International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1Undergraduate, Dept. of Mechanical Engineering, Bajaj Institute of Technology, Wardha, India

234Undergraduate, Dept. of Mechanical Engineering, St. Vincent Pallotti College of Engineering and Technology, Nagpur, India. ***

Abstract For the purpose of reducing carbon emissions, clean energy technologies are crucial. The electricity generation sector in today’s trend has started the deployment of solar photovoltaic (PV) as an alternative green source of energy on a large scale. The efficiency of the PV cell plays an important role in the manufacturing of PV modules and material selection as it affects the cost reduction for the processing of cells.

This study compares important characteristics that have a substantial impact on the performance of solar cells after analyzing different emerging technologies in the field of solar PV. The article also tries to discuss, solar panel types; their workingandemphasize the various applicationsandmethods to promote the benefits of solar energy. By implementing technical solutions, photovoltaic applications and structures will continue to advance, improving their effectiveness and efficiency and enabling them to handle a range of problems and deficiencies.

Key Words: Green energy, Modern solar, Photovoltaics, Electricity, Efficiency

Sunisanunlimitedsourceofenergywhichisavailableatno cost. The primary advantage of solar energy over other traditional power sources is that it be produced directly usingsolarphotovoltaiccells(PV),whichallowssunlightto be directly transformed into solar energy. Through the developmentofsolarcells,panels,andmodules,therehas been a significant amount of study done to integrate the solar energy for daily usage. In comparison to the cost of various fossil fuels and oils during the past ten years, the mostadvantageousaspectofsolarenergyisthatitisreadily available and free to the general public. Additionally, compared to traditional energy production technologies, solarenergyrequiressignificantlylessmanpowercosts.

Thus, high power conversion efficiency of solar cells is essential for producing more electrical power while occupyingasmallerspace,whichlowerstheoverallcostof producingsolarenergy.

Photovoltaic (PV) cells generate electricity directly from sunlightviaanelectronicprocess.ThePVcelliscomposedof semiconductor material; the “semi” means that it can conductelectricitybetterthananinsulatorbutnotaswellas a good conductor like a metal. There are several different semiconductor materials used in PV cells. By using solar radiation to liberate electrons from these semiconductor materials,electricalcircuitsmaybecreatedthatcanpower electricalappliancesorfeedelectricityintothegrid.

Photovoltaic Cell:

Thephotovoltaiccellsconvertssolarradiationdirectlyinto electricity. It consists various kinds of semiconductor materialsdependingupontheadvancementsintechnology. It has two types: positive charge (P type) and negative charge(N type).

Photovoltaic Module:

APVmoduleisthefundamentalcomponentofaPVsystem andismadeupofsolarcellcircuitssealedinanecologically friendly laminate. To accommodate the energy demand, severalPVmodulesareoftenstackedinseriesandparallel.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Thepropertiesofthelightsuchasitsintensity,wavelengths and other cell performance factors determine how much powerwillbegeneratedbyPVcells. Oneoftheimportant factors of PV semiconductors is the bandgap, which describeswhatwavelengthsoflightthesemiconductorcan absorb and convert to electrical energy The PV cell can effectively utilize all of the available energy if the semiconductor'sbandgapmatchesthewavelengthsoflight fallingonit.

Over the years, numerous technologies that increase the efficiency of photovoltaic (PV) have been developed by researchers.

Letusseedifferenttypesofphotovoltaicsdevelopedandare inmostcommonuse.

2.2 Types of Photovoltaics

Crystalline PV Cells:

Photovoltaic Panel: Anarrangementofphotovoltaiccellsinstalledinaframe workforinstallationisreferredtoasasolarpanel

Photovoltaic Array:

ItcontainsseveralamountofPVcellsinseriesandparallel connections. Series connections are responsible for increasing the voltage of the module whereas the parallel connectionisresponsibleforincreasingthecurrentinthe array. The total surface area of the array is directly proportionaltothesolarelectricityproducedbyit.

a) Monocrystalline PV Cell:

Monocrystallinesolarcellsaremadefromsinglecrystalline silicon.Astheyarefrequentlycoloredandhavecylindrical cells,theyhaveahighlyuniquelook.Manufacturersremove thefoursidesofthemonocrystallinecellstomaintainlow prices and maximum performance. They get their recognizablelookasaresult.

A PV cell's efficiency may be calculated as the ratio of the electrical power it produces to the energy from the light coming on it. This ratio shows how well the cell converts energyfromoneformtoanother.

Fig -4:Monocrystallinecells

b) Polycrystalline PV Cell:

Polycrystalline silicon cells (multi-crystalline silicon) are

createdfromcastsquareingots,whicharelargechunksof moltensiliconthathavebeenproperlycooledandsolidified. Theyaremadeupoftinycrystals,whichgivethesubstance itsclassicmetal flakeappearance.Themosttypicalkindof solar cell is polysilicon, which is less costly than monocrystallinesiliconbutalsolessefficient.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Multi junctioncellsaremadeupofseveralthinfilmseachof which is basicallya solarcell built ontop ofanother.Each layerhasadistinctbandgapenergythatenablesittoabsorb electromagnetic radiation across a particular regionof the spectrum,makinggreateruseofsunlightthansingle junction cells.

The process of creating a thin film solar cell involves depositing one or more thin layers of PV material onto a supportmateriallikeglass,plastic,ormetal.Therearetwo maintypesofthin filmPVsemiconductorsare:

Cadmiumtelluride(CdTe)

Copperindiumgalliumdiselenide(CIGS)

The efficiency rates for thinfilmsolar cellstypically range from7%to13%,dependingonthetechnologyemployed.

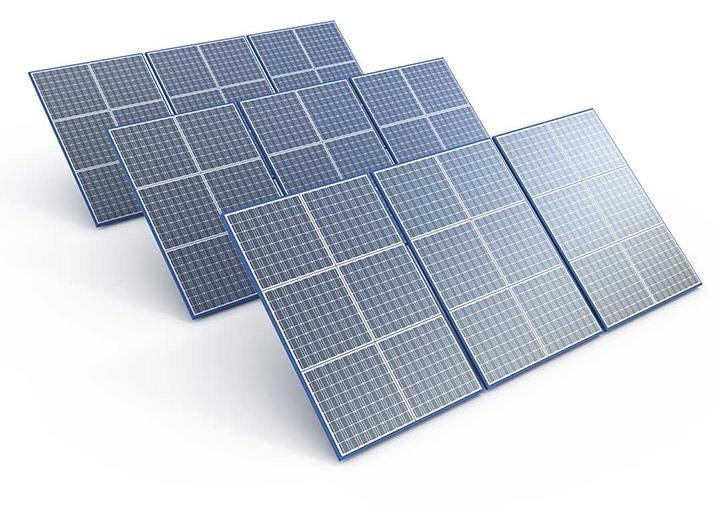

Perovskite solar cells are a type of thin film cell and are referredbytheirdistinctivecrystalstructure.Thelayersof materials used to construct perovskite cells are printed, coated, or vacuum deposited onto an underlying support layercalledthesubstrate.

Perovskite solar cells' efficiency have increased in the lab morequicklythanthoseofanyotherPVmaterial,from3%in 2009toover25%in2020[reportbyenergy.gov].Scaling up costs for perovskite solar cells are also anticipated to be exceedinglylow,makingthemahighlyalluringalternativefor commercialization.

Thelightthatisnotabsorbedbythefirstsemiconductorlayer iscollectedbyalayerbelowit,allowingmultijunctionsolar cellstoachieverecordefficiencylevels.Multijunctionsolar cells have shown efficiency of over 45%, but they are expensiveanddifficulttoproduce,thustheyareonlyusedin spaceexploration.

Concentration PV, sometimes referred to as CPV, concentratessunlightontoasolarcellbyutilizingamirroror lens. Less PV material is needed since sunlight is concentrated onto a smaller area. The highest overall efficienciesareattainedusingCPVcellsandmodulesbecause PVmaterialsbecomemoreeffectivewhenlightfallsbecomes moreconcentrated.

CPVsystemsarecategorizedaccordingtotheamountoftheir solarconcentration.Theyareasfollows:

LowConcentrationPV(LPV)

MediumConcentrationPV(MPV)

HighConcentrationPV(HPV)

Solartrackersandcoolingsystemsarefrequentlyusedwith CPVsystemstofurtherboostefficiency.CPVrequiresmore expensivematerials,manufacturingtechniques,andabilityto track the movement of the sun, so cost advantage over today'shigh volumesiliconmodulesisbecomingachallenge.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

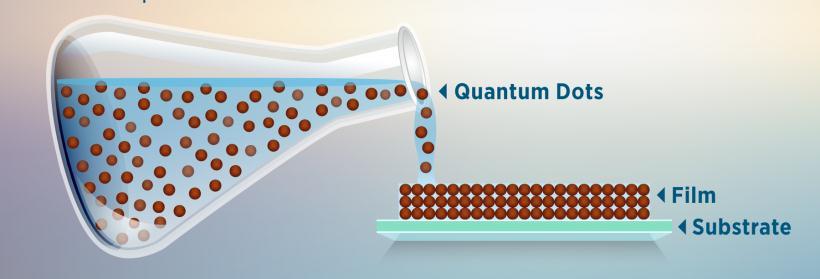

Quantum dot solar cells conduct electricity through tiny particles of different semiconductor materials just a few nanometers wide, called quantum dots. Quantum dots provide a new technique of processing semiconductor materials,theyarecurrentlynotparticularlyeffectivedueto thedifficultyofestablishinganelectricalconnectionbetween them. They can be applied to a surface using a spin coat technique,aspray,orroll to rollprinterslikethoseusedto printnewspapers.

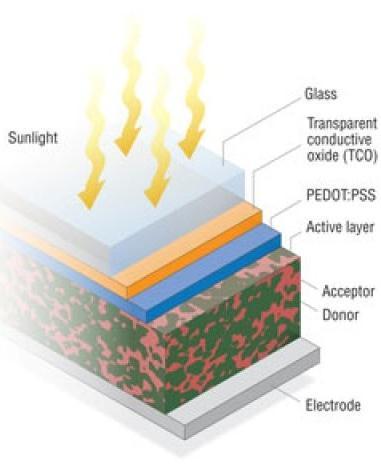

OrganicPV,orOPV,cellsaremadeoforganiccompoundsrich incarbon.TheycanbedesignedtoimproveaparticularPV cellproperty,suchasbandgap,transparency,orcolor.

Incomparisontoinorganicmaterials,theenergyconversion efficiencies obtained to date utilizing conductive polymers are quite low. However, Konarka Power Plastic reached efficiencyof8.3%[1].AlthoughOPVcellsarecurrentlyonly about half as efficient and have shorter working lives as crystallinesiliconcells,theyarelessexpensivetoproducein largequantities.

Anorganiccell'sactiveareaismadeupoftwocomponents: an electron acceptor and an electron donor. In contrast to most other solar cell types, when a photon is transformed intoanelectronholepair,whichnormallyoccursinthedonor material,thechargestendtoremaincoupledintheformofan exciton,separatingwhentheexcitondiffusestothedonor acceptorinterface.Theeffectivenessofsuchdevicesisoften constrained by the short exciton diffusion lengths of most polymermaterials.

Quantum dots are available in a range of sizes, and their bandgapcanbevaried,allowingthemtoabsorblightthatis challenging to absorb. They can be combined with other semiconductors cells, such as perovskites, to enhance the performanceofamultijunctionsolarcell.

In95%ofthemodulescurrentlysupplied,siliconisbyfarthe most common semiconductor material used in solar cells. The building blocks of crystalline silicon cells are silicon atomsinterconnectedtocreateacrystallattice.Thislattice offersawell organizedstructurethatimprovestheefficiency ofturninglightintoenergy.

P typeandN typesiliconarecombinedineverysolarcellto createthefundamentalp njunction,whichisessentialtothe solarcell'soperation.ThedifferenceisthatP typecellsuse an n type silicon base with an ultra thin layer of P type silicon,whereasN typecellsuseann typesiliconbasewith anultra thinlayerofP typesilicon

Currently,silicon basedsolarcellsprovideacombinationof highefficiency,lowcost,andextensivelifespan.Modulescan surviveforatleast25yearsandcontinuetogeneratemore than80%oftheirinitialpowerafterthat.

In the modern electronic age, when industrialization is expanding quickly, we can see ongoing advancements in photovoltaic cell technology. The third generation technologies,whicharethemostrecenttrend,haveincreased

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

overallefficiency,weightreduction,decreasedmanufacturing cost, and capacity to entrap maximum light under various climatic circumstances. After thorough investigation into manytechnologiesthatarenowaccessibleandthevarious metricsthatindicatetheirperformance,thetwomostrecent developing solar technologies have been taken into considerationforthisstudy.

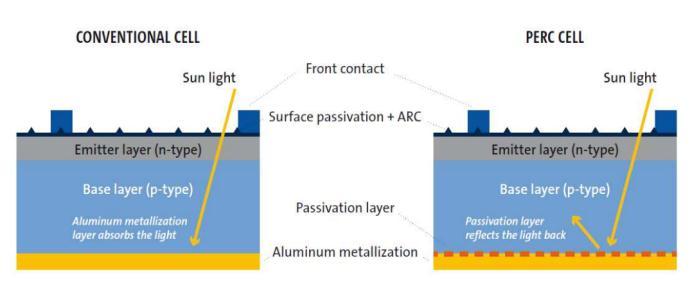

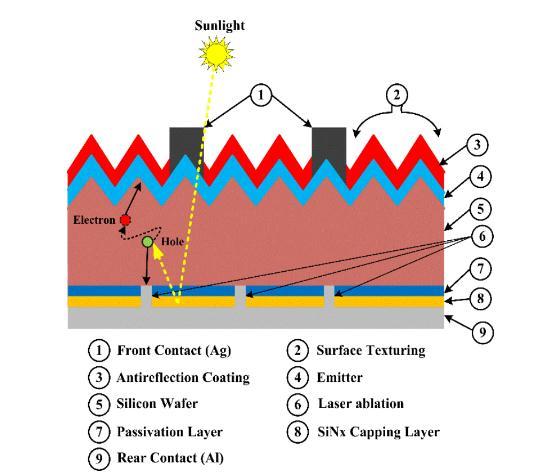

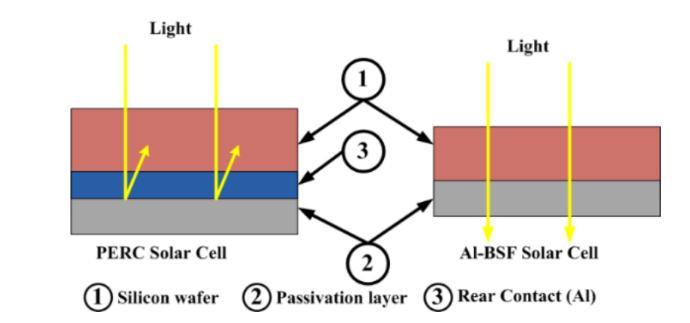

Powerconversionefficiency(PCE)developmentisessential for the expansion of the photovoltaic (PV) technology. Standardsolarcellswithanaluminumbacksurfacefield(Al BSF)havebeendeployedfordecadesusingthischaracteristic feature.Al BSFhasrecombinationlosses,whichlowersPCE andpresentasignificantissueforthePVsector.Passivated emitterrearcell(PERC),amodernfundamentaltechnology, is employedtoaddress thedrawbacks of theconventional solar cell. Due to its ability to minimize optical and recombinationlossesincomparisontoaregularsolarcell,it has emerged as a prominent PV technology. However, compared to all other PV technologies, PERC is more compatibleandcapableofcapturingmorelight.

Additionally,advancementsinthestructuralmethodsusedin PERC solar cells will increase their demand by the 2030s. Various passivating substances, including SiO2, Al2O3, and SiNx,areemployedasthepassivationlayersinPERCsolar cells. Such passivating materials improve the PCE of PERC solar cells, lower light reflectance while increasing light trapping,anddecreasingrearsiderecombinationlosses.

maindistinctionisthatPERCcellshaveoneadditionalrear surfacepassivationlayertoenhancecellefficiency[3].

IncomparisontoatypicalAl BSFsolarcell,thePERCsolar cell's PCE was improved by structural and technical advancements. By incorporating a rear passivation layer onto a conventional solar cell, PERC technology increases efficiency.TheSi wafer(porn type),antireflectioncoating (ARC),passivationlayeronthefrontandrearsidecontact, anddopedemittermakeupthestructuralarchitectureofthe PERCsolarcellasillustratedinFig.11.Furthermore,inthe PERC solar cell, several approaches including surface texturingandpassivationareusedtoenhancelighttrapping andlightabsorption[4]

TheprimarybenefitofthePERCtype,fromtheperspectiveof production,isthatitdoesnotneedsignificantchangestothe waythatmanufacturingproceduresareperformed,i.e.,only few modifications can be needed if the manufacturing processesarealtered[2].Asaresult,itencouragesproducers to create PERC cells with a significantly lower cost of production.ItisconstructedsimilarlytoastandardsolarPV cellandemployssiliconwaferstoproduceenergyusingsolar radiations.Incomparisontomono crystallinePVcells,the

value:

Fig 11:StructuredesignofPERCsolarcellwith passivatedlayer,texturingandrearcontact

Fromtheperspectiveoftheworkingprocess,therearethree possible outcomes for photons that impact the device's surface:i)absorption,ii)reflection,iii)transmission.Simply creatingelectron holepairsfromthephotonsthatarebeing absorbedproducesthecurrent.Astheydonotcontributeto the production of current, photons that are reflected backward from the front surface are regarded as lost in conventionalsolarcells.Astheypassthroughtheapparatus andarenotusedtogeneratecurrent,transmittedphotons withphotonenergiesbelowthebandgaparealsocountedas losses[4].

Recombination of charge carriers also reduces conversion efficiencyinthecommonsolarcell.TheAl BSF'sprimaryflaw is that Si wafer typically absorbs light up to a wavelength rangeof1180nm;however,lightwithawavelengthgreater

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

than1180nmistransmittedthroughthewaferandabsorbed bytheback metalsheet,producingheatasillustratedin

Fig. 12. Therefore, this heat loss lowers the device's efficiency.The PERC solarcell hasvariousadvantages and can solve these issues. The idea that incoming light with photon energies below the bandgap is regarded as unabsorbedlightinaconventionalsolarcellisseeninFig.12

restrictions,etc.Additionally,itisessentialtopayattentionto alternativetechnologiesasPERCcellsareapproachingtheir maximumlevelsofefficiency.

Fig -12:Conceptoflightabsorptionwithpassivationlayer inPERCsolarcellandwithoutpassivationlayerinAl BSF solarcell

The passivation layer provides this unabsorbed light a secondchancetobeabsorbedinthePERCsolarcell'sactive area. This procedure enhances the likelihood that an electron hole pair will form, which in turn improves the device's total conversion efficiency [5]. Additionally, the effectiveness of passivation schemes is crucial to the performanceofPERCsolarcells,andanefficientpassivation schememustbeusedtolowercarrierrecombinationonthe rearside.

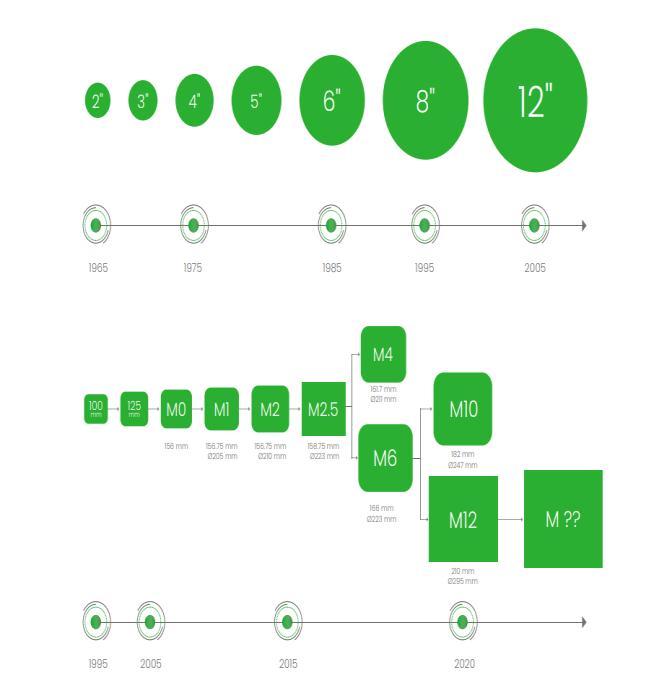

Therecentmarketstudystatesthattheaverageconsumer demandsandfavorstheM2sizeofsolarcells,whichhasbeen remainedsamesincepast10years.However,theneedfor morepowerproductionandadeclineinthelevelizedcostof electricity(LCOE) ofsolar PV madechange inevitable. The industrystartedtoadoptinspirationfromthesemiconductor industryinordertoimprovewafersize(seefigure13),which woulddirectlyboostpoweroutput.Withinaperiodofaround fiveyears,thewafer'ssizedevelopmentstarted increasing rapidly and changed from 156.75 mm/157 mm to an intermediatesizeof161.75mm/166mm,andthenonto182 mm/210mm.ThePVmodulemayhavehititssizelimitswith thecurrentconventionalcellsizes,whichrangefrom2.2to 2.4metersinlengthto1.1to1.3metersinwidth[6].Dueto thefactthatendcustomerscontinuetodemandhigherpower output, any additional increases in wafer size will be accompanied by an equal increase in module size. The economic benefit from such an improvement would be negatedbylimitsassociatedwiththeincreaseinmodulesize, suchasthecostofmanufacturing,one'sownweight,handling

Fig 13: Improvementinwafersizeofsolarcell 3.2.2

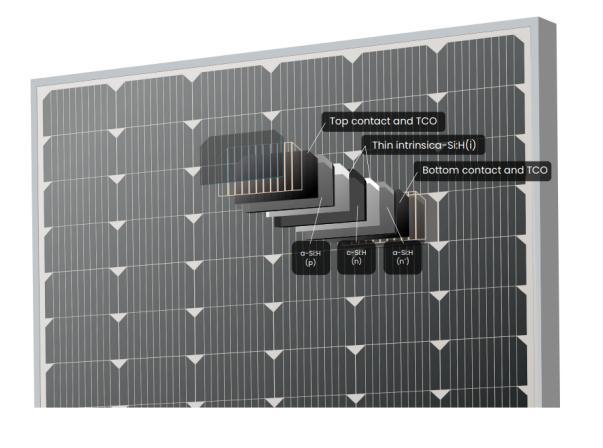

TheHJTsolarcelliscomposedofmanylayersthatarefused together,assuggestedbyitsname.Crystallinesiliconforms thecoreofthecell,whichissurroundedonbothsidesbythin filmsofamorphoussilicon.Thisindicatesthatabettercellis produced as a result of combining the advantages of improvedlight absorption (from the crystalline layer) and betterpassivationcapabilities(fromtheamorphouslayer). Thenextgenerationofmodulesmayfinallybeunlockedwith thehelpofHJTcells,whoselightconversionefficiencyrecord now stands at more than 26.5 percent. But efficiency enhancementisonlyoneofitsmanybenefits.Beforegoing throughallofitsbenefits,let'stakeamomenttograsphow theHJTcellismade.Onlyafterthatallofitsbenefitscanbe discussed

Asiliconabsorbermadeofn typecrystallinesiliconislocated in the center of the HJT cells (see Figure 15). It forms a p/i/n/i/n+ stacking because it contains both intrinsic (neutral)anddopedamorphoussiliconlayersoneitherside. Crystallinesiliconhasthevirtueofhigherlightabsorption, whichmeansitcanabsorbnearlyallofthelightthatstrikes it, producing more free carriers. There is inherent hydrogenated amorphous silicon (a si:H(i)) immediately aroundthen typecrystallinesilicon.Therewillbealossof carriersduetothehighresistanceofbareamorphoussilicon, despite the fact that it is simple to deposit on crystalline silicon and has many surface flaws. Amorphous silicon's bandgapisincreasedwhilethedefectdensityissignificantly reduced when it is hydrogenated in comparisonto the crystallinesilicon

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Bettersurfacepassivationismadepossiblebytheintrinsic (or undoped) layer of a si(H)(I), which implies that the departed electrons and holes does not tend to recombine beforebeingcollected.Thehydrogenatedamorphoussilicon layers,whichformtheP Njunctioninsolarcells,arelocated aftertheintrinsiclayers.Partofthelightthatstrikesthetop p type layer is collected through inter layer reflection as well as direct illumination. Similar to the top layer, the bottom layer likewise provides surface passivation while capturinganyleftoverlightthatmayhavegonethroughthe toptwolevels.Thea Si:Hlayer'sweakconductivityistypical andcouldnotbeenoughtoallowforasatisfactorycarrier (charge) collection through the metal contacts. This deficiencyissupportedusingtransparentconductiveoxide (TCO).

Onbothsidesofthea Si:Hlayer,theTCOlayerisdeposited. Theyfunctionbyencouragingagoodohmiccontact,allowing the transfer of lateral carriers, and acting as an anti reflectivecoating(ARC).Indiumtinoxide(ITO)isthemost widelyusedoftheindustrystandardTCOs.Itispossiblefor the top and bottom TCOs to have differing thicknesses. A reasonablesheetresistanceforcarriermovement,adequate transparency to prevent anomalous light absorption, and increasedlighttrappingareallachievedbyoptimizingthe toplayeroftheTCO'sthicknessandoxygencontent.

Oneofthemostimportantsolarmoduleparametersis temperature coefficient. It establishes the degree of powerloss thatthecell ormodulewouldexperienceif the temperature increased. Numerous variables, including series and shunt resistance, the degree of surfacepassivation,thequantityofinterstitialflaws,etc., affect temperature coefficient. The HJT cell offers the lowest thermal coefficients of any known solar PV technology because each interlayer works to improve light absorption, surface passivation at low series, and largershuntresistances.

The HJT modules are recognized to have the lowest power degradation rates since there are essentially no knownmechanisms thatmayeffectivelydamagethem. Additionally,theyareregardedtobemorereliablethan similartechnology.

Severaldifferentfactorsplayavitalroleintheefficiencyof the overall PV module. Even a slight change in any one of thesefactorsmaydrasticallyaffecttheperformanceandthe output generated. Some of these important factors considered in this study are explained in brief along with theircomparativestudytogiveaclearideaaboutPERCand HJTtechnologies.

1. Bifaciality: Whensubjectedtothesameirradiance,the bifacialityfactor(percent)isdefinedastheratioofrear efficiencytofrontefficiency.

2. Micro Crack Resistance: Micro fractures, often referred to as micro cracks, are a kind of solar cell deterioration that can have an impact on a solar photovoltaic (PV) system's lifetime and energy production.Theabilitytoresistsuchcrackgeneration overaperiodoftimeiscalledMicrocrackresistance

Nowthatthestructureisevident,it'stimetocomprehend thebenefitsthatHJTprovides:

ThemainbenefitofHJTisthatituseslessenergythan traditionalmethodsbecauseofthethinfilmdepositions oneachsideofthedevice.Alotofenergyissavedwhile making HJT cells since they are manufactured at a temperatureofunder250°C.Comparingthesecellsto the industry standard PERC, the number of processes needed to make them is cut in half. In addition, when stringingtheHJTcellsontoamodule,theyareonceagain treatedatroughlythesametemperature.

3. Long Term Power Degradation Rate: Degradation is thetermusedtodescribethegradualdecreaseinsolar panel output. According to NREL studies, solar panels degrade at a median rate of around 0.5% per year; however,inhotterareasandforrooftopsystems,therate maybegreater.

4. LID: PVmoduleshaveaperformancedeclineknownas light induced degradation (LID) during their first few hoursofexposuretothesun.

5. Low Light Performance: The ability of the PV cell to functionwhentheintensityoflightchangescanhavea majorimpactonthetotalefficiencyofthemodule.This terminologyistermedaslowlightperformancefactor.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Thefollowingtablerepresentstheseparameterswhichgives anidea abouttheoverall efficiencyofthePVtechnologies consideredinthisstudy.

Table no. 1: ComparativeTabulationofPVTechnologies

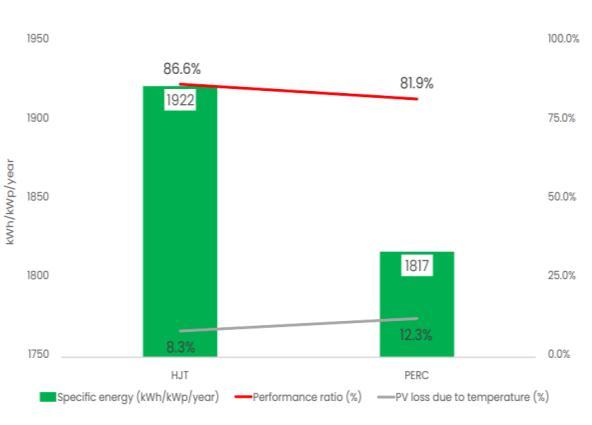

With HJT's improved surface passivation & low light performancecoupled withlowestinitialdegradation,HJT based power plants produce 1922 kWh/kWp/year of specificenergy,whichisabout6%morethanPERC based powerplants.

Finally,talkingaboutperformanceratio(PR)whichindicates howgoodorbadaplantisperforming.ThePRofHJTbased plant is 4.7% greater than the PERC based plant which clearly shows the advantages of utilizing HJT technology. Withsuchadvantages,HJTstandsouttallwhencomparedto itscompetitorsinalmostallthefields.

Thecomparisonof PERCandHJT, thetwoadvancedsolar technologies,isgiventheutmostattentionduringthisstudy. Thefollowingconclusioncanbededucedbythesame.

AstheabovetheoreticaldatashowsthatHJTissuperiorin manytermsthanPERC,itisstillimportanttocompareboth thetechnologiescommercially.Thefollowingcomparisonis basedonthecasestudybyWaareetechnologies[6].

Thestudywasdoneon1MWpowerplantinGujarat.Allthe factorslikemodulearrangement,tiltangle,loadingratio,etc. were kept constant for better comparative results The resultgivesgraphshowninFig:15.Thetemperaturelosses inamonoPERCmodule basedplantarearound50%more intermsofpowerplantoutput.Thisenergylosswillbemore whenconsideredforlargercapacitypowerplants[6]

Fig -15:ComparisonbetweenPERCandHJT

The growth of solar cell absorption, conversion efficiency, heat transfer, performance of parameters undervariedsituations,andproductioncostsareonlya few of the difficulties that needs to be overcomed to increasePVefficiencyinboththetechnologies.

ThesenewPVmodels(HJTandPERC)havetheabilityto work independently or in combination with other cell modelstoimprovecompetency.

While solar energy has enormous promise as a clean, abundant, economical energy source, it presents formidable basic research challenges in designing materials and in understanding the electronic and molecular basis of capture, conversion, and storage beforeitspromisecanberealized.

[1] Konarka Power Plastic PV tech.org. Retrieved 7 May 2011 [2] A.Blakers,DevelopmentofthePERCSolarCell,IEEEJ. PhotovoltaicsPP(2019)1 7. [3] A.T.SankaraSubramanian,etal.“Performanceanalysis of various photovoltaic configurations under uniform shading and rapid partial shading formations”, Biosci. Biotech.Res.Comm. Special IssueVol 13No (3)2020 Pp 185 192 [4] S.Kashyapet,al,ComprehensiveStudyonDevelopment ofPERCSolarCells IEEE2020 [5] H.Tang,Y.Liu,Q.Chen,etal.,“Opticaldesignofinverted pyramid textured PERC solar cells,” ACS Applied ElectronicMaterials,2019

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[6] Heterojunction PV Module white paper by Waaree Technologies

[7] Shaikh,MohdRizwan&etal(2017).AReviewPaperon ElectricityGenerationfromSolarEnergy.IJRASET

[8] Ashok Upadhyay, Arnab Chowdhury Solar Energy FundamentalsandChallengesinIndianIJSRP,Volume4, Issue10,October20141ISSN2250 3153

[9] M. A. Green, “The passivated emitter and rear cell (PERC): From conception to mass production,” Sol. EnergyMater.Sol.Cells,vol.143,pp.190 197,2015.

[10] G.K.Singh,“SolarpowergenerationbyPVtechnology”

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal