International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1 , D.

Sravya2

1PG Student, Department of civil Engineering, Velaga Nageswara Rao (VNR) College of Engineering, (Approved by AICTE and affiliated to JNTUK, Kakinada), G.B.C. Road, Ponnur 522124, GUNTUR, A.P (INDIA).

2Assistant Professor, Department of civil Engineering, Velaga Nageswara Rao (VNR)College of Engineering, (Approved by AICTE and affiliated to JNTUK, Kakinada), G.B.C. Road, Ponnur 522124, GUNTUR, A.P INDIA. ***

Abstract - High strength concrete (HSC) has been widely usedincivil engineeringin recent years. Thisisbecausemostof the rheological, mechanical and durability properties of these materials are better than those of conventional concrete. High strength is made possible by reducing porosity, inhomogeneity and micro cracks in concrete and the transitionzone. This is achieved by using superplasticizers and supplementary cementingmaterials suchassilicafume/micro silica. Fortunately, micro silica is an industrial by product and help in reducing the amount of cement required to make concrete less costly, more environmentally friendly and less energy intensive. HSC offers many advantages over standard concrete (SC). Its high compressive strength is advantageous and used in compression members like columns and piles. Higher compressive strength of concrete, results reduction in columnsize andincreases availablefloorspace.HSCcanalsobe effectively usedinstructuressuchasdomes,foldedplates, shells andarches where largein planecompressivestressesexist.The relatively higher compressive strength per unit volume, per unit weight will also reduce the overall dead load on foundation of a structure with HSC. In pre stressed concrete construction, a greater span to depth ratio for beams may be achieved with the use of high strength concrete. In marine structures, the low permeability characteristics of high strength concrete reduce the risk of corrosion of steel reinforcement and improve the durability of concrete structures. In addition, high strength concrete can perform much better in extreme and adverse climatic conditions and can reduce maintenance and repair costs. The production of HSC may or may not require the special materials, but it definitely requires materials of highest quality and their optimum proportions. In the production of HSC, use of strong, sound and clean aggregates is essential. The reduction of the capillary pores in the matrix and improving the bond strength betweencementmatrixandaggregateisessential.Thesecanbe accomplished by using low water cement ratio and incorporatingultra fine particles(particlesmuchsmallerthan the grains of cement, such as silica fume) in the concrete mix. Finally, high strength concrete having strength greater than 100 MPa is achieved using micro silica and superplasticizer. Utilization of standard and high strength concrete has increased enormously.

Words: M30,M90,Compressiontest,Splittensiletest, Flexuralstrengthtest.

Concrete has a highly heterogeneous and complex microstructure. Therefore, it is very difficult to design realisticmodelstopredictthebehaviouroftheconstituent materials in concrete. However, knowledge of the microstructureandpropertiesoftheindividualcomponents ofconcreteandtheirrelationshiptoeachotherisusefulfor exercisingcontrolontheproperties.Concretemicrostructure consists of two major components namely aggregate and hydrated cement paste. The interfacial transition zone betweenthetwocomponentsisgenerallytheweakestpart which may fail during the application of load. Hence, it is necessary to study the mechanical behaviour of concrete which inturnisinfluencedbythethreephasesofit.Eachof the three phases (namely aggregate, cement paste and interfacialtransitionzone)isitselfamultiphaseincharacter. The major components and the interfacial transition zone maycontainseveralmicro cracksandvoids which greatly affect the strength of concrete. Therefore, it is difficult to generatethe theoretical relationship models between the aggregate, matrix and the interfacial transition zone for predictingthebehaviourofmaterialsduetoheterogeneous distribution of cracks. In solids, there is an inverse relationship between porosity andstrength. In multiphase materiallikeconcrete,theporosityofeachcomponentofthe microstructureisoneofthefactorswhichaffectthestrength. Naturalaggregatesaregenerallydenseandstrong.Therefore, the porosity of the cement paste matrix as well as the interfacial transitionzone between the matrix and coarse aggregatedeterminesthestrengthof normalconcrete.

Concrete strength is affected by many factors which includepropertiesandproportionsofmaterialsthatmakeup thedesignmix,degreeofcompactionandheatofhydration. Thewater cementratioandporosityareimportantfactorsas theyaffectthefluiditybetweenthematrixandtheinterfacial transition zone. Direct determination of porosity of the individual components of concrete is impractical and therefore precise models of predicting concrete strength

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

cannotbedeveloped.However,overaperiodoftimemany empiricalrelationshavebeenfound,whichprovideindirect information about the influence of numerous factors on compressivestrength.Strengthofconcreteduetoitscomplex structureisdependentonvariousfactors:(1)characteristics andproportionsof materials(2)curing conditionsand(3) testing parameters. The selection of materials and their proportionsisthefirststeptowardobtaining aproductthat wouldmeetthespecifiedstrength.Manydesignparameters areinter dependentandthereforetheirinfluencesshouldbe studied.

The water cement ratio in concrete is one of the key factors for weakening of the matrix caused by increasing porosity.Asthewatercontentincreases,thereisanincrease inporosityofthematrixaswellasinterfacialtransitionzone whichreducesthestrengthof concrete.Butincaseoflow strength concrete, strength is not much influenced by the water cement ratio. The porosity in the matrix and the interfacial transition zone determines the strength in low gradesofconcrete

Theexperimentalprogramhasbeencarriedoutinthree phases.Firstphaseisrelatedtotheevaluationofproperties ofmaterialsusedinconcrete,mixdesignofM30andM90 gradesofconcrete,specimenshapeandsizeeffectonM90 grade concrete. In second phase, thermal stability of standardconcrete(M30)andhighstrengthconcrete(M90) atambienttemperatureandatelevatedtemperaturesupto 400°C has been carried out using thermogravimetric analysis. The study of the effect on compressive strength, splittensilestrengthandflexuralstrength.

Cement

Fineaggregate

Coarseaggregate

MicroSilica

2.2

Mixproportionsofstandardconcrete (M 30) are basedon guidelines of IS: 10262 2009.

Forhighstrengthconcrete(M90),mix proportions are achieved using ACI 211.4R 2008.

Table

S.No Particulars Test Results Requirements as per IS: 12269 1987

Chemical properties

1 Insolublematerial(%by mass) 0.68 28.96 Maximum 2 Magnesia(%bymass) 1.16 6.00Maximum 3 Sulphuricanhydride(% by 1.73 3.00Maximum mass) 4 Lossonignition(%by mass) 1.15 5.00Maximum 5 Totalchlorides(%by mass) 0.006 0.10Maximum

Physical properties

1 Finenessasweight retainedon 5.50% 10%Maximum IS90micronsieve 2 Standardconsistency(%) 30

3 Settingtime

a) Initial(minutes) 125 30Minimum b) Final(minutes) 225 600Maximum 4

Soundness a)Le chatelier method(mm) b) Autoclavemethod (%) 1 10.0Maximum 0.026 0.8Maximum 5

Compressivestrength (MPa)at3days at7days 39.61 27Minimum at28days 50.05 37Minimum 63.6 53Minimum

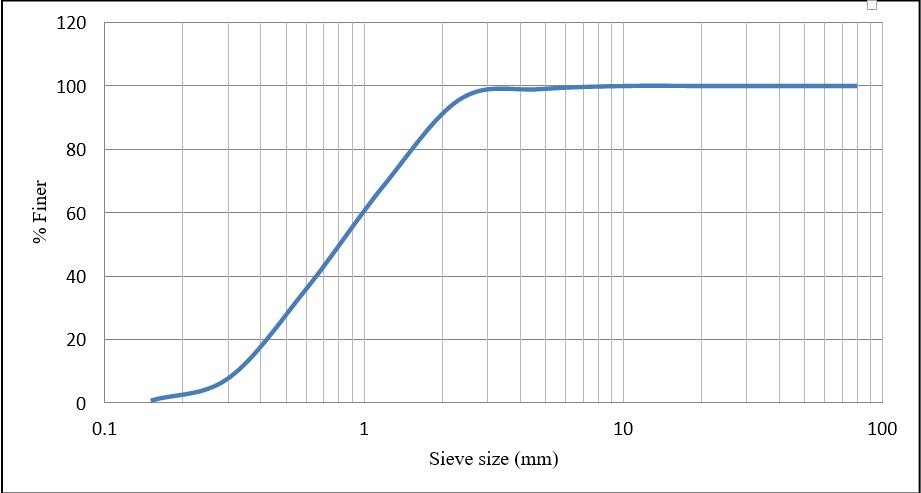

Chart 1:GradingsystemforFA(Fineaggregate)

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Typeofcement:OPC53grade

Minimumcementcontent:320kg/m3

Exposurecondition:severe

Typeofaggregate:crushedangularaggregate

Specificgravityofcement =3.11

Specificgravityoffine aggregate =2.65

Specificgravityofcoarse aggregate =2.78

Finenessmodulusoffine aggregate =2.92

Finenessmodulusofcoarse aggregate =7.38

Dryroddeddensityofcoarse aggregate =1700 kg/m3

Table 2: Studyofmixproportions

S.No. Ingredient

Standard concrete High strength concrete M 30 M 90

1 Cement(OPC 53grade) 370kg/m3 594kg/m3

2 Microsilica Nil 66kg/m3 (10%of cementitious material)

3 Fineaggregate 740kg/m3 650kg/m3

4 Coarse aggregate 1214 kg/m3 1105kg/m3

5 Water 165 l/m3 145 l/m3

6 Superplastcizer Nil 0.8%byweight of cementitious material

7 Workability 45mm slump 0.85 compaction factor

Basedonthedesignmixproportions,cubes,cylindersand prismsofconcretearecastandtestedinordertoinvestigate compressive strength, split tensile strength and flexural strength for standard concrete (M 30) as well as high strengthconcrete(M90)subjected tothermalcyclesafter curedfor28days.Eachthermalcycleconsistsofheatingof the specimens for 8 hours and subsequent cooling for the remaining period in a day. In the present chapter, experimental set up and testing methods for compressive strength, split tensile strength and flexural strength are mentioned.

Grade of concrete: Standard concrete (M 30) and high strengthconcrete(M90)

Temperature:27,100,200,300and400°C

Numberofthermalcycles:1,5,10,15,20,25,30,35,40,45 and50

Parameters:compressivestrength,splittensilestrength, flexuralstrengthandweightloss

The sequence of feeding ingredients in the pan mixer dependsonthepropertiesofmixandthoseofmixer.Inthis work,asmall amountofwaterisfedfirstinpanmixeras shown in fig 1, followed by coarse aggregate in saturated surfacedryconditionandfineaggregate.Thesematerialsare mixeduniformlyandthencementitiousmaterialisfedinto themixer.Afterattaininguniformmixtureofallingredients, waterisadded.

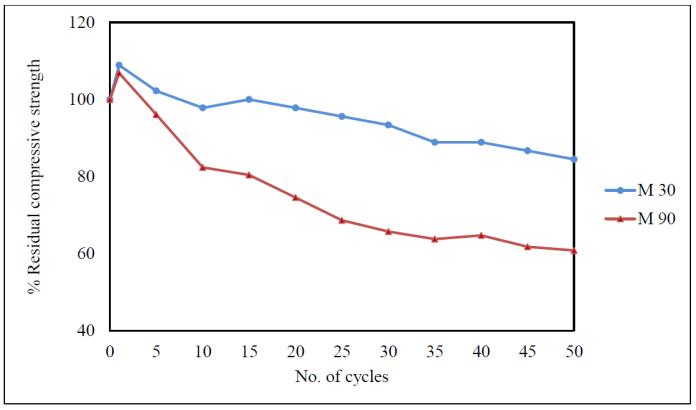

Chart -2:CompressivestrengthforM30andM90

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[1] Abdel FattahHishamandSameerAHamoush (1997),“Variationoffracturetoughnessofconcrete with temperature”, Construction and Building materials,Vol.11,No.2,pp105 108.

[2] ACI 116R (2005), Cement and concrete technology,ACITechnicalPublications.

[3] ACI 211.4R (2008), “Guide for selecting proportions for high strength concrete using Portlandcementandothercementitiousmaterials”, ACICommitteeReport,AmericanConcreteInstitute.

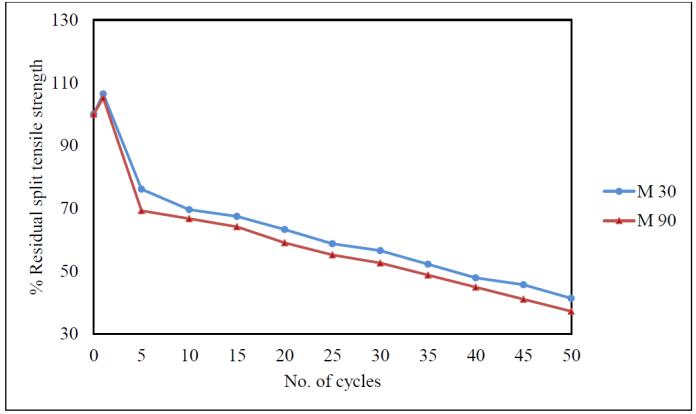

Chart 3:SplittensilestrengthforM30andM90

[4] ACI234R (2006),“Guidefor theuseofsilica fumeinconcrete”,ACICommitteeReport,American ConcreteInstitute.

[5] Adithyaa Saran A S and Magudeaswaran P (2016), “Concrete micro structure A review”, Imperialjournalofinterdisciplinaryresearch,Vol.2, Issue.12,pp.1670 1673.

[6] Aitcin P C (2004), “High Performance concrete”,E&FNSpon,London.

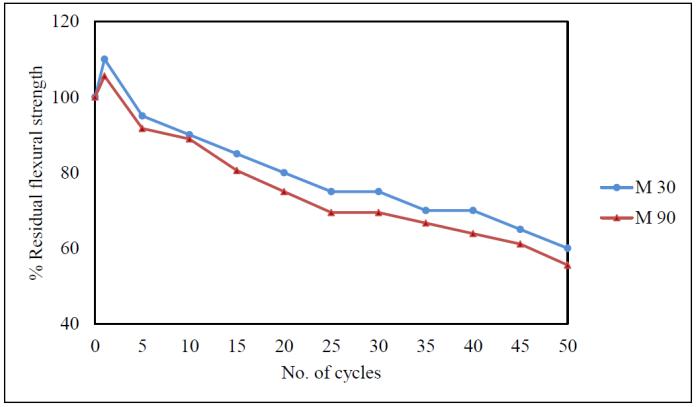

Chart 4:FlexuralstrengthforM30andM90

1. The cycles have more adverse effect on compressivestrengthofHSCthanSC.

2. At high temperature, the first thermal cycle causesbulklossinstrength.SCloses2.22,4.44and 11.12% at 200, 300 and 400°C respectively after firstthermalcycle.

3. But23.53,26.47and30.39%lossesinstrength areexhibitedbyHSCspecimens.

4. Whenconcreteisheatedto200°C,SCretained 82.22%ofitsinitialcompressivestrengthwhereas HSCretainedonly58.82%

5. At300°Candafter50thermalcycles,theresidual flexural strength of SC is 50% but HSC retained 47.22%ofitsoriginalstrength.

6. Asthenumberofthermalcyclesincreased,the residual split tensile strength decreased for both gradesofconcreteexceptatfirstthermalcycle.

[7] Alarcon RuizL,PlatretG,MassieuE,Ehrlacher A(2005),“Theuseofthermalanalysisinassessing the effect of temperature on a cement paste”, Cementandconcreteresearch,Vol.35,pp.609 613.

[8] Alma D R M, Martha L D P, Rosa M M A and Gerardo A R T (2014), “Characterization by thermogravimetricanalysisofpolymericconcrete with high density polyethylene mechanically recycled”, Journal of minerals and materials characterizationandengineering,Vol.2,pp.259 263.

[9] Alonoso C and Fernandez L (2004), “Dehydrationandrehydrationprocessesofcement pasteexposedtohightemperatureenvironments”, Journalofmaterialscience,Vol.39,pp.3015 3024.

[10] Al Tayyib A J, Baluch M H, Al Farabi M Sharif and Mahamud M M (1989),“The effectof Thermal cycling on the durability of the concrete made from local materials in the Arabian Gulf countries”, Cementandconcrete research,Vol.19, pp131 142.

[11] Al Qadi A N and Al Zaidyeen S M (2014), “Effect of fibre content and specimen shape on residual strength of polypropylene fibre self compacting concrete exposed to elevated temperatures”, Journal of King Saud University EngineeringSciences,26(1),pp.33 39.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

[12] Anders S (2016), “Comparison of residual strengthofconcretewithquarzitic,limestoneand slagsandconstituentsaftercyclichigh temperature exposure, Concrete Repair, Rehabilitation and RetrofittingIV Dehnetal.(Eds),TaylorandFrancis Group,London.

[13] ASTME1131 2008,“Standardtestmethodfor compositional analysis by thermogravimetry”, American society for testing and materials, ASTM International,U.S,2008.

[14] Aykut Ceiten and Ramon Carrasquillo L (1998), “High performance concrete Influence of coarse Aggregate on mechanical properties”, ACI Material Journal, Vol.95, No.3, May June, pp. 252 261.

[15] Bairagi N K and Dubal N S (1996), “Effect of thermal cycles on the compressive strength, modulus of rupture and dynamic modulus of concrete,” The IndianConcreteJournal,August,pp. 423 426.

[16] BalendranRV,MaqsoodT,NadeemA(2001), „Effectofcoolingmethodonresidualcompressive strengthofhighstrengthconcretecuredfor28days and 180 days And Heated To Elevated Temperatures‟,26thConferenceOnOurWorldIn Concrete&Structures:27 28August,Singapore.

[17] BazantZP(1978),“PorePressureandDrying of Concrete at High Temperature Journal of the EngineeringMechanicsDivision”,AmericanSociety ofCivilEngineers,Vol.104,Issue5,pp..1059 1079

[18] Belaoura Mebarek , Oudjit Mohamed Nadjib and Bali Abdelrahim (2013),Design of very high performance concrete using local aggregates‟,AmericanJournalofCivilEngineering, Vol.1,Issue.2,pp.68 73.

[19] BenjaminGraybealandMarshallDavis(2008), „Cylinderorcube: strengthtestingof80to200Mpa (11.6 to 29 ksi) ultra high performance fiber reinforcedconcrete‟,ACIMaterialsJournal,Vol.105, Issue.6,pp.603 609.

[20] BerteroVVandPolivkaM(1972),“Influenceof thermalexposures onmechanicalcharacteristicsof concrete”, International Seminar on Concrete for Nuclear Reactors, ACI Special Publication, Vol.1, Issue.34,pp.505 531.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal