International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1

2,3,4,5,6

Abstract Agriculture performs a critical role in Indian economy. The cause behind reduction in the productiveness of agricultural is weeds. Weed removal is serious problem faced by the farmers that will decrease the farmer pastime to proceed cultivation. The main objective of this paper is to assemble and advance a battery operated weeder to furnish the excellent possibilities for cultivation. The working of this task is relies upon on the battery panel. This is motorizedtools pushed through the battery energy which moves blades to cut the weeds by way of chain sprocket mechanism. The plan is simple and convenient to operate. This tools is designed to limit the human effort, to limit the price and provide the efficient work output. This weeder will fulfill the necessities of the marginal farmers.

Key Words: Weeder,Multicrop,Battery,weedermachine. Aggriculture.

Weed control is one of the most tough tasks in agriculture that debts for a substantial share of the value involved in agriculture production. Farmers usually expressedtheirsubjectforthehighqualityweedmanipulate measurestoarresttheboomandpropagationofweeds.In Indian agriculture, it’s a very hard venture to weed out unwanted flowers manually as nicely as using bullock operated gear which may additionally further lead to damage of main crops. More than 33 percent of the value incurred in cultivation is diverted to weeding operations there bydecreasing the profitshare of farmers.A weed is actuallyanyplantwhichgrowswhereitisunwanted.Aweed canbeconceptofasanyplantgrowingintheincorrectplace attheincorrecttimeanddoingextradamagethanaccurate (Parish, 1990). It is a plant that competes with plants for water,nutrientsandlight.Thiscanlimitcropproduction.

Weeding is an necessary however equally labour intensiveagriculturalunitoperation.Todaytheagricultural sectorrequiresnon chemicalweedcontrolthatensuresfood safety. Consumers demand high first rate meals products andpayone of a kindinteresttofoodsafety.Throughthe

***

technical improvement of mechanisms for bodily weed control,itmightbefeasibletocontrolweedsinawaythat meetsclientandenvironmentaldemands.Indianagriculture isreliantonhumanelectricityandalsoanimalpower.Itisa timeeatingprocess.MostoftheIndianfarmersarehaving small agricultural land. Farmers nevertheless follow the conventional techniques in the cultivation for weeding purpose.Thesetechniquesrequireexcessivelabourforceto operate the operations. The primary downside of the moderngearisitscosteffectivenessduetothefactmostof them are mechanized and driven via fuel. So they can infrequently afford such steeply priced equipment’s. The weedmanipulateoperationsarecommonlycompletedwith the aid of three methods such as bias operation, hand weedingandusingofherbicides.In biasoperation,weeds areeliminatedviausinganindigenous ploughafter35 40 DAS.Byhandweeding,weedsareremovedbyhandwhichis more wonderful but it is expensive, labour intensive as nicely as time consuming. Nowadays herbicide usage is increasing.Inviewpointoflabourscarcitycircumstances;it is preferred as a speedy and fine weed manage approach besides detrimental the rice plants. But, it has damaging effectsonhumanhealthandenvironment.

The weed manipulate operations are frequently executed withtheaidofthreetechniquessuchasbiasoperation,hand weeding and the use of of herbicides. In bias operation, weeds are removed by using using an indigenous plough after35 40DAS.Byhandweeding,weedsareeliminatedby wayofhandwhichismore finebutitisexpensive,labour intensive as properly as time consuming. Nowadays herbicide usage is increasing. In view factor of labour shortage circumstances; it is preferred as a speedy and effective weed manage approach barring unfavorable the riceplants.But,ithasunfavourableresultsonhumanfitness and environment. In order to verify the possibility of mechanizationoftheweedingoperation,thepoweroperated singlerowactiveweederareproposedtobedesignedand developedthinkingaboutthemostexcellentshape,sizeand location of reducing blades, comparison of its overall

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

performance with other weeding strategies in area conditions,optimizationofdimensionsoflaptopforbetter performance. The most important goal is to layout and fabricationofastrengthweeder,whileminimumdamages donetoriceplants,costeffectiveness,convenientmanual, low weight and fabrication through the usage of freely available components and handy preservation are most importantelementsofthisdesign.Herecomestherelevance ofmechanizedweeding,whichisnotabigtimeingestingand significantlyimprovesweedingefficiencyasproperlyasthe satisfactoryofweeding.Thiscomputerhelpstoreducethe feespromptedthroughlabourandfuel.

The objective of the present study as:

1. Todesignanddevelopthesinglerowactivepower weederforrice.

2. Toevaluateperformanceofdevelopedmachine.

3. Ergonomicalevaluationofthedevelopedmachine.

Thearangeoffactorsworriedinformathavebeenoperation safety, light weight of machine, overcomes man strength scarcity,savestimeandcost,easinessinfabricationaretaken intoaccount foritsdiagramprocedure.The operationand adjustmenthadbeenmadesimplesothatavillageartesian canfabricate,restoretheweederandfarmercanfunctionthe weeder easily.The substances and techniques about the developmentandtestingofenergyweederarementionedin thischapterpurposes.Suchfunctionscanbeconsideredas mechanisms,whichmayadditionallygeneratesomeothersin a causal sequence, and/or being linked with others at the identicallogicallevel.Theforemostpartsthatareusedinthe fabricationofbatterypoweredweederare:

Thebodyisthemostimportantphaseofthismachineshown inFig.2.1Thepinnaclesectionoftheframeholdsdealwith andatthebacksideendthechassisisorganizedtofixtheDc motorsandbatteriesonthefame.Arrangementsaremade onthemanagetorestorethebatterypanelandtokeepthe velocity controller. The chain sprocket mechanism is constantbeneaththechassisofthereputewiththeassistof twopedestalbearingsateachtheendsofthechassis.Two wheelsarelinkedtothebodywiththeassistoflockingpins.

This kind of DC motor consists of a gear head meeting which is linked to the electrical motor. The tools head helps in decreasing the velocity with the aid of increasingthetorque.Thistypeofmotorsisusedinoneofa kindfunctionssuchaselectricalpropulsion,industrialjacks, cranes, paper machines and rolling mills. By altering the operational voltage, motor velocityis varied. Two12V DC motorsareusedindividuallyforstrengthsupply.TheseDC motors are fitted on the body as shown in fig1.Two 12V batteriesareusedinthisprojecttoprovidethestrengthto the motors whilst they are in operational condition. Connections of these batteries made in series and are positionedontheframeasproveninfig2.2.1.

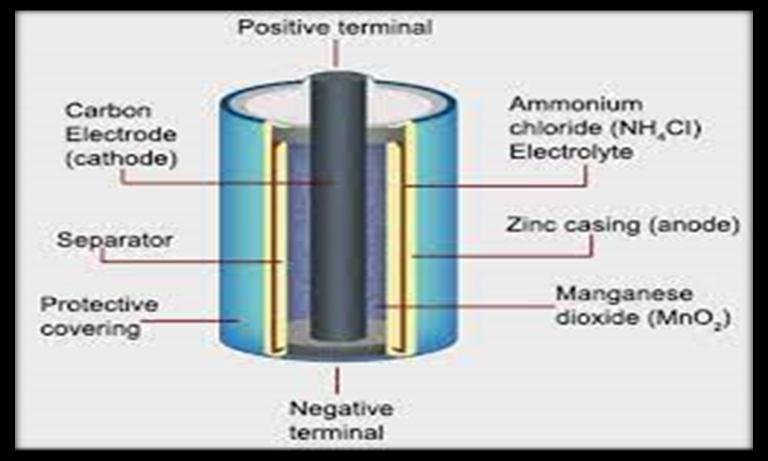

The most common kind of battery used these days is the "dry cell" battery. There are many exceptional types of batteries ranging from the extraordinarily large "flashlight"batteriestotheminiaturizedvariationsusedfor wristwatchesorcalculators.Althoughtheyrangeextensively in composition and form, they all work on the sample principle.A"dry cell"batteryisreallycomprisedofametal electrode or graphite rod (elemental carbon) surrounded

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

throughamoistelectrolytepasteenclosedinasteelcylinder asshowninFig2.2.2.

Weeder blades are the parts which are directly having an interaction with the soil and are having high impact on the weeding operation. The weeder blades are madeupofmildsteel.

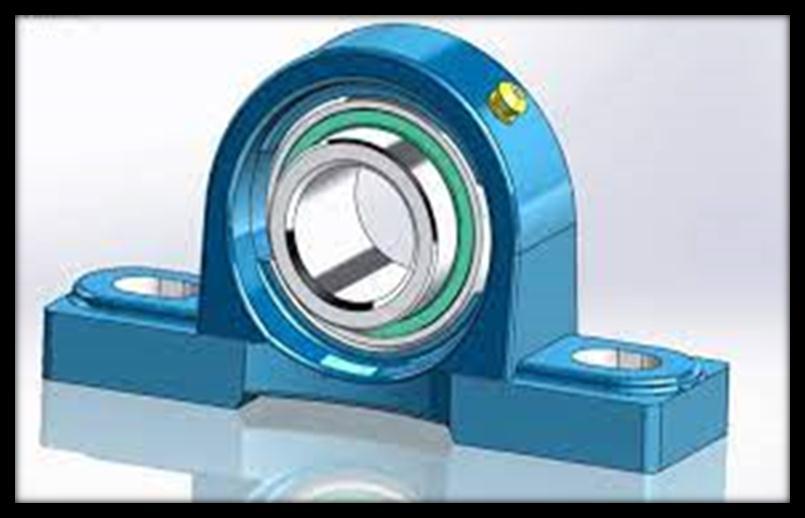

A pillow block bearing (or Plummer block) is a pedestalusedtofurnishsupportforarotatingshaftwiththe assist of well matched bearings and quite a number accessories.Themeetingconsistsofamountingblockwhich homes a bearing. A pillow block commonly refers to a housingwithanprotectedanti frictionbearing,whereinthe mountedshaftisinaparallelplanetothemountingsurface, andperpendiculartothecenterlineofthemountingholes, ascontrastedwithquiteanumbertypesofflangeblocksor flangeunits.Apillowblockcanalsocontainabearingwith one of several sorts of rolling elements, such as ball, cylindricalroller,sphericalroller,taperedroller,orsteelor artificialbushing.Thekindofrollingthingdefinesthekindof pillowblock.Thesedifferfrom"Plummerblocks"whichare bearing housings provided without any bearings and are typicallysupposedforhigherloadratingsandaseparately set up bearing. Plummer block bearings are designed for greatercorrosiveenvironments.

Speed manipulate is an electric circuit used to controlthespeedofthemotor.Thiscontrolisexecutedby theknobswhicharelinkedtothepotentiometerprovidedin thecircuit.Throughthistheoperatorcanchangethemotor speed according to the requirements. This offers the requiredoperationalspeed.Thepacecanbecontrolledby usingalteringthevoltagewiththehelpofknobs.

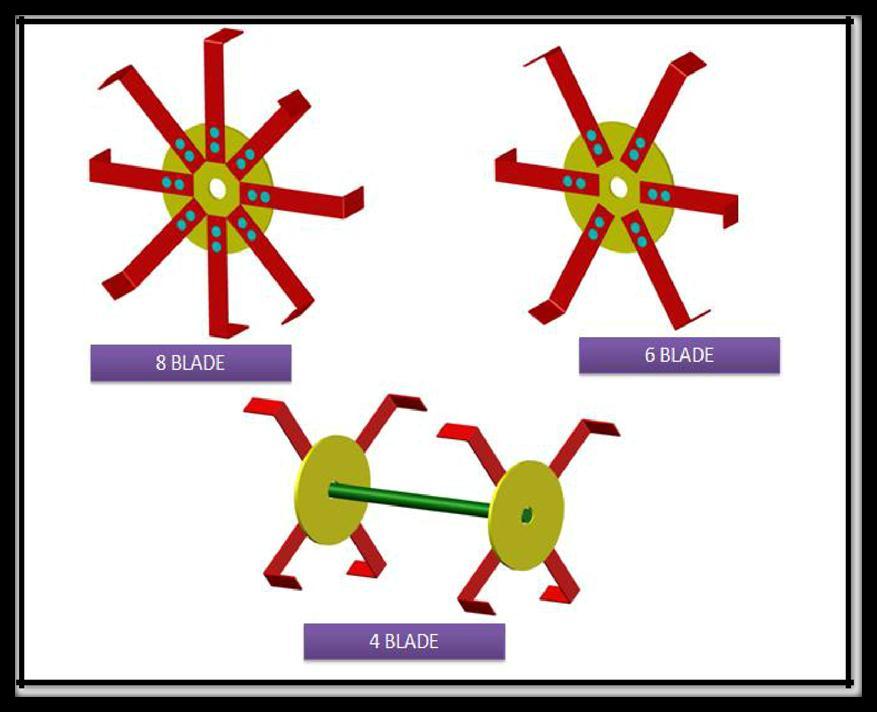

Blades of the rotor are the aspects which directly haveinteractionwithsoilandassuchhavemainimpacton the operation of the weeders. The cloth used for manufacturingmachinesoughttobemodifiedbutthiswill increasetherelatedpricessignificantly.Thewayoflowering thestrengthrequirementandtoimprovethelifeofmachine istoenhancegeometryofblade.Theinteractionbetweensoil andmachinestakesvicinityattheblades;thereforebymeans of enhancing their geometry the power required and the dimensionofmachinewillreduce.Thebladeisdesigned& developed the use of the popular blades designs used in marketonhandweedersasbase.Thefinalizedgeometryno longeronlyreducesthepowerrequiredbutalsodecreases the cost of manufacture. The weight of machine is additionallyreducedassmallerpowersource.

Differentparametersusedinthefindoutaboutand have been in consideration to provide safe strength and bendingvaluesformanufacturedbladesforthedurationof weeding operation. The calculation and assumptions are

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

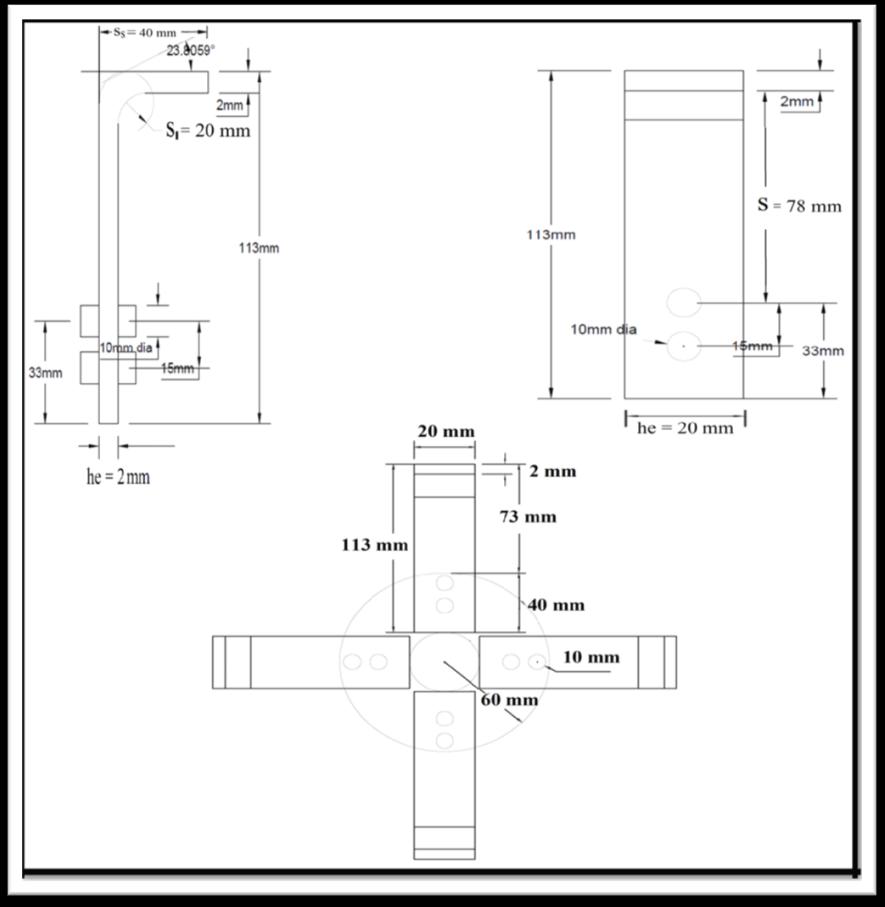

based on standard instruction manual of machine design werefollowed(Shigleyetal.,2004).Assumptionusedtobe madeasfollows;Numberofbladesinoneworkingset=4; Lengthofblade=11.3cm;Widthofblade=4cm.Tocalculate thedesignstrengthofblade;revolutionperminuteofrotor shaft (N) = 176 rpm; radius of engine output rotor (R) = 16cm.Therefore,paceofengineoutput(u)willbedecided aboveas2.94ms 1.

For cutter blade design, variety of blade, cutting widthandthicknesshavebeenessentialparameters.During cutting,bladeswouldbesubjectedtoshearingasnicelyas bendingstresses.Totalworkingwidthoftheweederwas300 mmhavingrotorshaftofsizeof250mm.Totalofeightblades hadbeenprovidedwithslicingwidthof40mm.Therefore,4 bladeshadbeenfurnishedoneveryflangeandtwoflanges weresetuponrotorshaft.Thesoil pressureactingonthe blade(Ke)wascalculatedviathefollowingequation:

Ke = = = 55.1 Kg

Where, Ks=Maximumtangentialforce,kg, Cp=Coefficientoftangentialforceas0.8, i=Numberofflangesis2, Ze=Numberofbladesoneachsideoftheflangesis4and ne=Numberofbladeswhichactjointlyonthesoilbytotal numberofblades.

Bysolvingeqn.3,thesoilforceactingontheblade (Ke)wasdeterminedas55.1kg.Thedimensionsoftheblades aregiveninFig.2.6.1

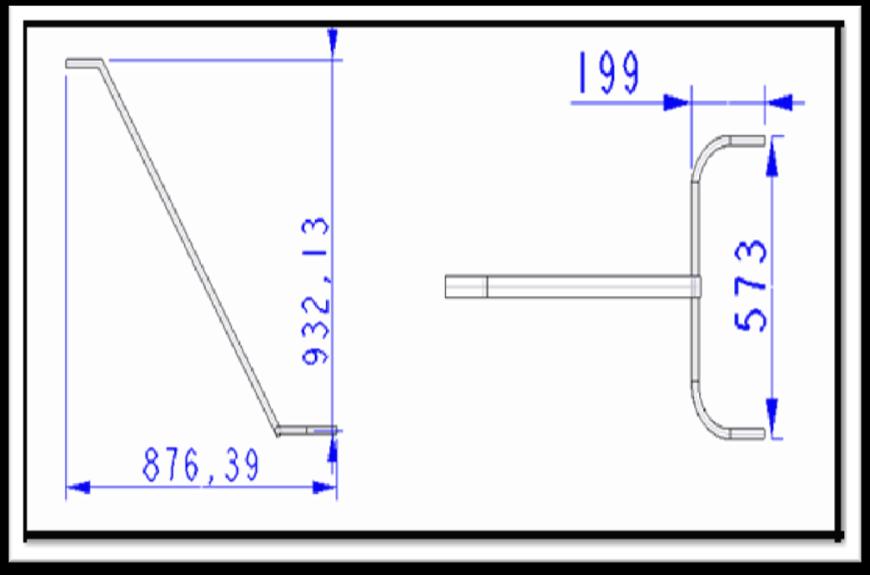

Fig.2.6.2

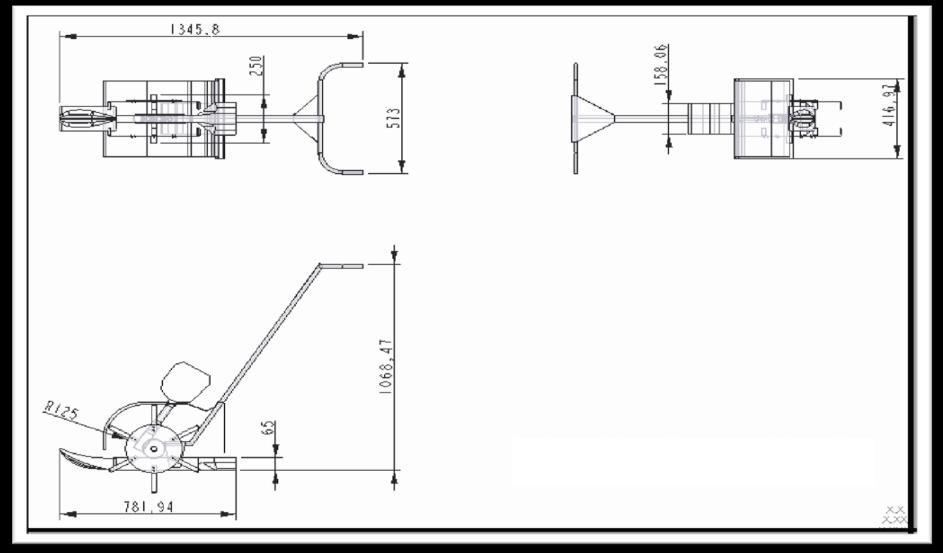

Handlesaremadeof20mmMSrectangularframeof length40mmandwidth18mmwithplasticgripfittedatthe ends. The overall length of handle is 1090mm With two bendsfrompointofattachmentandhaveaheightof1020 mmfromgroundlevel.Thelengthofhandlecrossbaris570 mmanddiameterofhandlegripis25mmwithalengthof 105mm.Thehandleisattachedonmainframeattherearof the machine with help of four pieces of nut and bolts of havingdia.10mm.Withhelpofhandle,themachinecanbe steered. A throttle lever is provided on right side of the handletocontroltheenginespeedFig.3.122 Ddiagramof thedevelopedmachine.

Fig.2.6.1

Fig.2.6.3

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Toavoidthrowingofmudandstonestowardsoperatorand asasafety,amudflapisprovidedcoveringtheupperand rearsideofthebladesoftherotarycuttingunits.Upperside ismadeupofplasticsheetoflength490mmandwidth262 mmandtherearsideiscoveredbyrubbersheetoflength 270 mm and width 190 mm. Both is connected and supportedtotheinnerendofthehandlebymeansof10mm diameter,20mmlengthnutandboltwiththehelpofMSflat ofsizeoflength232mmandwidth20mm.

This equipment is a type of agricultural weeder operated with the utilization of battery power. The drive mechanismofthismachineincludesonebatterypanel,two electricaldcmotors,twobatteries,rotarybladesandchain sprocketmechanism.Oneelectricaldcmotorisconnectedto thewheelsofthemachinewiththehelpofchainsprocket mechanism.Thesemechanismstransmitthepowerfromthe motortotheshaftsofthewheelsandweederblades.Inthis machineJ typerotarybladesareused.Thisshapeofblades mainly used for tilling hard soils such as dry lands. These rotary blades are attached to the rear end at the roots of weedsandaredrivenbyanotherelectricdcmotor.

Thetwomotorsareconnectedtothetwobatteries individuallyinseries.Batteriesareconnectedtothebattery panel.Thebatteryradiationimmersedonbatterypanel.By thisprocessthegeneratedbatteryenergyisconvertedinto electrical energy. This energy is stored in batteries. This storedenergyissuppliedtothedcmotorswhentheyneeded through whichthe wheelsand weeder bladesarerotated. Themotorspeedisvariedbyalteringtheoperatedvoltage outputthroughthespeedcontroller.

An effort is made to Design and fabrication of battery poweredmulticropweederisdone.Provisionsaremadeto utilizebatteryenergywassuccessfullycompleted.Thiswork isexecutedwithanideatoachieveaneffectivesolutionto theweedcontrol.Thedesignedequipmentissafetouseand ecofriendly. Single operator can operate this machine to weedouttheplants.Labourrequirementandfuelcharges aregreatlyreducedbythisweeder.whichismuchefficient whileasinglepersonoperatesthemachine.Deeperworking depth and a slow travel speed can achieve a good weed control.Weedremovingmachineaddthemodernizationand advancements in the agricultural field. This machine will makethefarmerindependentandnotrelyonthelabourers forremovingweed.

[1]Biswas(1984)accordingtothepowersourcesofweeder.

[2]Smith(1964)statedthatintercultivationisanoperation thatrequired somekindoftoolthatstirthesurfaceofthe soiltoashallowdepthinsuchamannerthatyoungweeds couldbedestroyedandcropgrowthpromoted.

Fig.3.1 Ddiagramofthedevelopedmachine

[3]Devnani(1988)andSinghetal.,(1996)reportedthatthe aimofintercultivationistoprovidebestopportunityforthe croptoestablishedandgrowvigorously,uptothetimeof harvest.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[4]RamamoorthyandBalasubramanian(1991)conducteda fieldexperimentonaclayloamduringthemonsoonseason todevelopaneconomicintegratedweedcontrolmethodfor uplanddirectseededrice.

[5]Venugopaletal.,(1983)observedthatweedcompetition wasmoreunderbroadcastsituation.Handweedinggavethe highestweedcontrolefficiency(89.74%)andhighergrain yield(63.55qt/ha)comparedtotheherbicidaltreatments.

[6]Yadav(1980)gavedetailsofserratedbladeforhoeand harrow,bullockdrawnbladecumtinehoeforweedingand interculturaloperationsindrylandfarming.

[7]Vega et al., (1985) recorded that Echinochloa crusgalli, EchinochloacolonumCyprusiria,commelinaBenghalensis andDigtariasauguinalisarethepredominantweedsinrice fields.

[8]B.T.S. Murthy (2004) Reported about the problem of weedsinuplandriceandgivestheweedsandtheirgroups.

[9]DuffandOricno(1971)reportedthatthetimingrather thanthefrequencyofweedingwasamajordeterminantof effectiveweedcontrolforrice.

[10] Datta et al., (1974) reported that the weeding is traditionallycarriedoutwithindigenoushandtools.

[12]SridharH.S.hasstudied,“Developmentofsinglewheel multiusemanuallyoperatedweeder”InternationalJournal of Modern Engineering Research (IJMER) Vol. 3, Issue. 6, Nov Dec2013pp 3836 3840ISSN:2249 6645.

[13]Nagesh Kumar (2014) has studied, “Performance evaluationofweeders”International Journal of Science, Environmentand Technology,Vol.3,Issue. 6,ISSN:2278 3687

Pravin Kokitakar, AssistantProfessor,Dr.A.D.Shinde CollegeofEngineering,Gadhinglaj, MaharashtraIndia.

Mr. Sanket Desai, UGScholar,Dr.A.D.ShindeCollegeof Engineering,Gadhinglaj,Maharashtra India.

Mr. Shubham Joshilkar, UGScholar,Dr.A.D.ShindeCollegeof Engineering,Gadhinglaj,Maharashtra India.

Mr. Pramod Dalavi, UGScholar,Dr.A.D.ShindeCollegeof Engineering,Gadhinglaj,Maharashtra India.

Mr. Dhanaji Zende, UGScholar,Dr.A.D.ShindeCollegeof Engineering,Gadhinglaj,Maharashtra India.

Mr. Shridhar Magdum, UGScholar,Dr.A.D.ShindeCollegeof Engineering,Gadhinglaj,Maharashtra India.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified