International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Akshat Ruhela1 , Aayush Srivastava2 , Akash Deepak Tyagi3,Shailendra Pratap Singh4

1,2,3 Student, ABES Engineering College, Uttar Pradesh, India 4ABES Engineering College, Uttar Pradesh, India ***

Abstract Weightdecreaseisoneofprimeproblemsforavehicle.Itwaschosentodecreaseweightofdiscbrakebymaterial AL 7075. CAD modelling software is used for designing of disc brake, brake pedal, Steering Hub etc for fulfilment of our conditions. Conditions are required to activate braking system and all wheels locking at same time. The research paper additionallyincludestheparameterfordisc,staticanalysis,andsteadystatethermalanalysisdependentondifferentparameter. Structural analysis is done because of mechanical strength of material and Thermal analysis is done on the basis of heat propertiesofmaterial.ThisresearchpaperstudiesanoptimizeddesignofthebrakingandsteeringcomponentofaGo Kart whichaimsatreducingweightandmaintainingthestrengthalongwithreducingthedeformationathighertemperaturesas comparedtotheOEMavailableinthemarket.

Abrakeisa mechanicaldevicethatutilizes retainingmovementbyactiveenergyfroma movingbodyandafterward changesoveritintoheatvitality.Thehydraulicsbrakeisakindofstoppingmechanismthatutilizesarotorisassociated withthehubofthewheelandsetof erosion material called as brake shoe is constrained generally by hydraulic poweredweightagainstthetwosidesoftherotorwhichmakesitstopwiththeassistanceofrubbing.Themostimportant parameterforanyvehicleisthebrakingsystem.Comparedtodrumbrakes,discbrakesbetter stoppingefficiency.Allthe elementsofthebrakingsystemplayanimportantroleinanyvehicle,itsfunctionsincludeslowingdownofthevehicle, maintainingthespeedduringdownwardoperation,andalsoholdingthevehicleafterithascometocompletestopthisis donebythedissipationofmechanicalenergyofthebodyintotheheatenergybythefrictionalforces.Inthehydraulic brakingsystem,thediscisbeingmountedonthewheelhubwhichmovesalongwiththewheel.Atthetimepressingbrake pedal,thepushrodconnectedtothehydraulicbrakecylinderpressurizethehydraulicfluidwiththehelpofapistontoa highextentbytakingtheadvantageofthepedalratiowhichisdefinedastheratiooftheleverageofyourclutchappliesto the hydraulic brake cylinder further thebrakefluidpassesthroughthebrakehoseswhichareconnectedtothebrake caliper.

Themechanismisofvitalapartofthedynamicstyleofanyautomobiletofacilitateaswishamendmentofdirectionsand builduseofthetiresabilitytogetlateralforcestotheverybestextent.Anathleticsdriver’ssensoryinputsprovidevisual, tactile,andmechanicalphenomenondatautilizedindevelopinga“feel”forautomotivehandlingandperformance.This feedbackiscriticalinsanctimoniesthedrivingforcetoextractmostperformancefromtheautomobile.thencethesteering isacrucialfeedbackmechanismgivingthedrivingforcedataonstabilityanddirectionalmanagement.Themanagementof associatedegreeautomobileisfinishedbymeansthatofamechanismthatprovidesdirectionalchangestothemoving automobile.TheintentionofAckermannpuremathematicsistostopthetires fromslipperyoutwardoncethewheels followaroundacurvewhereastakingaflip.theanswerforthiscanbethateveryonewheelstoowntheiraxlessettledas radiiofcircleswithastandardcenterpurpose.Sincetherearwheelssquaremeasurefastened,thiscenterpurposeshould lieonalineextendedfromtherearshaft.Thus,we'dliketocrossthefrontshafttothepresentlineatthecommoncenter purpose.whereassteering,theinnerwheelangleislargerthanouterwheelangle.Thus,forgettingtotallydifferentresults we'dliketovarytheparameterssoastogetdesiredsteeringpuremathematics.

K.SowjanyaandS.Suresh[1]havepresentedresearchpaperwhichgivesanoverviewof analysisofdiscbrakes.Brakesare mechanismsystemwhichisusedtoretardmotionofmovingbody.Discofbrakesismadeofcastironor,aluminiumcomposite.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

These areselectedbyrunningseveraltestsonsoftwarelikesPro/E(Creo Parametric)forsolidmodellingandstaticanalysis aredonebyCAD/CAEsoftwares.

Neeraj Singh at el [2] have worked on research paper which focuses around structure and test examination of braking mechanism for off road condition for BAJA 2016. Every part of braking mechanism was designed on CATIA V5 though investigatingandtemperatureanalysiswasfinishedbyANSYS16.

VivekSinghNegiatel[3]hasbeenexaminesthoughtsforutilizingdifferentparameterinthesystems,structurefactorsand rationalebehindthechoosingrightestimateofthefactors.Structureofbrakingsystemmechanismcomprisesofevaluatinghuge numberofasituationsandutilizingtoaccomplishtheideal,yetcompellingbraking.Informationidentifiedregardingtoutilized toremovenormalestimationsofdesignparameters,makinghypotheticalcountsasreasonableascouldbeexpectedunder circumstances.

KushSoniatel[4]hasbeendonethepartdeterminationofbrakingsystemmechanismistalkedabout.Differentcalculationof brakingpower,brakingtorqueandbrakeinclinationareappearing.Likewise,thesafetyofutilizingbikerotorisapprovedby calculationandthermalinvestigation.Ouressentialpointwastothinkofabrakingsystemmechanismthatisstraightforward andhasanadvancedloadalongbeingdependable.AccordingtotherulebookofSAEINDIA BAJA 2020, it was obligatory for the system to comprise of two independentoperated hydraulic circuits. Likewise, all the four wheels must be lock at the same timesimultaneously.

Sanket Nawade (5) They concluded that after the Software Computation Analysis and Numerical Analysis, & found the approximatesamedeformationinchassiswhichisnegligible.AlsoFEAanalysisissuccessfullycarriedoutonCADmodelto determineEquivalentStressesandFactorofSafety.AlsofoundtheFactorofSafetygreaterthan1,thatconcludetheirchassis designissafeandthematerialusedthatisAISI4130isbestmaterialforGoKartChassis.

MohdAnwar(6)InthisResearchPapermanualmechanicallinkagessteeringsystemisnotusedinheavyweightvehiclesdueto highaxleloads,althoughitissimpleindesignandeasytomanufacture,thereforeitiscommonlyusedinlightweightvehicles. Thevaluescalculatedinthepapermaydifferpracticallyduetosteeringlinkageserrororduetoimpropersteeringgeometry,so these values are useful to understand the interdependency of the quantities oneach other and to design a ideal manual mechanicallinkagessystemforthevehicle.

PRABHUDATTADAS(7)Thereportdiscussedaboutthedesignandfabricationofago kartvehiclegivingspecialattentionto improvementofsuspensionsystemanddynamicsoverlastmodel.Thefirsthalfofthereportdiscussesaboutthenodalanalysis ofpreviousmodelandnotingdownthepointsofreviewandlimitationsinoldmodel.Theotherhalfofthereportdiscusses aboutawholenewdesignwhichtriestoeliminatethedefectsofolddesignandalsoimplementingthepositivityofolddesignin thenewone.Italsodiscussesaboutnewdesignprocedureandthetransmission,suspensionandsteeringsystemofthenewgo kartmodel.

ArshadKhan(8)Inthispaper,ThesteeringmechanismusedwhichisAckermannsteeringgeometryisdiscussedwiththesteer casesandisexplainedinsimplequadrilateralnotationformwithtermsconsideredinmechanismandtheassumptionsmade duringthesolutionoftheAckermannsteeringgeometryproblems.Theanalysisofthesteeringsystemcomponentsthrough varioussoftware'scanbeperformedwhichdeterminesthestresses,loadsanddeformationofthesteeringsystemfromwhich thedesignengineerscanpredictthesafetyofthesystemandcanalsobemodifiedandminimizationoftheerrorsinthesystems canbedone.

Mr.GirishMekalke(9)Thispaperdiscussedaboutthedesignandfabricationofago kartvehiclegivingspecialattentionto improvementofchassissystem.Thusthekartwasdesignedusingbasicautomobileprinciples.Itisanalyzedusingfiniteelement techniquestoproveitseffectiveness.Finally,aneffectivedesignforthekartisdevelopedwhichcanoutperformtheexistingkarts andalsointheupcomingeraofautomobilevehicles.

RamagiriSaiKiran(10)Inthispapermodelofchassisisstructuredin3DCADModelingsoftwarewhichgivesextraordinary adaptabilitytothecreatoranditisveryeasytoimportforanalysisinANSYSorsomeothersimulationsoftware.Inthisstudy,it isclearlyseenthatthenaturalfrequenciesofAISI4130andAL 2014 T6arehigherincomparisonwithdifferentmaterial.AL 2014 T6wasselectedonaccountoflessdensityandhighyieldstrengthwhencomparedtoAISI4130alongtheselines,todesign ago kart,itisbasictothinkaboutthebodytoweightproportion.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Assumed and Experiment Values

PARAMETER VALUES Reference

Coefficientoffriction(RoadandTyre)µr 0.8 Experiment

Coefficientofstaticoffriction (brakepadanddisc)µbp 0.5 Experiment

Frontrotordiameter(RDF) 685.8 mm 170 mm Assumed

Rearrotordiameter(RDR) 170 mm Assumed

Massofvehicle 1371.6 mm Assumed

Effectivebrakepadsarea(ABP) 0.0018338 m2 Calculated

Maxvelocity(v) 12.5 m/s Transmission department

Areaofpistonofmastercylinder(AMC) 2.85 × 10-4 m2 Calculated

Wheelbase(L) 1371.6 mm As per therulebook Wheeldiameter(Front) 533.4 mm Transmission Department

Wheeldiameter(Rear) 558.8 mm Transmission Department

DistanceofCGfromrearaxle(a) 685.8 mm Roll Cage Department

Wheel

Fromequation (i), we get RF = 1943.98N

RF =W×(a+coefficientoffriction×h)×cos(b h ) (i)

Sliding force required to lock the wheel SF =µr×RF =1555.18N

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Braking Torque acting on front wheel - TF=SF×Radiusofwheel=

414.76NmThesametorquewillactonrotor

TF =TROTOR =414.76Nm (ii)

Fromequation(ii),weget

Radial Force acting on rotor

FRF =(TROTOR×2)/RDF =4879.529N

Force acting on brake pads

Fbp =µbp ×FRF ×2 =4879.529N

Pressure required for pulling caliper piston out

Pp =Fbp /AP1 =5.374MPa

Same Pressure will act on piston of master cylinder. Therefore, force required

FMC1 =PP ×AMC =1531.7N (iii)

Rear Wheel

RR=W×(L a µrh)cosβ/L (iv)

Fromequation(iv),weget =655.67N

Sliding Force

SR =µr×RR =524.536N

Braking Torque acting on rear wheel

TR =SR×Radiusofwheel =146.55Nm

TR=TROTOR= 146.55NmFRR= (TROTOR×2)/ RDR =1724.18N

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Force acting on brake pads Fbp = µbp ×FRR ×2 =1724.18N

Pressure required for pulling caliper piston out Pp =Fbp /AP2 = 2.14MPaFMC2 =PP ×AMC (v) =611N

Force required to pull piston of master cylinder

From equation (iii) and (v),wegetFMC =FMC1+F MC2 =2142.69N Mass Required =218.42Kg

Pedal Ratio =10:1

Mass required to press pedal = 21.84Kg

TakingAckermannprincipalofsteeringAckermannprincipleofsteeringisusedtoclarifytheequationofwheelsontheinside andoutsideofaturnrequiredtofindoutcirclesofvariousradius.

100%Ackermannsteeringgeometry.

Maximumroadbankangleis20°.

Optimumkingpininclinationanglerangeis4°to8°.

Fronttorearweightratiois40:60.

Takingaccelerationduetogravityas10m/s^2.

Goals:

Toenablesmoothandstablemanoeuvringofthevehicle.

Tooptimizethesteeringeffort.

Provideadjustabilityforparameterssuchascasterangleandtoe.

Toselectandimplementthebestmechanismthatsuitsthepurpose.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Camber:Thecamberangleissettozerodegreebecausewedonotusesuspensionsystemtoprovidedynamic camberduringcornering.

Caster: It is the angle formed by the axis of the bolt that is kingpin inclination whichconnectsthestub axlestotheknuckle.

KingpinInclination:DuetothegeometryofthestubaxletheKingpinoffsetishigh,whichdemandslarge kingpininclinationtominimizescrubradiuswhichisnotfeasible.Henceitissetto0(zero)degree.

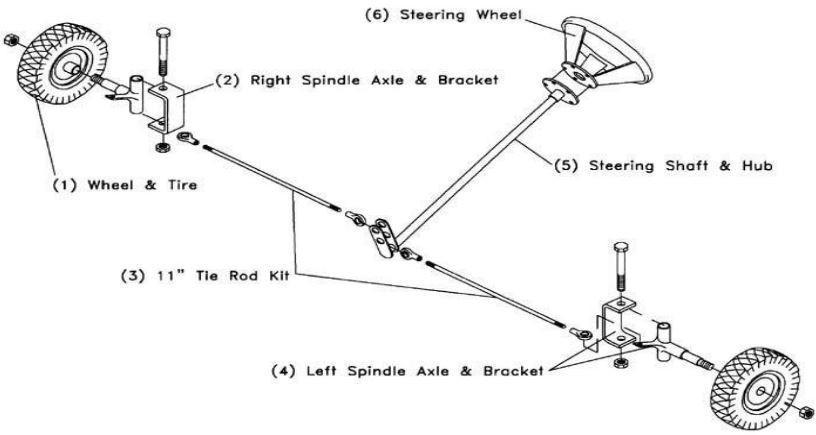

Fig: Steeringsystem CALCULATIONS Required

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

C. Outer angle (ϕ): Tanϕ=L/(R*sinδ+T/2)=1143/(2000+1016/2) Tanϕ=0.45574ϕ=24.50°

D. Actual turning radius: R”=√(B2+X2)R”=√[(457.2)2+(2000.28)2]R”=2051.86m E. Ackermann angle (��):

Adetailedstudywasdonetopickthemostcompatiblematerialforfabricationofthebrakingsystem.Variousfactorswere consideredwhileselectingthematerialsuchasavailabilityofmaterialwithmechanicalstrength,elongationatbreak,Hardness weldability,costetc.ThematerialwhichweselectedwasAl 7075T6becauseofitsbetteryieldstrengthandultimatetensile strengthascomparedtoothermaterial. Mechanical properties of AL 7075 T6 Properties Values Density 2.81g/cc Ultimate Tensile Strength 572MPa Tensile Yield Strength 503MPa

Adetailedstudywascarriedouttoselectthemostsuitablematerialdependingonthefactorssuchasavailabilityofmaterial, Yieldstrength,weight,cost,weldability.AISI4340wasselectedoverAISI1018onthebasisofavailability,cost,Yieldstrengthand fatiguestrength.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

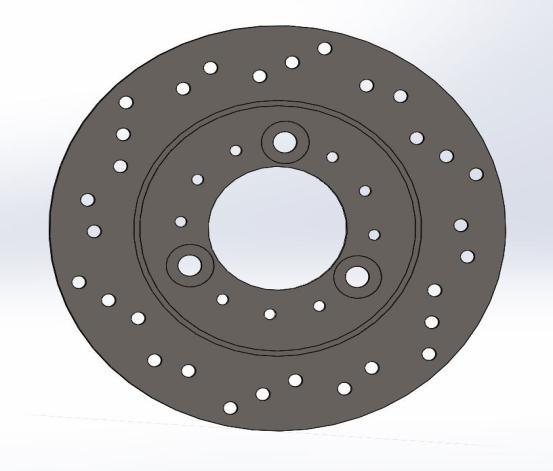

Figure: Model of rotor

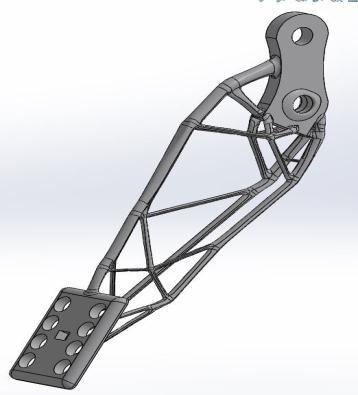

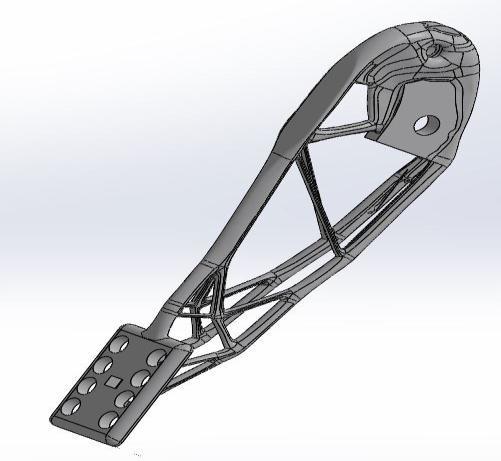

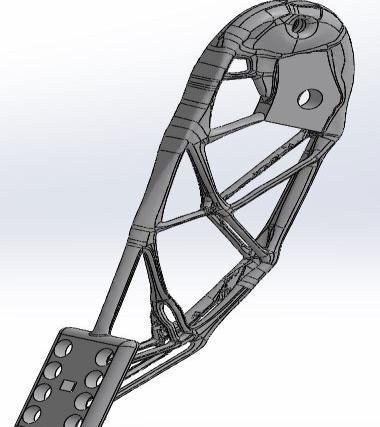

Figure: Model of brake pedal DESIGN: STEERING COMPONENTS

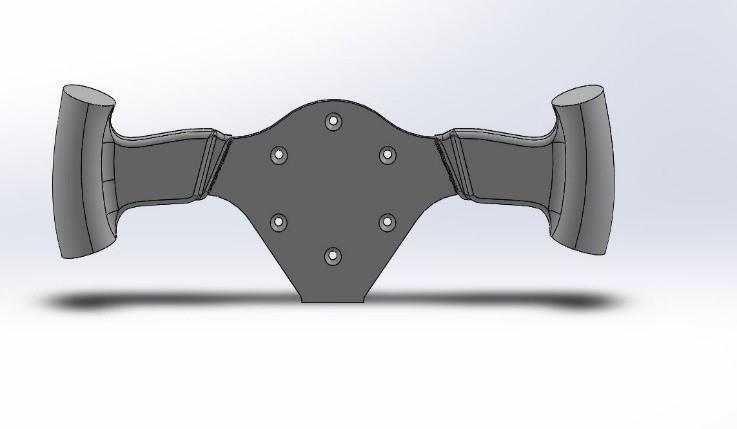

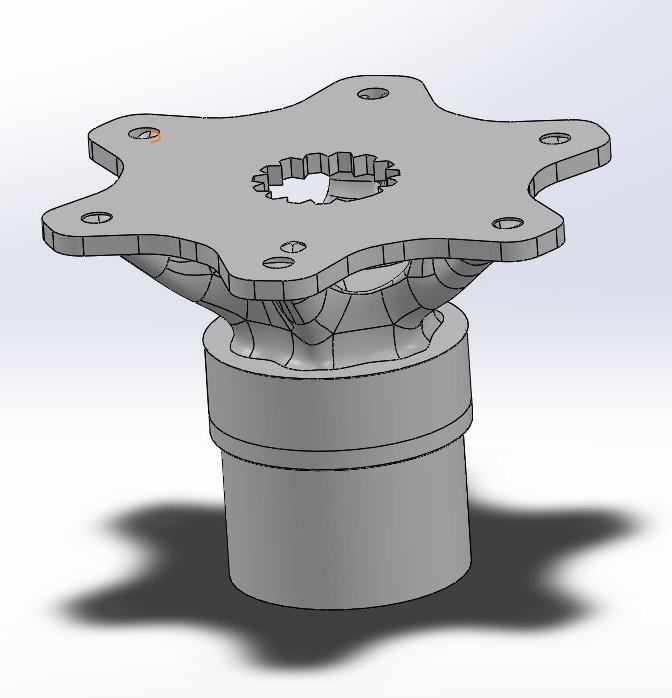

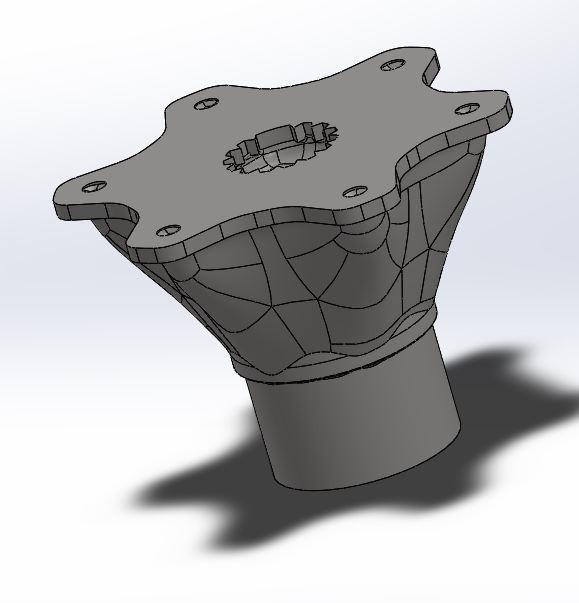

Figure: - Model of Steering wheel

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

ISSN:

0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

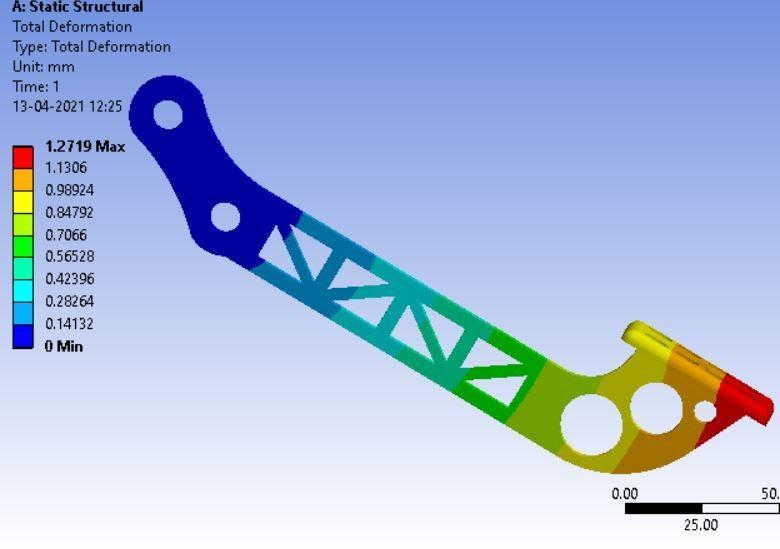

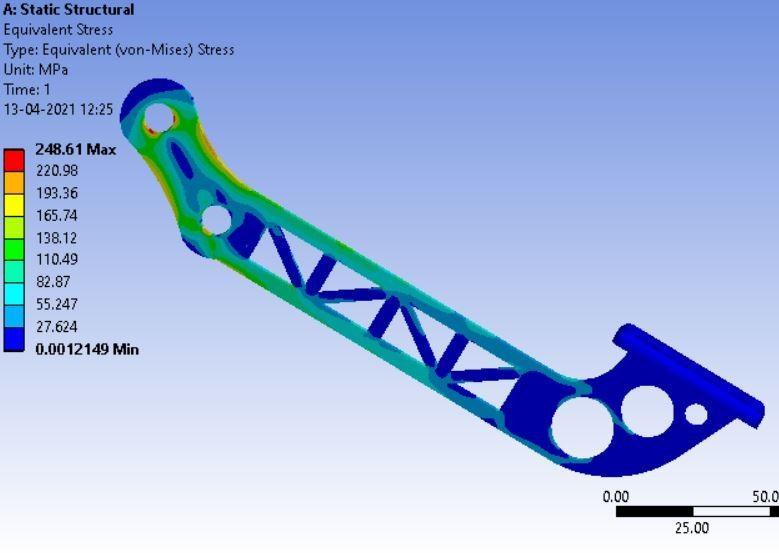

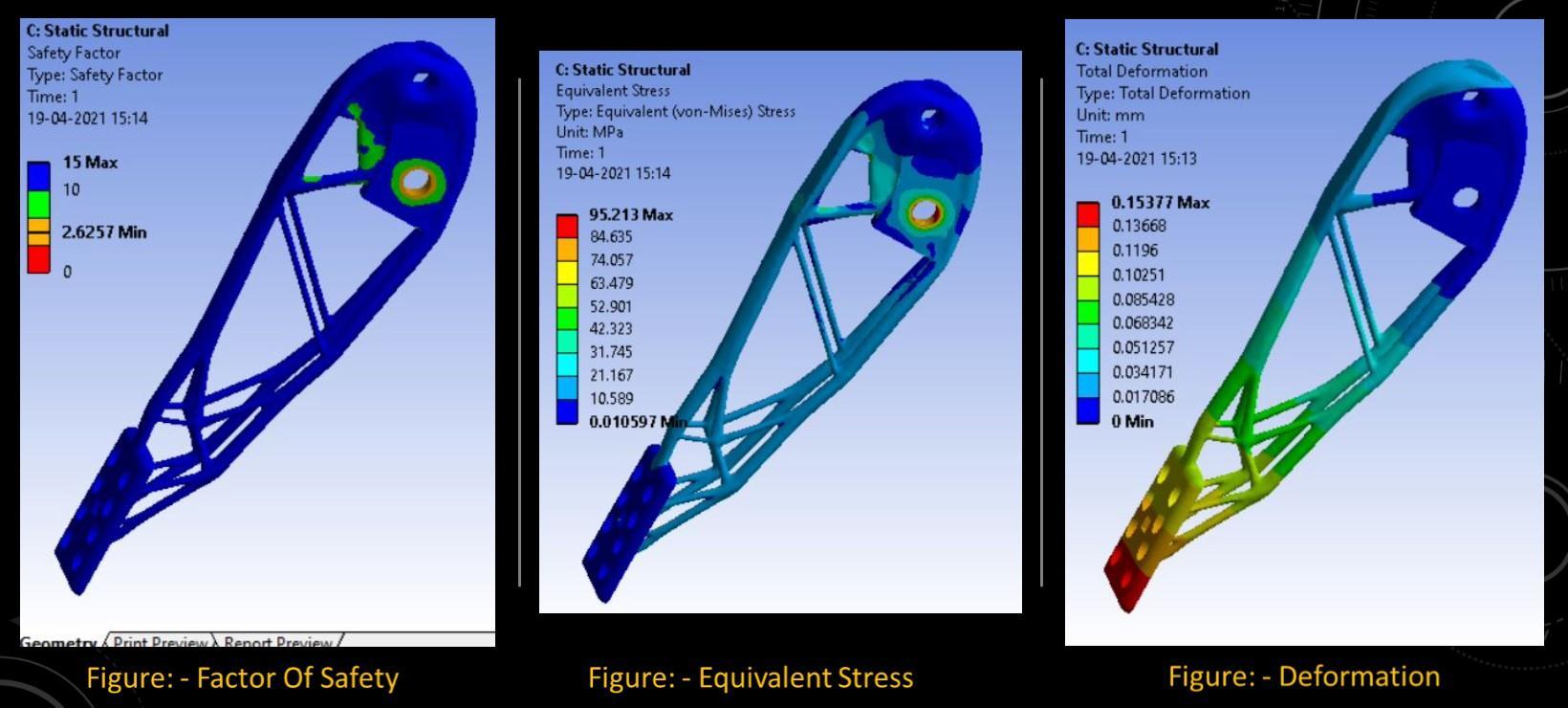

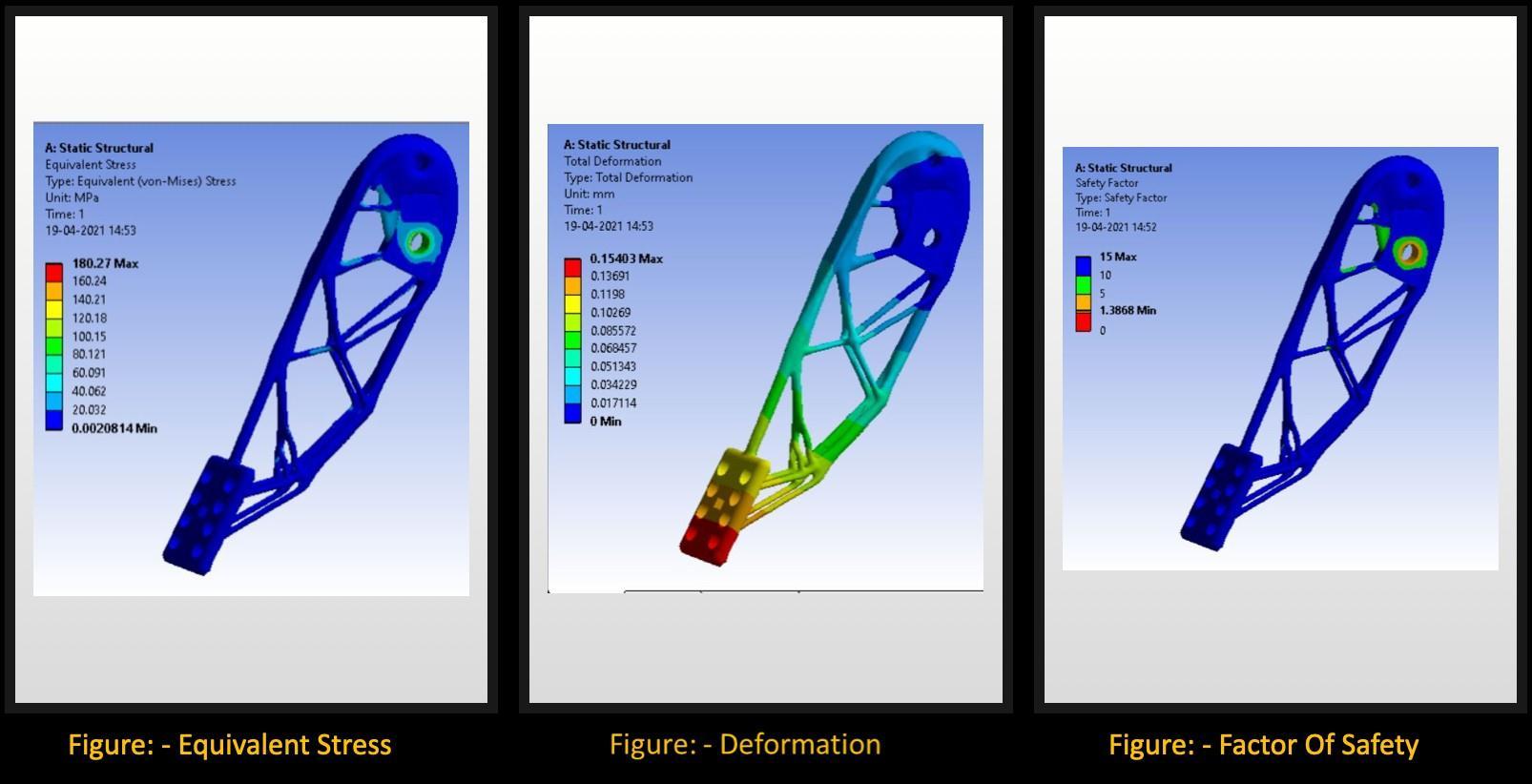

BRAKE PEDAL

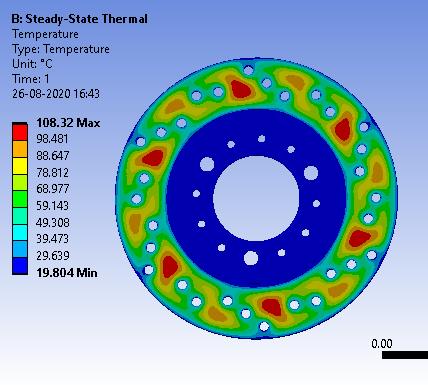

Figure: SteadyStateThermal

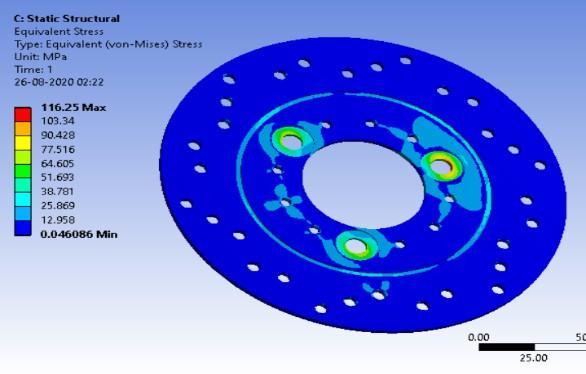

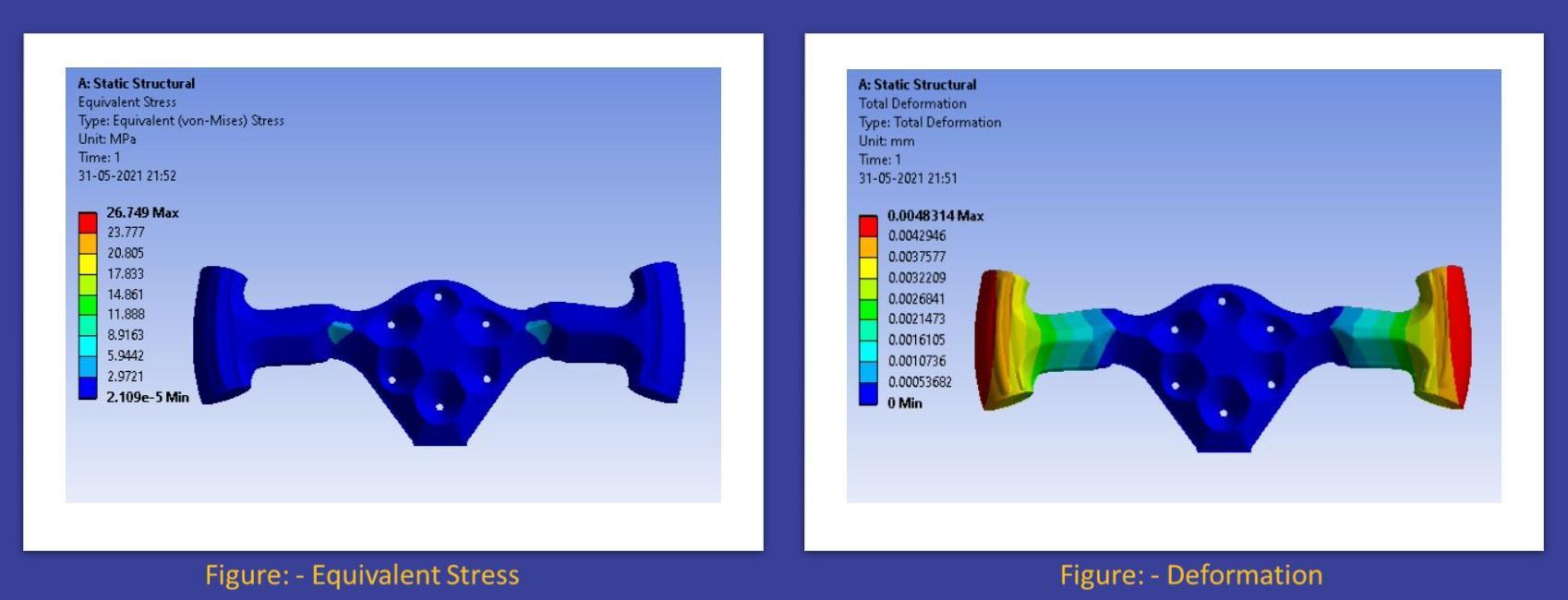

Figure: EquivalentStress

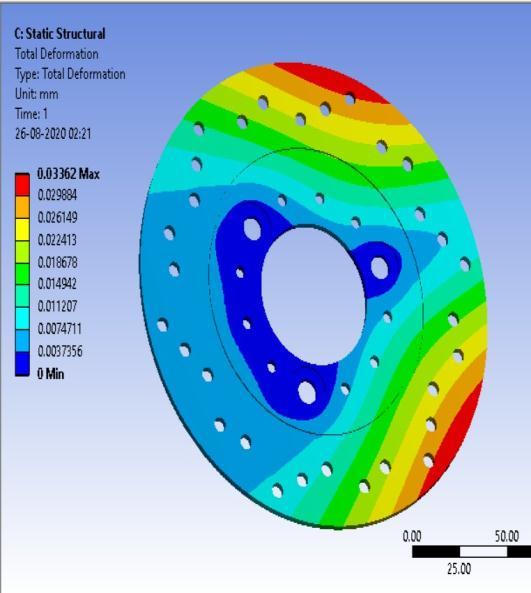

Figure: TotalDeformation

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Specifications: Volume = 30164.73mm3 Mass=81grams Analysis of Brake Pedal 2. Steering Wheel

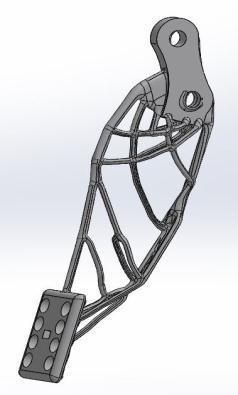

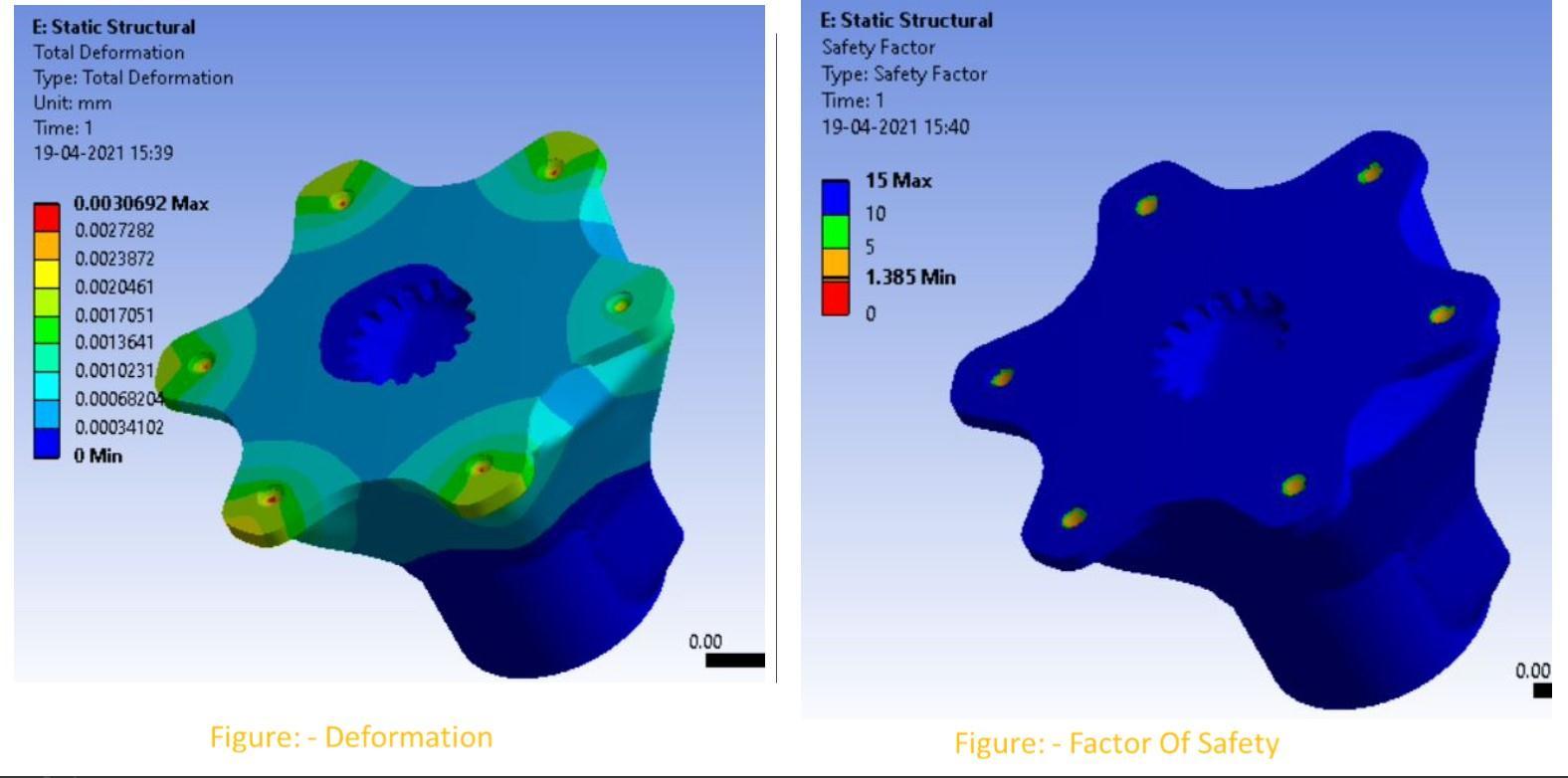

Specification: Volume = 326637.46 mm3 Mass=872grams

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

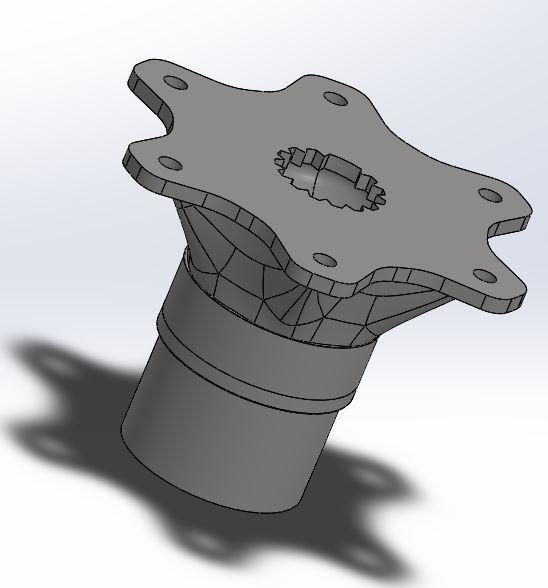

Specification: Volume=109316.98mm3 Mass=808grams

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

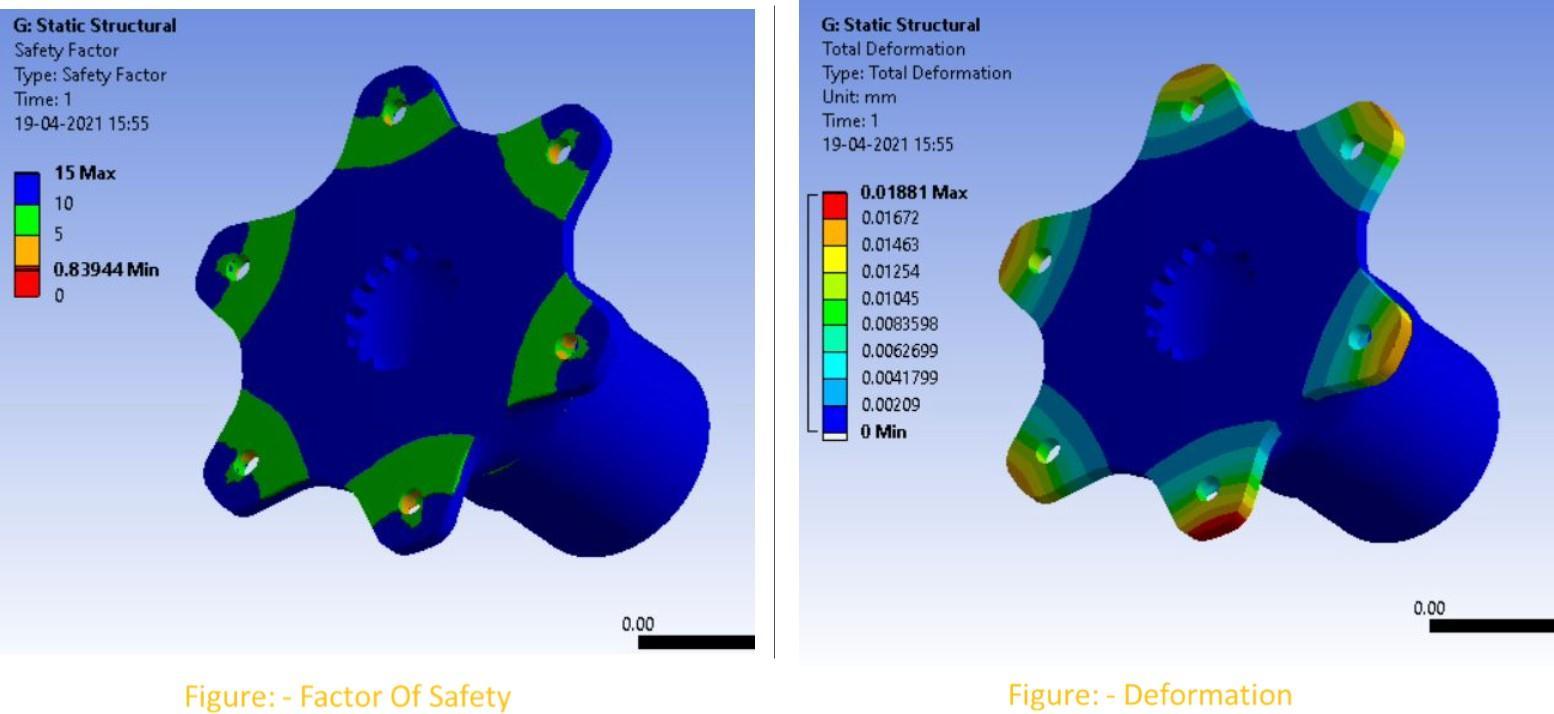

Specification: Volume = 71877.17 mm3 Mass=532grams

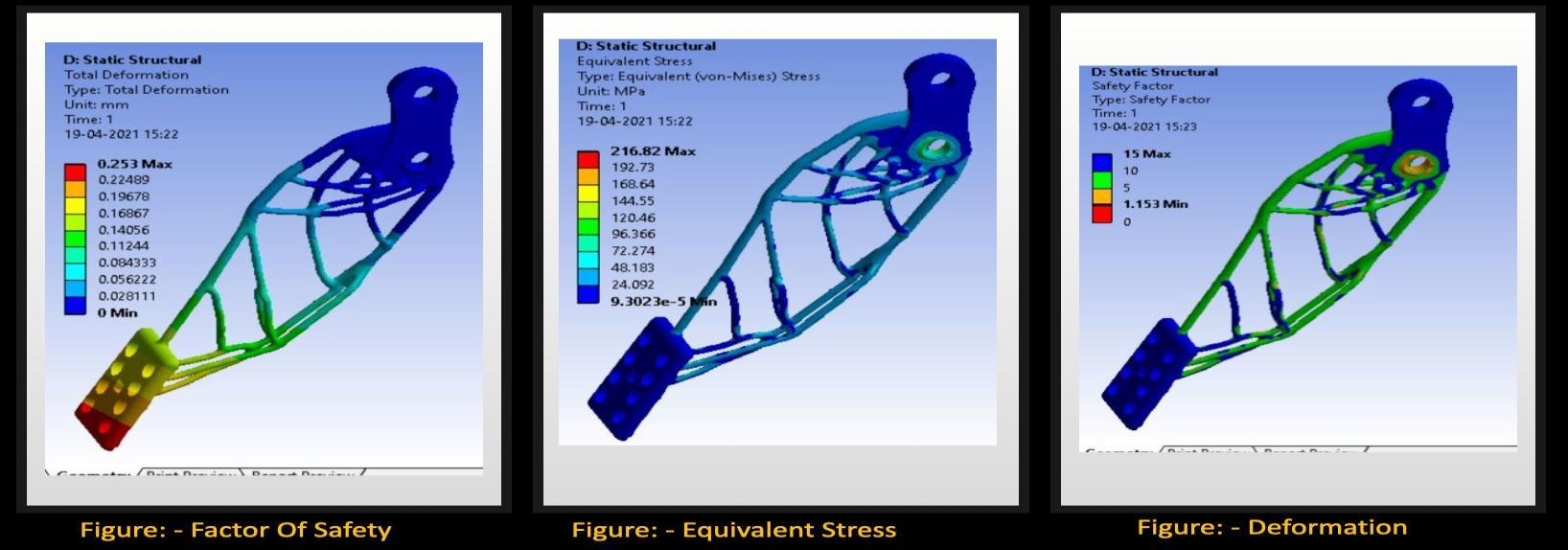

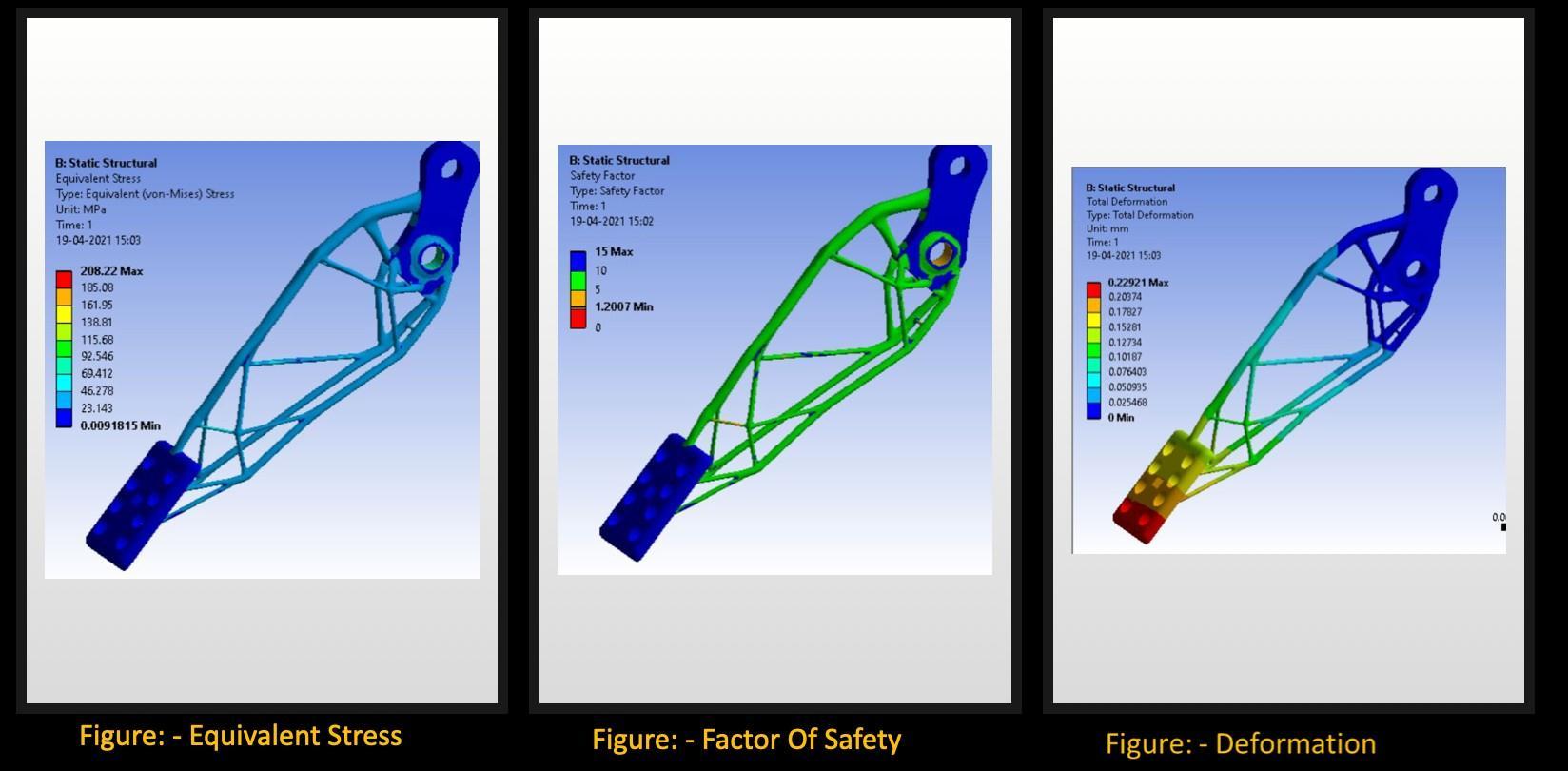

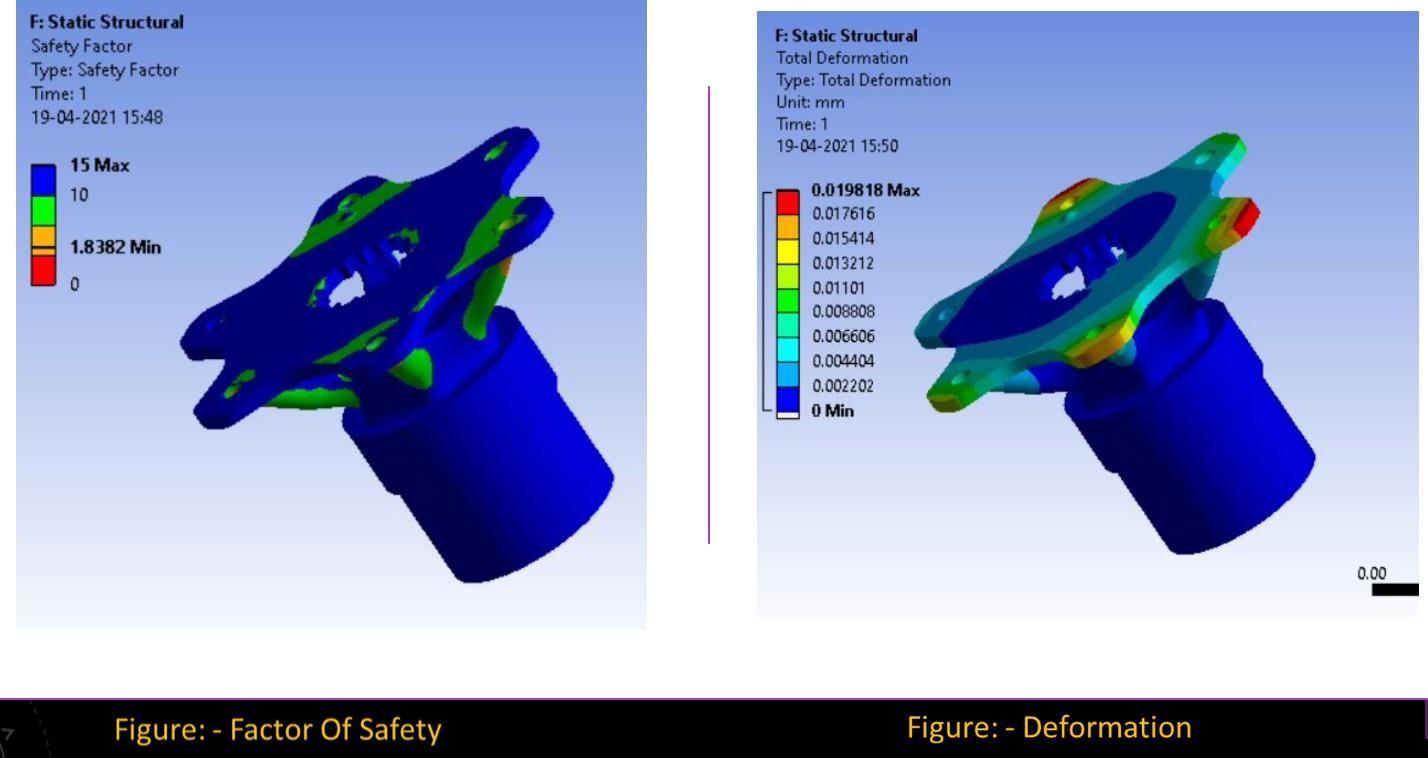

Analysis Of Steering Hub

• Inthispaperwehavediscussedthecalculationofsomebrakingparameterswhicheffecttheperformanceof ourvehicle,andweuseAL-7075T6fordiscbrake.Wegowithresults obtaininoursimulationonANSYS Workbench.Fromthesetofvariables,thebestresultsare found at deformation is 0.014503 mm, factor of safety is 1.89 and temperature at152.21Con4AL-7075T6with3.5mmthickness.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

• Inthecaseofthebrakepedal,theinitialweightofthecomponentwas296grams,thebestiterationtoobtain thehighestfactorofsafetywasiteration1withafactorofsafetyof 2.62.Theweightreductionwas58.78%fromitsoriginalweightage.

• Incaseofthesteeringwheel,theinitialweightofthecomponentwas2139.31grams,thebestiterationhasa factorofsafetyof7.62.Theweightreductionwas59.24%fromitsoriginalweightage

• IncaseoftheSteeringhub,theinitialweightofthecomponentwas1432grams,thebestiterationhasafactor ofsafetyof1.838(1stiteration).Theweightreductionwas89.8%fromitsoriginalweightage.

1. K.Sowjanya,S.Suresh,“StructuralAnalysisofDiscBrakeRotor”,InternationalJournalofComputerTrends andTechnology(IJCTT),Vol.4Issue7 July2013

2. NeerajSingh,R.S.Bharj,KamalKumar,“OptimumDesignandExperimentalAnalysisof BrakeSystemfor BAJAATV”,InternationalJournalofResearchinManagement,Science&Technology(E ISSN:2321 3264)Vol. 5,No.3,December17”.

3. VivekSinghNegi,NayanDeshmukh,AmitDeshpande,“DesignandAnalysisofBrakesystem”,International JournalofAdvanceEngineeringandResearchDevelopmentVol 4(11),November 2017”.

4. KushSoni,GaurangVara,IshitSheth,HarshilPatel,“DesignandAnalysisofBrakingSystemforISIEESVC”, InternationalJournalofAppliedEngineeringResearchISSN0973 4562Vol 13,Number10(2018)pp.8572 8576”.

5. NeerajSingh,R.S.Bharj,KamalKumar,“OptimumDesignandExperimentalAnalysisof BrakeSystemfor BAJAATV”,InternationalJournalofResearchinManagement,Science&Technology(E ISSN:2321 3264)Vol. 5,No.3,December17”.

6. VivekSinghNegi,NayanDeshmukh,AmitDeshpande,“DesignandAnalysisofBrakesystem”,International JournalofAdvanceEngineeringandResearchDevelopmentVol 4(11),November 2017”.

7. KushSoni,GaurangVara,IshitSheth,HarshilPatel,“DesignandAnalysisofBrakingSystemforISIEESVC”, InternationalJournalofAppliedEngineeringResearchISSN0973 4562Vol 13,Number10(2018)pp.8572 8576”.

8. VallamkonduArunKumar,SettyKalyan “ActiveSafetyBrakingSystem” InternationalJournalofScientific and Research Publications, Volume 3, Issue 12, December 20131 ISSN2250 3153

9. ISHWARGUPTA1&GAURAVSAXENA,“STRUCTURALANALYSISOFROTORDISCOFDISCBRAKEOFBAJA SAE2013CARTHROUGHFINITEELEMENTANALYSIS”,InternationalJournal ofAutomobileEngineering ResearchandDevelopment.

10. AkshatSharma,AmitKumarMarwah,“BrakingSystems:Past,Present&Future”,Vol.2,Issue 3,pp.29 31, March 2013ISSN 2250 1991