International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

SK. Samad1 , P. Raja Sekhar2

1PG Student, Department of civil Engineering, Velaga Nageswara Rao (VNR) College of Engineering, (Approved by AICTE and affiliated to JNTUK, Kakinada), G.B.C. Road, Ponnur 522124, GUNTUR, A.P (INDIA).

2Assistant Professor, Department of civil Engineering, Velaga Nageswara Rao (VNR)College of Engineering, (Approved by AICTE and affiliated to JNTUK, Kakinada), G.B.C. Road, Ponnur 522124, GUNTUR, A.P (INDIA). ***

Abstract The development of sustainable concrete has gained plenty of awareness in recent years. Researchers have conducted many experimental investigations for the manufacture of differentforms of concrete by using numerous low carbon footprint materials, such as granite waste andfly ash. The using oflow carbon footprint materials in construction industry will minimizetheexploitation of natural raw materials and promote sustainability in construction industry. This research thus aimed to investigate the influence of granite waste (GW) and fly ash on the production of self compacting concrete (SCC). This research was conducted in two phases. In the first phase, the preliminary investigation was carried out for finding the maximum adding percentage of GW and fly ash in the successful production of SCC. The GW was used in the proportion of 0, 20, 40, 60, and 80% as an alternative to fine aggregate (i.e. sand) by weight, while, fly ash was substituted with cement in the proportion of 0, 20 and 30% by weight. The fresh characteristics (slump flow, T500 flow, V funnel, J ring, and L box), mechanical characteristics (compressive strength and flexural strength) and durability characteristics (water absorption and ultrasonic pulse velocity) were evaluated. The findings of first phase revealed that the combined use of GW (up to 60%) and fly ash (up to 30%) in SCC has the potential to considerably enhance the fresh and water absorption properties (without adversely affecting strength characteristics). In the second phase, the percentage of fly ash (30%) was fixed and the percentage of granite waste (up to 60%) was varied.

Key Words: Compressive strength, Flexural strength, Waterabsorption,Scanningelectronmicroscope(SEM)

Self compacting concrete (SCC) is one of the major revolutions in the construction industry since its development in the later years of the 1980s SCC is the advancedformofnormallycompactedconcrete(NCC)that caneffortlesslyflowandspreadinthethinneranddensely reinforced section without any additional vibration. SCC technology can be termed as ‘‘smart concreting construction”whichdemandslessenergyandlowoperatives andsupportsinfastercastingwithlowermaintenance.Ithas variousbenefitsoverNCC,forinstance,reduceslabourcost andconstructiontime,providesflexibilityindesigning,and produces a homogeneous concrete matrix without

honeycombing.Further, SCC exhibits superior mechanical performanceascomparedtothatofNCCduetothebetter refinedmicrostructurecontributedbythepresenceofhigher finecontentinSCC

Theuseofstoneindustrywasteintheconstruction industry has gained a lot of interest worldwide. Indiaholdsvarietiesofstones,like,marble,granite, sandstone,limestone,andslate.

Granite industry is one of the primary stone industriesinIndia.Granitestoneisakindofigneous rock that is formulated through the gradual crystallizationofmagmaexistingbeneaththeearth.

Granite has been exploited as a building or decorativestonethroughouthumanhistorydueto its inherent hardness and strong characteristic (Mendoza et al., 2014). Accordingto the World Natural Stone Association report, in 2014, worldwidegranitestoneproductionaccountedfor approximately 349 million sqm/year, and India was the third largest producer nation of granite stoneintheworldafterChinaandBrazil (WNSA, 2014). As of 1st April 2015,India had a total of 46,320millioncumgraniteresources(IBM,2018).

Unfortunately, more than 30% is currently produced as granite waste (GW) during cutting and polishing ofornamental granite blocks in graniteindustries(Singhetal.,2017).

Thisresidueinitially producedinwetslurryform, whichisbeingthrownawayinappropriatelyonthe nearby dumpingsites as shown in Chart 1) asa wasteproduct.

Itthenconvertsintodryformaftersometimedueto the evaporation of water that becomes airborne, eventuallycausinghealthproblemsandaffectsthe surroundingecosystem(Ghannametal.,2016).

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Ceramicindustry

Tileandbricksmanufacturing

Indoorandoutdoorcladdingandpaving

Desulfurizationprocess

Thermosetresincomposites Roadembankments

Asphalt Masonry

Pavingblocks

Cement basedproducts(mortar,NCC,andSCC)

Polymer basedcompositematerials

Itdecreasesthecostofconstructionproductsonusing GWinsteadofcementandsand.

ItdeclinestheheatofhydrationonusingGWinsteadof cement.

Itincreasestheresistancetoexternalagentsonusing GWinsteadofcementandsand.

Itenhancesstrength.

It minimizes emission of greenhouse gases like CO2 and NOx etc. in the production ofcementclinkeron usingGWasareplacementofcement.

Itconservesasubstantial quantity ofnon renewable energyonusingGWasareplacementofcement.

It protects the environment by preserving the significantamountofnaturalminedmaterials.

Itreduceswastedisposalcost,whichiscontinuously risingbecauseoflandfilltax.

Itopensanewrecyclingbusiness.

Thephysicalandchemicalcharacteristicsofdifferent ingredients in the formulation of SCC mixtureshavebeen discussed in this section. Cement, fly ash, fine aggregate, coarse aggregate, granite waste (GW), water and superplasticizer have been used in the formulation of differentSCCmixtures.Scanningelectronmicroscopic(SEM), X ray diffraction (XRD) and X ray fluorescence (XRF) techniqueshavebeenutilizedtoevaluatethechemicaland microstructuralcharacteristicsofdifferentingredients.The SCCmixturedetailsandtheirmixingprocedurehavebeen discussedinthissection.

The testing procedures for fresh, mechanical, durabilityandmicrostructuralcharacteristicshave alsobeendiscussedinthissection.

OrdinaryPortlandcement(OPC;Ultratechbrand)of 43 grades was used conforming to BIS: 8112 (1989),anditschemicalcompositionandphysical properties are presented. XRF technique was utilized to determine the oxide composition of cement.

SEMimageofcementparticles.whichindicatesthat particlesofcementareangularandnon sphericalin shape.

Table 1: Physicalpropertiesofcementandflyash

Physical properties Cement Fly ash

Consistency(%) 27

Specificgravity 3.16 2.28

Soundness(mm) 1

Initialsettingtime(minute) 120

Finalsettingtime(minute) 241 Specificsurfacearea(m2/kg) 297 353 Compressivestrength(MPa) 3days 23.7 7days 34.5 28days 45.8

Table -2: Chemicalcompositionofcementandflyash

Chemical composition (%)

CaO 45.88 0.9 SiO2 31.3 58.19

Al2O3 3.49 26.93 Fe2O3 3.3 4.27

Na2O 0.22 0.07

K2O 0.69 1.1

MgO 5.21 0.69

P2O5 0.05 0.21

MnO 0.05 0.06

LOI 3.97 0.45

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

This section addresses the procedure of different tests (fresh, mechanical, durability and microstructure characteristics)whichwerecarriedoutonSCCmixturesin the fresh and hardened state. Fresh characteristics tests conveytheearly agebehaviourofconcretemixtures,whichis required for proper placement of concrete mixtures and ensuresitsintegrityinthefreshstate.Whereas,mechanical, durability, impact and fire resistance and microstructure characteristicstestsensuretheperformanceorintegrityof concrete mixture in the hardened state. The procedure of differenttestsperformedonconcretemixturesisdiscussed below.

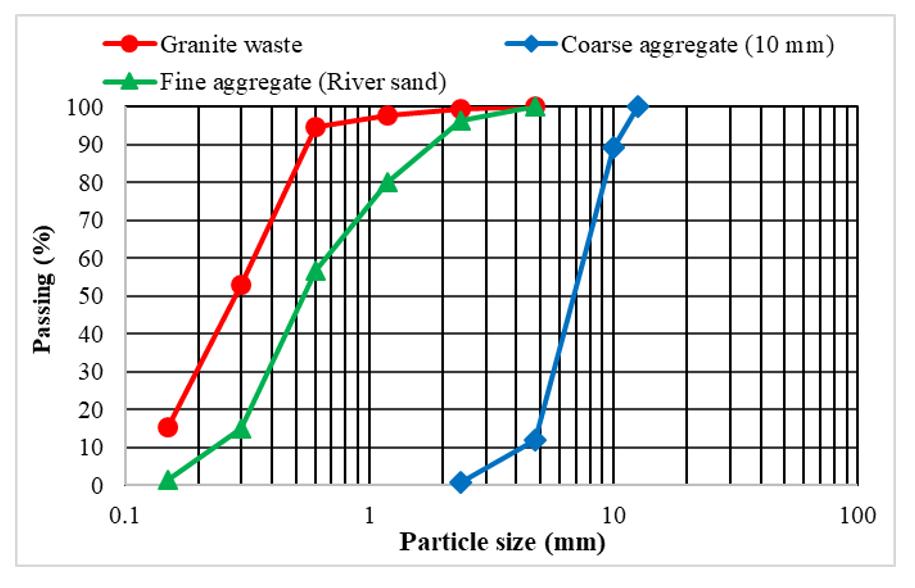

Chart 1:Sieveanalysisofaggregatesandgranitewaste

This study was conducted in two phases. In the first phase, the preliminary investigation was carried out for findingthemaximumaddingpercentageofGWandflyashas a replacement ofnatural fine aggregate and cement in the successfulproductionofSCC,respectively.Forthefirstphase, fresh (slump flow, T500 time, V funnel time, J ring and L box), mechanical (compressive and flexural strength), durability(waterabsorption)andmicrostructure(SEMand EDS)characteristicswereperformed.

Inthesecondphase,thepercentageofflyashwasfixed and the percentage of GW was varied.In this way, for the second phase, the comprehensive investigation for fly ash blendedSCC (preparedwithandwithoutGW)wascarried out by performing fresh, mechanical, durability, and microstructure characteristics. Additionally, impact resistance, fire resistance, economic and environmental characteristicswerealsoevaluatedforflyashblendedSCC.

For the first phase, three series of SCC mixtures were prepared. Series I included a control SCC mixture (i.e. 0% GW), and four other SCC mixtures prepared with GW as a partial substitute of fine aggregate in the different percentagesof20,40,60and80%.Series IIandIIIincludeda total of ten SCC mixtures prepared with same GW replacementasinseries Iexceptthatthe20and30%cement contentwaspartiallyreplacedwithflyashintheseries IIand III,respectively. Details of SCC mixtures (for preliminary investigation)

AlltheSCCmixturesweremadebymaintaininga fixed binder quantity of 546.79 kg/m3 and effective water to binderratioof0.37.TheSPdosagewasadjustedtoachieve slumpflowintherangeof700±30mm.ThemixIDofallthe SCCmixtures.Typically,GXFYstandsforX%substitutionof fineaggregatewithGWandY%substitutionofcementwith flyash.

SCCistheadvancedtypeofNCC.TheworkabilityofNCC canbedeterminedbyperforminganyoneortwotestslike slump, compaction factor, flow table, and vee bee consistometer,whereasthereisnouniversaltestforfinding the workability of SCC. The SCC must fulfill three characteristics named flowing ability, passing ability, and segregation resistance, for achieving the satisfactory workabilityoffreshlymixedconcrete.Theaforementioned SCCcharacteristicscanbemeasuredbyperformingfollowing tests,suchasslumpflow,T500time,V funneltime,L box,U boxandsievesegregation.

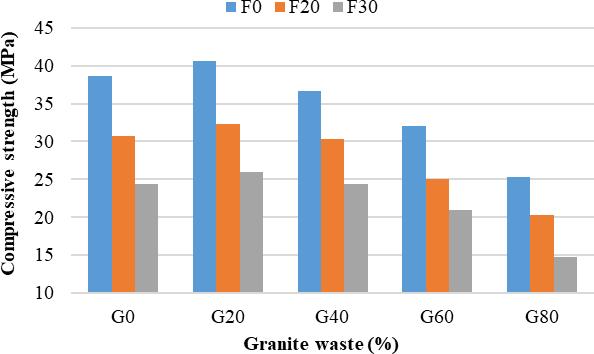

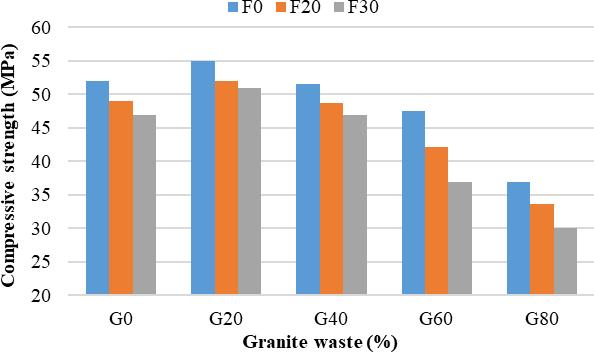

The compressive strength of the mixes at curing periodsof7and28days,respectively.Foralltheseriesand curingdurations,thecompressivestrengthinitiallyincreased atthe20%replacementlevelofGWandthendecreasedwith further increase of the GW content. However, at the replacement level of40% GW,theSCC specimens showed comparablestrength.Thehigherorcomparablestrengthup tothe40%replacementlevelofGWmaybeattributedtothe betterfillereffect,whichwasrelatedtothesmallsizeand irregularshapeoftheGWparticles.

ThesmallersizeGWparticleseffectivelyfilled the gaps between the coarser fraction of aggregate particlesaswellascementandsandparticles.

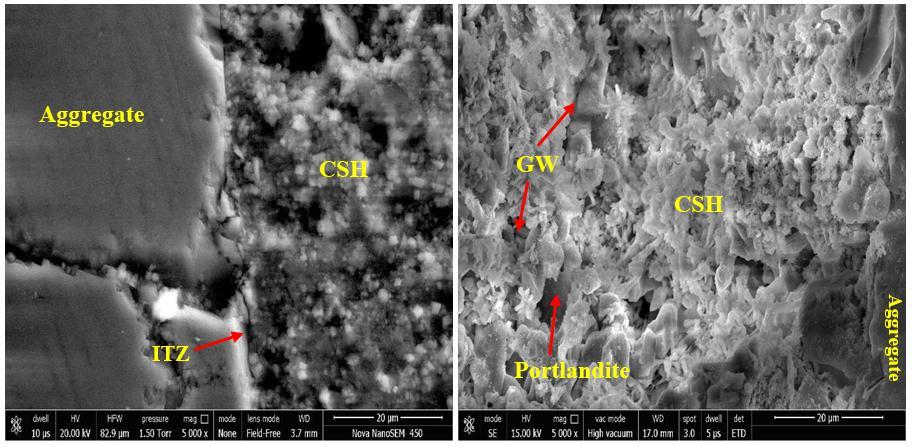

Moreover,thesurfaceroughnessoftheGWparticles made a proper interlocking with cement paste, leadingtoabetterinterfacialtransitionzone(ITZ) betweentheaggregateand pastematrixandthus improvedthecompressivestrength.

TheSEMimagesareshownlaterinChart 1,which substantiatesthisclaim.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

The inclusion of fly ash reducedthe compressive strength for all curing periods, which may be primarily due to lower hydration products, as observedintheSEMandEDSanalysis.

However,thelossincompressivestrengthreduced asthecuringdayswereprolonged.Forexample,the 7 daycompressivestrengthvaluesoftheG0F30mix reduced by 37.08% compared to the G0F0 mix, whereas the 28 day strength values of the G0F30 mixreducedbyonly9.62%comparedtotheG0F0 mix.

These results are in agreement with the observations of earlier researchers, who incorporated fly ash in SCC as a replacement for cement.

The improvement with increased curing duration maybeduetothecontinuouspozzolanicactivityof theflyashas thecuringwasprolonged.

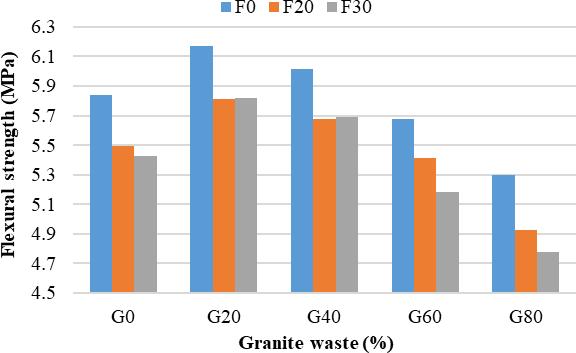

28 days are shown in chart 2. The flexural strength increased with thereplacement of fine aggregate by 20% GW for all the series and then decreased with further increaseinthereplacementlevelofGW.However,evenata 40% replacement level of GW, the SCC mixes showed improved flexural strength. The variation of the flexural strengthvalueswiththereplacementlevelofGWandflyash wassimilartothevariationobservedforthecompressive strength, except that the improved compressive strength wasobtaineduptoa20%replacementlevelonly.Theresults indicatedthatGWhadgreaterefficacyintheimprovementof theflexuralstrengthoftheSCCmixture.Theangularshape androughsurfaceoftheGWparticlesmayhaveprovided stiffpackingbetweenthebinderandaggregatephase,which resultedinimprovedflexuralstrength.Theothercausesof the improvement in flexuralstrength are similar to the reasons described for compressive strength. The results matchthefindingsofearlierresearchers,whoreportedthe improvement in flexural strength with increase of GW contentasasubstituteforfineaggregateinNCC.

Chart 1:7dayscompressivestrength

Chart -2:28dayscompressivestrength

Theresultsoftheflexuralstrengthofgranite basedSCC mixes,preparedwithandwithoutflyash,atcuringperiodof

Chart 3:Influenceofgranitewasteandflyashon flexuralstrengthofvariousSCCmixes

SEMimagesofselectedSCCmixturesaretakenfor28 daysofcuring.Minorcracks,voids,andweakerITZbetween the aggregate and cement paste matrix were observed in mixespreparedwithoutGW.

Ontheotherhand,compactpacking andstronger ITZ were observed between the aggregate and cementpastematrixinmixes preparedwith20% GW

This improved microstructure of the concrete matrixwiththeinclusionofGWmaybethereason for the highest strength and lowest water absorptionachievedata20%replacementlevelof GWinalltheseries.

The SEM images of the mixes containing a higher contentofGWwerealsoanalysed.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

GW)exhibitedlowerSPdosagesthantheOrdinary Portlandcement(OPC)basedcontrolSCCmixture.

All the developed SCC mixtures exhibited enough filling ability, passing ability and segregationresistanceandsatisfiedthecriterialaid downbyEFNARCstandards.

The bleeding for all the SCC mixtures was found withinthesatisfactorylimit(0.1 2.5%).

Table 3: Elementalcompositionofgranite basedSCC mixespreparedwithandwithoutflyash

ents

Oxyge n(O) 4 8.1 1 50. 23 52. 4 52. 86 51.4 2 42.0 5 42. 17 48.9 6 51. 26 Calciu m (Ca)

1 9.2 1 18. 56 23. 08 22. 92 20.4 8 22.8 9 21. 85 19.5 3 25. 79 Silico n(Si) 1 8.1 6 20. 79 16. 45 14. 46 15.3 8 13.1 1 12. 3 13.5 3 12. 04 Alumi nium (Al) 1 .86 0.9 2 3.0 8 4.8 6 4.14 4.66 4.2 2 4.11 3.7 2 Potas sium (K) 0 0.7 4 0.6 9 1.5 1.97 1.59 6.3 9 1.84 1.1 9 Iron (Fe) 1 .48 0.8 5 0.5 4 2.0 2 2.15 1.83 1.5 2 1.9 2.1 4 Magn esium (Mg) 1 .44 1.2 8 0.4 3 0 1.44 1.48 0.6 7 1.33 1.7 3 Sodiu m (Na) 1 .23 0.6 2 0.1 8 0 0 3.5 0.4 6 0.36 0 Carbo n(C) 8 .5 6.0 1 2.8 7 1.3 7 3.02 7.91 9.8 8 8.44 2.1 4 Ca/Si ratio 1 .05 8 0.8 93 1.4 03 1.5 85 1.33 2 1.74 6 1.7 76 1.44 3 2.1 42

Incorporation of up to 30% GW declined the superplasticizer (SP) dosages of fly ashblended SCC.Moreover,alltheflyashblendedSCCmixtures (preparedwithandwithout

FlyashblendedSCCmixturescontainingupto40% GWshowedhighercompressivestrengththanthe flyashblendedcontrolSCCmixture(madewithout GW)forallthecuringdays.Whereas,flyashblended mixturescontainingupto40%GWshowedbetter compressivestrengththanOPCbasedcontrolSCC mixturefor180and365dayscuringtime.

FlyashblendedSCCmixturescontainingupto50% GWshowedhighertensilestrengththantheflyash blendedcontrolSCCmixtureforallthecuringdays.

Whereas,flyashblendedmixturescontainingupto 50%GWshowedbettertensilestrengththanOPC basedcontrolSCCmixturefor180dayscuringtime.

The higher mechanical performance of fly ash blendedSCCmixtures(madewithGW)ascompared toOPCbasedcontrolmixturewasduetothefiller effectofGWaswellaspozzolanicactivityofflyash.

The water permeability (i.e. water penetration depth), water absorption, percentage of permeable voids and sorptivity (i.e. the capillary riseofwater)oftheflyash blended SCCmixtures containingupto50%GWwaslowerthantheflyash blended control SCC mixture, which indicated the better impermeability of fly ash blended SCC mixtures(preparedwithGW).

Moreover,flyashblendedSCCmixturecontaining upto50%GWalsoexhibitedhigherimpermeability against water than the OPC based control SCC mixture.

[1] Aarthi,K.,Arunachalam,K.,2018.Durabilitystudies on fibre reinforced self compacting concretewith sustainable wastes. Journal of Cleaner Production 174,247 255.

[2] Abukersh,S.,Fairfield,C.,2011.Recycledaggregate concreteproducedwithredgranitedustasapartial cement replacement. Construction and Building Materials25(10),4088 4094.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[3] ACI:544, 1999. Measurement of properties of fiber reinforced concrete. West Conshohocken, Pennsylvania,UnitedStates.

[4] Allam, M., Bakhoum, E., Garas, G., 2014. Re use of granitesludgeinproducinggreenconcrete.

[5] JournalofEngineeringandAppliedSciences9(12), 2731 2737.

[6] Anand, N., Godwin, A., 2016. Influence of mineral admixtures on mechanical properties of self‐compacting concrete under elevated temperature. FireandMaterials7(40),940 958.

[7] Apeh, J.A., 2019. Properties of self compacting concrete containing granite dust particles.

[8] Challenge Journal of Concrete Research Letters 10(2),34 41.

[9] Aquino,C.,Inoue,M.,Miura,H.,Mizuta,M.,Okamoto, T., 2010. The effects of limestone aggregate on concrete properties. Construction and Building Materials24(12),2363 2368.

[10]Ardalan, R.B., Joshaghani, A., Hooton, R.D., 2017. Workabilityretentionandcompressivestrengthof self compacting concrete incorporating pumice powderandsilicafume.ConstructionandBuilding Materials134,116 122.

[11]Aslani,F., Ma, G., YimWan,D.L.,Muselin,G.,2018. Developmentofhigh performanceself compacting concreteusingwasterecycledconcreteaggregates andrubbergranules.JournalofCleanerProduction 182,553 566.

[12]ASTM:C138,2016.Standardtestmethodfordesnity (unitweight),yield,andaircontent(gravimetric)of concrete,ASTMInternational,WestConshohocken, PA

[13]ASTM:C157,2017.Standardtestmethodforlength change of hardened hydraulic cement mortar and concrete,ASTMInternational,WestConshohocken, PA.

[14]ASTM:C232, 2014. Standard test method for bleeding of concrete, ASTM International, West Conshohocken,PA

[15]ASTM:C618,2017.Standardspecificationforcoalfly ashandraworcalcinednaturalpozzolanforusein concrete,ASTMInternational,WestConshohocken, PA

[16]ASTM:C642,2013.Standardtestmethodfordensity, absorption,andvoidsinhardened concrete,ASTM International,WestConshohocken,PA

[17]ASTM:C876, 2015. Standard test method for corrosionpotentialsofuncoatedreinforcingsteelin concrete,ASTMInternational,WestConshohocken, PA

[18]ASTM:C1585, 2013. Standard test method for measurement of rate of absorption of water by hydraulic cement concretes, ASTM International, WestConshohocken,PA

[19]ASTM:C1621, 2017. Standard test method for passing ability of self consolidating concrete by J Ring,ASTMInternational,WestConshohocken,PA

[20]ASTM:G109, 2013. Standard test method for determining effects of chemical admixtures on corrosion of embedded steel reinforcement in concreteexposedtochlorideenvironments,ASTM International,WestConshohocken,PA

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal