International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

1M.Tech, Civil Engg (Structural Engineering)

BRCM College of Engineering & Technology, Bahal, Bhiwani 127028

2 Assistance Propessor, Department of Civil Engineering

BRCM College of Engineering & Technology, Bahal, Bhiwani affliated to Maharishi Dayanand University, Rohtak ***

Abstract:

Freeze and Thaw resistance is an important durability criterionofconcrete incoolareas.Tofurtherimprovement in freezing and thawing resistance of concrete, carbon Fibre was added into the concrete. Rehashed absorbing water will speed up the freeze thaw harm of concrete, resulting in the declination in compressive strength of concrete.

Consequently, a repetitive Freeze Thaw test, in which samples (Specimens) of carbon Fibre Reinforced concrete were frozen for 16h followed by 8h of thawing, was completed to gauge the relationship of the carbon Fibre and Freeze Thaw resistance. The outcomes show that adding Carbon Fibre content upto optimum limit into concrete could diminish the rate of weight loss of the concrete during the Freeze Thaw investigation. The increment in Fibre content into the concrete resulted in improvement in compressive strength (28 days) of concrete significantly. Compressive strength losses was 1.055%, 7.656%, 23.243% and weight losses were 0.114%, 0.552%, 1.333% at 10, 25 and 50 Freeze Thaw cycles of PlainCementConcrete.

The experimental results indicate that the Fibre Reinforced concrete made with carbon Fibre is suitable as construction material in cold regions when the optimal addition of amount of carbon Fibre is 1 % of the weight of thecement.

Keywords: Carbon Fibre Reinforced concrete, Carbon Fibre, Slump, Freeze Thaw Resistance, Compressive strength.

Concrete is a versatile widely utilized construction material. Since concrete has been laid out as a material for construction, investigators have been attempting to work on its quality improvement. As a brittle material, concrete is strong under compression and weak under tension as well as in Flexure. This issue might be lightenedbytheadditionofshortcarbonFibres.

About portion of substantial structures have various levels of freeze thaw damage around the world. Worldwide, in cold areas, like Japan, Russia, Canada and United States, substantial designs have various levels of freeze thaw damage, and the expense for upkeep and support is very huge. The financial misfortune brought about by the freeze defrost harm of structures is much higher than the construction cost. Concrete structures are frequently exposed to freeze thaw cycles, and their durability and mechanical properties will be decreased by different degrees or even harmed, particularly in a salt rich climate. Subsequently, it is exceptionally important to study how to improve the freeze thaw resistanceofconcrete.

Material

Cement: OrdinaryPortlandcementgradeof43(OPC 43)

Coarse Aggregate: Crushedcoarseaggregatessizeof 20mm. Fine Aggregate: Thecoarsesand

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

ResinDia:7µ

Fig 2(CarbonFibre)

Design Mix: M35 Table 1 Mix

Cem ent in Kg

Coars e Aggre gate

Fine Aggre gate Wat er

Carb on Fibr e Disper sant Admix ture

C1/0 .00 390 1222 664 156 0.00 2.34 3.9

C2/0 .25 390 1222 664 156 0.98 2.34 3.9

C3/0 .50 390 1222 664 156 1.95 2.34 3.9

C4/0 .75 390 1222 664 156 2.93 2.34 3.9

C5/1 .00 390 1222 664 156 3.90 2.34 3.9

C6/1 .25 390 1222 664 156 4.88 2.34 3.9

Each material was weighed as per design proportion of the Design Mix. Firstly carbon fibre was immersed in water upto marginal height with addition of dispersant and vibrated by the Oscillation machine for 15 min, to makecarbonfibresolution.

Cement, Coarse aggregate, Fine aggregate, water reducing agent (Admixture) was uniformly mixed by concrete mixture and then carbon fibre solution were mixed with it. Cube moulds of size 150x150x150mm werepreparedandtotal72nosspecimenswascastedas

per variability of carbon fibre content. The mould shall be of 150 mm size conforming to IS 10086: 1982. The specimens werekept under clean waterfor 28days and waterrenewedatevery7daysinterval.

To calculate the 28 days compressive strength of the specimens, 3 specimens from each type were taken out from the curing tank and kept at room temperature for 30 minutes prior to the test and same was tested for compressive strength and the results of specimen is giveninTable 3

Specimen oven dried for 24 hrs and cooling at room temperature, the weight of specimens calculated. Cubes were placed in individual containers resting on ceramic tiles. And the containers were filled with 3% sodium chloridesolutionatatemperatureof27±2 ֯Cfor24hrs. Thelevelofsolutionwaskept2mmabovethesurfaceof the specimen. Following the 24 hrs saturation period cubesweresubjectedtocontinuousfreeze thawcycles.

Saturated cubes were kept in freezing chamber for 16 hrs at 15 ֯C temperature. After completion of 16hrs in freezingchambercubeswereplacedinthawingchamber for8hrstocompletetheonecycleofFreezing Thawing. Thesameprocessoffreezingandthawingwererepeated for10,25and50cycles.

After completion of freezing and thawing cycles, the specimens washed with 3% sodium chloride solution to remove all loose particles. These particles and spelled materialwashedandstainedthroughafilteranddriedto a constant weight. The residues weighted after 10, 25 and50cyclescumulatively.

Fig 3(CubeSpecimens)International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

The specimens were tested for compressive strength after10,25and50cycles

Mechanical Properties of concrete decreases with increases in Freeze Thaw Cycles in which the compressive strength is the most delegated parameter. The compressive strength test was conducted at room temperatureaccordingtoIS:516asshowninfig 4.

resulted lower value of compressive strength as comparedtoC5/1.00cubesstrength.

After the completion of 50 Freeze Thaw cycles the compressivestrengthofCubeswerecalculated.Thecube strength of Plain Cement Concrete was recorded 33.43 MPa. The result shows that when small amount (0.25% by weight of Cement) of carbon fibre added, the compressive strength was recorded 33.38 MPa but it is 99.85% of Plain Cement Concrete Cube Strength (after 50 Freeze Thaw Cycle) while it reduces 17.885% as compare to its 28 days strength. The cubes made with 1.95Kg/m3 (ie 0.50% by weight of cement) had the compressive strength of 42.29MPa that is reduces by 1.182% to its 28 days strength. While specimens of C4/0.75 had the compressive strength of 44.59MPa and it is 0.695% lower than its 28 days strength. The compressive strength 47.26MPa resulted for C5/1.00 specimens and it is just only 0.381% lower than its 28 days compressive strength. The cubes made with more than 1% carbon fibre content resulted decreasing in compressive strength after completion of 50 Freeze Thawcycles.Thevalueofcompressivestrengthrecorded was37.22MPai.e. Lowestvaluerecordedascompareto otherspecimensanditis11.741%lowerthanits28days strength.

Fig 4

Plain Cement Concrete (C1/0.00) has resulted value of compressive strength (28 days) was 41.20MPa. The Carbon Fibre Reinforced Concrete (C2/0.25) cubes have the compressive strength (28 days) 39.35MPa which is lowest value of compressive strength w.r.t. other specimens. When the carbon fibre resins were 0.25% of the weight of the cement used the compressive strength decreases with certain amount while the carbon fibre resins were 0.50% of the weight of the cement used the compressive strength starts increasing that is slightly morethanthePlainCementConcrete.

When amount of 2.93kg/m3 carbon fibre (i.e. 0.75% weight of cement) added to concrete mix the compressivestrengthresulted1.09timeshigherthanthe PlainCementConcrete.CarbonfibreReinforcedConcrete withcarbonfibrecontentof 1%hadthehighestvalueof compressive strength i.e. 47.44Mpa. However fibre resins added more than 1% of weight of cement compressive strength starts decreasing. Cubes made with addition of Carbon content of 1.25% by weight

Hence the outcomes showed that when a small quantity ofcarbonfibrewasconsideredthecompressivestrength of the Carbon Fibre Reinforced Concrete (CFRC) was lower than that of Plain Cement Concrete and when the quantityaddedmorethan0.5%byweightofcement,the compressive strength of Carbon Fibre Reinforced Concrete (CFRC) was more than that of Plain Cement Concrete. Thus optimum value of Carbon Fibre Resins is 1%byWeightofCement(3.90Kg/m3).

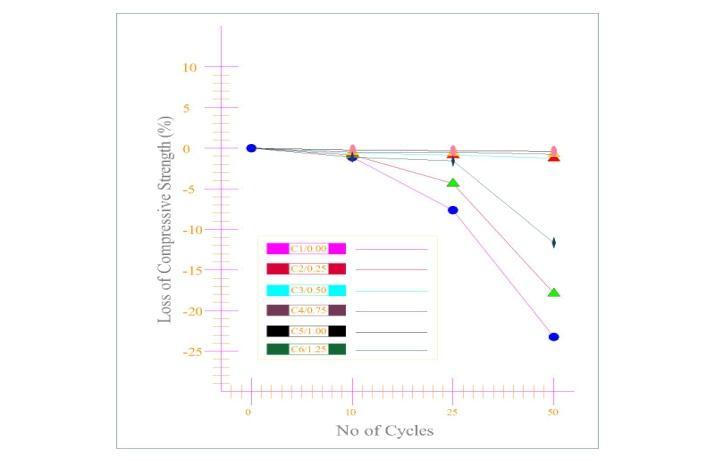

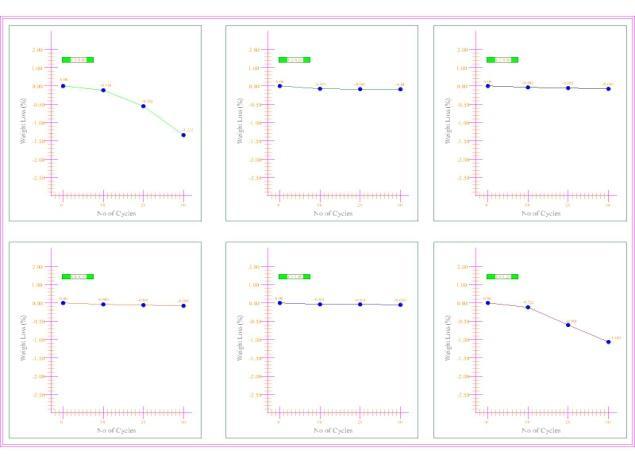

In the Freeze Thaw resistance test, impact of Carbon fibreresinsonweightlossandcompressivestrengthare shown in Table 2 & 3 and fig 5 and 6 respectively The cubes made with Plain Cement Concrete (C1/0.00) shown the maximumweightloss 1.333%after 50cycles of freezing and thawing while (C5/1.00) shown the minimumweightloss0.039%.

e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Table 2

Mix 28 days Weight

% Loss after 10 Cycles

% Loss after 25 Cycles

% Loss after 50 Cycles

C1/0.00 8.451 0.114 0.552 1.333 C2/0.25 8.452 0.071 0.083 0.084 C3/0.50 8.488 0.047 0.051 0.059 C4/0.75 8.518 0.047 0.051 0.058 C5/1.00 8.609 0.031 0.031 0.039 C6/1.25 8.482 0.122 0.601 1.061

Table 3

Mix 28 days Strength

% Loss after 10 Cycles

% Loss after 25 Cycles

% Loss after 50 Cycles

C1/0.00 41.20 1.055 7.656 23.243 C2/0.25 39.35 0.768 4.321 17.885 C3/0.50 42.79 0.635 0.825 1.182 C4/0.75 44.9 0.447 0.582 0.695 C5/1.00 47.44 0.275 0.296 0.381 C6/1.25 41.59 1.069 1.563 11.741

The frost resistance mark displayed on concrete cube in increasing pattern with increase in carbon fibre content before 1 % by weight of cement. When carbon fibre content increase more than 1% then, it shown not any further improvement in frost resistance in concrete. When the water present in pores experienced frost resistance its volume increased and which would cause of tensile stress development and microcracks forms. The improvement in frost resistance by using carbon fibreinconcretepreventedtheformationofmicrocracks. Therefore the addition of optimum carbon fibre content that is 1 % by weight of cement used can improve the frostresistanceinconcrete.

Conclusions:

By increasing Carbon Fibre Content from 0% to 1.25% by weight of cement showing a decrease pattern in workability. Slump value decreases from146mmto78mm.

The mixing of Carbon fibre into concrete could compressive strength decrease first and cause increase after that, the value of maximum compressivestrengthafter50cyclesreportedis 47.26MPa which is just only 0.381% lower than its28daysstrength.

Themixingofcarbonfibrecontentintoconcrete candecreasetheweightlossoftheconcrete.

Reference:

Karahan, The durability properties of polypropylenefiberreinforcedflyashconcrete.

Yu Effect of expansive agent, fiber or their combination on freezing thawing durability of highperformanceconcrete.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Wenguang Kan, Zailin Yang and Liangliang Yu studyonfrostresistanceinfibreconcrete Wang Chuang, Zhao Li ping on Influences of molding processes and different dispersants on the dispersion of chopped carbon fibers in cementmatrix

Huai Shuai Shang, Ting Hua Yi: Freeze Thaw DurabilityofAir EntrainedConcrete