International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

2

1

Abstract Safe disposal of waste plastic is a serious environmental concern which needs to be mitigate. Being a non biodegradable material, it does not decay over time and even if dumped in landfills, finds its way back in the environment through air and water erosion, can choke the drains and drainage channels, can be eaten by unsuspecting grazing animals causing them illness and death, can contaminate the construction fill, etc. The use of plastic shall be refused as much as possible. This paper investigates the effect to fusing waste plastic materials on the concrete. Waste plastic used in this study were collected from home which are almost available in our homes. The plastic can be used as filler material in concrete as well as it can be used to improve the mechanical properties of concrete. Concrete is a composite material which comprises Cement, Coarse Aggregate, Fine Aggregate, Water and Admixtures. In this project, M25 grade of concrete with W/C 0.46 is adopted and the percentage of waste plastic added as 0%, 2%, 4%, 6%, 8% and 10% to study the strength of concrete. High compressivestrengthwas found with 8% of waste plastic added in the concrete.

Key Words: Waste plastic, Concrete, OPC, Aggregate

Concreteisthesecondmostwidelyusedmaterialon the planet, after water. The manufacturing of concrete generatesabout4.5percentoftheworld’shuman induced carbondioxideemissions.Replacingevenasmallportionof concretewithirradiatedplasticcouldthushelpreducethe globalcarbonfootprint.Theplasticindustryisamongstthe fastestgrowingmarkets;thisisattributabletoitsusein a variety of sectors. In India, about 80% of the total plastic consumptionisdiscardedaswaste,atleast40%ofwhichis uncollected. Plastic is an organic hydrocarbon based material,itshighcalorificvaluecanbeusedforincineration or in other high temperature processes. But, burning of plastics releases varieties of poisonous gases which contaminates the air. However, the versatile behavior of plastic(itislightweight,flexible,strong,moisture resistant, and cheap) can make it a replacement of aggregates in makingconcrete.

Aggregatesarenaturalmaterialsofgreatdemand,andthey are the most mined materials. They are directly used for constructionorasconstituentsofready mixedconcreteor asphalt products, and they appear as an index of the economic activity of a country. Distance between quarries and demand points controls the price of high place value products such as aggregates. Their potential exploitation depends on factors such as geology, environmental and heritage protection laws, or even on social rejection near populatedareas.Thesefactorsareforcingquarriestomove away from demand areas and make the aggregates to be transportedforlongerdistances,withassociatedeconomic, environmental,andsafetyissues.Tomitigatethisissue,this workhasfocusedontheusageofwastematerialsthatwere alsoadverselyaffectingtheenvironment.Someoftheseare alreadyinusesuchasIronslag,CrusherDust,etc.andmany others are under research. Hence, usage of these waste materialshelpingindualrolebyminimizingtheusageofraw materialofconcreteandbyusingthewastematerialsthatare affecting the environment. Its beneficial properties which include (i) Low density extreme versatility; (ii) Lighter weight without sacrificing strength; (iii) Durability and longevity;(iv)Resistancetochemicals,water,andimpact;(v) Unique ability to combine with other materials and (vi) Highlyweatherableandlowmaintenance.

T. Bragadeeshwaran, A.S. Kiruthika Devi, D. Manju Shree, R Pakya Sree in2021performedastudyonPartial Replacement of Coarse Aggregate with Waste Plastic in Concrete.Theyusedhighstrengthofconcretew/c0.35and thepercentageofwasteplasticreplacedby3,6,9,12,15and 18% of cement, coarse aggregate in concrete. They concluded that the use of waste plastic in cement based composite can significantly reduce cost of construction throughfullorpartialreplacementofaggregates.Theuseof waste plastics in constructions will grossly reduce rate of solid waste accumulation in the environment and income willbegeneratedfromitsutilization.

Azad Khajuria, Puneet Sharma in2019performedstudy on use of plastic aggregates in concrete. They performed

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

studytotestthemechanicalpropertiesoftheconcretewith plastic coarse aggregates. Concrete was prepared using plasticcoarseaggregatesinvaryingproportionsof0,2.5,5, 7.5 and 10%. It was observed while experiment that the compressivestrengthofconcreteinitiallyincreasesat2.5% PCAbutfurtheradditionofPCAshowsreductioninstrength. Theyconcludedthattheoptimumcompressivestrengthwas obtained at 2.5% PCA and the Flexural Strength shown similarresulttothatofcompressivestrength.

Elango A and Ashok Kumar A in2018performedstudy concrete with plastic fine aggregates. They used OPC 53 grade,Riversandandcrushedaggregates.Theyusedplastic inplaceoffineaggregatesinproportionof10%,20%and 30%.Theytestmechanicalanddurabilitypropertiesontheir concrete samples. They found the decrease in strength of concrete. But found that the concrete shows good results against acid attacks and increase in elasticity. So, they concludedthattheplasticaggregateconcretecanbeusedin placewhereweneedlesscompressivestrengthbutmore durability.

Lhakpa Wangmo Thingh Tamanget. al. in 2017 performed experiment on Plastics in Concrete as Coarse Aggregate. They performed the testing of mechanical properties of concrete containing Plastic aggregates. They useplasticaggregatesinproportionof10%,15%,and20%. They found marginal reduction in strength and suggested theoptimumresultas15%replacement.

B Jaivignesh and A Sofi in 2017 performed Study PropertiesofConcretewithPlasticWasteasAggregate.They replace coarse aggregates in proportion of 5%, 10% and 20%.Theyfoundthattheconcretewaslighterinweight.But the compressive strength was lesser than that of conventional concrete. They also found that the concrete with10%plasticaggregatesshowsstrengthnearlysimilarto theconventionalconcrete.So,theoptimumresultwas10% plasticaggregates.

M Mahesh, B Venkat Narsimha Rao, CH. Satya Sri in 2016, performed work on Re Use of Polyethylene Plastic WasteinConcrete.Theypreparedconcretewith2%,4%,6% pulverized/nonpulverizedpolyethylenematerialafterdoing the mix design. They concluded that waste plastic can be effectively re used without affecting the mechanical properties considerably (5 10%). With increase in the percentageofplastictherewasasuddendecreaseinearly strength,butthestrengthdevelopedtothevalueasthatof the conventional M25 concrete when 28 day tests were performed.Forlesspercentageaddition(2 4%)ofplastic, there was no considerable variation in 7, 14 and 28 days compressionstrengthandsplittensilestrength.

Praveen Mathew et. al. in2013studytheuseofRecycled PlasticsasCoarseAggregate forStructural Concrete.They performed test on concrete with various proportions of

plasticaggregatesinreplacementofcoarseaggregatesand found the optimum result at 22% replacement of coarse aggregateswithplasticaggregates.Theyfurtherperformed thetestforotherpropertiesonconcretewith22%plastic aggregatesandfoundthatconcretewithplasticaggregates wasweakerinfireresistance.

S. Vanitha et al. in 2015 performed studies on use of waste plastic in Concrete Blocks. Paver Blocks and Solid Blocksofsize200mmX150mmX60mmand200mmX 100mmX65mmwerecastedforM20gradeofconcreteand testedfor7,14and28daysstrength.Plasticwasaddedtoa proportion of 2%, 4%, 6%, 8% and 10% in equal replacementofaggregates.Theyfoundtheoptimumresult forpaverblockat4%replacementofaggregateswithplastic aggregates.And2%ofplasticincaseofsolidblocks.

Daniel Yaw Osei in 2014 performed experiments on plastics aggregate in concrete. He replaces the coarse aggregatesinconcreteofratio1:2:4by25%,50%,75%and 100% with plastic. He found that there was reduction in strength of concrete as well as density of concrete. They suggestedthatreplacementofaggregatesmorethan36%is not suitable for structural concrete. They also suggested plasticasamediumforproductionoflightweightconcrete.

T.Subramani and V.K.Pugal in 2015 performed an experiments on plastic waste as coarse aggregates in concrete. They prepared the concrete with 5%, 10% and 15% replacement of aggregates in concrete with plastic. They found the optimum results at 10% replacement of aggregateswithplastic.Furtherincreaseinplasticcontent decreasesthestrengthofconcrete.

Amalu.R.Get. al. in2016performedthestudytheuseof wasteplasticasfineaggregateinconcrete.Theyuseplastic assubstituteoffineaggregatesinproportionof10%,15%, 20%and25%.Theyfoundreductioninstrengthofconcrete butsupporttheuseofplasticinnon structuralconcretefor the reason it shows higher workability and reduce environmentalwaste.

Manhal A Jibrael and Farah Peter in2016studiesthe StrengthandBehaviourofConcreteContainsWastePlastic. Theyreplacefineaggregatesinconcretewithplasticbottles andplasticbagsinvaryingproportionsfrom0%to5%.They concludedtheresultstousetheplasticinconcretefornon structuralpurposesasitreducesthestrengthinbothcases.

Themethodologyadoptedforthisexperimentalstudyisas under:

a) Literaturestudywascarriedoutbasedondataavailable onuseofwasteplasticinconcrete.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

b) Waste plastic was collected, cleaned, dried and shredded.

c) Testrelatedtopropertiesofcementandaggregatesare performed.

d) Proportion of plastic coarse aggregates (PCA) in differentmixesisselectedbasedonavailableliterature.

e) Mix design for different proportions of concrete is prepared and tests are conducted to obtain the mechanicalpropertiesofdifferentmixes.

f) Basedontheliteraturesurveyandoptimumquantities ofplastic,thefollowingcombinationsareadopted.

Cement: Ordinary Portland Cement (43 grade) with 29% normal consistency conforming to IS: 8112 1989 is used. The specific gravity and fineness modulus of cement are 3.15.

Coarse Aggregate: Natural crushedstoneconformingtothe IS 383 2016 is used. The shape of coarse aggregate is angular, water absorption capacity is 0.5%, fineness modulusis4.50andspecificgravityis2.68.

Fine Aggregate: Uncrushednaturalriversandisusedasfine aggregate. In accordance with IS 383 2016 tests were conducted and concluded that the fine aggregate falls in Zone II. The water absorption capacity is 1%, fineness modulusis2.60andspecificgravityis2.62.

Water: Waterisanimportantingredientofconcreteasitis actively participates in chemical reactions with cement thereforecleanpotablewaterconformingtoIS456 2000is usedforthepreparationofconcretemixture.

Plastic: Studieshaverevealedthatwasteplasticshavegreat potentialforuseinconcreteasitsadditioninsmalldoses, about6 12%,byweightofaggregateshelpsinsubstantially improvingthestrengthofconcrete.Thewasteplasticusedin thisstudyconformstothesizepassing2.36mmsieveand retained on 600 micron sieve. Dust and other impurities shallberemovedandnotbemorethan1%.Plasticsusedin thisstudyandsourcesaregivenintable1below

Table 1: Plastics used and sources

High Density Polyethylene (HDPE)

Low Density Polyethylene (LDPE)

Carry bags, bottle caps, householdarticlesetc.

Carry bags, milk pouches, and other packaged household items pouches likedetergent,salt,teaetc.

Polyethylene Terephthalate (PET)

Drinking water bottles, soft drink water bottles etc.

ThemixdesignispreparedinaccordancewiththeIS10262 2009andmixproportionsofingredientsareshowninTable 2below

Table 2: Mix proportion Unit of batch

Ceme nt (kg)

Fine Aggrega te (kg)

20m m (60 %) 1 cum. Conte nt 370 809 430 645 170 3.7

Coarse Aggregate (kg) Wat er (kg) Admixtu re (kg) 10m m (40 %)

Ratio 1 2.2 1.2 1.7 0.46 0.01

Furthermixesarepreparedpartiallyreplacingwasteplastic tocoarseaggregateofpercentage0%,2%,4%,6%,8%and 10%.

Table 3: Percentage of waste plastic adopted for replacement

Concrete Trial No. Natural Coarse Aggregate (%) Waste Plastic (%)

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Table 5: Compressive strength of concrete

Concrete Trial No. 7 days strength (N/mm2)

14 days strength (N/mm2)

28 days strength (N/mm2)

Fig. 1: Mixing of shredded waste plastic with concrete

(i) Workability: Slumptestwasperformedtomeasurethe workabilityofconcrete.Workabilityofconcreteisdefinedas theeasetodoworkwithit,withoutsegregation.Workability of concrete is an important property of fresh concrete. Concreteshouldhavegoodworkability.Theresultofslump testshowsthattherewasfirstlyincreaseinslumpupto4% additionofplasticandthenitstartsreducing.Theslumptest resultsareshownintable4below.

Table 4: Workability of concrete

Percentage replacement of aggregate Slump (in mm) 0 88 2 85 4 89 6 93 8 91 10 87

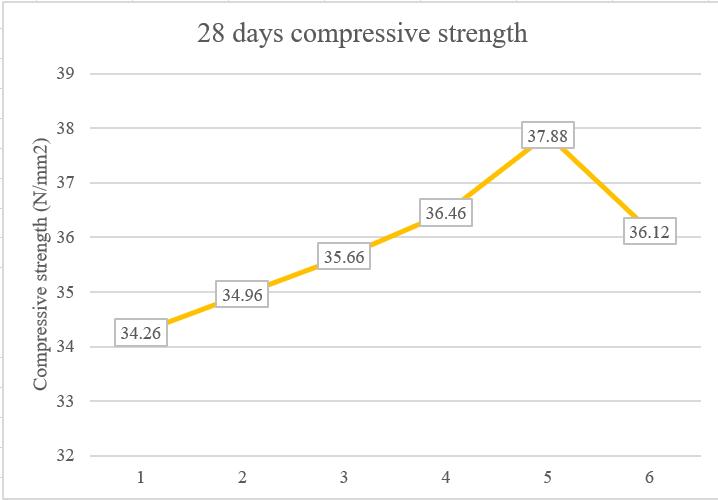

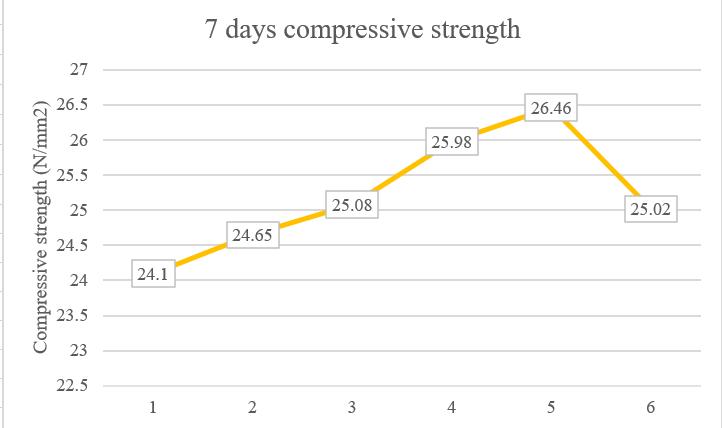

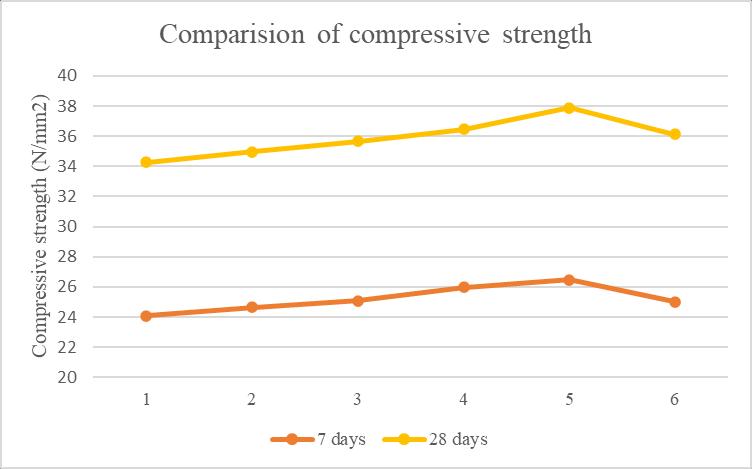

(ii) Compressive strength test: Thistestisperformedon hardened concrete, to check the strength of concrete in accordancewiththeIS516 1959.Testresultsareshownin Table5below.Itisnotedfromtheresultsobtainedthatthe strength of concrete achieved at 7 & 28 days using 0% of waste plastic and 10% are almost similar. It is also noted thatadditionofwasteplasticcontentat2%,4%,6%and8% strengthened the concrete and 8% provided optimum strengthvalue.

1 24.10 30.50 34.26 2 24.65 30.98 34.96 3 25.08 31.32 35.66 4 25.98 31.89 36.46 5 26.46 33.12 37.88 6 25.02 31.00 36.12

Case I: 7 days compressive strength

Chart- 1: Variation of compressive strength on concrete after 7 days

Case-II: 28 days compressive strength

Chart 2: Variation of compressive strength on concrete after 28 days

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Comparison of compressive strength of concrete

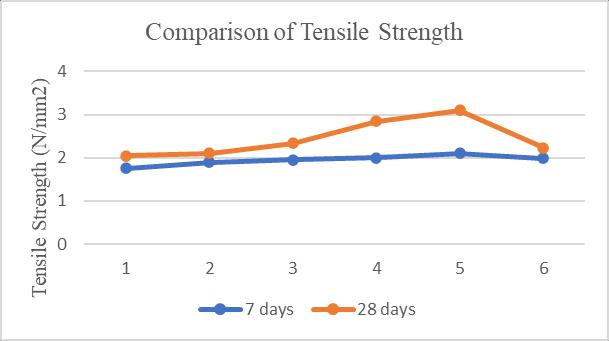

(iv) Split Tensile Strength: The split tensile strength of concreteisevaluatedat7and28daysofcure.Resultsare shownintable7below.Itisobservedthattensilestrengthis increasingwhileweaddwasteplasticcontentonasimilar linetocompressivestrength.Themaximumtensilestrength achievedat8%ofwasteplasticcontent.

Table- 7: Split Tensile strength of concrete

Concrete Trial No. 7 days strength (N/mm2)

28 days strength (N/mm2)

Waste plastic content (%)

1 1.75 2.05 0 2 1.89 2.10 2 3 1.95 2.33 4 4 2.00 2.85 6 5 2.10 3.10 8 6 1.99 2.23 10

Chart 3: Comparison of compressive strength of concrete at 7 and 28 days

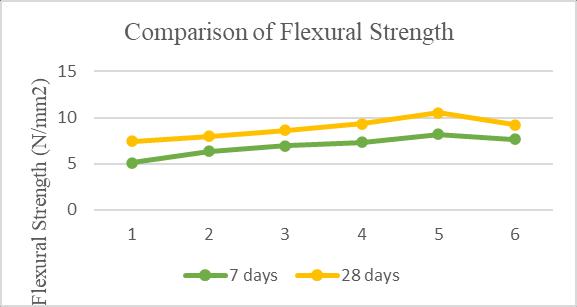

(iii) Flexural Strength: The flexural strength test is conducted for the beams. Results of flexural strength of concreteareshownintable6below.Itcanbeseenfromthe resultsthatthereisanincreasewhileaddingwasteplastic however,aftertrial5thereisareductioninstrength.

Table 6: Flexural strength of concrete Concrete Trial No. 7 days strength (N/mm2)

Comparison of split tensile strength of concrete

Waste plastic content (%) 1 5.11 7.43 0 2 6.36 7.95 2 3 6.96 8.64 4 4 7.31 9.35 6 5 8.16 10.54 8 6 7.64 9.24 10

28 days strength (N/mm2)

Chart 4: Comparison of flexural strength of concrete at 7 and 28 days

Chart 5: Comparison of split tensile strength of concrete at 7 and 28 days

Wasteplasticisaddedtoconcreteinreplacementofcoarse aggregatesbyproportionof0%,2%,4%,6%,8%and10%. Based on the results obtained from the present study, followingconclusionsaredrawn

(i)Thematerialusedintheexperimentisfoundworkable. As the percentage of plastic increases workability also increasesduetosmoothnessandwaterabsorptioncapacity ofwasteplasticislowincomparisontoaggregate.

(ii)Themodifiedconcretemixwithadditionofwasteplastic replacing coarse aggregate up to 8% achieved strength withinpermissiblelimithence,thematerialusedaresafefor constructionpurpose.

(iii) The flexural strength at each curing age is prone to decrease with increase of the waste plastic and aggregate ratio.Thistrendcanbeattributedtodecreaseinadhesive

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

strengthbetweensurfaceofthewasteplasticparticlesand thecementpaste.

(iv) It is noted that tensile strength results are better and declinedattrialno.6.

(v)Itisnotedthatthedensityofconcreteisdecreasedwhile enhancingwasteplasticcontent.

(vi)Usingwasteplasticinconcretecanbeagoodoptionto improve strength of concrete and thereby environment friendly.

(vii) Using waste plastic as replacement of aggregate is useful whereaggregates are incrisis,andthis will help to conservenaturalresources.

1. Elango A and Ashok Kumar A “Study on Partial Replacementofplasticwasteasfineaggregateinconcrete” InternationalJournalofCurrentEngineeringAndScientific Research,Volume5,Issue5,2018,ISSN(Print):2393 8374, ISSN(Online):2394 0697

2.LhakpaWangmoThinghTamang,TsheringWangmo,Karma TsheringDarjay,KarmaSangayPhuntsho,PhuntshoNamgyal, UgyenWangchuk “Use of Plastics in Concrete as Coarse Aggregate”InternationalJournalofEducationandApplied Research,Volume7,Issue5,2017,ISSN(Print)2249 4944, ISSN(Online)2348 0033.

3.Amula.R.G,AzeefAshraf,MuhammadHussain,Rejith.K.U, Vijitha.V. “ use of waste plastic as aggregates in Concrete” Panda,B.;Paul,S.C.;Lim,J.H.;Tay,Y.W.D.;Tan,M.J.Additive manufacturing of geopolymer for sustainable built environment.J.Clean.Prod.2017,167,281 288.[CrossRef]

4.Paul,S.C.;vanZijl,G.P.A.G.;Tan,M.J.;Gibson,I.Areviewof 3D concrete printing systems and materials properties: Current status and future research prospects. Rapid Prototype.J.2018,24,784 798.[CrossRef]

5.BabooRai,S.TabinRushad,BhaveshKr,andS.k.Duggal, “Study of Waste Plastic Mix Concrete with Plasticizer”, International Scholarly Research Network, ISRN Civil Engineering,Volume2012,ArticleID469272

6.T.Bragadeeshwaran,A.S.KiruthikaDevi,D.ManjuShree, R.PakyaSree,“PartialReplacementofCoarseAggregatewith WastePlasticinConcrete”,ISSN:2348 4098.Arivalagan.S, “Experimental Investigation on Partial Replacement of Waste Plastic in Concrete”, International Journal of EngineeringSciences&ResearchTechnology,ISSN:2277 9655,November2016.

7.Anumol S,Dr.ElsonJohn, “Studyontheperformance of plasticsasreplacementforaggregates”,InternationalJournal of Engineering & Technology (IJERT), ISSN: 2278 0181, November2015.

8.IS10262 2009,“ConcreteMixProportioning Guidelines”

9.IS383 2016,“SpecificationforCoarseandFineAggregates fromNaturalSourcesforConcrete”

10.IS456 2000,“Plain and ReinforcedConcrete Code of Practice”

11.IS516 1959,“MethodofTestsforStrengthofConcrete”

AmitKumarPandey

M. Tech (Structural Engineering)

FinalYearStudent RadhaGovindEngineeringCollege, Meerut to

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal