International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

SELVAKUMAR S1 , Dr.G.SELVARAJ 2 , Mr.R.KANDASAMY 3

1Student, ME Industrial Safety Engineering, Selvam College of Technology, Namakkal, Tamilnadu, India

2Professor and Head, Department of Mechanical Engineering, Selvam College of Technology, Namakkal, Tamilnadu, India

3Assistant Professor, Department of Mechanical Engineering, Selvam College of Technology, Namakkal, Tamilnadu, India ***

Abstract - In most of the developing countries like India, focuses on industrial safety only little much. Workplacesafety is most important for both employee and employer to save the lives of human being from the accidents. If a workplace is full of safety, then there is negligible chance of happening for accidents. According to the report of International Labour Organization (ILO), everyday people met with an accident resulting in loss of human lives. This study mainly focuses on identifying various occupational hazards in brakes producing industry. The occupational hazardsareidentifiedandrectified by deep analysis. Once the hazards are identified and the associated risks are assessed, then it must be followed to prevent accidents and injuries. This study shows the subsequent risk assessment approach to a proactive path toward injury and illness prevention associated with the brakes production industry.

Key Words: Accidents, Hazards, Occupational Health & Safety,RiskAssessment.

Toidentifyhighriskofhazardsandreducingthecause ofaccidents

Reducinghealthimpactsduetohazards

Topreventemployeefromthehazards

Toimprovehighlysafeworkingenvironment

as a part of support to the products. Working in unsafe procedure in machineries may lead to accidents, leads to injuryofemployeeandeventothelevelofloosinglives.Also exposureofskintotheflammableliquidsalsocreatesvarious diseasestotheemployeeleadingtothehealthissues.

In peoples working in many industries of various nations suffersa lot due to accidents happened due to the lackofsafety.Inordertoprotectthelivesofpeopleworking inindustry,InternationalLabourOrganizationtookastepto eradicate and solve it. As a result of it, ILO introduced a program named “ILO Flagship Programme” with slogan “Safety+HealthforAll”.Themainmotiveofthisprogramis toeducatetheemployeesandemployerstoimplementthe newstrategiesforresolvingthelackofsafety.

Toimprovethesafepathwaystoincreasedproduction

Topreventdamagestotheworkplaceandenvironment

Indiaisadevelopingcountry,wherevehiclesplayan important role.In sucha way the parts of vehiclesare not producedbythesamebrandmanufacturers,insteadmany industriessupportsbyproducingpartsofavehicle.Likewise thisindustryproducesBrakesforvariousvehiclesofvarious brandssuchastwowheelers,passengervehicles,commercial vehiclesetc.Thisindustryisoneofthelargestproducersof brakes in India and having an employee of more than five thousand. Occupational Health and Safety is an another aspectwhichplaysanimportantroleinthisindustry.

Themanufacturingunitsofthisindustryuseheavy machineries,materialhandlingequipments,flammablefluids

Fig 1:SloganofILOFlagshipProgramme

Mostoftheemployeesworkinginthisindustry,are notwearingproperPersonalProtectiveEquipments;tosafe guard themselves from the hazards. This may lead to the severeinjuriesifahazardhappens.Theemployeesarenot wearinghandglovesandnoiseprotectionearplugs.Refusal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

to wear hand gloves may lead to injuries leads to severe bloodloss.

Overcrowding orcrowding isthecondition where more people are located within a given space than is considered tolerable from a safety and health perspective. Overcrowding at workplace is another major issue that happensatthisindustry.Mostoftheemployeeswandering hereandthereandcrowdingatsingleplacenearmachines andactivitieslikeplaying,talking,kiddingetc.,happens.This culturemayleadtosevereaccidentsandsometimesleadto deaths. Overcrowding must be avoided by maintaining minimumdistanceforeachworker.Alsoavoidunnecessary talking,kidding,playing,etcatworkplace.

Impropermaterialstorageisalsoanothercommon hazards found in this industry. Materials and storage containers are stored improperly other than the places allotted. Materials and storage containers are stored near machines,onthemachines,onthepathwaysetc.Thesetype arrangements may lead to difficulties in emergency exits. Storageofmaterialsandcontainersonornearmachineries mayleadtoaccidents.Materialstoragecontainersmustbe removedfromworkplacewhennotinuseanditshouldbe locatedataplaceactuallywhereitisallotted.

Impropermaterialhandlingisanothermajorissuein thisindustry.Materialhandlingequipmentslikemovinginan unsafepathway.Thistypeofmovementmayleadtofallingof materials,machinesetcwhichaccountsinfailureofsafety.

Working at height is another major issue in this industry. Employees are working without proper safety precautionswhichmayleadtofallofladderorobjectsfrom height etc. This practice will lead to severe injury even sometimestolossoflife.

Working with flammable liquids without proper protective devices will lead to damage of skin. Exposing flammableliquidstohightemperaturewillcreatepathway forfireaccidentsisalsoananotherproblem.

Safetyauditingisthewayofassessingtheworking nature in which the industry involved whether in safe

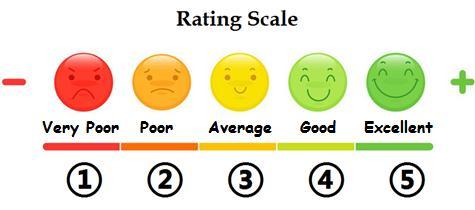

workingconditionornot.Safetyauditistobedonebythe well trained expert. Safety audit will gives the report of hazardousarea,wherethesafetyistobeimproved.Asper theIndianstandardsIS14489,Safetyauditingismandatory for all industries. Generally safety auditing will be questionnaire in nature and it is asked to the working employees of that particularcompany. For eachand every questions asked by the safety expert, the employee may answerbygivingappropriaterating.

The table given below is the questions asked to the employeesofvariousshiftsofthisindustry,inordertocheck thesafetylevel.

Istrainingprovidedforeach personnewlyassignedtoajob?

initialtrainingincludesa reviewofhazardsand accidentsassociatedinthisjob?

adequateinstructioninthe useofpersonalprotective equipmentprovided?

resourcesavailabletodeal witheasily(drinkingwater, rawmaterialetc)?

ventilationequipment workingeffectively?

thefumeanddustcollection hoodworkingeffectively?

theleveloflightadequatefor safeandcomfortable performanceofwork?

lightingproduceglareon worksurfaces,monitors, screensandkeyboards?

properroomtemperatureis maintained?

thefumeanddustcollection hoodworkingeffectively?

allworkareascleanand freeofdebris?

toolskeptintheirproper

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

place? 14 Arefloorsfreeofoilspillageor leakage?

② ③ ④ ⑤ 15 Isabsorbentavailablefor immediatecleaningofspills andleaks?

allflammableand combustibleproductsstored appropriately?

Work Process 17 Arerepetitivemotiontasks properlypacedandkepttoa minimum?

② ③ ④ ⑤ 18 Arethematerialsafetydata sheetsplacedinlocations accessibletoallemployees?

③ ④ ⑤ 19 Ishazardsignaledbysigntags? ① ② ③ ④ ⑤ 20 Havealltrucks,forkliftsand otherequipmentbeen inspectedandmaintained?

Areextensioncordsoutofthe aisleswheretheycanbe abusedbyheavytraffic?

Ispermanentwiringused insteadofextensioncords?

Areregularnoisesurveys conducted?

Ishearingprotectionavailable andusedproperly?

Arerestroomskeptcleanand sanitary?

ingoodrepair?

Arecafeteriafacilitiesprovided awayfromtoxicchemicals?

washingfacilities available?

Medical and First Aid

Doallemployeesknowhowto getfirstaidassistancewhen needed?

21 Isthereaclearfireresponse planpostedineachworkarea?

23 Aremockdrillsheldregularly?

24 Arefireextinguisherschosen forthetypeoffiremostlikely inthatarea?

③ ④

② ③ ④ ⑤ 22 Doallworkersknowthe emergencyexitplan?

thereemployeestrainedas first aidpractitionersoneach shiftworked?

Arefirst aidkitsprovidedas perjurisdiction’sfirst aid regulations?

25 Arethereenoughextinguishers presenttodothejob?

③ ④ ⑤ 26 Areextinguishersproperly mountedandeasilyaccessible?

③ ④ ⑤ 27 Areallextinguishersfully chargedandoperable?

thereenoughexitstoallow promptescape?

haveeasyaccess toexits?

unlockedtoallow egress?

Arefirst aidsupplies replenishedastheyareused?

DoesnecessityofwearingPPE wasexplained?

Isrequiredprotective equipmentprovided, maintainedandused?

Doesequipmentmeet requirementsandreliable?

AretheareasrequiringPPE usageproperlyidentifiedby warningsigns?

clearlymarked?

③ ④ ⑤ 32 Areexitsandexitroutes equippedwithemergency lighting?

Machine Guards

alldangerousmachine partsadequatelyguarded?

Domachineguardsmeet standards?

Arelockoutprocedures followedwhenperforming maintenancewithguards removed?

allmachinesproperly grounded?

Areportablehandtools groundedordoubleinsulated?

Arejunctionboxesorsockets closed?

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

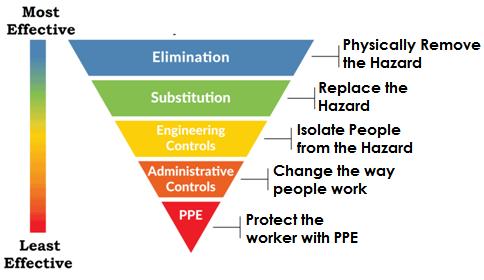

Hazard elimination or removal is the only way to protect employees from the accidents. But eliminating of hazardispossiblewhentheinvolvementofbothemployee and employer shows interest in it. By educating the employeesandproperplanningwillsurelyhelptoeliminate thehazardsinvolvedintheprocess.Whenevertheemployee identifies the hazards and the same is to be analyzed and recognizedbytheemployerandviceversa.

According to Occupational Safety and Health Administration (OSHA), the employer must give proper trainingprogramsintheaspectofsafetyatregularintervals. Theeffectivemanagementwillfocusonthehazardsinvolved and gives the alternate way after measuring the effects of hazardsinvolved.Theguidelinesonsafetymustbetagged withslogansandshouldbeplacedattheworkareinvolved withhazards.Thelanguageusedforslogansmustbeeasyso thateachandeverypeoplewillunderstand.

Conduct regular inspections of all operations, equipment,workareas,andfacilities.Ensureallemployees areparticipatingontheinspectionteamandtalkingtothem about hazards that they identify Always record the statements by voice or written statement, so that later it maybeconsideredforcorrectiveactions Eithertakephotos or video of hazardous areas that are identified for later discussions and brainstorm about how to eliminate them. Use checklists containing set of predefined questionnaire which highlights things to look for. The various hazards identified will fall into several major categories, such as workpractice,electricalhazards,typeofmaintenance,type ofemployee(experiencedorfresher)etc.

Fig 4:KeyElementsofSafetyMahagement

Amock fire drillis a method of training workers, howtoevacuateduringthetimeoffireaccidentsinasafe manner. This training will help the workers to exit the company through the nearest exit. This mock drill varies fromplacetoplacei.e.,typeofworkingnature.Italsogives the knowledge to employees about how to set off fire by meansofwaterorfireextinguishers.

Fig 6:SafetyInspectionClipart

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

12 4 14 28 37 45 13 6 13 28 33 48 14 7 11 31 36 43 15 9 12 28 48 31 16 5 9 27 31 56 17 2 18 23 35 50 18 4 14 25 38 47 19 7 17 27 33 44 20 5 15 23 35 50 21 6 17 22 38 45 22 3 19 20 33 53 23 8 11 31 39 39 24 3 15 31 38 41 25 8 12 28 28 52 26 4 18 27 36 43 27 6 12 23 48 39 28 7 14 25 31 51 29 9 18 27 35 39 30 7 20 23 33 45 31 3 11 25 36 53 32 8 15 26 48 31 33 10 12 28 31 47 34 9 14 28 38 39 35 3 13 31 28 53 36 8 12 28 36 44 37 4 14 27 48 35 38 6 18 28 31 45 39 7 20 28 35 38 40 9 11 21 41 46 41 5 15 28 33 47 42 3 11 27 35 52 43 3 18 23 38 46 44 8 13 31 33 43 45 6 11 28 39 44 46 7 12 27 37 45 47 5 9 23 33 58 48 3 19 25 38 43 49 8 11 27 33 49 50 5 14 23 36 50 51 6 12 28 37 45

52 7 18 31 33 39 53 9 12 28 36 43 54 6 12 31 34 45

Based on the responses received from the employeesofvariousshifts,thefollowingresultsarederived basedontheopinionoftheemployees.Thisresultsindicates fewprocessoractivitiesorworkingenvironmentinvolves hazards working environment along with the lack of employeesnegligenceinmaintainingsafety. S.No.

Thus this study of occupational health and safety analysisinthisindustrywasanalyzedcarefully.Eventhough thisindustryisbeingawardedwithISO14001andOSHAS 18001 and following the procedures of IS 14489, there is somepartofnegligenceisfoundin thesafetyprocedures. Fromthisstudythetotalpercentageofoccurringaccidents intheimpactofhazardsisbelow20%(i.e.,16.15%)andthe impact of hazards from average impact to low impact is about83.85%.Ifthisanalysisistakenintoaccountandthe placehavinglackofsafetyistobemonitoredandeliminate theoccupationalhazards.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

[1] “Safety and Health Information, 2012”, Directorate General, Factory Advice Service and Labor Institutes (DGFASLI), Ministry of Labor and Employment, GovernmentofIndia.

[2] “Theoccupationalsafety,healthandworkingconditions code,2020”,DirectorateGeneral,FactoryAdviceService andLaborInstitutes(DGFASLI),MinistryofLaborand Employment, Government of India. https://dgfasli.gov.in/sites/default/files/2018 12/OSH_Gazette.pdf

[3] Guidelines on occupational safety and health management systems ILO OSH 2001, International Labour Organization.http://www.ilo.org/wcmsp5/groups/publ ic/ ed_protect/ protrav/ safework/documents/ normativeinstrument/wcms_107727.pdf

[4] IndianStandardCodeofPracticeonOccupationalSafety andHealthAudit(IS14889:1998).

https://law.resource.org/pub/in/bis/S02/is.14489.199 8.pdf

[5] National Policy on Safety, Health and Environment at Work Place, Ministry of Labor and Employment, New Delhi. https://labour.gov.in/sites/default/files/SafetyH ealthandEnvironmentatWorkPlace.pdf

[6] “Beyond death and injuries, 2008”: The ILO's role in promoting safe and healthy jobs. http://ilo.ch/wcmsp5/groups/public/ dgreports/ dcomm/documents/publication/wcms_ 094524.pdf

[7] “BasicOccupationalHealthServices”,IndianJournalof Occupational&EnvironmentalMedicine,Vol13,No1, pp1 2.

[8] SaiyedHNandRRTiwari(2004):“OccupationalHealth Research in India”, Industrial Health, Vol 42, No 3, pp 141 48.

[9] Occupational Health and Safety in India: Now and Future:ShyamPingale,Medical&occupationalHealth, RelianceIndustriesLtd.India

[10] Occupational health and safety in industries in developingworldIftikharAhmad1,AbdulSattar2,Allah Nawaz2,1DepartmentofCommunityMedicine,Gomal Medical.

[11] OSHIndia2016:TransformingIndia’sWorkplaceSafety AndHealth.

[12] Finnegan, L. 1998. OSHA studying safety incentive programs.OccupationalHazards,60:13 13.

[13] FundamentalsofIndustrialSafetyandHealth:Vol. 2by K.U.Mistry

[14] Workplace Safety: A Guide For Small & Mid Sized Companies, by Dan Hopwood and Steve Thompson, ISBN 13:978 0782136043&ISBN 10:0782136044

SELVAKUMARS

Student(II Year), ME IndustrialSafetyEngineering, Selvam College of Technology, Namakkal,Tamilnadu,India

Dr.G.SELVARAJ

ProfessorandHead, DeptofMechanicalEngineering, Selvam College of Technology, Namakkal,Tamilnadu,India

Mr.R.KANDASAMY

AssistantProfessor, DeptofMechanicalEngineering, Selvam College of Technology, Namakkal,Tamilnadu,India

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |