International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Gokhul.K 1 , Usha.S 2

1Department of Mechanical Engineering PG, M.E. Thermal Engineering, Government College of Technology, Coimbatore 641 013, Tamil Nadu, India.

2Assistant Professor, Department of Mechanical Engineering Government College of Technology, Coimbatore 641 013, Tamil Nadu, India. ***

Abstract - Solar energy represents a great potential of renewable energy source in the world. The solar irradiation and the ambient temperature affect the output power of photovoltaic (PV) system. The efficiency of solar panels decreases whenthe temperature ofthe solar panels increases. In order to control and maintain the operating temperature, coolingofPV module shouldbecarriedout.Thethermoelectric effect is the effect in which the difference in temperature produces anelectricpotential.Thermoelectricdevicesareused to convert thermal energy into electrical energy by which it acts as both generator and cooler. Bismuth Telluride (Bi2Te3) is the frequently used thermoelectric material for the applications working at room temperature. In this project work, graphene as a thermoelectric material is analyzed and compared with bismuth telluride. The analysis of this project work eventuates that the graphene based TEG/TEC, gives larger current output and absorbed heat than Bismuth Telluride.

Key Words: PV module, Bismuth telluride, Thermoelectric, graphene, PV cooling

Inthisindustrial era,mainsourceiselectricityanditis being obtained majorly from fossil fuels. This led to large consumptionoffossilfuels.Therefore,itisinevitabletoshift to renewable energy sources from fossil fuels. Among the renewable energy sources, solar energy is prominent and used worldwide. Almost for all the renewable energy the source is sun. The solar energy from the sun can be convertedintoelectricitybymeansofphotovoltaiccell.

Theefficiencyofthesolarthermalconversionsystemis ranging from 40 to 60 % and that of photovoltaic cell is between10and20% [1,2].PVcellsproduceelectricitywhen thewavelengthrangesaround400 to700 nm [3,4].Usually theshorterwavelengthhashigherenergyphotons,butthe high energyphotonswilldamagethephotovoltaiccell.The generation of electricity from the PV cells is increased by decreasingtheoperatingtemperature[5 7].Also,thelifeofPV getsincreased,sothatwegetmoreelectricity.

The solar panel gets affected by various environmental factors such as ambient and module surface temperature, shading, sunlight, wind speed, humidity, dust, etc. But the importantfactorhereissolarirradianceandtemperature. The material of solar PV cell also plays major part in the efficiency,variousresearcheswerecarriedoutbycomparing thematerialssuchasMAPbI3,CdTe,andGaAsandresulted perovskite poly crystalline do better than inorganics [8].WhenthePVcellgetsheatedupmorethantheoperating temperature, the electricity generated is decreased. Since, energyfromsunisenormous,only5 20%isconvertedto electricity [9,10].Remainingoftheenergyisabsorbedasheat which gives rise to the cell temperature up to 70°C. This affects the properties of solar cells and decreases their efficiency.CoolingofPVmoduleshenceincreasetheannual performance ofPV.RatherthancoolingofPV module,the thermalwastecanbeusedbyaffixingthermoelectric(TE) converters to the backside of PV modules. Due to the differenceintemperatureintheTEconverterelectricitycan begenerated.

TE technology has gone through stages of important research and growth. The See beck, Peltier and Thomson effects were first identified between 1821 and 1851, and their applications to thermometry, power generation and refrigeration were recognized [11]. The thermoelectric technology hasincreased slowlyup tothe1930’s, the fast developmentsinmajorareasofTEhappenedandinthemid 1960’s, thermoelectric devices are developed for applications in the cooling of aerospace and space craft power.Developmentinimprovingefficiencywasretarded and research has gone high in 1963, and again a narrow declineinTEresearchaboutthreedecades [12].Butin1990 there was again interest in thermoelectric technology because of factors combination, also due to the environmental concerns regarding refrigerant fluids, alternative refrigeration and cooling of electronics [11] Recently, the thermo electric materials research has been developedtoaextentwhereflexiblematerials,conducting polymersaredesigned.[13]

Inthisprojectwork,forcoolingofsolarpanel,Thermo electric cooling method is followed and graphene as a thermoelectric material is analyzed and compared with bismuthtelluride.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

TheperformanceofThermoelectricgeneratorsandThermo electriccoolersdependonthedimensionlesstermZTwhich is a thermoelectric property of material used in correspondingdevices,alsoknownasthermoelectricfigure ofmerit.

2 ZTSTk

whereSisSee beckcoefficient,σiselectricconductivity,k is thermal conductivity of material. Itis nowclear that for greaterthermoelectriceffectmaterialselectionisimportant. Z, See beck coefficient is defined as the amount of voltage inducedduetothetemperaturegradientacrossthematerial anditisdescribedasS=V/ΔT.Thetemperaturedifference (ΔT)canbeachievedbetweentheroomtemperatureandany wastesourceofheatsuchasexhaustinheatengine [14] .

Bismuthtellurideisthewidelyusedmaterialformostof the Peltier devices and thermoelectric generators. This is because around room temperature Bi2Te3 (alloys with Sb2Te3 as p type and Bi2Se3 as n type material) has the highest thermoelectric figure of merit, zT, of any material. BismuthTelluride(Bi2Te3)isthemostlyusedTEmaterialfor anyapplicationworkingatroomtemperaturewhichhasSee beckcoefficientapproximately 149μv/°c.(maximumvalue 288μv/°cat540°catambienttemperature)

Inrecentyears,wehaveseenaampleinteresttowardsthe electrical properties of graphene. Graphene has unique propertiessuchashigherthermalconductivity,fastmoving electronsandcanbeusedinnanoapplications[15].Thefigure ofmeritisdirectlyproportionaltotheoverallperformanceof TEG.Hence,graphenehasagreaterchanceregardingTEG. HigherelectricalconductivityandlargerSee beckcoefficient andlowthermalconductivityisnecessaryforamaterialto attainthermoelectricfigureofmerit.Hence,figureofmeritof the material’s also depends on power factor, given in equation (2). In solids, conduction is happening by the vibration combinations and molecular collisions, phonons propagationandcollisions,andoffreeelectronsdiffusionand collisions. Thus, the thermal conductivity of solids are as follows, 2PS

kt is total thermal conductivity, ke is electronic contribution to thermal conductivity and kph is thermal conductivityduetophononconductance.Phononisdefined as“collectiveexcitationinaperiodic,elasticarrangementof atomsormoleculesincondensedmatter,likesolidsandsome liquids,oftendesignatedaquasiparticlewhichrepresentsan excitedstateinthequantummechanicalquantizationofthe modes of vibrations of elastic structures of interacting particle”.Graphenehasanadvantageoftransportproperties asapossiblethermoelectricmaterial,buthasalimitationdue to high thermal conductivity. In graphene, the main factor limitingtheTEconversionisthehighthermalconductivityby phonon. So, graphene has a low figure of merit with high powerfactor.Theusualideatoenhancefigureofmeritisto placephononscattererstoreducetheconductanceofphonon whilemaintaininghighelectricalconductanceandSee beck coefficient. Table: 2.1 Thermo electric properties of Bismuth telluride and Graphene

A model is designed to perform a comparative analysis betweenthethermo electricmaterialsBismuthtellurideand graphene. For simple design and analysis purpose, with standarddimensions,thethermo electriccoolermoduleis attached to copper alloy and total current density and temperatureanalysisiscarriedout.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

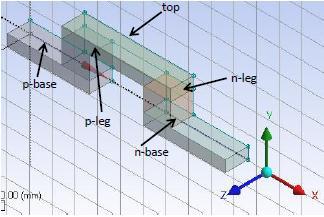

Fig:2.1 Parts of the Model

Table 2.2 Dimensions of the model

NAME DIMENSION

Baselength 36mm

Baseheight 5mm

CopperalloyLength 54mm CopperalloyHeight 5mm

PandNtypeTECLength 10mm

PandNtypeTECHeight 10mm Width 10mm

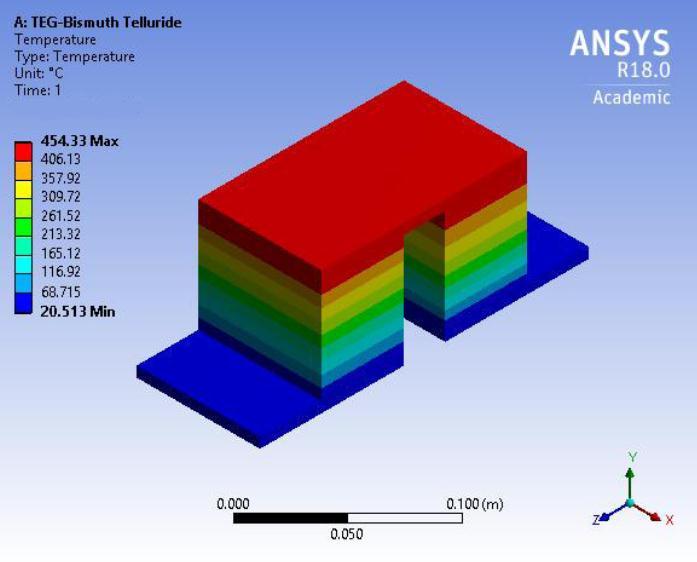

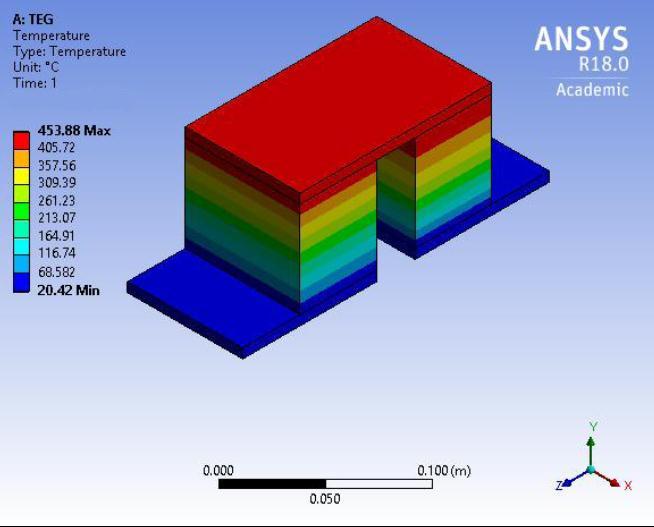

To run a simulation of Thermo electric Generator and Thermo electricCoolerinAnsys,afundamentalmodelwitha single cell was designed. This fundamental model was designedinfollowingtheregularmodelofThermo electric Cooler (TEC) with Bismuth Telluride (Bi2Te3) but in an amplifiedscaleofasinglecell.Twosimulationsarecreated, one with the regular Bi2Te3 and the other is graphene in speculationwithBi2Te3.Thesamegeometrywillbeusedin both simulations. The geometry was imported to design modelerofAnsysworkbench.Theboundaryconditionsatthe hot junction and cold junction temperatures were also maintained same in both simulations. The boundary conditionsforthedesignedmodelaregivenasperthetable (2.3)

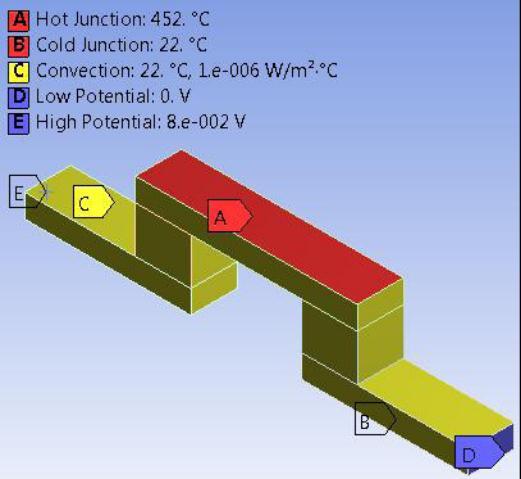

Fig. 2.2 Boundary Conditions

Table 2.3 Boundary Conditions

Name Values

HotJunctionTemperature 452c Cold Junction Temperature 22c ConvectionTemperature 22c LowPotentialvoltage 0v HighPotentialVoltage 8.e 002v

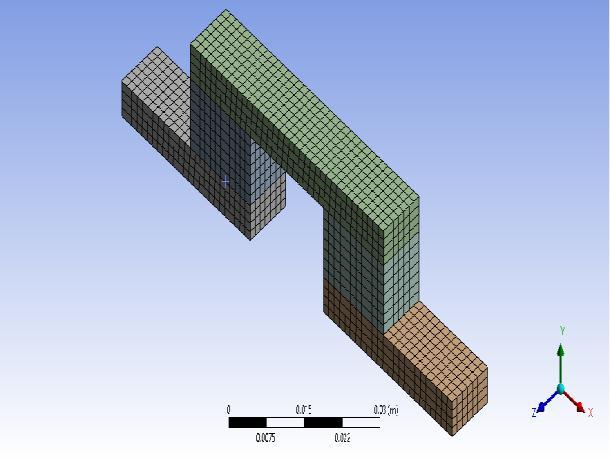

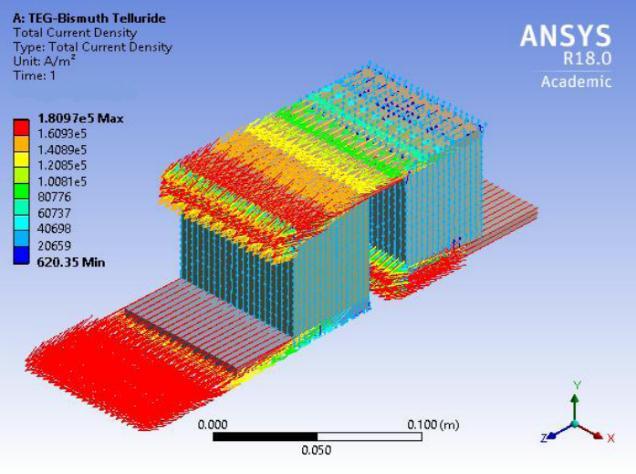

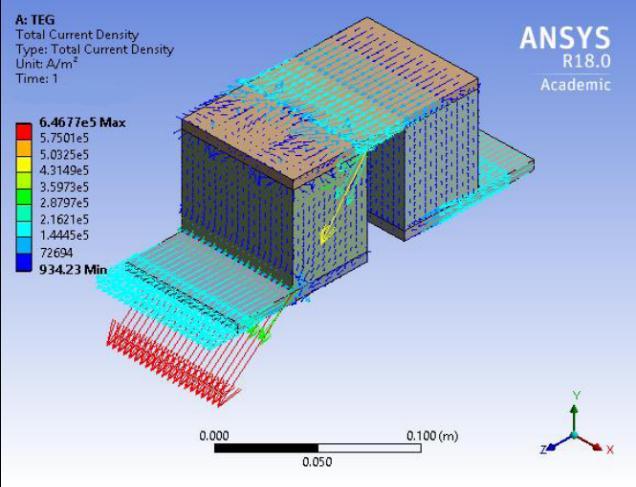

The model of thermos electric module attached with a copperalloyhasbeendevelopedandanalysishasbeendone using ANSYS Workbench18.0. The analysis has been performedfortwodifferentmaterialsBismuthtellurideand graphene.Thermo electricanalysishasbeenperformedfor finding parameters like temperature difference, Total current density. In Ansys the simulation for thermal and electric fields can be simultaneously analyzed by Steady StateThermal Electricanalysis.ThisanalysiscancheckSee beck, Peltier, and Thomson effects for thermoelectricity. BismuthtellurideandgrapheneTECmaterialsarecompared bytheanalysisoftotalcurrentdensityandheatabsorbed. Current density is defined as thetotal amount of current flowingthroughaunitvalueofancross sectionalarea.

AfterimportingthegeometryintoANSYSThermo electric, themeshingisdividingthedomainintovariouspartssuchas nodesandelements.Themeshingaccuracyisrespectivefor user. Based on the computational power, shapes such as

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

● Heatabsorbed=mCp∆T

Where,m =massflowrate (Bi2Te3=0.0007624Kg/s, Graphene=0.1439kg/s)

cp =specificheat (Bi2Te3=165Jkg 1 K 1 , Graphene=21Jkg 1K 1)

∆T=temperaturedifference

● GeneratedCurrent=Currentdensity*Area Where,Area=0.0004669m2

The results are given in table 3.2. It is obvious that the Thermo electricgeneratororThermo electriccoolerhaving graphene results in a higher output of current and heat absorbed is larger. Hence, it is clear that graphene works efficientlyasathermoelectricmaterial.

Table 3.2 Comparison of Generated Current and Heat absorbed between Bi2Te3 and Graphene.

TYPE (Ampere)

Heat absorbed (Watt)

P and N junction Bi2Te3 84.40 54.60 P junction graphene and N junction Bi2Te3 94.46 1311.8

The design and analysis of two different TEC materials is carried out in this project work. The results from the analysisareasfollows:

● The Thermo electric generator with graphene based, gives a larger output of current and heat absorbedislargerthanBi2Te3

● Thus,forcoolingofsolarpanelusingTECmethod, GrapheneincorporatedTECispreferred.

[1] M.A. Bashir, H.M. Ali, K.P. Amber, M.W. Bashir, A. Hassan,S.Imran,M.Sajid,“Performanceinvestigation of photovoltaic modules by back surface water cooling”, Thermal Science, 22 (2018) 2401 2411. https://doi.org/10.2298/TSCI160215290B

[2] M.A. Bashir, H.M. Ali, M. Ali, S. Khalil, A.M. Siddiqui, 2014,“Comparisonofperformancemeasurementsof photovoltaicmodulesduringwintermonthsinTaxila, Pakistan”, Int. J. Photoenergy, Article ID 898414. https://doi.org/10.1155/2014/898414

[3] J.Siecker,K.Kusakana,B.P.Numbi“Areviewofsolar photovoltaic systems cooling technologies”, Renew. Sustain. Energy ,79(2017)192 203. https://doi.org/10.1016/j.rser.2017.05.053

[4] F. Grubsic Cabo, S. Nizetic, T.G. Marco,” Photovoltaic Panels:aReviewoftheCoolingTechniques”,2016,vol. 1,,pp.63 74,

[5] B. Koteswararao, K. Radha, P. Vijay, N. Raja, “Experimental analysis of solar panel efficiency with differentmodesofcooling“,2016,8(3) 1451 1456.

[6] M. Hasanuzzaman, ”Global advancement of cooling technologiesforP.V.systems”, areview,Sol.Energy 137 (2016) 25 45. https://doi.org/10.1016/j.solener.2016.07.010

[7] D. Du, J. Darkwa, G. Kokogiannakis,“ Thermal management systems for photovoltaics (P.V.) installations:a critical review”,Sol.Energy97(2013) 238 254. https://doi.org/10.1016/j.solener.2013.08.018

[8] FanZhang,JoseF.Castaneda,ShangshangChen,etal. “Comparative studies of optoelectrical properties of prominentPVmaterials:Halideperovskite,CdTe,and GaAs”, Materials Today, 36(2020)18 29. https://doi.org/10.1016/j.mattod.2020.01.001

[9] L. Dorobant¸u, M.O. Popescu, C.L. Popescu, A. Craciunescu,“Experimental assessmentofPVpanels, frontwatercoolingstrategy”,InternationalConference onRenewableEnergiesandPowerQuality,1(2013)1 4. https://doi.org/10.24084/repqj11.510

[10] I.Ceylan,A.E.Gürel,H.Demircan,B.Aksu,“Coolingof a photovoltaic module with temperature controlled solar collector”, Energy Build. 72(2014) 96 101. https://doi.org/10.1016/j.enbuild.2013.12.058

[11] G.S.Nolas,J.Sharp,H.J.Goldsmid,“Thermo electrics Basic Principles and New Materials Developments” , Springer,2001, pg.1 5.

[12] C.B.Vining,D.M.Rowe,J.Stockholm,K.R.Rao,“History of the International Thermoelectric Society”, in Thermoelectrics Handbook Macro to Nano, D.M. Rowe,CRCTaylor&FrancisGroup,2006 Appendix1 8.https://doi.org/10.1201/9781420038903

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1808

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

[13] Li Zhang, Xia Lei ShiYan ling Yang, Zhi Gang Chen, “Flexiblethermoelectricmaterialsanddevices:From materials to applications”, Materials Today,46(2021)62 108.

https://doi.org/10.1016/j.mattod.2021.02.016

[14] Mahmoud, Lama, et al. “Characterization of a graphene based thermoelectric generator using a cost effective fabrication process", Energy Procedia 75(2015) 615 620.

https://doi.org/10.1016/j.egypro.2015.07.466

[15] Sankeshwar,N.S.,S.S.Kubakaddi,andB.G.Mulimani, "Thermoelectric power in graphene", Advances in GrapheneScienceandtech,2013.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal