International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Aditya Doshi1 , Bhargav Tewar2 , Nikunj Dave3

1Student, faculty of technology, CEPT University, Ahmedabad. 2,3 Professor, faculty of technology, CEPT University, Ahmedabad. ***

Abstract With rapid increase in population inIndia there is a growing demand in construction, but lack of land has led to increase in land prices. To suffice the landrequirement an idea of creating floating concrete islands is presented. Seven new mixes of floating concrete have been developed; each have a different densities under 1000 kg/m³. A scaled model of a platform has been created for testing and demonstration of the idea of floating islands. During the creationof the different mixes various factors like chemical reaction, w/c ratio, materials (properties), density, porosity, durability, etc. are taken into consideration. Different light weight aggregates are used with cement, fly ash, glass fibers and different air entraining agents. Concrete mixes having densities ranging from 700 kg/m³ 1000 kg/m³ have been developed. The concrete can achieve higher strength allowing us to use this low density concrete in structural components which would reduce the amount of raw material usage and reduce the dead load of the structure.

Key Words: Floating, Concrete, Density, Perlite, lightweight, dead load.

Floatingconcreteisalightweightconcretehavingadensity oflessthan1000kg/m³.Conventionalconcretehasadensity of around 2400 kg/m³. Floating concrete is made up of a mixture of cement, fly ash, light weight aggregates and admixtures.

The floating concrete can have a density ranging between 500 kg/m³ to 1000 kg/m³. Its lightweight property is suitable for use in non load bearing walls and can alsobe usedfor thermal insulation, sound insulation and product makingfornow.

There is a need for a material which is more durable and whose usage reduces the threat to the environment. The "Floating concrete" with density lesser than 1000 kg/m³ meetstherequirementstoreplacematerialssuchaswoodor anyothersimilarmaterialsfortheserequirements.

Floatingconcretecanbeachievedby:

1.1 By replacing the usual mineral aggregate by light weight aggregate [1]

Lightweight concrete can be achieved by using light weightaggregatestoreplacethecommonlyusedaggregates.

Lightweightaggregatessuchaspumice,perlite,vermiculite., havebeenusedforachievinglightweightconcrete.

1.2 By introducing gas or air bubbles in mortar (Aerated concrete) [1]

Aerated concrete is a low density concrete which is producedbyinsertingairorgasintoacement basedmortar. This can be achieved using foaming agents or using aluminiumpowderandheatingit.Thiswouldalsoresultina negativeeffectoflowerstrength

Theobjectivesofthisprojectare:

Toreplacelowdensitymaterialssuchaswood have been used in applications where the structuremustfloat(suchasinthebuildingof boathouses,canoes,etc.)

Toreducetheself weightof theconcreteand concretestructures.

Toexperimentwiththematerialsrequiredto developfloatingconcrete.

The floating concrete should be durable and water resistant without applying an outer coating.

Todevelopdifferentmixesforfloatingconcrete basedontrials.

Tocomparecompressivestrengthofdeveloped mixesandfindthebestmix.

Thistopiccontainsphysicalpropertiesofvariousmaterials usedthroughouttheexperimentalworkandtheprocedure adoptedbasedonthefactorsthatwillaffectthepropertiesof concrete.

Acementisabinder,asubstanceusedinconstructionthat sets and hardens and can bind other materials together.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Concrete whichisacombinationofcementandaggregateto formastrongbuildingmaterial.[1]

Flyashalsoactsasabinderandisusedtoreplacecement,it providesbetterstrengthandfinishinconcrete

Itisanaturalmaterialfoundinvolcanicregions.Itisusedto replace aggregates in concrete as it has a density of 1100 kg/m3.Itisusedtomakelightweightconcrete.

Itisareplacementforaggregatesasitisverylightinweight havingadensityof16kg/m3.

Foaming agent is mixed with water which introduces air voidswhenmixedwithconcretethusreducingitsdensity.[4]

Waterproofing agent provides a membrane so that water doesnotpenetratetheconcrete.

Aluminiumpowderwhenmixedwithconcreteitreactswith cementtoproducehydrogengaswhichformsvoidsinthe concretethusreducingitsdensity.

A glass fiber net or glass fibers are used in the mix to increase its tensile strength and also to provide reinforcement.

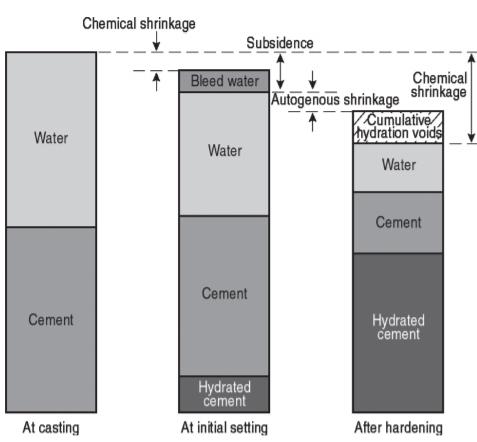

After casting the reactions start to take place and as time passesmorehydrationofcementtakesplace.

Figure 1: Concretecompositionwithtime[5]

At first there might be inter connecting voids but as time passesthecementhydratesmakingalayerbetweenvoids and also this layer might be very thin initially and so the sampleorproductshouldnotbedisturbedormovedasit might cause microscopic cracks that might lead to inter connectedvoids.

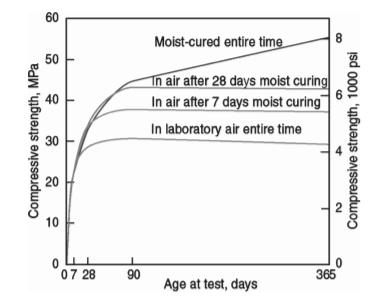

The graph below shows how the strength increases with time.

[5]

A misconception has been assumed by many that only 0.2 w/c is required for hydration of cement, but research has provedthatwaterisalsorequiredforthegelpoursifthese pours are not filled the C S H gel production also stops reducingthestrengthofconcrete.Sotheminimumw/cratio shouldbe0.4.[6]

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

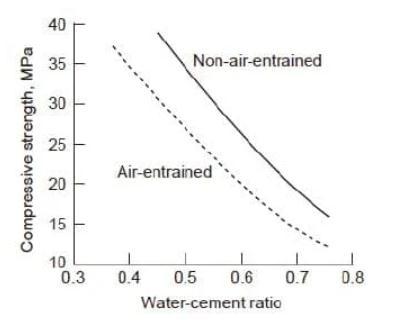

The compressive strength decreases with increase in w/c ratioand for floating concrete, strength is one ofthe main propertiessoleastamountofwatershouldbeusedbutthe concreteshouldalsobeworkable.

The porosity in the concrete decreases as hydration of cementprogresses.Atcompletehydrationthepastewillhave acertainamountofporosityasaresultofexcesswater.At very low overall porosities, the hardened material has a closedporestructure,theporesarenotinterconnected.At higher porosities, the pores become inter connected and form an open pore structure. The degree of porosity thus influencesconcretepermeability.

Figure 3: Effectofw/cratiooncompressivestrength.[5]

The initial density (24hr) of concrete is less than the final density(28days)ofconcrete,itisdueto: Hydrationofcementastimepasses Shrinkageofconcrete

So,thisfactorhastobetakenunderconsiderationwhena mixisdesignedforfloatingconcrete,iftheinitialdensityis just a little less than 1000 Kg/m3 but as time passes the densityreachesabove1000Kg/m3duetoshrinkagewhich wouldcausetheconcretenottofloatanymore.

Most lightweight aggregates absorb water, and thus more waterisrequiredbutitalsohelpsininternalcuringofthe concrete.

In floating concrete due to this perlite has been used as it doesnotabsorbasmuchasotherlightweightaggregates,so it does it helps in internal curing of concrete but does not increasethedensityverymuch.

Having thinlayers between the voidsgreatcareshouldbe taken for the initial 7 days so no microscopic cracks are created. Floating concrete being porous is resistive to freezingandthawing.

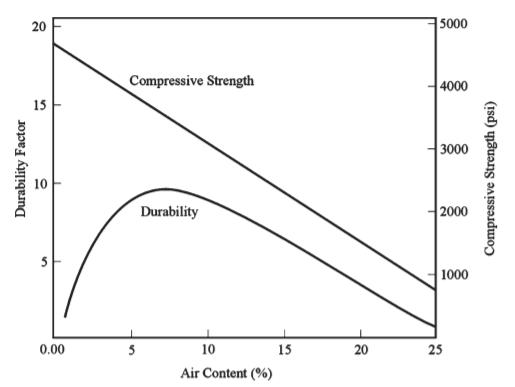

Figure 4: Effectofaircontentoncompressivestrengthand durability[5]

Researchshowsthatalossof5%incompressivestrengthof concrete occurs when1% by volume of entrained air is introducedintheconcrete.

Figure 5: Freshconcreteshowingairbubblesthatare createdduetofoamingagent

Duetothistheporositymustbekeptatalevelwheremax porositycanbeachievedwithoutinter connectingvoids.

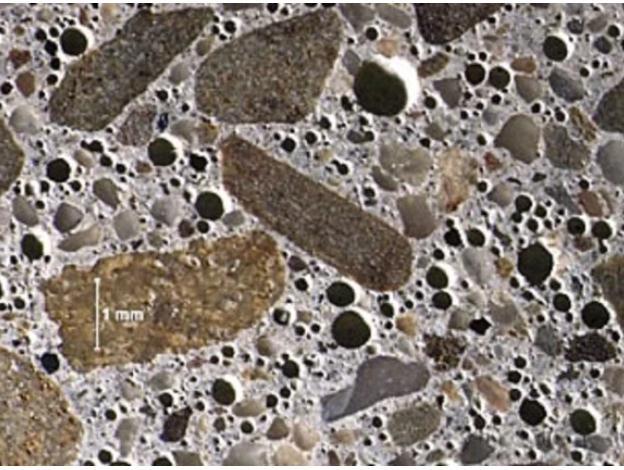

Figure 6:

viewofconcretewithairvoids[5] Duetothefoamingagenttheporosityincreasesandsoafter castingthecompactiondoneshouldbeminimum.Themost importantpartinthemixisthemixingoffoamingagentand theamountused.

The method of mixing adopted is weigh batching using mortarmixtureandpanmixturedependingonthequantity.

Calculated quantities (all quantities are weighed) of the materialsweremixedwithrequiredw/cratioandkeptaside.

Drymixcontainingcement(+flyashifused)andaggregates (ifany)ispreparedandmixedfor2minutes.Thenwaterand otherfluids(ifany)areaddedandmixedforhalfminutethen the foam that is made before hand by mixing water and foaming agent is added and mixed for 1 min. Then it is transferredintothemoldandkeptonthevibratingtablefor lessthanaminute.

Thisprocedureisadoptedtocastthespecimens.Placethe mouldsonthevibratingtableandpourthewetconcretemix insidethemouldsinthreelayers.Compacttheconcreteby boththroughhandcompactionusingtampingrodandtable vibrator. Vibration should not be more, otherwise segregationwouldhappen.Afterfillingthemouldswithwet concrete, level the surface. Demold the specimen after 48 hours.

Incaseifaluminumpowderisusedtheprocessremainsthe sameinthestart,insteadoffoamingagentaluminumpowder isaddedafterthewetmix.Thenthemoldisfilledtohalfthe levelwiththeslurryandkeptintheovenat80degreesfor 6hrs,inthistimethealuminumpowderreactswithcalcium hydroxide to produce hydrogen gas which forms the individualvoidsinconcrete.

Thetestsconductedarespecificallyforfloatingconcrete

After7days,thecubesareweightedandallthedimensions aremeasured,thedensityiscalculatedandifthedensityof thecubesarelessthan1000kg/m3thenfurthertestscanbe conducted.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Table 2:Densitiesfordifferenttrials

Trial no. Density (Kg/m3) 21 850 22 730 24 830 28 880 29 920 30 840 32 970

3cubesareplacedinwaterafterlettingthemstayinaroom for7days,tocheckifitfloats.Ifthey float,thenamountof waterabsorptionmustbemeasured.Theabsorptionshould onlybeonthesurface,soplacethecubeinwaterfor24hrs. Removethecubefromthewaterletitsurfacedryforafew minutesandweightit.Thedifferenceinweightismeasured andtheamountofwaterabsorptioniscalculated.

Table 3: Waterabsorption%fortrials.

Trial no. Water absorption %(w/w) 21 1.6 22 1.92 24 1.44 28 1.18 29 0.92 30 1.4 32 0.86

ThespecimencubetestisplacedintheCTM,andtheloadis applied,andthecompressivestrengthisfound.[2]

Table 4: Compressivestrengthfortrials.

Trialno. Compressivestrength(N/mm2) (7 daytest) (28 daytest) 21 1.81 2.92 22 1.6 2.51 24 2.53 3.90 28 4.34 6.62 29 3.54 5.45* 30 3.63 5.58* 32 6.76 10.40*

*Not tested, it is calculated with reference to 7 day test

Table 5:Comparisonwithnormalconcrete

M25 M20 M15 FC Unitcost (Rs./kg)

Density (Kg/m3) 2400 2400 2400 970 Cement(kg) 470 350 280 450 5.5 Flyash (kg) 80 60 40 100 1.2 Sand (kg) 550 600 650 0 1 Aggregate (kg) 1080 1220 1300 0 1.2 LWA (kg) 0 0 0 210 4.5 foaming agent(kg) 0 0 0 1.6 80

Water(0.4) (kg) 220 170 130 210 7 day strength (MPa) 16.25 13 9.75 6.76 28 day strength (MPa) 25 20 15 10.4* Unitcost (Rs./m3) 4,527 4,061 3,798 3,668

*Nottested,itiscalculatedwithreferenceto7 daytest

Thecomparisonshowsthatfloatingconcreteuseslesserraw materials than conventional concrete and it is economical whenproducedinbulk.

Withlowerdensityithasachievedacompressivestrengthof 10MPa,withfurtherresearchandexperimentationhigher compressivestrengthcanbeachieved.

The following observations were made based on the experimentsconductedonfloatingconcrete.

1. More the amount of foaming agent, the density decreases but the strength also decreases. The compressivestrengthdecreaseswiththedecreasein density.

2. Ifthereareinterconnectingvoidstheconcretewill absorbthewatertofillthevoidsandthespecimen willnotfloat,soitisimportantthattheconcretehas

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

individualvoidwhichisgovernedbytheproportion offoamingagent.

3. The specimen should be handled with care as it takes time to reach itsfinal strengthandwhile its gainingstrengthifitisnottakencaretherewillbe minorcracksinsidewhichwouldconnectthevoids.

4. Ifaluminumpowderisusedthew/cratioshouldbe high and very well mixed. The powder forms individual voids and provides good strength concrete.

5. Aluminumpowderisrecommendedbutitrequires tobeheatedtoahightemperaturebeforeitcanbe used.

6. Thermocoldoesnotbondwithcementinconcrete.

7. Ifcuringisdoneusingconventionalmethods,itwill increasethedensitybyfillingwaterinsidethevoids.

6. Flyashisusedasapartialreplacementofcementto increasethestrength.

7. Aluminumpowderisusedinsteadoffoamingagent.

8. Curingagentshouldbeusedornocuringshouldbe donefor14days.

9. Higher strength can be achieved with further experimentationwhichcouldleadtomakingdurable floatingislandsandalsohelpreducedeadloadsin structures.

Figure 8: 7Successfulmixdesigncubes

Basedonthestudydone,thefollowingconcludingremarks aremade

1. Above mention 7 mix design were experimented floatingconcrete

2. Perlitecanbeusedasalightweightaggregates.

3. Foamingagentusedshouldbeinproperproportion, iflessthedensitywouldbehigherthanrequiredand if more is used the concrete obtained will be too brittle.

4. Glassfiberisusedtoincreasethetensilestrengthof concrete

5. Thermocolasalightweightaggregateisnotfound successful.

1.Floatingconcretewithhighercompressivestrengthsoit canbeusedasstructuralelements.

2.Floatingconcretewithothercementitiousmaterialshaving lowerspecificgravity.

3. Floating concrete of larger dimension, and be used as platforms for houses, agricultural farms or solar farms, floatingislands,etc.

4.Developmentofsmallproductsmadeoffloatingconcrete forarchitecturalpurpose.

5.Furtherresearchintodesigningoflargescaledplatforms

6.Developmentofadmixturetohelpachievehigherstrength offloatingconcrete.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[1] Thousif Khan, Ibrahim Killedar, Sharu Malik H N, MuhathasheemRF,JagannathaGM,Dr.ShivakumaraB. AnExperimentalStudyonFloatingConcreteUsingLight Weight Materials. https://www.irjet.net/archives/V5/i5/IRJET V5I5444.pdf

[2] BUREAUOFINDIANSTANDARDS.(2004). IS516 1959:MethodofTestsforStrengthofConcrete.IS516 1959:MethodofTestsforStrengthofConcrete.

[3] Arpit Sharma, ManaliSehrawat, Kamaldeepsingh, MadhurSaraf. Floating concrete by using light weight aggregates. https://www.journalcra.com/sites/default/files/issue pdf/22553.pdf

[4] Foaming Agent (admixture) https://www.fairmate.com/productscategory/products detail/1/4

[5] Boyd, A. J., &Skalny, J. (2007). Environmental deterioration of concrete. In Environmental Deterioration of Materials. https://doi.org/10.2495/978 1 84564 032 3/05

[6] Mather, B., &Hime, W.G. (2002). Amount of Water RequiredforCompleteHydrationofPortlandCement.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal