International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

P.Mohanakkumar

P.Mohanakkumar

1 ,

N.Vadivel 21 M.E. Thermal Engineering, Government College of Technology, Coimbatore, India.

2Assistant Professor, Department of Mechanical, Government College of Technology, Coimbatore, India. ***

In todays modern world growing power demand has not been diluted the need for alternate power source. Thus producing clean power from the renewable source of fuel has been a interesting and serious debate over the impacts on environment in a positive way as green energy fuel cell comes into picture using Hydrogen as a fuel makes the pollution free power generation. Hence improvements such as waste heat recovery and combined power generation makes the technology more efficient and reliable. The analysis has been approached through MATLAB Simulink and various conceptual ideas has been implemented on simulation. Additionally the efficiency using waste heat recovery system has been studied for an solid oxide fuel cell using MATLAB Simulink coding tab and the results were analyzed.

Key words: Fuel cell, Solid Oxide Fuel Cell (SOFC), Thermo Electric Generator, Electrolysis, hydrogen recirculation, Seebeck Generator,wasteheatrecoverysystem(WHRS).

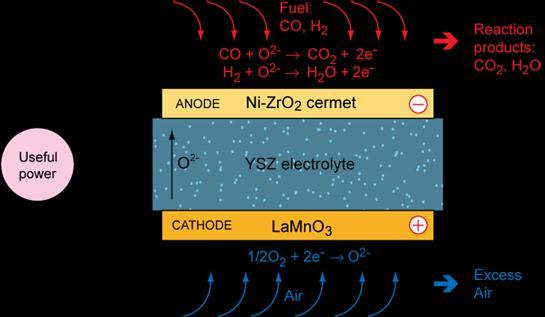

Thefuelcelltechnologyhasbeenrecognizedasthegreenenergyasitdoesnotreleasetoxicsootparticles,oranysuch harmfulemissions,asitcleanerwhilegeneratingpower.Theprinciplebehindthefuelcelltechnologyisthechemicalreaction turns into an electrical energy, thus the chemical reaction gives the byproducts such as water, carbon monoxide, carbon dioxide, etc.., because of the absence of combustion process the system does not liberate any harmful emissions, in simple termstheworkingofthefuelisthereversereactiontakesplaceintheelectrolysisprocess.Heretheanodeoffuelcellcollects thehydrogen,cathodecollectstheatmosphericoxygen,theuseofelectrolyteistoallowthehydrogenionstopassthroughand makes the reaction continuous, the main drawback of the fuel cell is the storage of hydrogen in its pure form due to low volumedensityanditsmeltingpointitshardtostoreatroomtemperatures.

The existing fuel cell types are in research are SOFC [Solid Oxide], AFC [Alkali], DMFC [Direct Methanol], MCFC[MoltenCarbonate],PAFC[PhosphoricAcid],PEMFC[PolymerElectrolyteMembrane].Thesefuelcellshasanmeritsand demerits based on the operation temperatures, fuels used, catalyst used to ionize the hydrogen etc.., these fuel cells while operating as a single stage power generator the efficiencies are around [50% 65%]. as the remaining energy has been liberated as a waste heat and the byproduct from the fuel cell has not been utilized properly. thus the over all efficiency is poor,whichleads totheresearchonwasteheatrecoveryand,hydrogen[fuel]re circulationcomesintopicturetomakethe systemmoreefficientonworking.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

As we discussed earlier the problem identified in the conventional methods has been analyzed and the various solutionshasbeendiscussedinthelaterpart.

1. UsingThermo ElectricGenerator[TEG],

2. Hydrogenrecirculation,

3. Multistagepowergeneration.

The above listed are the key areas where the improvements in the solid oxide fuel cell has been analyzed and the workinghasbeenstudiesinthefollowingstages.

The multi stage power generation and waste heat recovery management using Seebeck generators[TEG], and the process of hydrogen circulation into the fuel cell back from the hydrolysis of water which is the byproduct of fuel cell. such that the overallefficiencywillbeimprovedsothatcostcanalsobesavedbecauseoftheusageofreproducedhydrogenfromthewater.

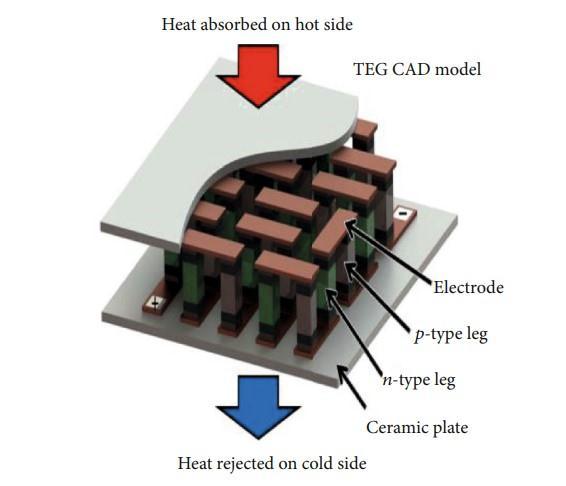

When we use TEG in the fuel cell the waste heat of fuel cell has been utilized to the maximum extend and provides sufficientcoolingandoptimumtemperaturefortheworkingoffuelcell[18].TheTEGarethenconnectedinseriestoproduce thenecessaryvoltageandsuppliedforauxiliarypowersystemwhichhelpstheefficientfunctioningofthefuelcell andithelps tofindthealternatesolutionfortheproductionofhydrogenfromthisusefulpower

Asdiscussedthe byproduct ofthe mostcommon fuel cellsarewaterandcarbo di oxide.,asthe waterfromthefuel cellhasahightemperatureduetoexothermicreactionofwaterandhydrogenthesamewaterisrecirculatedasthesourcefor hydrogenbyfurtherelectrolysisusingthepowerfromtheTEG.,

The concept of multi stage power generation is helpful when we need to increase the over all system efficiency by utilizing the stage 1 as input for stage 2 as we can have a different configuration of fuel cell either a SOFC as stage 1 and PEMFCasstage2duetohigherheatproductioncapacityofSOFCfuelcelltheTEGworksbetterinSOFCandthepowerfrom TEG of SOFC(stage 1) can be utilized to produce hydrogen from the water from the same SOFC stack and the hydrogen is recirculatedtothePEMFCandthecombinedpoweroutputhasbeenachieved.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2088

International Research Journal of Engineering

Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

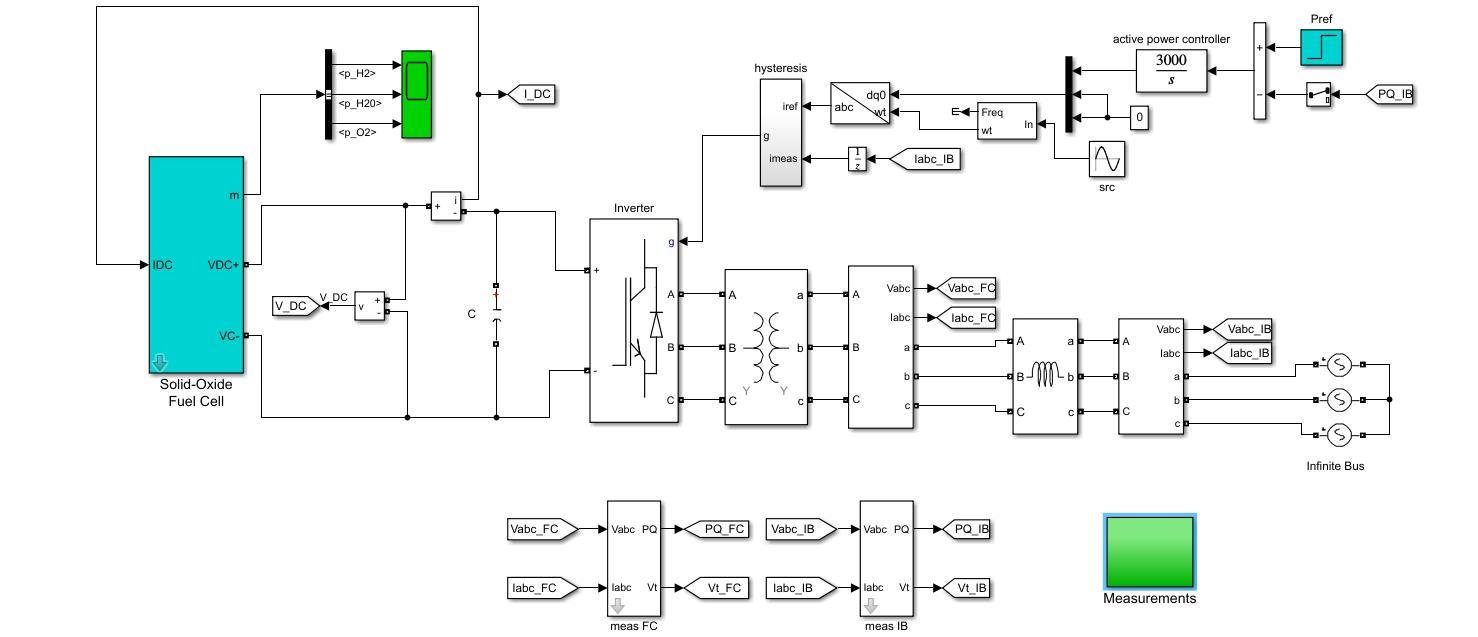

Thefuelcell[SOFC]hasbeenpreferredduetoitscostofoperationandtheamountofheatproducedwhileoperating is much higher compared to other efficient fuel cell such that the heat from the SOFC stack has been utilized for power generation using seebeck generator such that the effective voltage produced is used to electrolyze the byproduct hot water from the fuel cell. And the hydrogen from the electrolysis has been recirculated into the anode so that the system overall efficiencywillbeimproved.

InSOFCstacktheyttriumstabilizedzirconiahasbeenusedasasolidelectrolytewhichenablesoxygenion conduction while blocking the electronic conduction. To achieve the sufficient ion conduction, an SOFC with a YSZ electrolyte must be operatedathightemperaturebetween800oC 1000oC,themainadvantageofusingSOFCisitscheapoperatingcostandthe cheap electrolyte used the efficiency of SOFC is around 60 65% the commercial manufacturer of SOFC stack is bloom energy[31]

Therearecommercialfuelcellplantswheremulti layerSOFCstackhasbeenusedtogeneratepoweroutofitnearlyto 50KW. Hence further improvement and research helps to increase overall efficiency and produce high power density SOFC stack.

ThemainadvantageofusingSOFCisthecostwheretheanode,cathodeandelectrolytecostisbearablecomparedto otherfuelcellsfurtherutilizationofthewasteheatrecoveryandanodegas(hydrogen)recirculationwillhelptoincrease the efficiencyandreducethecostperwattgeneration.ByusingthepowerfromtheThermo ElectricGenerator[TEG]thevoltage hasbeengeneratedandthepowerfromthemultipleTEGwherecoupledandtheelectricalpowergeneratedhasbeenutilized tocarryouttheelectrolysisprocessfromthehotwaterwhichisthebyproductofthefuelcell.Themainadvantageofusinghot water is that the electrolysis voltage is much lower when compared to the electrolysis required to carry out in room temperature. The resulting product from electrolysis will liberate hydrogen and oxygen the hydrogen recirculated back into thesameSOFCstackortheotherlowpowerproducingfuelsuchthatthewasteheatmanagementhasbeencarriedoutandthe overallpowerproducedwillalsobeimproved.

Type of fuel cell Applications Core temp. efficiency Advantages Limitations

Proton Exchange Membrane (PEMFC) Portable,stationary andautomotive 50 100°C; 80°Ctypical; 35 60%efficient

Alkaline (AFC)

Molten Carbonate (MCFC)

Phosphoric Acid (PAFC)

Solid Oxide (SOFC)

Direct Methanol (DMFC)

Space,military, submarines,transport 90 100°C; 60%efficient

Largepower generation 600 700°C; 45 50%efficient

Mediumtolarge powergeneration 150 200°C; 40%efficient

Mediumtolarge powergeneration 700 1000°C; 60%efficient

Portable,mobileand stationaryuse 40 60°C; 20%efficient

Compactdesign,long operatinglife,quick start up,well developed

Lowpartsand, operationcosts;no compressor;fast cathodekinetics

Highefficiency, flexibletofuel,co generation

Goodtolerancetofuel impurities;co generation

Lenienttofuels;can usenaturalgas,high efficient

Compact;feedson methanol;no compressor

Expensivecatalyst; needschemicalgrade fuel;complexheat andwatercontrol

Largesize;sensitive tohydrogenand oxygenimpurities

Highheatcauses corrosion,long startup,shortlife

Lowefficiency; limitedservicelife; expensivecatalyst

Highheatcauses corrosion,long startup,shortlife

Complexstack;slow response; lowefficiency

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Table 2: Fuelcellefficiencywithwasteheatrecovery

Absolutetemperature 1273K

Initialcurrent 100A

UniversalgasconstantJ/(kmolK) 8314

Faraday'sconstant(C/kmol) 96.487e6

Idealstandardpotential(V) 1.18

Numberofcellsinseries 450

Maximum,minimalandoptimalfuelutilization [0.90.80.85]

Valvemolarconstantforhydrogen,waterandoxygen(kmol/(satm) [8.43e 4,2.81e 4,2.52e 3]

Ohmiclosspercell(ohms) 3.2813e 004

Ratioofhydrogentooxygen 1.145

Fuelprocessorresponsetime(s) 5

Absolutetemperature 1273K

Initialcurrent 100A

UniversalgasconstantJ/(kmolK) 8314

Faraday'sconstant(C/kmol) 96.487e6

Idealstandardpotential(V) 1.18

Numberofcellsinseries 450

Maximum,minimalandoptimalfuelutilization [0.90.80.85]

Valvemolarconstantforhydrogen,waterandoxygen(kmol/(satm) [8.43e 4,2.81e 4,2.52e 3]

Ohmiclosspercell(ohms) 3.2813e 004

Ratioofhydrogentooxygen 1.145

Fuelprocessorresponsetime(s) 5

Table -3: SOFCstackparameters

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2090

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Fig 1:SOFCpowergenerationunit

Fig 2:TEGmodelforanfuelcellstack

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2091

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

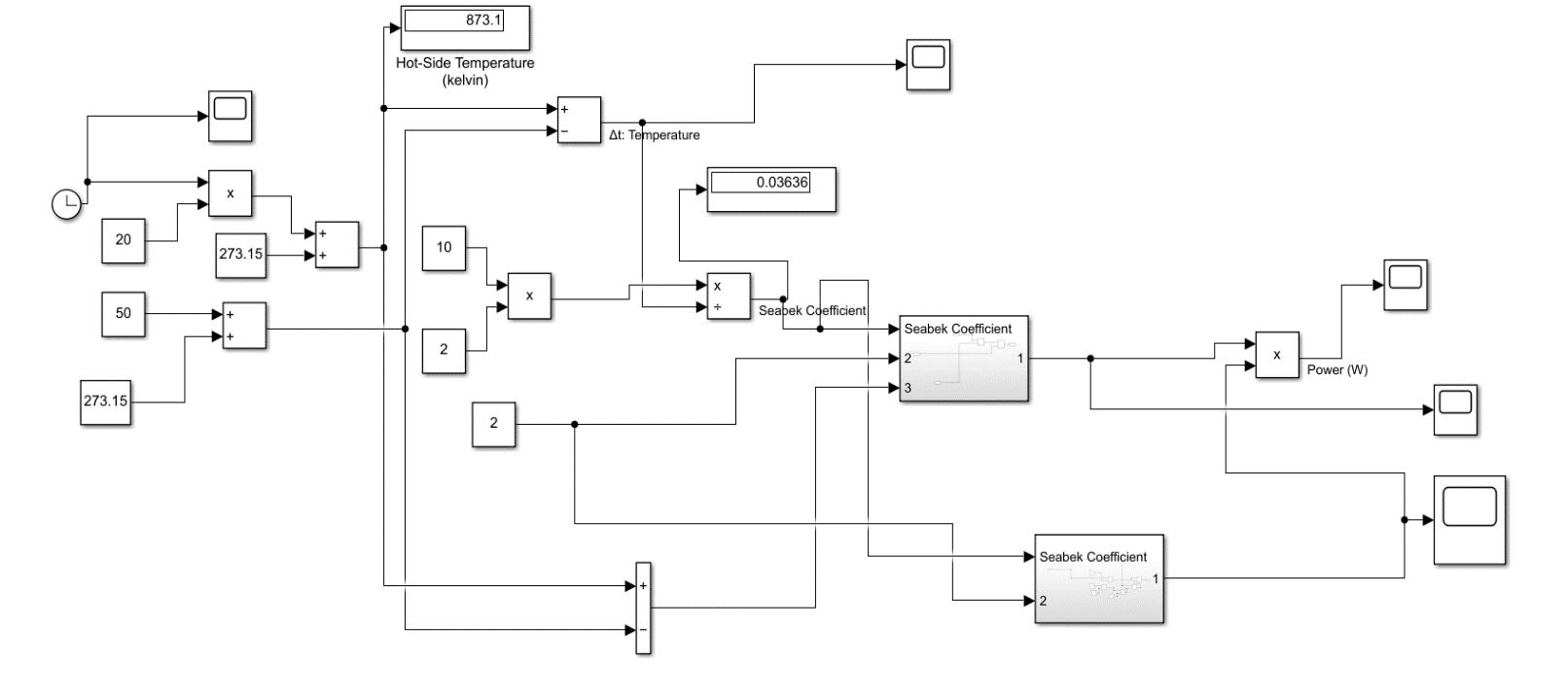

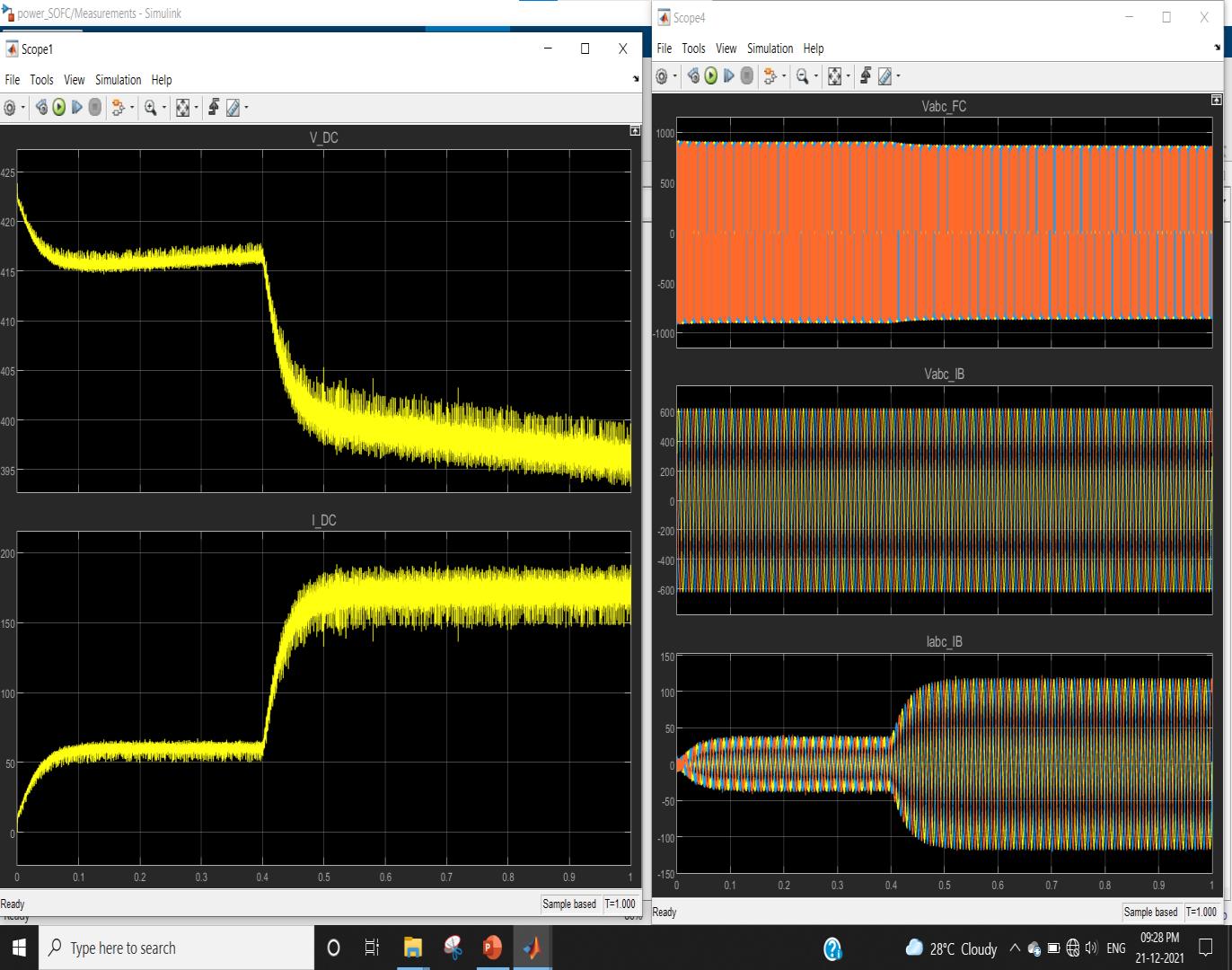

Fig 3:powercharacteristicsofaSOFCfuelcell

Thusthemulti stagefuelcellwithwasteheatrecoveryandanodegas(hydrogen)recirculationusingTEGimprovingthe overallsystemefficiency usingthewasteheatoffuelcellstackandthehotwaterwhichisthebyproductoffuelcellhasbeen utilizedandthemodelhasbeenproposedonvariousideologyandworkinghavebeendiscussed.

[1] Al Khori,K.;Bicer,Y.;Koc,M.2020IntegrationofSolidOxideFuelCellsintoOilandGasOperations:Needs,Opportunities, andChallenges.J.Clean.Prod.,245,118924.

[2] Mehmeti, A.; Mcphail, S.J.; Pumiglia, D.; Carlini, M. 2016 Life cycle sustainability of solid oxide fuel cells: From methodologicalaspectstosystemimplications.J.PowerSources,325,772 785

[3] Lee, Y.D.; Ahn, K.Y.; Morosuk, T.; Tsatsaronis, G.2015 Environmental impact assessment of a solid oxide fuel cell based combinedheat and power generationsystem.

[4] Buchgeister, J. 2012 Comparison of Sophisticated Life Cycle Impact Assessment Methods for Assessing Environmental ImpactsinaLCAStudyofElectricityProduction;

[5] Meng, F.; Dillingham, G.2018 Life Cycle Analysis of Natural Gas Fired Distributed Combined Heat and Power versus CentralizedPowerPlant.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2092