International Research Journal of Engineering and Technology (IRJET)

e ISSN:2395 0056

International Research Journal of Engineering and Technology (IRJET)

e ISSN:2395 0056

2

1

Abstract Use of recycled waste glass in concrete as partial replacement of Ordinary Portland Cement has attracted a lot of interest worldwide due to the increased disposal cost and environmental concern. Waste glass when ground to very fine powder shows pozzolanic property which improves the strength of the concrete. But the workability of waste glass replaced in concrete decrease as the amount of glass powder increases due to reduction in fineness modulus of cementitious material. Chemical admixtures and mineral admixtures are commonly used to increase the workability of concrete. This study evaluates the effect of bio admixture, Water Hyacinth plant extract as a replacement for Conplast SP430 admixture The waste glass powder is replaced at 10% to 25% with an increment of 5% of cement and Water Hyacinth extract at 10% to 25% with an increment of 5% of Conplast SP430 has been studied. It is tested for compressive strength and split tensile strength at 7 and 28 days. Workability and water absorption also conducted and compared with those of conventional concrete. Result shows that replacement of 20% cement by glass powder and 20% of Conplast SP430 by water hyacinth extract was found to have higher strength. Using bio admixture and waste glass in concrete will make the concrete economical and environmentally friendly. Presence of fatty acids and pozzolanic materials in water hyacinth extract and glass powder will results in increased compressive strength of concrete. On other hand, the absorption of water by fresh concrete enhances adhesion of cement paste to aggregate and thus the tightness of hardened concrete. It results in higher strength and better durability of concrete so that it can be used in exposed surface.

The most unbelievable thing about cement is that themanufacturing of these material is responsible for 7% of global carbon dioxide emissions. Thus, cement replacementinconcreteresultsinsubstantialreductionin carbon footprint and it also reduce cost of raw materials usedforcementmanufacturing.

Glasspowderasacementreplacementwasdiscoveredby manyscientists[1].Glassismainlycomposedofsilica.Use of recycled waste glass in concrete as partial replacement of Ordinary Portland Cement has attract a lot of interest worldwide due to the increased disposal cost and environmental concern. Waste glass when ground to very fine powder shows pozzolanic property which improves the strength of the concrete[2]. Use of grounded waste glass in concrete as partial replacement of cement could beanimportantsteptowarddevelopmentofeco-friendly, energy-efficient,andeconomicalsystem.

WaterhyacinthisanaquaticplantnativetoSouthAmerica andisknownasthe“terrorofBengal”duetoitsextremely rapidgrowthtendencies.Oneofthefastest-growingplants known, water hyacinth can produce thousands of seeds each year, and these seeds can remain viable for more than 28 years. Water-hyacinthblocks waterways and limits boat traffic, causes destruction of fish habitant thus killingfishandprovisionofasuitablebreedinggroundfor mosquitoes[3]. Water hyacinth does not produce oxygenas compared to other submerged vegetation and phytoplankton. This leads to low levels of dissolved oxygen concentration thus negatively affecting water quality. Research on effective methods for controlling waterhyacinthisstillgoingon.

Today, concrete is the most consumed material in the world.Acrosstheworld30billiontonsofconcreteisused each year and the biggest reason it is so popular around the world is thatit is extremely durable. Concrete is weatherproof, it can withstand almost all elements. It is also resistant to erosion that it will last longer than other building materials. Cement is the main ingredient used to make concrete and itcomprises from 10 to 15 percent of the concrete by volume. But cement is manufactured through the chemical combination of many ingredients.

Concrete admixtures are used to improve the behavior of concrete under a variety of conditions. The use of admixtures in now the concrete industry is increasing days,especiallytheuseofbio-admixtures.Themarketsize forconcreteadmixturehadsurpassedUnitedStatesDollar 17.78billionin2020.Itisevidentthatthecostofconcrete will be reduced if admixtures are cheaper and easily available. Water hyacinth extract can be used for this purpose. Gas Chromatography-Mass Spectrometer analysis revealed concentrations of lingo cellulose, saturated and unsaturated fatty acids which make the extractasuitablebioadmixture[4].Waterhyacinthextract was added at 0, 10, 15, 20 and 25% replacement of conplast sp430, and the mechanical properties of the concreteweredetermined.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page180

Geeja K George2 , Aswin Das A S 1 , Breeze Joy K1 , Georgootty K Milson1, Jeeva Varghese1 Student, Dept. of Civil Engineering, Mar Athanasius College of Engineering, Kerala, India Associate professor, Dept. of Civil Engineering, Mar Athanasius College of Engineering, Kerala, IndiaInternational Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

To study the effect of water hyacinth extract as a bio admixture for replacing Conplast SP430 to increase the workabilityofcementreplacedglassconcrete.

As concrete is most widely used material in the world

thedisposalofwasteglassasapartialreplacementforthe cement is considered. During this process the workability will decreases, and it can be increased by adding admixture. Replacing chemical admixture by a bio admixture from an aquatic weed water hyacinth makes concretemoreeconomicalandeco friendlier.

Basedontheliteraturereview [5]M40mixisprepared in different proportion with glass powder and water hyacinth extract and analyzed the properties of concrete. Thevariousprocessinvolvedintheexecutionoftheworks isgivenintheflowchartbelow.

PROPERTYTESTONCEMENTANDAGGREGATE(IS2386)

SELECTIONOFADMIXTURESP430[4]

COLLECTIONOFWATERHYACITHPLANTANDWASTE GLASS[1]

PREPARATIONOFBIOADMIXTUREFROMWATER HYACINTHPLANTANDCONDUCTEDPROPERTYTEST[4]

ANALYSISANDCOMPARISONOFRESULTS

3.1. Glass Powder

Wasteglasspowderiscollectedandgrindedintothin powders. Figure1 shows thepictureofglasspowder prepared.

Figure1GlassPowder

3.2.

EVAULATIONOFTHECOMPONENTSOFWASTEGLASS[6]

MIXDESIGNOFM40CONCRETEASPERIS10262:2019

PREPARATIONOFCONCRETECUBESATVARIOUS PROPORTION

OrdinaryPortlandcementof53gradeisbeingusedinthe present investigation. The cement was tested for various physical properties according to relevant Indian Standard IS 8112. Table 1 shows the chemical composition of cementandglasspowderprepared.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page181

International Research Journal of Engineering and Technology (IRJET)

e ISSN:2395 0056

Table1Chemicalcompositionofcementandglasspowder

Composition Cement(% bymass) Glasspowder (%bymass)

Silica(SiO2) 20.2 72.5 Alumina(Al2O3) 4.7 0.39 Ironoxide (Fe2O3) 3.0 0.21

Calciumoxide (CaO) 61.9 9.64 Magnesiumoxide (MgO) 2.6 3.3 Sodiumoxide (Na2O) 0.19 13.2

Potassiumoxide (K2O) 0.82 0.13

Sulphurtrioxide (SO3) 3.9

Fineness% passing(sieve size)

97.4(45 µm) 80(45µm)

Lossofignition 1.9 0.36 Unitweight, kg/m3 3140 2573 Specificgravity 3.14 2.57

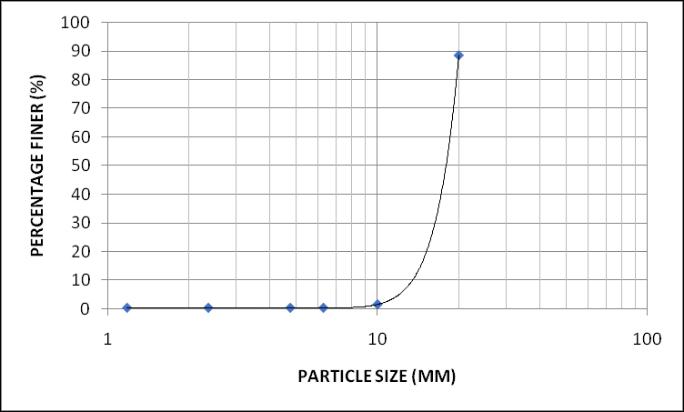

Crushedgrindedangularaggregatefromlocalsource, havingmaximumsize20mmwasusedforthestudy. Figure2showsthecoarseaggregatesample.

Table2ObservationofGradationAnalysisof

Particlesize(mm) Percentage weight retained(%) 40 0.0 20 11.45 10 87.0 6.3 1.24 4.75 0.0 2.36 0.0 1.18 0.0 PAN 0.15

The grain size analysis of the aggregate sample was conducted according to the procedure conforming to the IS2720PartIVofBIS.GradationanalysisshowninTable1 andthegradationcurveisshowninFigure3

Tests are conducted to evaluate the properties of coarse aggregates.

Table3showsthepropertiesofcoarseaggregates.

Table3PropertiesofCoarseAggregates

TEST RESULT

Specificgravity 2.8 Uniformitycoefficient 1.587 Coefficientofcurvature 1 Waterabsorption 0.719

Fineaggregateistheinertorchemicallyinactivematerial. The fine aggregate serves the purpose of filling all the open spaces in between the coarse particles. The fine aggregate used for the present study in manufactured sand Table4showsthepropertiesoffineaggregates.

Specificgravity 2.75 Zone ZoneII

Uniformitycoefficient 8.057 Coefficientofcurvature 0.97 Waterabsorption 1.9%

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page182

International Research Journal of Engineering and Technology (IRJET)

e ISSN:2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN:2395 0072

Water hyacinth plant is harvested from Kochi. It is then

cleaned, washed, and dried under shade. The dried water hyacinthplantis powdered.500gofthepowderis wetted by 1 litre of clean potable water and soaked in 30 ml of ethanol for 24 hours. The extract obtained is filtered and stored. To identify the components of water hyacinth extract Gas Chromatography-Mass Spectrometer (GCMS) analysis is performed[4]Figure 4, Figure 5 and Figure 6 are shows various steps in the preparation of water hyacinth extract. Table 5 shows the organic compounds identifiedfromGCMStestofwaterhyacinthextract.

Component Formula Molecular Weight (g/mole)

1 Ethyl 2 pyrrolidinone

C6 H11 NO 113

2 Pentenal(E) C5 H5 O 84 Piperidine,2,3 dimethyl C 2H15N 113 Pantolactone C 6 H10 O5 130

1 Butanol,2 methylacetate C7 H24O2 130 Octanoicacid,o hydroxyphenyl ester

Hexadecenoic acid,methylester

C 14H20 N5 236

C17 H54 O2 270

9 Hexadecanoic acid C 16H50O2 254

n Hexadecanoic acid C18 H22 O2 256

9,12 Octadecadieonic acid(z,z)

C18 H52 O2 280

6 Heptene 2 one,7 phenyl C15 H150 188

Conplast SP430 significantly improves the workability of site and precast concrete without increasing water demand.Table6Table6PropertiesofConplastSP430.

The common specifications regarding quality of mixing water are water should be fit for drinking. Such water should have inorganic solid less than 1000 ppm. This content led to a solid quantity 0.05% of mass of cement whenw/cratioisprovided0.45resultingsmalleffect onstrength[3].

Concrete mix design is prepared as per IS 10262:2019. The mix design obtained contain desired properties like workability,durability,strengthetc.

International Research Journal of Engineering and Technology (IRJET)

e ISSN:2395 0056

Mix design for the cement replaced by glass powder concrete at various proportions are evaluated. Table 7 shows the various samples prepared in different proportions[2]

Sample 1 0% 2 10% 3 15% 4 20% 5 25%

Cement (kg) 11 9.9 9.35 8.8 8.25 Coarse Aggregate (kg)

39.25 39.25 39.25 39.25 39.25

The test was conducted as per IS 1199. The test is performed at various mix proportions. Figure 7 shows slumpconeprepared.

Fine Aggregate (kg)

19.6 19.6 19.6 19.6 19.6 Glass powder (kg)

0.0 1.1 1.65 2.2 2.75 Water (Litre) 3.7 3.7 3.7 3.7 3.7

Mixdesignforthepartiallyreplacedglasspowderand waterhyacinthextractconcreteatvariousproportionsare showninTable8

Sample 1 0% 2 10% 3 15% 4 20% 5 25%

Cement (kg) 11 9.9 9.35 8.8 8.25

Coarse Aggregate (kg)

39.25 39.25 39.25 39.25 39.2 5

The test was conducted as per IS 516. The specimens are testedbycompressiontestingmachineafter7and28days ofcuring. Figure 8showscompression testing ofconcrete cubes.

Fine Aggregate (kg)

19.6 19.6 19.6 19.6 19.6 Glass powder (kg)

0.0 1.1 1.65 2.2 2.75 Water (Litre) 3.7 3.7 3.7 3.7 3.7 Conplast sp430(ml) 60 54 51 48 45

Water Hyacinth extract (ml)

0.0 6 9 12 15

The test was conducted as per IS: 5816 and IS:456. The specimens are tested by compression testing machine after 7 and 28 days of curing. Split tensile strength test is illustratedinFigure9

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page184

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN:2395 0072

ThetestwasconductedasperIS1124.Waterabsorptionis used to determine the amount of water absorbed under specifiedconditions.Thedryweightofthesampleistaken andthenitisimmersedinwaterfor48 hoursis shownin Figure10

The workability of waste glass replaced concrete will decreases as amount of glass powder increases due to reduction in fineness modulus of cementitious material. This effect can be compensated by adding admixtures. This study evaluates the effect of bio admixture, Water Hyacinth plant extract as a replacement for Conplast SP430.It can also be observed that as the amount of the water hyacinth extract increases, workability also increases. This indicates that the water hyacinth extract retards the hydration rate and hardening making the concrete to flow longer hence high flowability and filing ability.[4]

The compressive tests were conducted, and the results obtained fordifferent mixes testedaftercuring periods of 7dayand28daysareillustratedinFigure12.

The workability of concrete is measured from slump test. The Figure 11 shows the slump cone value of various mixes.

Figure11Slumpcone

32.178 33.913 34.321 37.106 35.98

49.534 52.706 55.017 56.92 55.54 20 30 40 50 60 0 10 15 20 25 C O M P R E S S IVE

7thday 28thday

Waste glass when ground to very fine powder shows pozzolanic property which improves the strength of the concrete. The presenceof fatty acids in the water hyacinth extract could be the reason of increased compressive strength with the increase in the amount of water hyacinth extract. After 20% replacement, compression strength decreases due to high fluidity causingsegregationandbleedingofthematrix[1]

The split tensile strength tests were conducted on concrete cylinders. The results obtained for different mixestestedaftercuringperiodsof7daysand28daysare illustratedinFigure13

E N G TH(k

SP L IT TEN SIL E ST

International Research Journal of Engineering and Technology (IRJET)

e ISSN:2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN:2395 0072

2.819 2.82 3.351 3.22 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 0 10 15 20 25

compressive and tensilestrength.

Water absorbing property of Water hyacinth extract and cementpowderreplacedconcretecubeislessthannormal concrete [Figure 14]. Higher water absorption decreased the resistance to sulfate attack of concrete and hence is moredurablethanthenormalconcrete

7. CONCLUSIONS

Conclusionsthatmadefromthisstudy:-

Optimumvalueforadditionofwaterhyacinthwas obtainedas20%ofadmixture.

Optimum value of addition of glass powder was obtainedas20%ofcement

Compressive and tensile strength for the above two criteria sample is greater than the normal concrete.

Water absorbing property of the Water hyacinth glassconcreteisgreaterthanthenormalconcrete henceitcanbeusedinexposedsurfaces[5].

Weight of water hyacinth glass concrete is less than that of the normal concrete, hence can be usedforlightweightconcretestructures[4]

Withtheadditionofglasspowder,thestrengthof concrete increases, but the workability of concretedecreases[2] Additionofwaterhyacinth willcompensatethesame[4].

Water absorption is defined as the amount of water absorbedbyamaterialandincrementwaterabsorption percentageisgiveninFigure14

[1] S.ShaikhandD.Kshirsagar,“EffectiveUtilisationof

WasteGlassinConcrete,”2015.[Online].Available: www.ijera.com

[2] C.ShiandK.Zheng,“Areviewontheuseofwaste glassesintheproductionofcementandconcrete,” Resources, Conservation and Recycling,vol.52,no. 2,pp.234 247,Dec.2007,doi: 10.1016/j.resconrec.2007.01.013.

[3] J.MariamBoban,P.vNair,S.T.Shiji,andS.Elsa Cherian,“IncorporationofWaterHyacinthin Concrete.”[Online].Available:www.ijert.org

14

[4] G.D.O.OkwadhaandD.M.Makomele,“Evaluation ofwaterhyacinthextractasanadmixturein concreteproduction,” Journal of Building Engineering,vol.16,pp.129 133,Mar.2018,doi: 10.1016/j.jobe.2018.01.002.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page186

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN:2395 0072

aggregateforsustainablecement based constructionmaterials:Areview,” Journal of Building Engineering,vol.28.ElsevierLtd,Mar.01, 2020.doi:10.1016/j.jobe.2019.101052.

[6] G.M.S.Islam,M.H.Rahman,andN.Kazi,“Waste glasspowderaspartialreplacementofcementfor sustainableconcretepractice,” International Journal of Sustainable Built Environment,vol.6,no. 1,pp.37 44,Jun.2017,doi: 10.1016/j.ijsbe.2016.10.005.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page187