Design and Analysis of Brake Component

Akshat Ruhela1 , Aayush Srivastava2

1,2 Student, Department of Mechanical Engineering, ABES Engineering College, Uttar Pradesh, India *** Abstract - Theperformanceandsuccessofanyvehicledependontheabilityofitscomponentstofunctionproperlyunderany conditionssuchaswettrack,drytrack,andoff roadterrains.Theperformanceofthevehiclecanfurtherbeimprovedby making the components more robust along with the proper reduction in their weight. The safe operation of any vehicle requiresconstantadjustmentsofitsspeedunderchangingtrafficconditionsandthebrakediscisanimportantcomponentfor thedecelerationandmaintainingthespeedofavehicleundercontrolwhichincludesstopping.Thisresearchpaperstudiesan optimized design of the brake disc which aims at reducing weight and maintaining the strength along with reducing the deformationathighertemperaturesascomparedtotheOEMavailableinthemarket.Thebrakediscisbeingmodelledin SOLIDWORKSandanalysedviaFEAinANSYSforstaticandthermalloads

1. INTRODUCTION

Brakeisacomponentusedtodeaccelerateavehicle.MaincomponentsofbrakeareBrakepedal,mastercylinder,hydraulic pressuresensors,thebrakehoses,hydrauliccontrolunit(ECU),caliperanddisk. Brakepedaldesigningplaysaveryimportant factorintheforceanalysisofmastercylinderasthereisalwaysaspaceconstraintindesigninganATVresulting,thatdriver willnotabletoapplyforceonpedalsuchthatonregularvehicles.Duringbrakepedaldesignspaceconstraintandresting positionofadrivershouldbecomfortableforapplyingforcesufficienttodrivemastercylindertoitsfullstroke.

2. LITERATURE REVIEW

• [1]K.Sowjanya,S.Suresh,“StructuralAnalysisofDiscBrakeRotor”,InternationalJournalofComputerTrendsand Technology(IJCTT),Vol.4Issue7 July2013

• [2]NeerajSingh,R.S.Bharj,KamalKumar,“OptimumDesignandExperimentalAnalysisofBrakeSystemforBAJAATV”, InternationalJournalofResearchinManagement,Science&Technology(E ISSN:2321 3264)Vol.5,No.3,December 17”.

• [3]VivekSinghNegi,NayanDeshmukh,AmitDeshpande,“DesignandAnalysisofBrakesystem”,InternationalJournal ofAdvanceEngineeringandResearchDevelopmentVol 4(11),November 2017”.

• [4]Kush Soni, Gaurang Vara, Ishit Sheth, Harshil Patel, “Design and Analysis of Braking System for ISIE ESVC”, InternationalJournalofAppliedEngineeringResearchISSN0973 4562Vol 13,Number10(2018)pp.8572 8576”.

• [5]KKDhande,NIJamadarandSandeepGhatge July2014 “DESIGNANDANALYSISOFCOMPOSITEBRAKEPEDAL: AN ERGONOMIC APPROACH”, International Journal of Mechanical Engineering and Robotics Research (IJMERR), Volume3(3),pp.474 482.

• [6] Nand Mangukia and Nandish Mangukia 2018 “Design and Fabrication of Brake Pedal for All Terrain Vehicle “,INTERNATIONALJOURNALOFENGINEERINGDEVELOPMENTANDRESEARCH (IJEDR),Volume6(2),pp.562 568.

• [7] Miss. ASHWINI N.GAWANDE, Prof.G.E.KONDHALKAR, and Prof. ASHISH R.PAWAR , May 2017 “STATIC STRUCTURALANALYSISANDOPTIMIZATIONOFBRAKEPEDAL”,InternationalResearchJournalofEngineeringand Technology(IRJET),Volume:04(5),pp.3222 3227.

3. METHODOLOGY

Thisstudyiscompletedin2parts.Firstpartcoversthemodellingandanalysisofstressgeneratedinthecomponent,second partcoversthestudyofstressesandoptimisationofthebrakepedalthroughtheconceptofbiomimicry.CADmodelofthe brakepedalisdevelopedinSolidworksandtheFEAanalysishasbeencarriedoutinANSYSWorkbench2019R1.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1836

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Initial calculations and design considerations.

CAD Modelling (Creo parametric 5.0)

FEA Analysis (ANSYS Workbench 2019 R1)

YES NO Yes

Study of stresses generated

Optimisation of CAD Model Again FEA Analysis (ANSYS Workbench 2019 R1)

Design Evaluation Design Evaluation Final result and finish

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

t= t=0.96sec

Calculation for weight distribution and required braking force

RF =W×(a+coefficientoffriction*h)×cos( ) =2452.5× RF =1858.13N

MASS ON FRONT AXLE DURING DYNAMIC CONDITION

= = 189.41kg

Masstransferonfrontaxleduringbraking=189.41kg

Frontbrakingforcerequiredforfrontaxle= 189.41×17.34=3284.36N

Forcerequiredforeachwheel= =1642.18N

Torquerequiredforeachwheel= FFrontwheel ×Wheelradius = 1642.18 241.3 =396.25Nm

T Frontwheel=TFrontrotor

T Frontwheel =F rotor rotorradius FRotor = = Frotor =3635.32N

5. MATERIAL SELECTION

Thebrakepedalsaremadefromdifferentmaterialssuchcastiron,aluminium,andmildsteel.Adetailedstudywascarriedout toselect themostsuitable material dependingonthefactorssuchasavailabilityof material,Yieldstrength, weight,cost, weldability.AL 7075T6wasselectedoverGreybasedonavailability,cost,Yieldstrengthandfatiguestrength.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

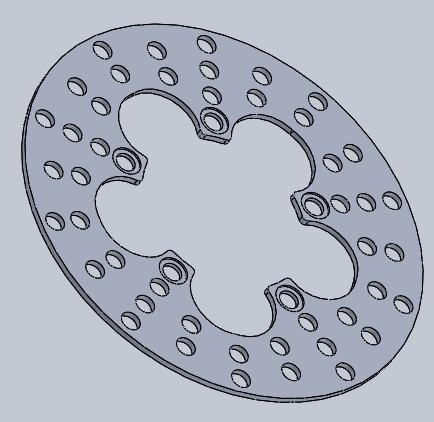

6. DESIGN: CAD MODELLING

TheinitialCADmodelofthebrakepedalhasbeencreatedinSolidworks2019.Itconsistsofmountingpointsforitselfand2 mastercylinders.Thedesignprocesseswerestartedwithdefiningandevaluatingallthedesignconstraints.

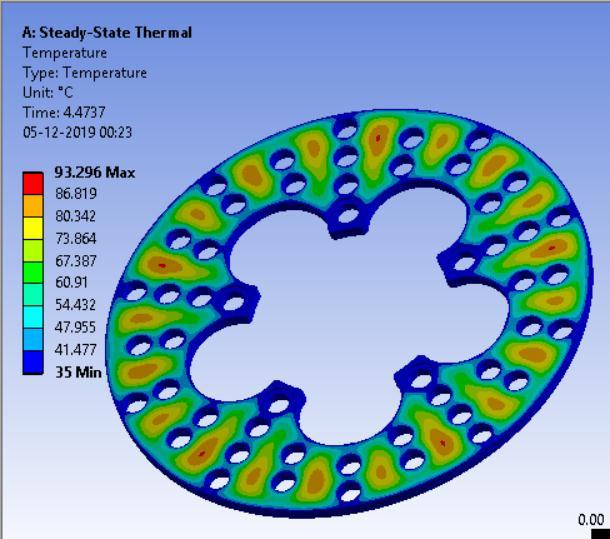

Fig1: ModelOfDiscBrake

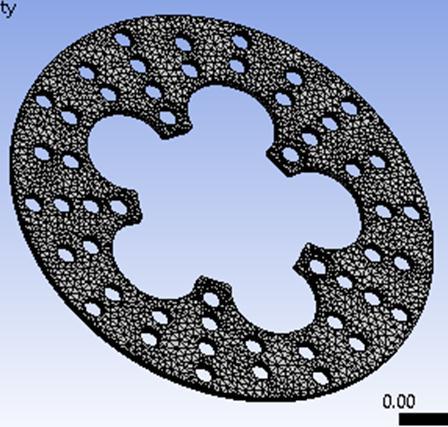

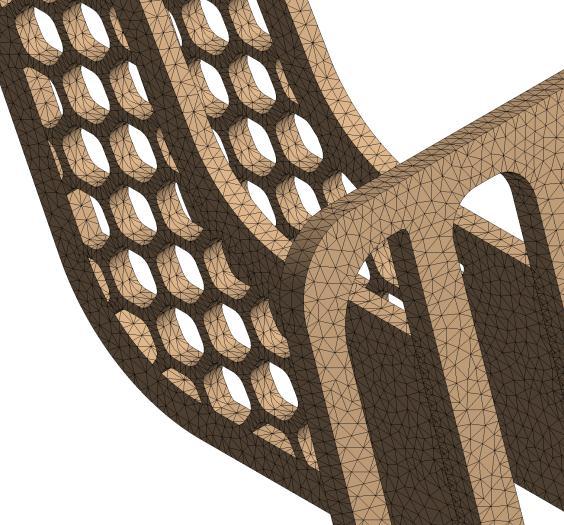

7. MESHING

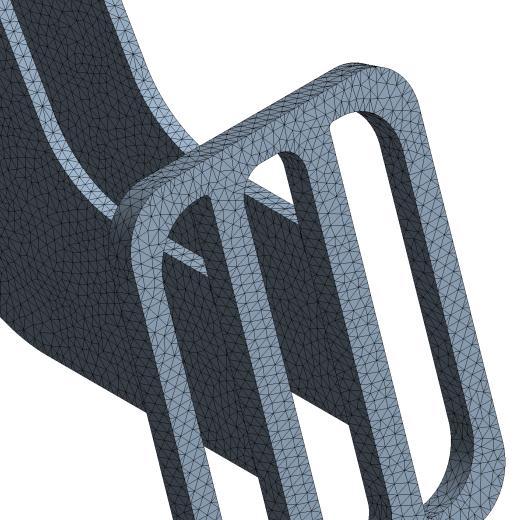

TheCADmodelisimportedintoANSYSWorkbench2019R1.Theautomaticmeshwithsize1mmisusedforthisstudy. Nodes 134283 Elements 73230

Fig 2:MeshModel

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

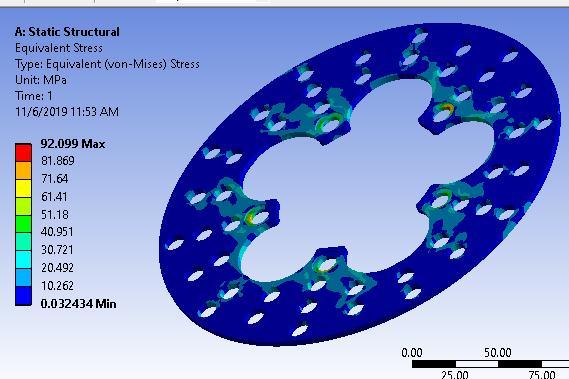

ANALYSIS

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

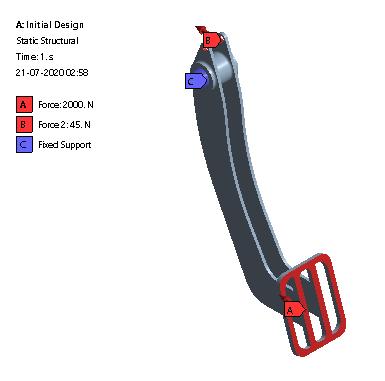

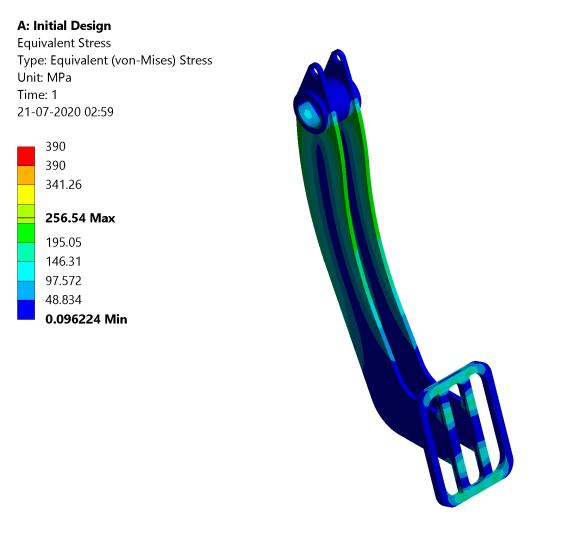

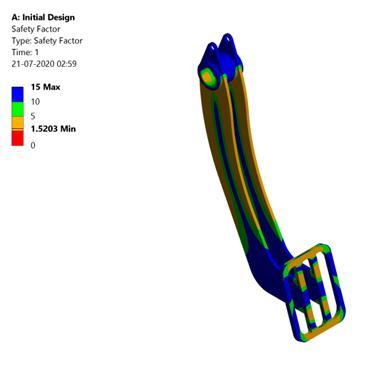

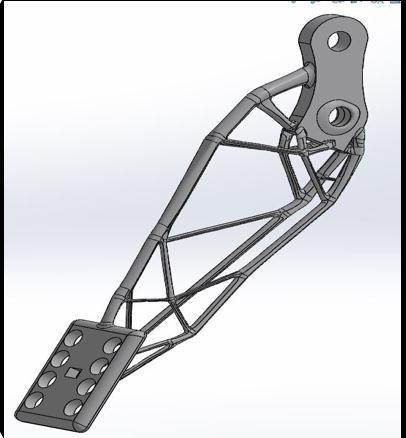

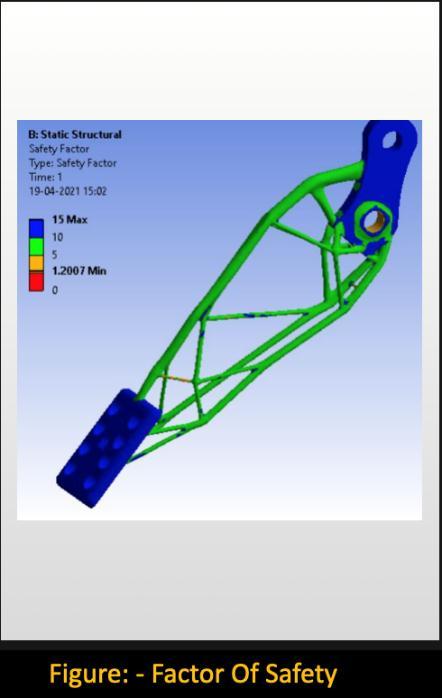

9. DESIGN: INITIAL CAD MODELLING: Brake Pedal

TheinitialCADmodelofthebrakepedalhasbeencreatedinPTCCreoParametric5.0.Itconsistsofmountingpointsforitself and2mastercylinders.Thedesignprocesseswerestartedwithdefiningandevaluatingallthedesignconstraints.Themodeof manufacturingforthisbrakepedalisweldingoflasercutparts.Thegeometryalsoincludesfilletsof4mmaroundthefootrest andpivotregiontorepresentweldbead.InitialCADmodelofthebrakepedalis

Nodes 134283 Elements 73230

Boundaryconditions:

Aof2000Nisappliednormallybydriverin xaxisonthefootrest.

Thepivotpointisfixed.

Forceof45Nisappliedin xaxistosimulatetheforcepresentedbymastercylinders.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

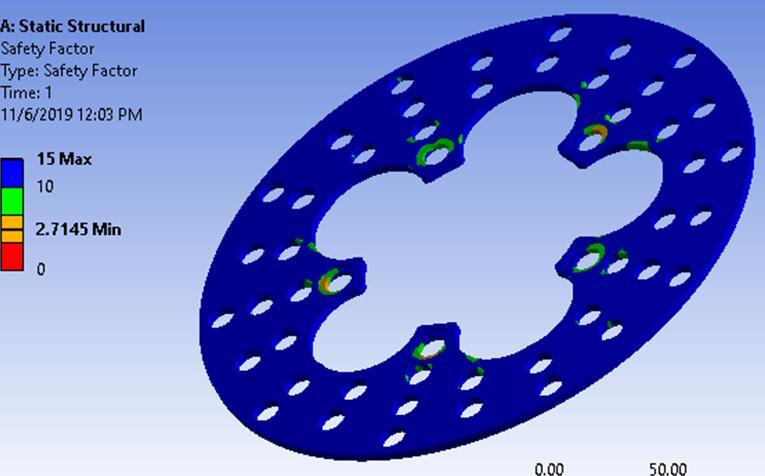

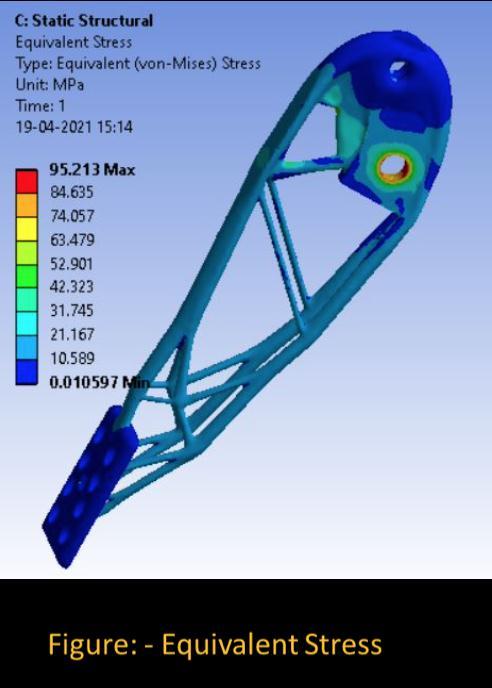

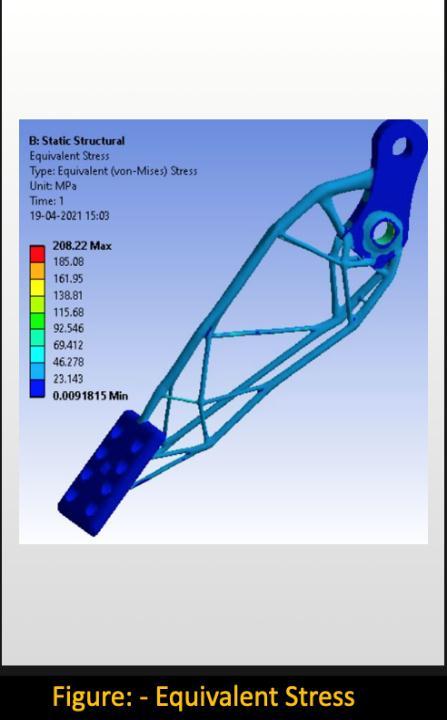

Study of generated stresses:

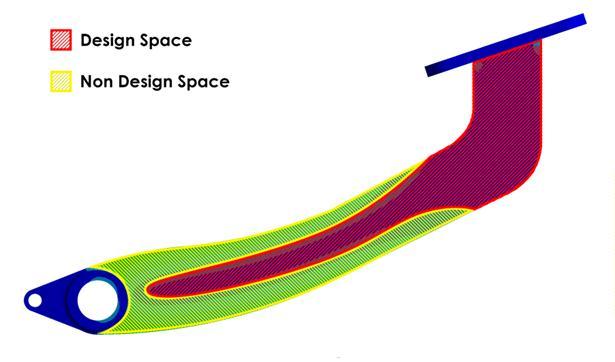

Thesecondpartofthisresearchincludestheoptimisationofbrakepedaltominimisetheweightofthecomponentandto remove extra material.Theinspirationforoptimisationwasdrawnfroma honeycombstructure.Ahoneycomb structure providesrigidityandefficientstressdistributionalongwithminimalweight.

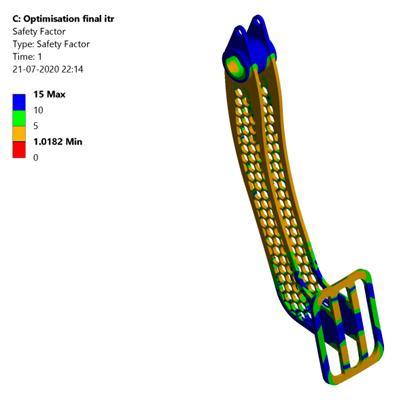

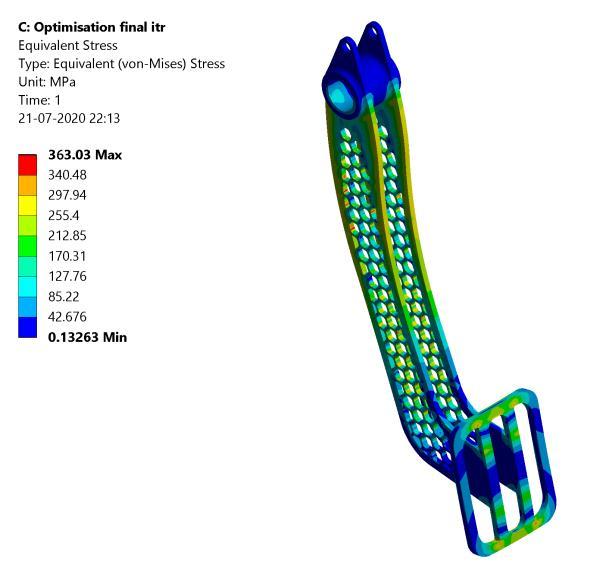

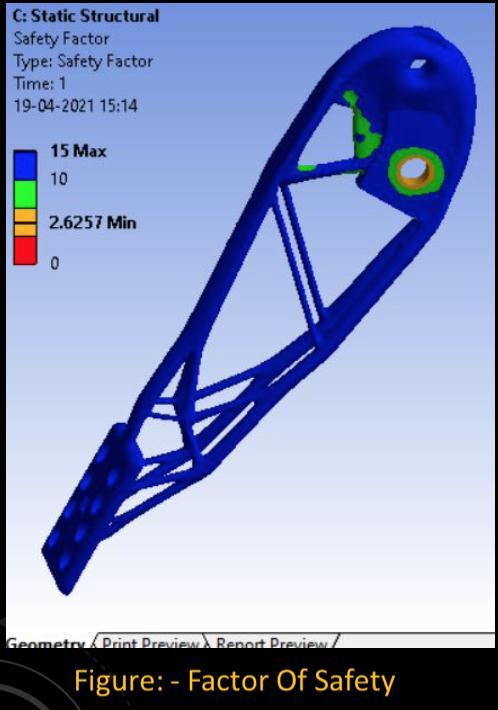

Thevon Misesstressesandsafetyfactorobtainedfromtheanalysisareusedtomaptheregionwheretheoptimisationstudy canbecarriedoutinordertoremoveextramaterial.TheregionwheretheoptimisationstudyisneededisshowninFig*.The Redregiondefinesthedesignspacewheretheoptimisationstudyiscarriedout;thestressesinthisregion arelowwhich

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1842

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

contributestohighsafetyfactorwhichinturnmeansthatthereisexcessmaterialavailableinthisregion.Theyellowregion enclosesthespacewherehighstressesarebeinggeneratedthusnooptimisationstudyisrequiredinthisregion.

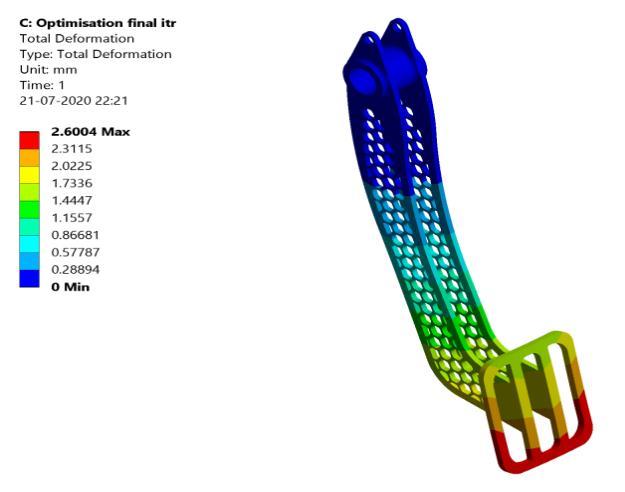

DESIGN: OPTIMISATION CAD MODELLING

TheoptimisedCADmodelofthebrakepedalhasbeencreatedinPTCCreoParametric5.0.Itconsistsofmountingpointsfor itselfand2mastercylinders.TheDesignspacehasbeenoptimisedwithahexagonallatticestructureforweightreduction. OptimisedCADmodelofthebrakepedalisshowninFig*\

ANALYSIS:

The Mesh and boundary conditions are kept same for the second analysis.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Results:

MaximumEquivalentvon MisesStress=363Mpa

MinimumSafetyFactor=1.02

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

10. CONCLUSION

1.Uponcomparisonitwasobservedthatthedesign2ofGenerativedesignModelhasthehighestfactorofsafetyforsimilar working conditionsi.e."2.6257" and weight of the brake pedal was reduced from "256 grams" to "122 grams" which is "52.34%"weightreduction.

2.Allstressesareunderallowablestressinstructuralanalysis.

3.Fromthesetofvalues,thebestoutcomesarefoundatdeformationis0.014503mm,stress 92.09MPaandtemperatureat 93.296ConAL-7075T6with5mmthickness

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

11. REFERENCES

[1]K KDhande,N I JamadarandSandeepGhatge July 2014 “DESIGN AND ANALYSIS OF COMPOSITE BRAKE PEDAL: AN ERGONOMIC APPROACH”, International Journal of Mechanical Engineering and Robotics Research (IJMERR),Volume3(3),pp. 474 482.

[2] Nand Mangukia and Nandish Mangukia 2018 “Design and Fabrication of Brake Pedal for All Terrain Vehicle “,INTERNATIONALJOURNALOFENGINEERINGDEVELOPMENTANDRESEARCH (IJEDR),Volume6(2),pp.562 568.

[3] Miss. ASHWINI N.GAWANDE, Prof.G.E.KONDHALKAR, and Prof. ASHISH R.PAWAR , May 2017 “STATIC STRUCTURAL ANALYSIS AND OPTIMIZATION OF BRAKE PEDAL”,InternationalResearchJournalofEngineeringandTechnology(IRJET), Volume:04(5),pp.3222 3227.

[4] MIM Sargini , SH Masood , Suresh Palanisamy , Elammaran Jayamani and Ajay Kapoor , “Finite element analysis of automotive arm brake pedal for rapidmanufacturing”, IOP Conference Series: Materials Science and Engineering, doi:10.1088/1757 899X/715/1/012020.

[5]Degenstein,Thomas,Winner,Hermann,“DynamicMeasurementoftheForcesintheFrictionAreaofaDiscBrakeduringa Brakingprocess”,Vol.2,pp.19,2006.

[2]AkshatSharma,AmitKumarMarwah,“BrakingSystems:Past,Present&Future”,Vol.2,Issue 3,pp.29 31,March 2013 ISSN 2250 1991

[3]K.Sowjanya,S.Suresh,“StructuralAnalysisofDiscBrakeRotor”,InternationalJournalofComputerTrendsandTechnology (IJCTT),Vol.4Issue7 July2013

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1846