International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Shafna K J1,Aswin Subhan2,Sathyajith P3,Anagha Ullas4,Shereena M J5, Twinkle Thomas6

Assistant Professor, SNMIMT, Kerala1 Assistant Engineer projects, PMU Chellanam2 UG Students , SNMIMT, Kerala3,4,5,6

Aseawallisastructuremadeofstones,concrete,masonryorsheetpiles,builtparalleltotheshoreatthetransitionbetween thebeachandthemainlandordune.Seawallsaregenerallymadeofarmourstone.Thestonesarereadilyavailableandarenot consideredasamanufacturedproductjustbecausetheycomedirectlyfromquarry.Sincetheyarenaturallyformed,theyare notathreattomarinelifeinanyway.Thestonesgenerallyhavealonger lifecomparedtotherestofthesafetymeasures.The onlythreatisthattheymaybewashedawayduetothehightidestrength.

Armour stone packaging is important for preparing goods for containment, protection, transport, handling, distribution, delivery and presentation. During the construction of seawalls, it is necessary to have proper packing of armour stone. It's impossibletoarrangethestonesonebyonemanuallyfortheconstructionoftheseawallbecauseofthefollowingreasons

• Workingontheshoresisbothdifficultanddangerousatthesametime

• Averylargenumberoflaboursarerequired

• Itsimpossibletohandleverystonesusingmanuallabours

• It’llliterallytakeyearsfortheconstructionifit’sdonemanually.

• Asalotoflaboursarerequiredthecostisincreasedrastically.

ThereforeonewayofachievingpackingefficiencyistoarrangearmourstoneusingheavymachinerieslikeacraneoraJCB.

Whilepackingstonesitisessentialtohavevoidsofacertainpercentage.Thisisbecauseastructurepackedin0%voidcanbe easilybrokenbywaveaction.Whenavoidisgiven,acertainamountofseawaterpassesthroughitandtheimpactofthewave ontheseawalldecreases.

Packingaffectstheshapeofthestructuresoitisimportanttohaveproperpacking.Usuallywhileconstructionofaseawallthe onlygradationofarmourstonesareconsidered,butifonlygradationisconsideredthequalityandoverallbillareaffected.For example if the design condition is to have stones of grade 350 700 and we used any stones within this grade irrespective of their shape and quality there is a chance of huge void formation within the structure which can adversely affect the bill and overallstabilityofthestructure.Thusshapeisanimportantfactorthathastobeconsidered.

TheArmourstonefortheconstructionoftheseawallsareobtainedfromthequarry’s.Thestonesobtainedfromthequarryare blastedtobecometheproductwewant.Stonesblasted inthiswayareavailableinvariousshapesandsizes.In theolddays, weused split stones for the construction of sea wall. It was made of exactly the same cubical shape. The void ratio between themwaslessthan5%asitisnotavailableforconstructionnow,blastedstonesareusedinstead.

Theblastedstonescomeinvariousshapesandsizelikeflaky,cubical,elongatedetc.Thereforeitisveryimportanttoselectthe appropriately shaped stones during construction. In this project we have used two parameters to determine which shaped stonesaresuitableandwhichisnotoneisaspectratioandtheotherisblockiness.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

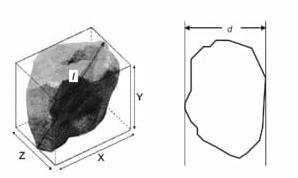

Aspect Ratio (Length to thickness ratio) is defined as the maximum length(m) divided by the minimum distance, d (m), between parallel lines through which the particle would just pass. This form description is the industry standard now embodiedinEN13383forbotharmourstoneandaggregates.

FIG4.2ASPECTRATIOOFSTONE

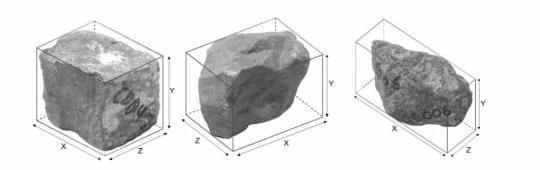

• Blockiness(BL)isdefinedasthevolumeofastonedividedbythevolumeoftheenclosingXYZorthogonalboxwitha minimumvolume.

• Higher blockiness can lead to higher density, more numbers of contact points and finally it will result into greater interlock.

FIG4.3BLOCKINESSOFSTONE

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Armourstonewithanaspectratiogreaterthan3 isconsideredasanelongatedor Flakystonesosuchstonesshould not be usedanditshouldberejected.Stoneswithanaspectratiobetween1to2aremostpreferredastheyprovidebetterpacking

Blockness of a perfectly cubic stone is 100% so as the number goes down the shape of the stone becomes lesser cubic and more of an elongated or flakey shaped stone, but 100% blocky stones is nearly impossible to obtain because these are obtained from blasting there for the cubic stones that we get usually have a blockness of 60 to 70% sometimes up to 80 percentage.

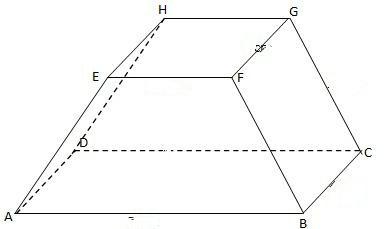

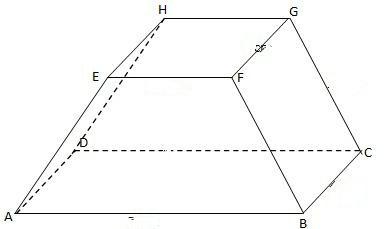

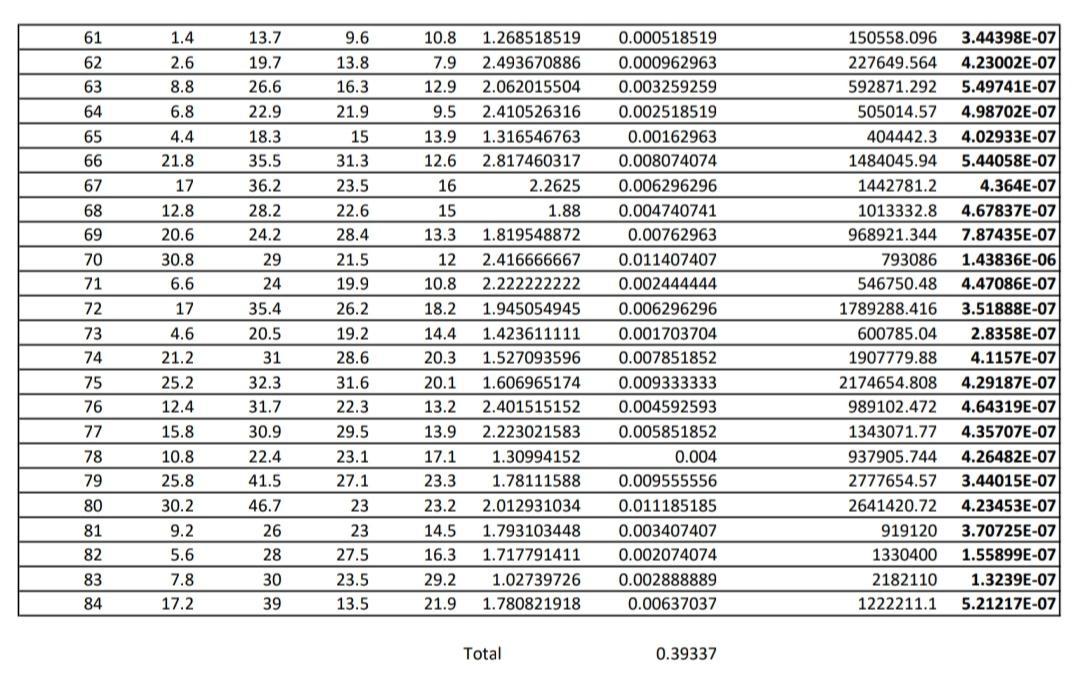

We collected 70 samples of armour stone for this experiment. 70 stones were randomly taken and had different shapes and sizes.Usingthesestonesweconstructedafrustumembankmentbydroppingeachstones.

Thedimensionsofthesoformedembankmentweremeasuredandnoteddown, Theresultantembankmenthasthefollowingdimensions.

Baselength=170cm

Basewidth=90cm

Toplength=110cm

Topwidth=50cm

Height=75cm

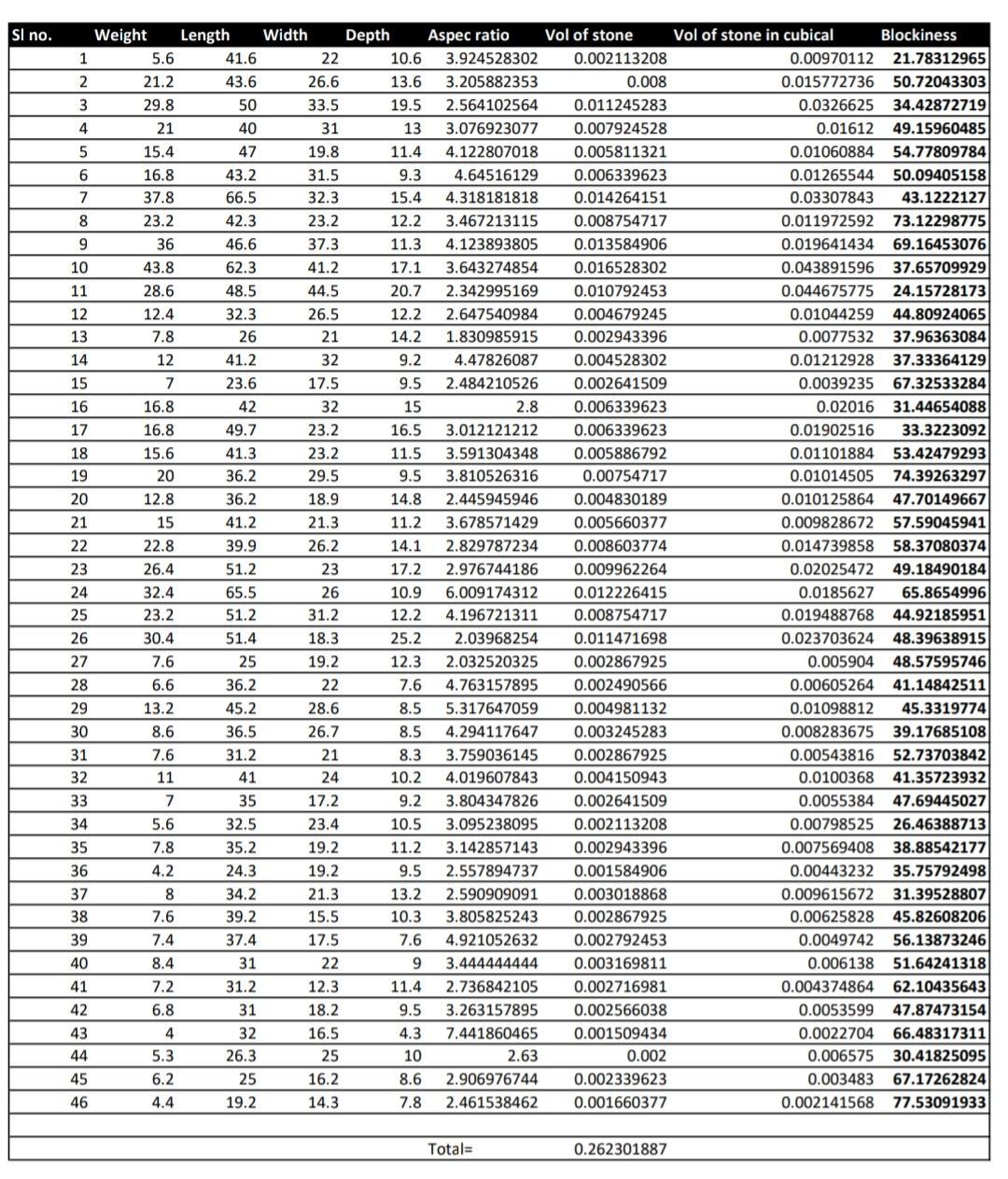

Usingtheobtaineddata’swewereabletocalculatethevolumeofthefrustumsection.Eachstonefromtheembankmentwere taken out to measure it’s weight and dimensions(length,breadth,depth).These readings were noted down. Using these readings,wecalculatedtheaspectratio(AspectRatio=(L/D)andblockiness(BL=[Vstone/Vcubical]x100)ofeachstone.

NowtofindVolumeofvoidsweneedtosubtractthetotalvolumeofstonesfromthevolumeoftheembankment. Nextstepis tofindthevalueVoidRatio&Porosity.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1911

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

VoidRatio=(VolumeofVoids/Totalvolumeofstones) Porosity=(VolumeofVoid / Totalvolumeofembankment)

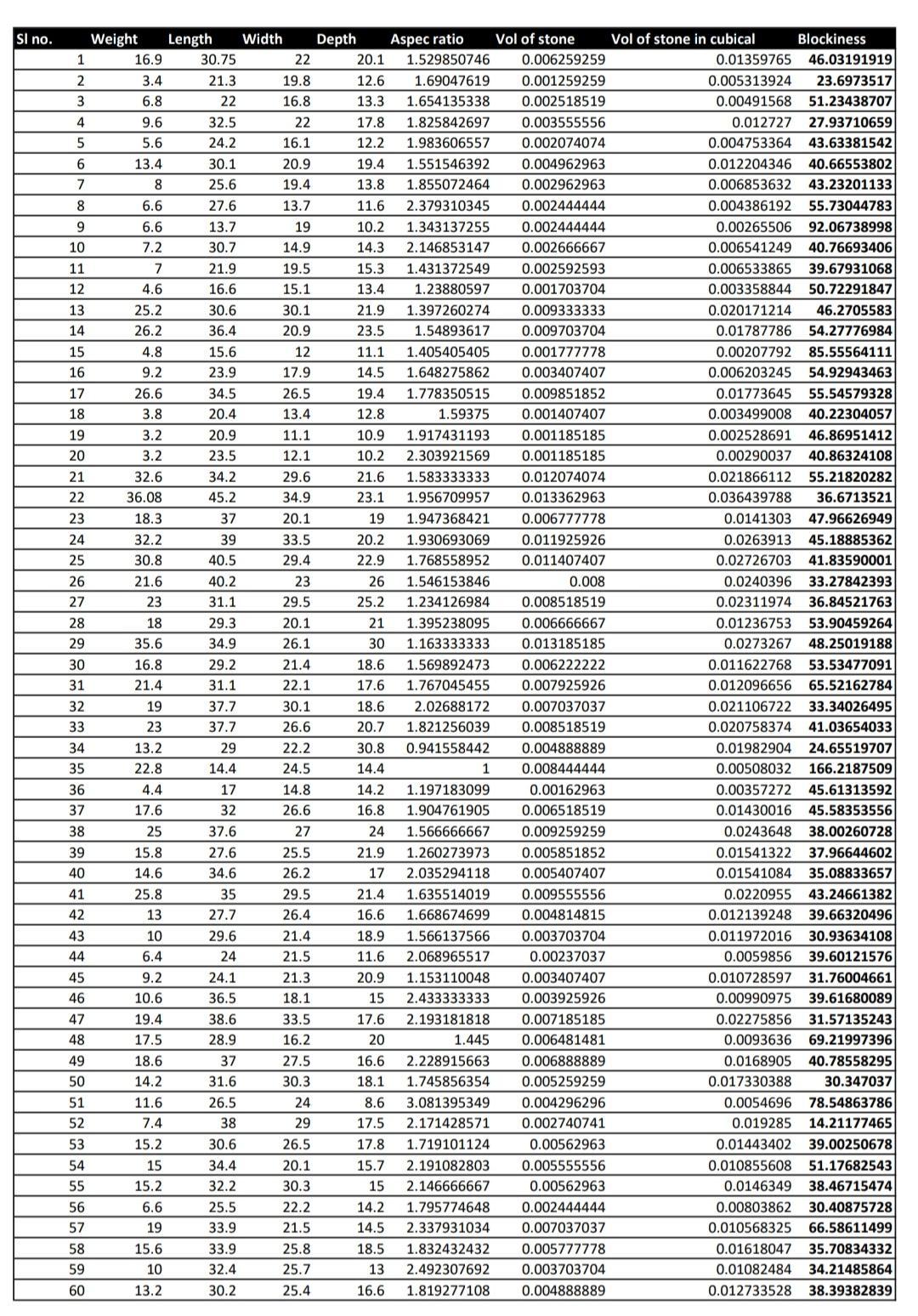

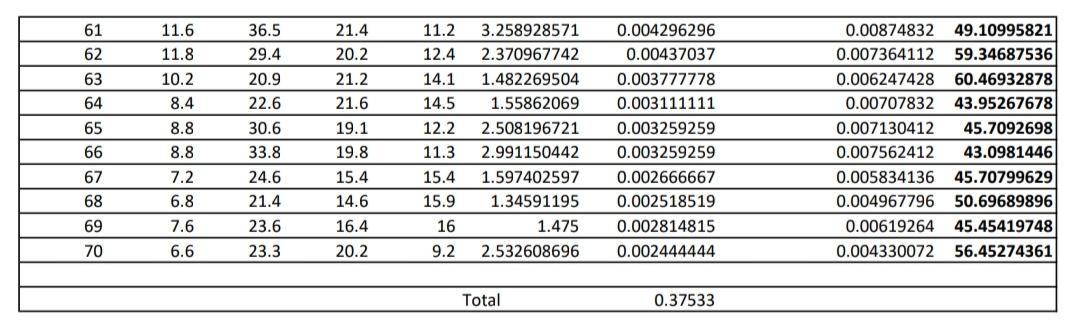

We collected 84 samples of cubical armourstone for this experiment. Although these are cubical stones they are not exactly cubical but resembles cubical stones .Using these stones we constructed another frustum embankment by dropping each stones.

Thedimensionsofthesoformedembankmentweremeasuredandnoteddown, Theresultantembankmenthasthefollowingdimensions

Baselength=160cm

Basewidth=90cm

Toplength=100cm

Topwidth=30cm Height=70cm

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

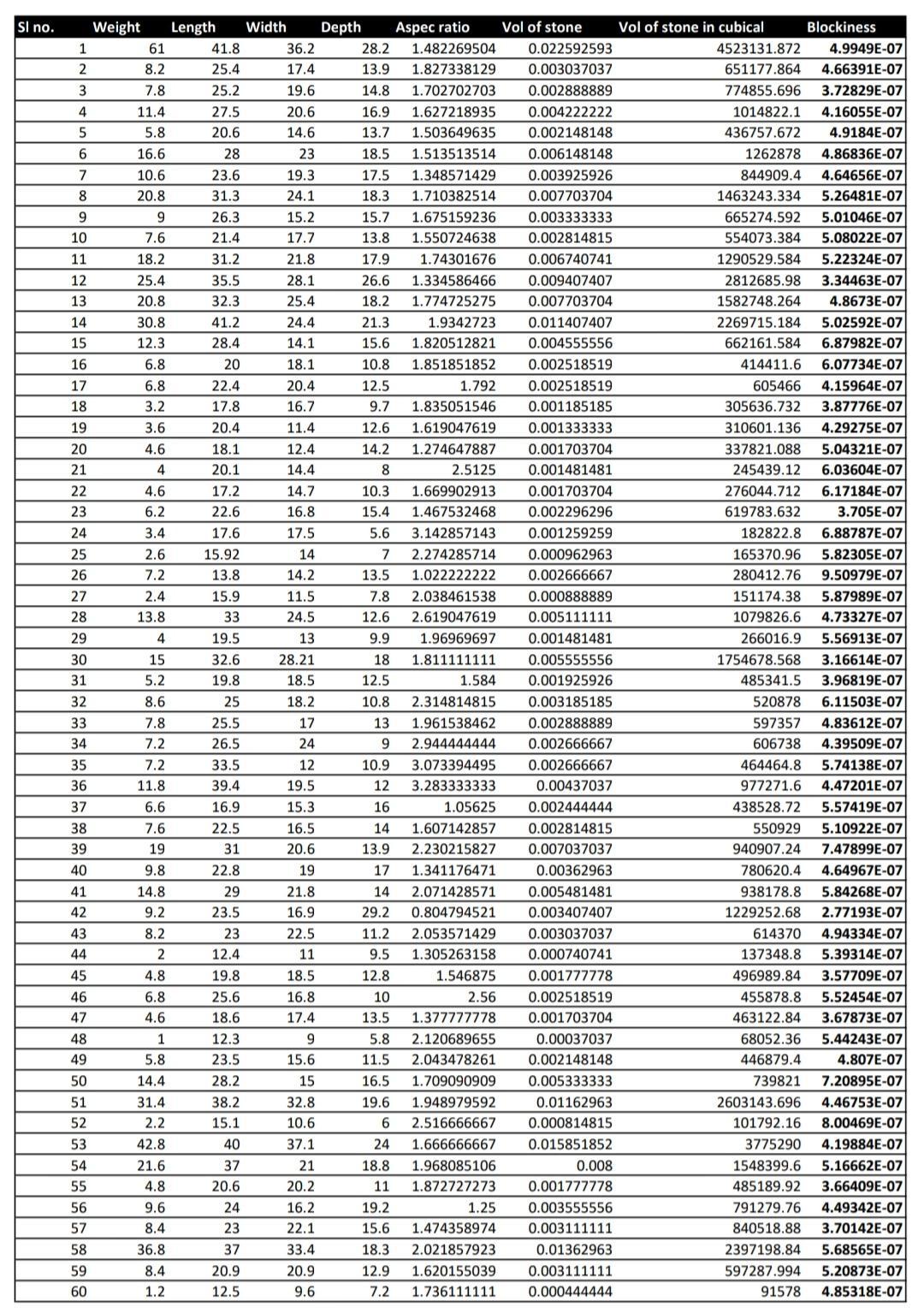

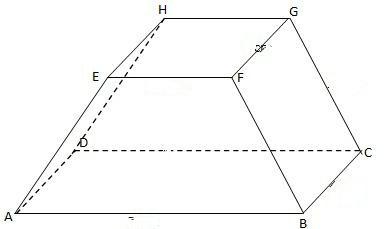

Using the obtained data’s we were able to calculate the volume of the frustum section. One by one each stone from the embankment were taken out to measure it’s weight and dimensions(length,bredth,depth).These readings were noted down. Usingthesereadings wecalculatedtheaspectratio(AspectRatio=(L/D) andblockiness (BL=[Vstone/Vcubical]x100)ofeach stone

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

NowtofindVolumeofvoidsweneedtosubtractthetotalvolumeofstonesfromthevolumeoftheembankment. Nextstepis tofindthevalueVoidRatio&Porosity.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

CALCULATION

Totalvolumeofstones=0.39337m^3

Volumeofembankment=0.0.55936m^3

Volumeofvoids =Volumeofembankment Totalvolumeofstones =0.16599m^3

VoidRatio(e)=(VolumeofVoids / Totalvolumeofstones) 0.16599/0.39337=0.42196

Porosity(n)=(VolumeofVoid / Totalvolumeofembankment) 0.16599/0.55936=0.2967 =29%

Wecollected46samplesofflakyandelongatedarmourstoneforthisexperiment.Nowit’sclearlyvisiblethatthenoofstones decreaseddrasticallythisshowsthepresenceofvoids&decreaseinstonevolume.Usingthesestonesweagainconstructeda frustumembankmentbydroppingeachstones.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Thedimensionsofthesoformedembankmentweremeasuredandnoteddown, Theresultantembankmenthasthefollowingdimensions

Baselength=160cm

Basewidth=90cm

Toplength=95cm

Topwidth=50cm

Height=70cm

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Using the obtained data’s we were able to calculate the volume of the frustum section. One by one each stone from the embankmentweretakenouttomeasureit’sweightanddimensions(length,bredth,depth). Thesereadingswerenoteddown. Usingthesereadingswecalculatedtheaspectratio(AspectRatio=(L/D) andblockiness (BL=[Vstone/Vcubical]x100)ofeach stone

NowtofindVolumeofvoidsweneedtosubtractthetotalvolumeofstonesfromthevolumeoftheembankment. Nextstepis tofindthevalueVoidRatio&Porosity.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

CALCULATION

Totalvolumeofstones=0.2623m^3

Volumeofembankment=0.6398m^3

Volumeofvoids=Volumeofembankment Totalvolumeofstones =0.3775m^3

VoidRatio(e)=(VolumeofVoids / Totalvolumeofstones) 0.3775/0.2623=1.43

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Porosity(n)=(VolumeofVoid / Totalvolumeofembankment) =0.3775/0.6398=0.590 =59%

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Totalvolumeofstones=0.375m^3

Volumeofembankment=0.749m^3

Volumeofvoids=Volumeofembankment Totalvolumeofstones =0.37367m^3

VoidRatio(e)=(VolumeofVoids / Totalvolumeofstones) 0.37367 / 0.37533=0.995

Porosity(n)=(VolumeofVoid / Totalvolumeofembankment) 0.37367 / 0.749=0.5 =50%

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Therearetwobulkvolumestoconsider.Beforeconstructionthedesignbulkvolume,Vd,isrequired.Thisvolumeequalsthe areaAtimestheorthogonalthicknessTd,whichisatheoreticallypredictedaveragethicknessthattheengineerhasintroduced forthedesigndrawings,usingrecommendedlayerthicknesscoefficients.Clearly,foragivenrangeofarmourstoneweightsor sizes, the best design guidance on the expected single or double layer thickness is required. These volume calculations are necessary for ordering the quantities prior to construction. After construction, in addition to profile tolerance conformance checks, it may be necessary to determine volumes for payment purposes. Having surveyed the under layer surface and the armour layer surface, the average cross sectional area, D, times the chainage length L gives the surveyed bulk volume, Vs. FromDandthedown slopelength,anactualaverageorthogonalthicknesscanbededucedandthisoftenmakesaninteresting comparison with the orthogonal thickness shown on the design drawings. Large differences generally lead to contractual problems.

Considerbuildingaseawallwithdimensions2m,3m&5m.

Letthisseawallextendtoalengthupto5km.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Volumeoftheentireembankment=([3+5]/2)*2*5000=40000m^3

For30%voids

40000*0.7=28000m^3volumeofstonesareneeded ie40000*0.3=12000m^3volume isjustvoids

Weightofthestonesinton=volumeofstonesinembankment*specificgravityofstone

Weight=28000*2.65=74200 ton stones are needed (Ideal)

For10%voids

40000*0.9=36000m^3volumeofstonesareneeded Example 40000*0.1=4000m^3volumeisjustvoids

Weightofthestonesinton=Volumeofstonesinembankment*specificgravityofstone

Weight=36000*2.65=95400 ton stones are needed

For40%ofvoids

40000*0.6=24000m^3volumeofstonesareneeded ie40000*0.4=16000m^3volumeisjustvoids

Weightofthestonesinton=volumeofstonesinembankment*specificgravityofstone

Weight=24000*2.65=63600 ton stones are needed

For20%decreaseinvoidswithrespectto30%voids Increaseinstonesvolume=95400 74200=21200ton(forthe contractor)

Consideringthecost1 tonofstonecosts710rs

Exampleif10%volume ofvoidsareconsideredtotalcostwouldbe 95400*710=6.77CR

Costofstonesfor30%voids=74200*710=5.26CR

Example 6.77 5.26=1.51CR extra cost for 20% decrease in voids with respect to 30% voids

For10%increaseinvoidswithrespectto30%volume decreaseinstonesvolume=74200 63600=10600ton(forthe company)

Consideringthecost,1tonofstonecosts710rs

Exampleif40%volumeofvoidsareconsideredtotalcostwouldbe 63600*710=4.51CR

Costofstonesfor30%voids=74200*710=5.26CR

Example5.26 4.51=0.75 CR decrease in cost for 10% increase in voids with respect to 30% voids

Among the three experiments conducted cubical stones gave better packing with a porosity 30% .The 30% void gives favourablecostforbuyersandsellersinSeawallconstruction.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1922

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Good interlocking property was provided for the sea wall when using cubicle stone Secondly, we used flaky stones for the experimentinwhichthestructurewasnotstablewiththisstone WithflakystonesRvaluabletolateralforces Thesekindsof stonestendtobreakwhendroppedfromacertainheightsinceit’sporosityvalueismore.

Finally, mixed stones like flaky, elongated and cubical were used for the structure the porosity value that we got for the structureis50%soit'sbettertousecubiclestoneswhichisbetterfortheconstructionofseawallthanmixedstonestructure

1. BS EN 1097 1. 2004. Tests for Mechanical and Physical Properties of Aggregates Part 1: Determination of the ResistancetoWear(Micro Deval).BSI,London

2. CIRIA,CUR,CETMEF.2007.“TheRockManual.TheUseofRockinHydraulicEngineering(2nd Edition)”.C683,CIRIA, London

3. Curtis,R.V.,Juszczyk,A.S.,Analysisofstrengthdatausingtwo andthreeparameterWeibullmodels.J.Mater.Sci.33, 1151 1157,1988.

4. Davies,I.J.,2001.“Empiricalcorrectionfactorforthebestestimateof Weibullmodulusobtainedusinglinearleastsquareanalysis”.J.Mater.Sci. Lett.20,997 999,2001.

5. Hudson,R.Y.,DesignofQuarry StoneCoverLayersforRubble Mound Breakwaters:U.S.ArmyEngineerWaterwaysExperimentStationResearch ReportNo.2 2,Vicksburg,MS,39p.,1958.

6. Weibull,W.,“Astatisticaldistributionfunctionofwideapplicability”.J.Appl.Mech.,293 297,1951.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1923