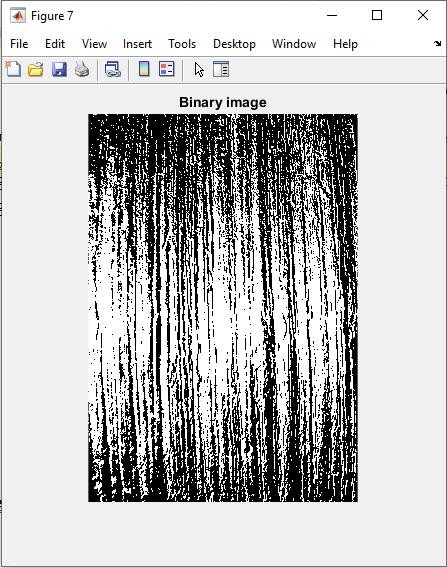

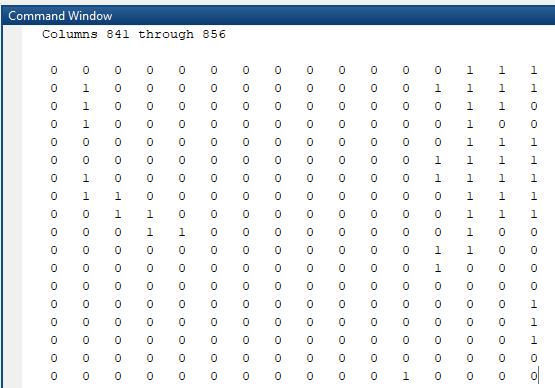

The normalized matrix is then transformed into binary matrixform.Whereitcontainsonly1and0.1isbrightest and0isdarkestpixelofimage.TheRMSvaluesofimageis calculatedbyusingthebinarymatrixofimage.Figure(9)is binaryimageofthespecimen1at ,whichischangedfrom normalizedimagetobinaryimage

Figure 9:Binaryimage

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Table 6:RMSvaluesofspecimensbyusingImageProcessing

Angular Position Specimen 1 Specimen 2 Specimen 3 Specimen 4 Specimen 5 Specimen 6 Specimen 7 Specimen 8 Specimen 9

0 0.5775 0.5773 0.5769 0.5771 0.5771 0.5776 0.5773 0.5770 0.5774 45 0.5776 0.5776 0.5776 0.5774 0.5772 0.5777 0.5771 0.5772 0.5766 90 0.5772 0.5769 0.5771 0.5784 0.5778 0.5779 0.5770 0.5774 0.5772 135 0.5772 0.5773 0.5774 0.5776 0.5777 0.5774 0.5771 0.5771 0.5776 180 0.5775 0.5779 0.5774 0.5774 0.5771 0.5772 0.5778 0.5769 0.5771 225 0.5774 0.5770 0.5770 0.5773 0.5778 0.5774 0.5776 0.5771 0.5771

270 0.5771 0.7022 0.5774 0.5778 0.5776 0.5771 0.5771 0.5772 0.5769 315 0.5773 0.6947 0.5776 0.5773 0.5776 0.5775 0.5770 0.5774 0.5770

Average 0.57735 0.607613 0.5773 0.577538 0.577488 0.577475 0.57725 0.577163 0.577113

Fromthevaluesobtainedbyimageprocessingthestandard deviation is observed as 0.02 µm. The average surface roughness is0.58069µm.Fromthetable6itisobserved that the value of the surface roughness is minimal for the specimen9astheexperimentalresultforsurfaceroughness.

Figure (10) represents the binary image pixel value for column841to851andupto20rowsofspecimen1at

In similar manner for remaining 8 specimens the binary matrixispreparedatdifferentangularpositionof 450,900 ,1350,1800,2250,2700and3150.TheRMSandRavaluesare tabulatedinthetable6

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Table 7:RavaluesofspecimensbyusingImageProcessing

Angular Position Specimen 1 Specimen 2 Specimen 3 Specimen 4 Specimen 5 Specimen 6 Specimen 7 Specimen 8 Specimen 9

0 0.5042 0.5002 0.5007 0.4956 0.5006 0.5040 0.4990 0.5032 0.4996

45 0.5006 0.4963 0.4993 0.5047 0.4978 0.5022 0.5027 0.5035 0.4990 90 0.4959 0.4964 0.5034 0.5067 0.5023 0.4989 0.4985 0.5033 0.4965

135 0.4986 0.5012 0.4993 0.4977 0.4985 0.5001 0.5004 0.4989 0.4996

180 0.5038 0.5034 0.4999 0.4990 0.4959 0.4988 0.5005 0.5035 0.5024

225 0.4958 0.5007 0.5019 0.4956 0.4968 0.5009 0.4978 0.4993 0.4983

270 0.4984 0.5020 0.5044 0.4997 0.4976 0.5008 0.5017 0.5027 0.4985

315 0.4993 0.5014 0.4963 0.4956 0.5041 0.4983 0.4993 0.5017 0.4964

Average 0.499575 0.5002 0.50065 0.499325 0.4992 0.5005 0.499988 0.502013 0.498788

Thestandarddeviationofthevaluesfromtable7is0.00264 µm,theaveragevalueis0.5µm.Theleastaveragevalueof surfaceroughnessisobtainedfromspecimen9.

[1] Shi, F., Long, H., Zhan, M. and Ou, H., 2014. Uncertainty analysis on process responses of conventional spinning using finite element method. Structural and Multidisciplinary Optimization,49(5),pp.839 850.

[2] B Ravikumar, Dr S Gajanana, Dr K. Hemachandra Reddy, M. Krishna Reddy (2019): "Experimental Investigation and Numerical Simulation of Metal Spinning on A12024 using a Cylindrical Mandrel”.International Journal of Research and Analytical Reviews, Volume 06, Issue 1,January,2019

[3] HayamaM,KudoH,ShinokuraT:"StudyofthePass ScheduleinConventionalSimpleSpinning".Bulletin ofJSME,13,1358 1365,1970

The Rms value of binary image matrix is more adoptative than Ra value of the binary image matrix their values are moreappropriatewiththeexperimentvaluesmeasuredby Talysurf.Thestandarddeviationofexperimentalvaluesis closer to the RMS values of specimen using image processing.Thesurfaceroughnessisfoundtobeminimalfor

specimen 9 by both experimental result and by image processingmethod.Henceitisrecenttoadopt,theimage processingcanbeusedformeasuringthesurfaceroughness

[4] Sandeep Kamboj , Bharat Atray , Neeraj Kumar : "AnalysisTheEffectsOfDifferentTypesOfToolOn Metal Spinning Process" International Journal Of ResearchInEngineeringAndTechnologyVolume: 03Issue:02164 70,Feb 2014.

[5] Music, O., Allwood, J. M., & Kawai, K. (2010). A reviewofthemechanicsofMetalSpinning.Journal ofMaterialsProcessingTechnology,210(1),3 23. https://doi.org/10.1016/j.jmatprotec.2009.08.021

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[6] Tennant,R.(1992),"MechanicalSurfaceFinishingin theAerospaceIndustry",AircraftEngineeringand Aerospace Technology,Vol.64,No.3,pp.414.https://doi.org/1 0.1108/eb037216

[7] DaksheshDarji,DarshanBhatt(2020).“Designand Investigationofspringloadedtoolinmetalspinning process in lathe”, journal of engineering sciences, vol.11,Issue6,June,2020

[8] Ali, Mahashar & . H, Siddhi Jailani & Murugan, M.. (2019). Surface Roughness Evaluation of Milled SurfacesbyImageProcessingofSpeckleandWhite LightImages.10.1007/978 981 13 1724 8_14.

[9] Zhongxiang, H., Lei, Z., Jiaxu, T., Xuehong, M. and Xiaojun,S.,2009.Evaluationofthree dimensional surface roughness parameters based on digital image processing. The International Journal of Advanced Manufacturing Technology, 40(3 4), pp.342 348

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal