International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

ACTIVATED FLUX WELDING: A REVIEW

A. Kaloshkar1

, S. Bradeesh Moorthy2

1PG Research Scholar, Department of mechanical engineering, Government College of Technology, Coimbatore.

2Assistant Professor, Department of mechanical engineering, Government College of Technology, Coimbatore. ***

Abstract Intherecentyearsmoreimportanceisgivento increaseproductivityiseveryengineeringactivity.Welding is one of the important joining techniques and hence researches constantly work on impurity productivity of welding processes. One of the techniques employed to improve penetration of welding thereby improving its productivity is to use activated flux. In this article a clear review is done on the published articles with usage of activatedfluxinwelding.Variousresearchershavereported significantimprovementinpenetrationofupto300%with the usage of activated flux. Some of the common fluxes employedforweldingareSiO2,TiO2,Cr2O3,MnO2,Fe2O3,ZnO, Na2CO3,NaHCO3,CaCl2,MoO3,MgCO3,Al2O3 andboraxetc., The review shows that activated flux welding can be successfullyemployedforjoiningcompoundslikestainless steel, Mild steel, Nickel based alloys, magnesium based alloysandP91steel.

Key Words: Activated flux, improving productivity, penetration,SiO2,TiO2.

1. INTRODUCTION

Weldingisatechnologyforjoiningmetalsinmanufacturing industries. Arc welding is undoubtedly one of the most commonandimportantjoiningtechniquesusedtoday.Gas TungstenArc welding(GTAW)andGasMetalArc welding (GMAW) is the most popular arc welding process. GMA weldinginvolvesafeedwirewhichmovesthroughthegun constantlytocreatethesparktoformaweldbymeltingit. GTA welding uses long rods to join two metals directly together. The main drawback of the Arc welding process include: (a) its relatively shallow penetration capability, particularlyinsinglepassweldingoperations;(b)thehigh sensibility of the weld bead shape to variations of the chemical composition of the base metal; and (c) low productivity[1].GTAWiswidelyusedinindustrieswhich are also termed Tungsten inert Gas welding. GTAW is effectiveforastablearcwithdifferenttypesofmetals.There are some limitations of using GTA welding along with benefitslikethereisalimitedthicknessofmetaluptowhich singlepassGTAweldingmethodcanbeused,weldingspeed islowinGTAweldingandthedecreaseddepositionrate[2]. MIGweldingisanarcweldingprocedureinwhichajobis producedincoalescencebyheatinganarcbetweenametal electrodefeedandworkpiece.Itismostcommonlyusedin industriesandtermedasGMAweldingprocedure[3,4].This canbesuitableforferrousaswellasnon ferrousmaterials.

It produces electrical arcs with a power supply between consumable electrodesand workpiecein theMIG welding procedure. Various kinds of shielding gases used in MIG welding are Argon, Carbon dioxide, Helium, and different compositionweretakenbasedonthematerialcomposition. MIG welding efficiency and productivity depend on the number of welding parameters such as welding voltage, welding current, gas flow rate, welding speed, nozzle distance,electrodeangle,shieldinggastypes,etc[5].

1.1 Activated Flux Welding

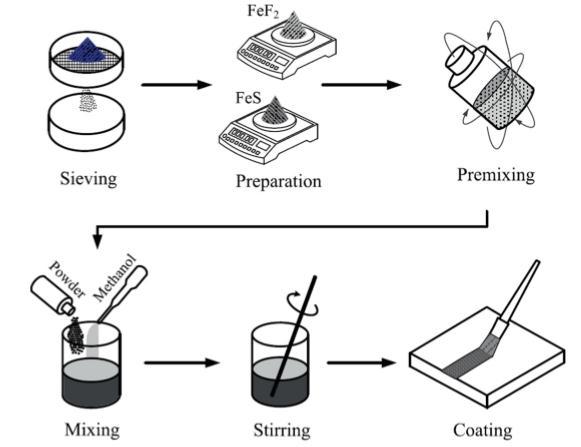

Higherefficiencyanddeepweldpenetrationcanbeachieved by the addition of oxygen. The activated flux TIG (A TIG) welding method is a method in which a small amount of dioxide or fluoride is smeared on the surface of the plate beforeweldingorsomeoxygenorcarbondioxideismixed intotheinertshieldinggas[6].Inorganicmaterialismixed withavolatilemediumtoformactivatedflux.Fluxesbecome conducting when it is in a molten state. In activated Tungsten Inert Gas welding, although the depth of penetrationcanbeincreased,therewasanissuewithoverall efficiency. In evolved advanced A TIG method, double shielding gas was used. The pure inert gas is used inside while on the outer side as shielding one, oxide or carbon dioxide is mixed with inert gas in order to protect the tungstenelectrodefromoxidization[7].Althoughactivated fluxweldingisaneffectiveweldingmethodtoobtaindeep penetration,thecostforpreparationofadoubleshielding torch and two types of gas increases and restricts its applicablefields.Asimplifiedactivatedfluxweldingmethod using only a simple nozzle cap was tried by some researchers.Thenozzlecapwasdesignedtoaspirateoxygen from the atmosphere into the molten pool [8]. Various properties of the weld were analyzed with the help of different apparatus like image analyzer or stereo graphic analyzer[9].Thequalityofweldingcanbedetermined by meansofthedepthofpenetration.TheQualityofwelding also depends upon the thickness of the material. It is impossibletoapplythefluxevenlyontheweldsurfacewhen itisinapowderedform.Hence,thepowderisconvertedto pasteformbymixingitwith methanol orothersubstance whichencompassesatendencytovaporizequicklyleaving the evenly distributed oxide flux on the surface as representedinfig.1[10].

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Fig 1:Methodofapplyingflux

2. LITERATURE REVIEW

Fanetal.(2009)[11]studiedtheweldbeadpenetrationof magnesium alloy with activated flux coated electrode. Weldingplasmaofmagnesiumalloyisstudiedbyemission spectrum diagnostic technique. An acquisition system of plasmaspectrumisintroducedandtheeffectoffluxonarc plasma isanalyzed through the comparison of the plasma spectra of TIG welding with normal wire and flux coated wire.Themechanismthatleadstoincreasedpenetrationof the weld bead in flux coated wire weld is analyzed. The increase of the weld bead penetration favours the arc constrictionmechanismsincetheactivatedfluxisimported intotheweldingarcdirectlybyfillerwire.TwofluxesTiO2 andcompositefluxAFM01areusedtoexaminetheeffectof the fluxes on weld penetration of magnesium alloy. The compositefluxnamedasAFM01isself madeandconsistsof variousmetaloxidesandchlorides.Theuseofelectrodewith theabove flux resulted in obvious increasein penetration comparedtothenormalwire.Incertaincasesthewelding penetrationwasimprovedupto200%.Atthesametime,the compositefluxcoatedwirealsocausedmarginalincreasein weld width. The TiO2 flux coated wire has a little effect in increase depth penetration and width. Vasudevan muthukumaran et al. (2012) [12] discussed the flux formulationforenhancingpenetrationofausteniticstainless steel. The Penetration Enhancing Activating Flux (PEAF) formulationwhichispreferablyobtainedaspastewasused alongwithTungstenInertGas(TIG)weldingoralternatively termedasGasTungstenArc Welding(GTAW).ithasbeen observedthat87.7%SiO2,12.3%TiO2 and0% Cr2O3 have better depth of penetration and bead width and the penetration was improved by 300 % in comparison with conventionalTIG.Dhandha&Badhekaetal.(2015)[13]to results of the study demonstrated that the mechanism responsible for growth in depth of penetration and also decreaseinweldbeadthicknesshasbeenachievedbyarc constriction. The improvement in weld penetration and decrease in bead thickness were observed using MnO2, Fe2O3, ZnO, Cr2O3 fluxes, among these fluxes higher penetration was found in ZnO flux with an aspect ratio of

penetrationtoweldbeadwidthof0.95.Vidyarthy&Dwivedi et al. (2016) [14] discussed identifying the cause for an increase in weld penetration by the A TIG process. It is proposedthatoxidesandhalidesarethemostremarkable influencers on penetration due to the vaporization of flux whichconstrictsthearcandthefluxappliedonthesurface will reverse the direction of surface tension resulting in a reverse marangoni mechanism. The improvement in penetration was observed due to arc constriction and reversemarangonimechanismformostofthesteels.Anup Kulkarnietal.(2018)[15]theinvestigatesactivatedfluxTIG weldingofdissimilarsteelcombinationof8mmthickplates ofModified9Cr 1Mo(P91)steeland2.25Cr 1Mo(P22)steel. Theeffectofdifferentfluxesnamely SiO2,TiO2,Cr2O3,MoO3 andCuOontheweldbeadgeometrywasinvestigated.ATiO2 flux has a higher aspect ratio compared to other fluxes. Ramkumar et al. (2018) [16] discussed that the microstructureattributesandstructuralintegrityofTi 6Al 4Vweldsof5mmdepthwereembracedusingtriggeredflux (SiO2) using ATIG welding procedure utilizing oxide surfactant.Thesignificantinferenceswhichreportedinthe analysiswere:there’sanincreaseinLengthofpenetrationin welding present (100 240A) and also decrease in bead thickness on the usage of chromium surfactant and the tensilestrengthwassignificantlyimprovedwithA TIG. Liu et al. (2019) [17] Findings demonstrated that the AZ31B magnesiumalloyand6061aluminiumalloywereweldedby the longitudinal magnetic field hybrid cold metal transfer (CMT)weldingprocess.Threemagneticpolestructureswere designedandthedistributionsofthemagneticfieldswere simulated. The results show that the platform shaped magnetic pole structure can improve the longitudinal direction of a magnetic field in the weld zone, which was suitabletoredistributetheweldingheatsourceanddecrease welding spatters. The Al/Mg interface can be divided into three zones, mixed zone (Mg17Al12 + α Mg), Mg rich zone (Mg17Al12),andAl richzone(Mg2Al3).Theappliedmagnetic oscillation obviously reduced the thickness of the Mg2Al3 layeranddispersedthedistributionofstrengtheningphases Mg2Si that can prevent crack propagation. The micro hardnessvalueattheinterfacelayerwasincreasedandthe shear strength of the Al/Mg joints reached a maximum of 1411N with magnetic oscillation that was higher than the normal welding process of 1072N. The increasing shear strengthofweldedjointswasmainlyduetothereductionof weld pores, the suppression of brittle phases, and the distributionofstrengtheningphases.Nilakanthasahuetal. (2021)[18]discussedvariouscompositionofmetaloxides withdifferentweightpercentages whichareusedinmetals like stainless steel 316L and alloy 800 in TIG welding. It’s observedthatthelargeimprovementindepthofpenetration willbeobtainedbyusingmulticomponentflux.FluxA(35% TiO2,40%SiO2,15%NiO,10%CuO)andFluxB(35%TiO2, 40%SiO2,15%ZnO,10%MoO3)visualisetheshapeofweld bead,corrosive behaviouranddepthofpenetrationofthe weld.Theresultedfluxoffullpenetrationwasonlyobserved usingFluxB.AnandBagheletal.(2021)[19]demonstrated

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

the5typesofactivatedfluxeswhichwereexaminedatthe AISI1018duringMIGwelding.Amongthefivefluxesnamely Al2 (SO4)3, NaOH, Na2CO3, NaHCO3 and borax, the better penetrationoftheweldwasseenonborax.Anandbaghelet al. (2021) [20] This article discussed with the effect of chlorideandoxidefluxesviz.calciumchloride(CaCl2)and ferric oxide (Fe2O3) on microstructural and mechanical properties of TIG welded joints of dissimilar SS304 and SS202steels.Resultsreflectedthatuseofoxideandchloride fluxes significantly affects the weld bead geometry, bead dimensionsandpenetration.Theusageofoxidefluxresulted inthecompletepenetrationandapproximatelylinearrootof weldwithgoodfusionofboththebasemetals.Fusionzone showedcolumnardendriticcastgrainstructurewhilecoarse grain structure was obtained in heat affected zone. PratishthaSharmaetal.(2021)[21]Describedfluxassisted tungsten inert gas (FA TIG) welding of bimetallic P92 martensiticsteel 304Hausteniticstainlesssteel(ASS)was carriedoutusingSiO2 TiO2 binaryflux.Sevenbinaryfluxes werepreparedbyvaryingtheproportionsoffluxpowders (SiO2 andTiO2)andtheeffectoffluxcompositiononweld bead cross section was studied. The experimental results indicated that binary flux (flux B) with composition 90% SiO2+10%TiO2yieldsbetterpenetrationandreducedbead width.

3. USES OF ACTIVATED FLUX IN ARC WELDING PROCESSES

The uses of activated flux for different welding processes weretriedbyresearchers.Someofthearticlesrelatedwith usage of activated flux for TIG and MIG /MAG welding processesarediscussedasbelow.

3.1 Activated TIG Welding Process

TIG welding process also known as GTAW process, is the mostpopularmethodusedinmanufacturingindustriesfor thinner materials to obtain high quality welds. A Major disadvantageofthisprocessisthattherewerelimitationsin penetration during single pass, poor tolerance to many materialcompositionsandmoreconsumptionoftime[22]. Recentlyattentionhasbeenpaidtoanewvariantwelding knownasE.O.PatonElectricweldinginstitutein1960[23]. MorerecentlyvariousactivatingfluxeslikeSiO2,TiO2,Cr2O3, HgO have become commercially available from several sources and are available in the form of powder or paste (mixtureoffluxpowderandappropriatesolvent)whichis appliedonthefayingsurfacestobeweldedwiththehelpofa brush.Thesefluxesareusedforweldingmaterialsi.e.C Mn steel,Cr Mosteels,stainlesssteelsandnickel basedalloys, Aluminium and Titanium in industries for various applications [24]. Due to the application of flux, A TIG process should be improved in weld penetration significantly[25].ThehigherpenetrationinA TIGwelding processcanbeobtainedwiththehelpofsomemechanisms includingreverseMarangoniEffect,Arcconstrictiondueto

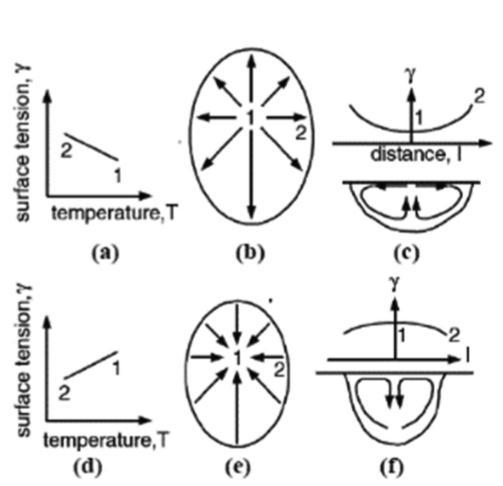

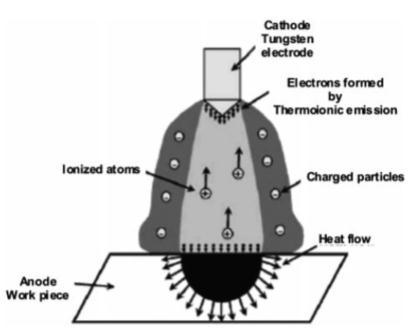

theirnegativeionsandtheinsulatingsurfaceofflux,gravity force and Electromagnetic or Lorentz force and friction factor. But, the most proposed mechanism for deeper penetrationisreversemarangoniandarcconstriction[26, 27]. In the reverse marangoni effect, the surface tension gradient changes negative to positive that results the convectiontoturninoppositedirectionandflowtowards centrefromedgewhichleadstoincreaseinpenetration.The change in magnitude and direction of surface tension gradientisduetosurfaceactiveelementssuchasO2andS [28].DuringconventionalTIGwelding,convectioncurrents move in a centrifugal direction and the surface tension gradientisnegative.HenceconventionalTIGweldingresults in a shallow and low depth of penetration. But in A TIG welding, when flux material is added, the directions of convectioncurrentsareinversedtoacentripetaldirection andthesurfacetensiongradientbecomespositiveresulting in deep penetration as shown in fig.2. An anode spot is formed on the joint surface due to the flux powder which attractselectronsfromtheelectrodethatactsasacathode. Due to the formation of anions at the edge of the arc, the density of current tends to increase at the centre of the anode.Hence,thearcisfocusedsharplyontheweldjoint, leading to deeper penetration as shown in fig.3 [29]. The activated flux TIG welding process is utilized for various typesofferrousandnon ferrousmetals[30].Theeffectof Cu2O,NiO,Cr2O3,SiO2andTiO2wereinvestigatedonSUS304 usingtheGTAWprocess.Theoxygencontentincreasesthe depthtowidthproportionwhenitisintherangeof70 300 ppm and also changes the surface tension gradient which results in increased penetration [25]. The increase in penetration was observed due to the reverse marangoni effect in a single component and multi component oxide fluxes in case of Inconel 718 alloy steel. The single component fluxes used in the initial experiment for the activating flux with TIG (A TIG) welding technique were SiO2, NiO, MoO3, Cr2O3, TiO2, MnO2, ZnO, and MoS2. Four fluxeswerechosentomakesixnewmixturesutilising50% ofeachoriginalfluxduetotheincreasedDWRofweldbeads. A TIGweldmentscoatedwith50/50SiO2andMoO3fluxand a 75 degree electrode tip angle offered enhanced welding performance[31].

Fig-2:Reversedmarangonieffect

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

themostcommonactivatedfluxwhichcomesacrossmore frequentlyinresearcharticles.

Theusageofactivatedfluximprovedpenetrationof welding while performing welding on stainless steel, Mild steel,Nickelbasedalloys,magnesiumbasedalloysandP91 steel.Eventhoughastandardactivatedfluxforaparticular application is not getting arrived. It is clearly evident that activated fluxes can be effectively used for productivity improvementinwelding.

REFERENCES

[1] Modenesi,P.J.,Apolinario,E.R.,&Pereira,I.M.(2000), “TIGweldingwithsingle componentfluxes”, Journal of materials processingtechnology, 99(1 3),260 265.

3.2 ACTIVATED MIG WELDING PROCESS

MostoftheresearchhasbeencarriedoutonA TIGmethod, but limited research articles only reported the usage of activatedfluxesinthecaseoftheactivatedGMAWprocess. Activating flux helped GMAW to improve the weld region and penetration and additionally enhance the tensile strengthoftheirGMAWjointwhereasthedistortionoftheir weldmentswasdecreasedbythefluxhelpedGMAW.MgCO3, SiO2,Fe2O3theseoxidefluxesareusedinAISI1020steel.It’s resultedthatanMgCO3 fluxproducedthemost noticeable effectandbettertensilestrengthandhardness[32].While comparedwithtwootherfluxessuchasSiO2andCr2O3inthe activated MIG welding of stainless steel. In addition, they performed optimization of parameters such as welding speed,current,arcvoltageontheweldqualityandhardness ofweldment[33].UsingthreevariousfluxesTiO2,Al2O3and Fe2O3intheactivatedMIGweldingofMildsteel.Inaddition, process parameters such as welding speed, current, arc voltageontheweldqualityandhardnessofweldmentand tensile and hardness tests were conducted to analyze the mechanical properties of flux coated welds with conventionalMIGweldingprocesswithoutflux.Itisresulted that TiO2 coated MIG weld has shown better results comparedtoaluminiumoxideandironoxide[34].Influence of flux coating on the penetration depth, micro hardness, tensilestrengthandmetallurgicaltraits.Theexperimental designisdevelopedforthreefactorsofcurrent,travelspeed and flow rate with three levels. Further, with the aid of radiography,itisconcludedthatthedefect freeweldsand tensile tests have also shown better quality using the activatedfluxtechnique[35].

4. CONCLUSIONS

Acomprehensiveontheusageofactivatedfluxtoimprove penetration of fusion welding was done. A variety of activated fluxes like SiO2, TiO2, Cr2O3, MnO2, Fe2O3, ZnO, Na2CO3,NaHCO3,CaCl2,MoO3,MgCO3,Al2O3 andboraxetc., weretriedbyvariousresearchersSiO2andTiO2,seemstobe

[2] Tseng, K. H., & Hsu, C. Y. (2011), “Performance of activated TIG process in austenitic stainless steel welds”, Journal of Materials Processing Technology, 211(3),503 512.

[3] Sen,R.,Choudhury,S.P.,Kumar,R.,&Panda,A.(2018), “A comprehensive review on the feasibility study of metal inert gas welding”, Materials Today: Proceedings, 5(9),17792 17801.

[4] Kanakavalli,P.B.,Babu,B.N.,&Sai,C.P.V.(2020),“A hybridmethodologyforoptimizingMIGweldingprocess parameters in joining of dissimilar metals”, Materials Today: Proceedings, 23,507 512.

[5] Madavi, K. R., Jogi, B. F., & Lohar, G. S. (2022), “Investigationalstudyandmicrostructuralcomparison ofMIGweldingprocessforwithandwithoutactivated flux”, Materials Today:Proceedings, 51,212 216.

[6] Ramkumar, K. D., Goutham, P. S., Radhakrishna, V. S., Tiwari, A., & Anirudh, S. (2016), “Studies on the structure property relationships and corrosion behaviour of the activated flux TIG welding of UNS S32750”, Journal of Manufacturing Processes, 23, 231 241.

[7] Zou,Y.,Ueji,R.,&Fujii,H.(2014),“Effectofoxygenon weldshapeandcrystallographicorientationofduplex stainless steel weld using advanced A TIG (AA TIG) weldingmethod”, Materialscharacterization, 91,42 49.

[8] Morisada,Y.,Fujii,H.,&Xukun,N.(2014),“Development ofsimplifiedactivefluxtungsteninertgasweldingfor deeppenetration”, Materials & Design (1980 2015), 54, 526 530.

[9] A.B. Sambherao. (2013), “Use of Activated Flux For Increasing Penetration In Austenitic Stainless Steel While Performing GTAW”, International Journal of EmergingTechnologyandAdvancedEngineering.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[10] Varshney,D.,&Kumar,K.(2021),“Structuredreviewof papers on the use of different activating flux and welding techniques”, Ain Shams Engineering Journal, 12(3),3339 3351.

[11] Zhang, Z., & Zhang, F. (2009), “Spectral analysis of welding plasma of magnesium alloy using flux coated wire”, Materials Transactions, 50(8),1909 1914.

[12] Muthukumaran,V.,Bhaduri,A.K.,&Raj,B.(2012),“U.S. Patent No. 8,097,826”Washington,DC:U.S.Patentand TrademarkOffice.

[13] Dhandha, K. H., & Badheka, V. J. (2015), “Effect of activatingfluxesonweldbeadmorphologyofP91steel bead on plateweldsbyfluxassistedtungsteninertgas weldingprocess”, JournalofManufacturingProcesses, 17, 48 57.

[14] Vidyarthy,R.S.,&Dwivedi,D.K.(2016)’“Activatingflux tungsten inert gas welding for enhanced weld penetration” Journal of Manufacturing Processes, 22, 211 228.

[15] Kulkarni, A., Dwivedi, D. K., & Vasudevan, M. (2018), “Study of mechanism, microstructure and mechanical propertiesofactivatedflux TIGwelded P91Steel P22 steel dissimilar metal joint” Materials Science and Engineering:A, 731,309 323.

[16] Ramkumar,K.D.,Varma,V.,Prasad,M.,Rajan,N.D.,& Shanmugam, N. S. (2018), “Effect of activated flux on penetration depth, microstructure and mechanical propertiesofTi 6Al 4VTIGwelds”, JournalofMaterials ProcessingTechnology, 261,233 241.

[17] Liu,Y.B.,Li,J.Z.,Sun,Q.J.,Jin,P.,Sun,Q.,Li,B.P.,&Feng, J.C.(2019),“Optimizationofmagneticoscillationsystem and microstructural characteristics in arc welding of Al/Mg alloys”, Journal of Manufacturing Processes, 39, 69 78.

[18] Sahu,N.,Barik,B.K.,Sahoo,S.,Badjena,S.K.,&Sahoo,S. K. (2021), “Studies on metallurgical and corrosion characteristicsofdissimilarGTAWweldingofalloy800 and SS316L using multicomponent activated flux” Materials Today:Proceedings, 44,2533 2536.

[19] Baghel,A.,Sharma,C.,Rathee,S.,&Srivastava,M.(2021), “Influence of activated flux on micro structural and mechanical properties of AISI 1018 during MIG welding”, MaterialsToday:Proceedings, 47,6947 6952.

[20] Baghel,A.,Sharma,C.,Rathee,S.,&Srivastava,M.(2021), “Activated flux TIG welding of dissimilar SS202 and SS304 alloys: Effect of oxide and chloride fluxes on

microstructure and mechanical properties of joints”, Materials Today:Proceedings, 47,7189 7195.

[21] Sharma, P., & Dwivedi, D. K. (2021), “Study on Flux assisted Tungsten inert gas welding of bimetallic P92 martensitic steel 304H austenitic stainless steel using SiO2 TiO2binaryflux”, InternationalJournalofPressure Vessels and Piping, 192,104423.

[22] Kumaar, S. S., & Korra, N. N. (2021), “Effects of using oxidefluxesasactivatingfluxonActivatedfluxTungsten Inert Gas welding” A review. Materials Today: Proceedings, 46,9503 9507.

[23] Kumar, V., Savabi, M. R., Guerrero, F. M., & Tansel, B. (2009),“WaterRetentionandHydraulicConductivityof Different Media Used for Containerized Agriculture Systems”,In WorldEnvironmentalandWaterResources Congress 2009:Great Rivers (pp.1 11).

[24] Vora, J. J., & Badheka, V. J. (2015) “Experimental investigation on mechanism and weld morphology of activated TIG welded bead on plate weldments of reducedactivationferritic/martensiticsteelusingoxide fluxes”, JournalofManufacturingProcesses, 20,224 233.

[25] Lu, S., Fujii, H., Sugiyama, H., Tanaka, M., & Nogi, K. (2002), “Weld penetration and Marangoni convection with oxide fluxes in GTA welding” Materials Transactions, 43(11),2926 2931.

[26] Berthier,A.,Paillard,P.,Carin,M.,Pellerin,S.,&Valensi, F. (2012), “TIG and A TIG welding experimental investigationsandcomparisonwithsimulation:part2 arc constriction and arc temperature” Science and Technology of WeldingandJoining, 17(8),616 621.

[27] Berthier,A.,Paillard,P.,Carin,M.,Valensi,F.,&Pellerin, S. (2012), “TIG and A TIG welding experimental investigations and comparison to simulation: Part 1: Identification of Marangoni effect”, Science and technology of weldingand joining, 17(8),609 615.

[28] Vidyarthy, R. S., Kulkarni, A., & Dwivedi, D. K. (2017), “Study of microstructure and mechanical property relationshipsofA TIGweldedP91 316Ldissimilarsteel joint”, Materials Science and Engineering: A, 695, 249 257.

[29] Bhattacharya, A. (2016), “Revisiting arc, metal flow behavior in flux activated tungsten inert gas welding”, MaterialsandManufacturingProcesses, 31(3), 343 351.

[30] Tathgir, S., & Bhattacharya, A. (2016), “Activated TIG weldingofdifferentsteels:influenceofvariousfluxand

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

shielding gas”, Materials and Manufacturing Processes, 31(3),335 342.

[31] Lin,H.L.,&Wu,T.M.(2012),“Effectsofactivatingflux on weld bead geometry of Inconel 718 alloy TIG welds”, Materials andManufacturingProcesses, 27(12), 1457 1461.

[32] Huang, H. Y. (2010), “Effects of activating flux on the welded joint characteristics in gas metal arc welding”, Materials&Design(1980 2015), 31(5),2488 2495.

[33] Chaudhari, P. G., Patel, P. B., & Patel, J. D. (2018), “Evaluation of MIG welding process parameter using Activated Flux on SS316L by AHP MOORA method”, materialstoday:proceedings, 5(2),5208 5220.

[34] Moorthy,M.S.B.,Santhosh,M.M.,Akbarali,M.I.M.,& Premkumar,M.B.(2020),“InvestigationontheEffectof ActivatedFluxonMetalInertGasWeldment”, Int.J.Eng. Res. Technol., 9(2),488 491.

[35] Babbar, A., Kumar, A., Jain, V., & Gupta, D. (2019), “Enhancement of activated tungsten inert gas (A TIG) welding using multi component TiO2 SiO2 Al2O3 hybridflux”, Measurement, 148,106912.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal