International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1M.tech (Transportation Engineering) Sam Higginbottom University of Agriculture Technology Sciences, Naini, Prayagraj U P 2,3Faculty of SHUATS 4,5Team of QC staff of OSEPL PCSPL Project ***

Abstract - Presently, theconstructionindustryworldwideis using more and more natural resources for producing course aggregates required in concrete construction. Demolished wastematerialgenerated fromBuilding demolitionetc. is not put to use in direct construction except for filling low lying land areas. Such large scale demolition waste or MALWA should be put to better use as far as possible. Recycling of demolished waste can offer not only the solution of growing wastedisposalproblem, but willalso helpto conserve natural resources for meeting increasing demand of aggregates for long time to come for construction.

This paper reviews the outcome of tests carried out in the laboratory on use of Recycled Concrete Aggregate (RCA) and MALWA Aggregate tried in Concrete making. The basic properties of these aggregates are determined and compared with conventional and local aggregate. In the present experimental investigation, these materials in different combinations are tried to produce concrete of grade equivalenttoM20orhigher. ItisfoundthatRecycledConcrete Aggregate from Waste Concrete & MALWA Aggregate can be gainfully used in making fresh Concrete for general construction purposes

Development of Infrastructure in India has become necessaryforthebettergrowthofCountry’sEconomywhich isreachingnearing10%ofGDP.But,thereissevereshortage of infrastructural facilities in India. Thus, rapid developments of infrastructure facilities like Buildings, Roads,Bridges,PowerPlants,etc.areneededinabigway. Constructionhasamajorshareindevelopinginfrastructure inanyCountry,andforcreatingthesefacilities;largescale Constructionisalreadygoingon.Theplanningcommission allocated approximately 50% of capital outlay for infrastructuredevelopmentinsuccessiveplansandnowin 11th five year plan. Accordingly, in the next five years, infrastructureinIndiawillrequireanexpenditureofmore thanRs.15,200billion.Rapidinfra structuraldevelopment such as highways, airports etc. and growing demand for housingrequireshugeconstructionmaterials.Inthisentire infrastructure, Concrete Construction is preferred as they havelongerlife,lowmaintenanceandbetterperformance.

ConcreteisalsoavitalcomponentofeverydayConstruction bycommonmenandisbeingextensivelyusedforalltypesof Constructionincludinghousing.Concreteisalsothelargest constructionmaterialusedallovertheworld,asthiscanbe madeinanygradeorstrengthandcanbecasteinanyshape orsizeasrequiredfor structuresonland,seaorevenonany planet.

In our country and world over, huge amount of demolishedwasteMaterialisgeneratedeverydaywhichis not put to use in construction, except it is disposed off by dumpingaslandfill.Dumpingofwastesonlandiscausing shortageofdumpingplaceinurbanareas.Further,due to urbanization growth, distance between demolition waste generation area and disposal land area has also become longer and therefore, transportation cost of disposal has increased.

Concrete is a heterogeneous material which is made with Cement, Aggregate (Stone Chips), Sand & Water. A typical distributionofconstituentmaterialsinconcreteisgivenin figure1.Outofthetotalingredientsinconcrete,about50% isCoarseAggregate.Allthesematerialsarenotavailablein Plenty and they cost money, so their use should be economizedasfaraspossible.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Presently,the constructionindustry worldwide is using more and more natural resources of aggregates. To makeaggregate,wehavetobreakstonesavailableinhillsor collectthemfromriverbedaspebbles.Environmentstudy saysthatsuchrocks/materialshouldnotbedisturbedasfar aspossible.Ifwebreakmore&morehillocks,thentherewill beindirecteffectonenvironmentlikedeforestation,floods etc. Further, the cost of construction is continuously increasingduetoincreasingcostofconstructionmaterials. In many places, supply of good quality aggregates is depleting,andistobebroughtfromlongerdistanceswhich greatly increase the hauling cost and ultimately the construction cost. Presently, due to huge developmental workbeingcarriedoutintheCountryandconstructiontogo onforever,stoneaggregatesarerequiredforthemanyyears tocomeandtheremaybeashortageofnaturalaggregates after few centuries. Therefore, for conservation of natural resources and protection of environment, it is necessary that.Alternatesourcesofaggregatesbesearchedwhichis necessaryforanydeveloping/developedcountry.

Inthecountryandworldover,hugeamountofdemolished waste Material is generated every day. Central Pollution ControlBoardhasestimatedcurrentquantumofsolidwaste generationinIndiatothetuneof48milliontons;outofthis, waste from construction industry accounts for more than 25%. Management of such high quantum of waste puts enormouspressureonsolidwastemanagementsystem.The basic composition of Solid waste or Garbage varies in compositionfromplacetoplaceandfromtimetotime,buta typical distribution of basic constituents in solid waste is showninfigure2.Though,theorganicwastecanbeputto use for making Bio gas & Manure and Metal pieces & Polyurethaneforrecycling,butMALWAordemolitionwaste is not put to use anywhere. However to do all these processes,itisnecessarytosorttheSolidwasteindifferent categories.Thisisalsotheneedofhourandisbeingdonein mostadvanceCountries.Ingeneral,MALWAgetsmixedup with organic waste or garbage, so it becomes difficult to processthegarbageevenfororganicmanureorbiogasorfor any other thing. However, by observing a few simple precautions during the demolition process of depilated buildings, or renovation of Buildings, the potential for sorting or recycling of the demolished Waste can be improvedandthevalueofproductintheformofMALWA& RECYCLED CONCRETE AGGREGATE (RCA) may be more usefulinConstructionIndustrywherehugequantitiescanbe consumed.

MALWAandConcreteWastearegeneratednotonly throughdemolitionofthedeterioratedstructuresbutalso

due to natural calamities like earthquake, windstorm etc. Thesedepleted buildingsarebrokenorremodeled,which gives rise to lots of waste material called MALWA. This MALWAhasinitbrokenbrickpieces,plaster/setmortar pieces, aggregate, sand etc. More than 12 million tons of demolished waste are generated every month by the construction industry and it is increasing every day. It is therefore, desirable to start recycling and use garbage, MALWA and demolished concrete waste to save environment and energy. Thus, it will conserve natural resources and reduce the space required for the landfill disposal.

TIFAC had conducted a techno market survey on ‘UtilizationofWastefromConstructionIndustry’targeting housing/buildingandroadsegment.Thetotalquantumof wastefromconstructionindustryisestimatedtobe12to15 milliontonsoutofwhich8to10milliontonsareconcrete& brick waste. Such material is not put to use. According to publicsurveyfindings,70%oftherespondenthadgiventhe reasonfornotadoptingrecyclingofwastefromConstruction Industry as "Not aware of the recycling techniques" while remaining30%haveindicatedthat“theyarenotevenaware of recycling possibilities”. Further, the user agencies/industriespointedoutthatpresently,theBISand otherCodalprovisionsdonotprovidethespecificationsfor useofrecycledproductintheconstructionactivities.Inview oftheneedtouse MALWA inConstructionIndustry(Being thelargestIndustry),thetechnologyisbeingdevelopedto explore the role of recycled construction material and its technology for the use in development of urban infrastructure.

Thispaperdealswiththefeasibilitystudyfortheutilization of Demolition waste or MALWA in Construction Industry.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

MALWAcanbeusedformakingrecycledcoarseaggregate for making Concrete. Such MALWA / concrete can be crushed to required size, depending upon the place of its application and crushed material is screened in order to produce recycled aggregates of appropriate sizes. An aggregateproducedbydemolishedbuildingswillbecalled MALWA aggregate and broken concrete to be known as RecycledConcreteAggregates(RCA).

NormallycoarseAggregateisthefracturedstonefromrocks inhillsorpebblesfromriverbed,andbecauseofdepletion ofsupplyofgoodconventionalaggregateincertainregions, the need for development of MALWA & CONCRETE as RECYCLEDAGGREGATEtechnologyisbeingdeveloped.Itis similar to fly ash, which is available from electrostatic precipitatorsofvarioussuperthermalpowerstations,andis aindustrialwastematerial.Itischemicallyreactivewhen, mixedwithcementforuseinconcrete.Thisisaveryuseful asapartialsubstitute,asitgivesbetterconcreteandhaving better impermeability record. Thus, it has a wider use in Construction Industry. This is also a common byproduct used in making Portland Pozzolana Cement by cement IndustryandFlyashConcrete.Similarly,largescalerecycling of demolished waste and concrete will offer, not only the solution of growing waste disposal problem, but will also helpconstructionIndustryingettingaggregates.

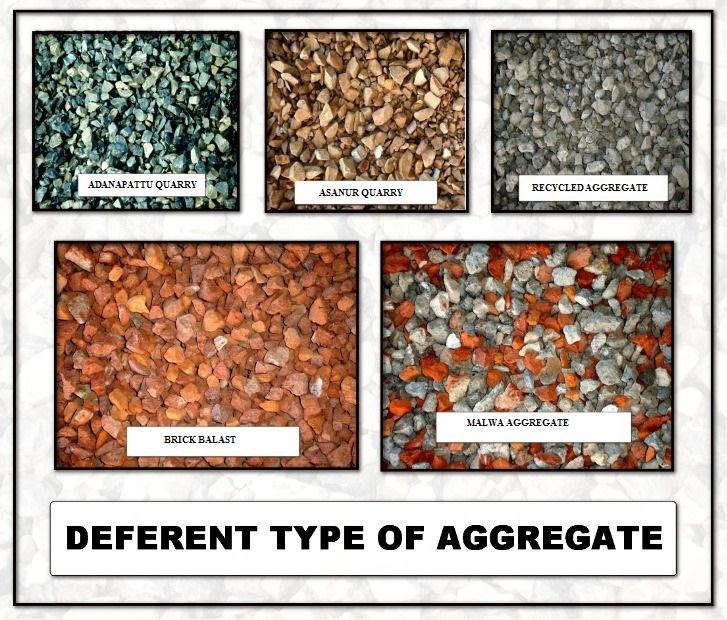

Experimentalinvestigationshavebeencarriedout soastodevelopthemethodologytocollectMALWAandits conversiontorecycledaggregate.Itsuseasaggregateinlow to middle range Concrete strength is investigated. In the presentexperimentalinvestigation,conventionalaggregate, local and brick aggregate have also been taken for comparison on the parallel basis. Thus, following five materialsindifferentcombinationsaretried.

1. Fresh Conventional Aggregate; (Granite from AdanapattuQuarry,Tamilnadu).

2. Fresh Local Aggregate; (Sand stone from Asanur Quarry).

3. Extracted / Recovered Aggregate From Old ConcreteWorks RCA

4. BrokenBrickpieces BRICK Aggregate

5. BrokenBuildingPart MALWA Aggregate

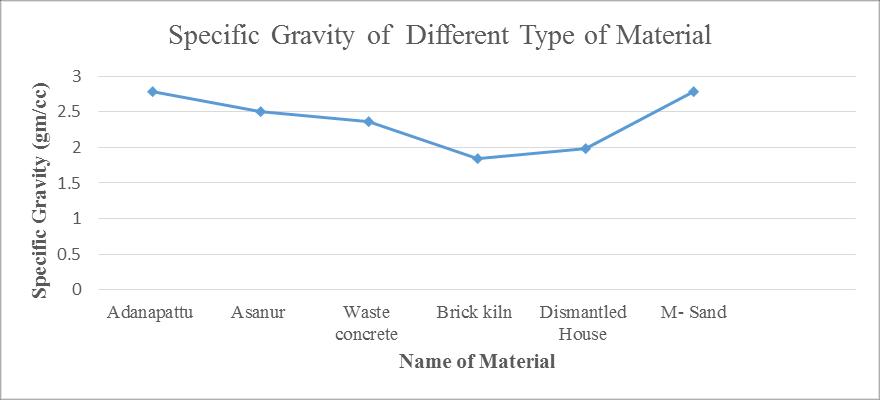

Typical photograph of these five type of aggregates are showninFigure3.Allthesematerialshavebeentestedfor theirphysicalpropertieslikeaggregateimpactvalue,specific gravity, water absorption, bulk density etc. Physical propertiesofthesematerialsaregivenintable1.Aplotof specific gravityofthesefive typeofaggregateisshownin figure4.ItshowsthatspecificgravityofMALWAaggregate is about 72% of fresh Adanapattu aggregate which is not verylow.

TheMALWA,Brick bates&concretedebriswerecollected from different sources and broken into the pieces of approximately20&10mmsizewiththehelpofhammer.On largescalethiscanbebrokenbyCrushers.Theforeignmatter was sorted out from the Solid waste. Further, Aggregate piecesweremechanicallysievedthroughISsieveof26.5mm and 4.75 mm to remove higher & finer particles. The fine particlesseparatedoutcangobacktoriverbedinthesame truckswhichbringriversand.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

2.FivecombinationofRecycledConcreteAggregate (RCA) with fresh ADANAPATTU aggregate in thecombination of 0,30, 50,70and 100% of freshaggregate.

3. Five combination of MALWA Aggregate with fresh ADANAPATTU aggregate in the combinationof0,30,50,70and100%offresh aggregate.

Allthesematerialsweretakenforasmallerbatch andweighedasperdesignrequirementgivenintables2,3& 4.Thesetablesalsogivethequantityofothermaterialsused forM20gradeconcrete.Materialsweremixedinlaboratory mixture.12cubes(150x150x150mmsize)werecastfor each mix. In addition 3 Cylinders each of size 150 mm diameter and 160 and 300mm height were cast for determiningpermeabilityandelasticmodulusofconcretein allthesecases.Cubes&cylinderswerecuredincuringtank. Thecubesweretestedon7,28,60&90days.Eachcubewas alsoweighedandconcretedensitywascalculated

TABLE 2 Design Mix Proportion for Equivalent to M 20 gradeConcrete For Five Different Aggregates

Material Units Fresh Adanapattu Fresh Asanur RCA Brick MALWA

a) Concrete Mixes:

ToseethepossibilityoftheuseofMALWA in construction Industry, experimental investigations are carried out in laboratory to evaluate the Strength, permeability etc. The ConcretemixparametersofMALWAandrecycled Concreteaggregatealongwithothermaterialswere determined for the concrete mix of M20. The propertiesof conventional aggregates used in the normal concrete and design mix with recycled aggregates are the main parameters to compare about the usefulness of these aggregates from strengthconsideration.

Cementusedininvestigationsconfirmstovarious propertiesgiveninIS:12269 1999andhavingCompressive Strengthof53MPaat28days.Freshcoarseaggregatesfrom Adanapattu & Asanur Quarry are conforming to IS: 383 specifications. Fineaggregateisfromriverbed.Waterused is from deep bore well, which is potable quality and free from impurities.Usingthese5typesofaggregategiven in table1,severalconcretemixeswerepreparedinthegrade equivalenttoM20byconventionaldesignmethod(ISCode Method). Following combination of concrete mixes were made.

1. Concrete mixes with the basic five aggregates givenintable1.

TM 2 TM 1 TM 3 TM 5 TM 4

Cement Kg 350 350 350 350 350 20mm Kg 443 577 562 291 286 10mm Kg 646 395 359 424 480 Sand Kg 702 702 702 702 702 Water Kg 210 210 210 210 210 W/C Ratio % 0.60 0.60 0.60 0.60 0.60

TABLE 3 Design Mix Proportion for Equivalent to M 20 grade Concrete For Fresh Adanapattu & RCA in different proportions

Material Units

Fresh Adanapattu (100%)

Fresh 70% RCA 30%

Fresh 50% RCA 50%

Fresh 30% RCA 70%

RCA (100%)

TM 2 TM 7 TM 6 TM 8 TM 3

Cement Kg 350 350 350 350 350 20 mm (Adanapattu) Kg 443 406 221 221 20mm(RCA) Kg 187 187 343 562 10mm (Adanapattu) Kg 646 332 332 129 10mm(RCA) Kg 109 265 281 359

Sand Kg 702 702 702 702 702

Water Kg 210 210 210 210 210

W/C Ratio % 0.60 0.60 0.60 0.60 0.60

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Thedetailsoftheinvestigationaresummarizedand discussedinthefollowingheads. 1. MixReology 2. Compressive.Strength. 3. DensityOfConcrete. 4. FractureMechanismatFailure 5. Permeabilityofconcrete Detaileddiscussionsaregivenbelowunderaboveheads.

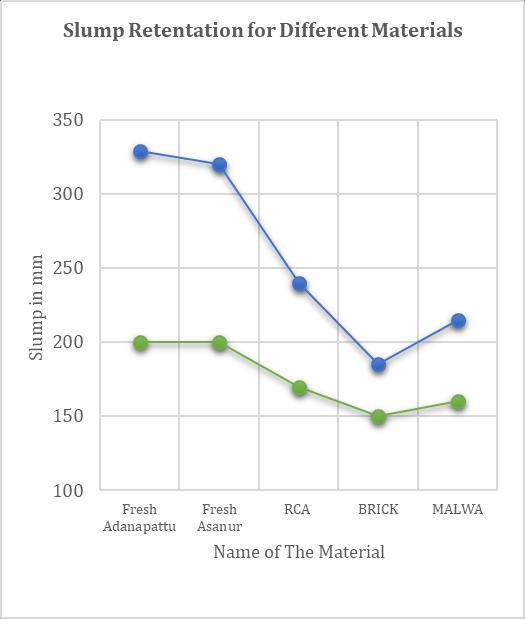

Various observations mix Reology and generalbehaviorforeachmixwasobserved.Freshconcrete mix in general and in slump cone has been carefully examined.Themixwasfoundtobecohesivetextureinall thecases.Togetworkablemixaslightadjustmentinwater cementratiowasmade.Noadmixturewasusedinanymix tobeconsistent.Atypicalshapeofthemixinslumpconeis showninfigure5.Nobleeding,segregationorshearing of slumpconewasobserved.Itwasseenthatconcretebehaves verymuchlikenormalconcretewithtrueslump

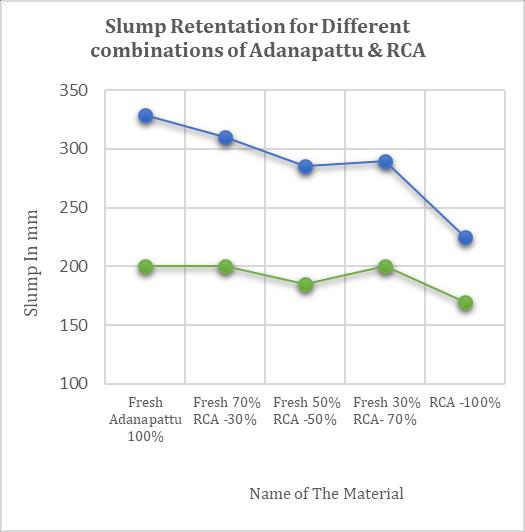

The retention of workability / slump was also recorded for 60 minutes. The details of observations for three broad classifications are given in tables 5, 6 & 7. Variationinslumpvaluefor5basicmaterialsinitiallyand after 60 minutesisshowninfigure6.Itisseen, thateven after60minutestheconcreteremainsworkableforRecycled aggregatesincludingMALWA

Units Fresh Adanapattu Fresh Asanur RCA BRICK MALWA TM 2 TM 1 TM 3 TM 5 TM 4

InitialSlump mm 200 200 170 150 160

Initial Temperature 0C 26.1 18.2 26.8 23.8 25.2 AmbientTemp 0C 29.4 24.3 29.1 26.5 28.2 SlumpAfter1hour mm 129 120 70 35 55

Bleeding No No No No No Segregation No No No No No TypeOfSlump True True True True True

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Slump After 1hour mm 129 120 90 80 55

Bleeding No No No No No

Segregation No No No No No Type Of Slump True True True True True

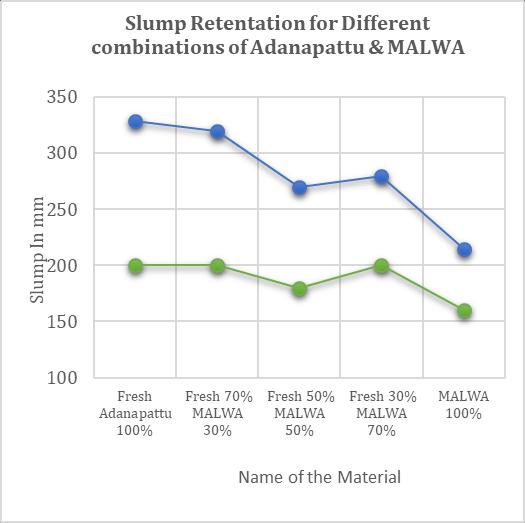

Figure 8 - Value of slump for 5 Different combinations of combinations of Adanapattu & MALWA

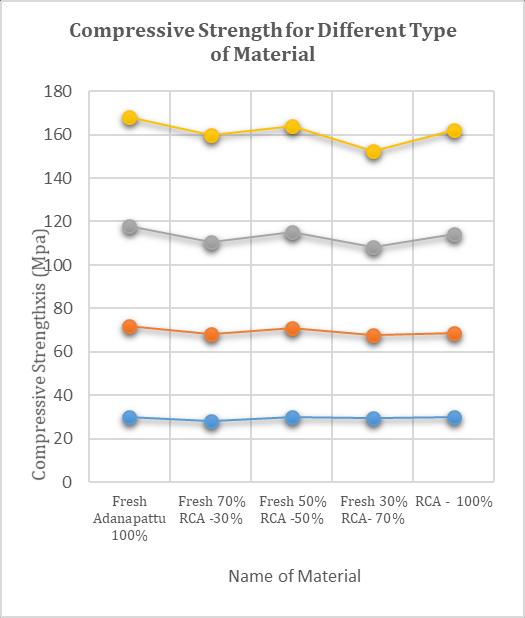

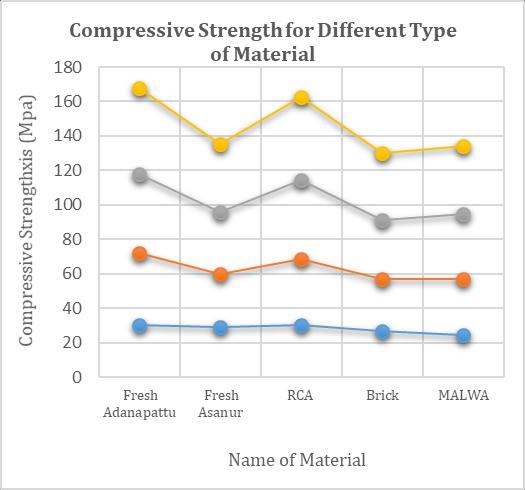

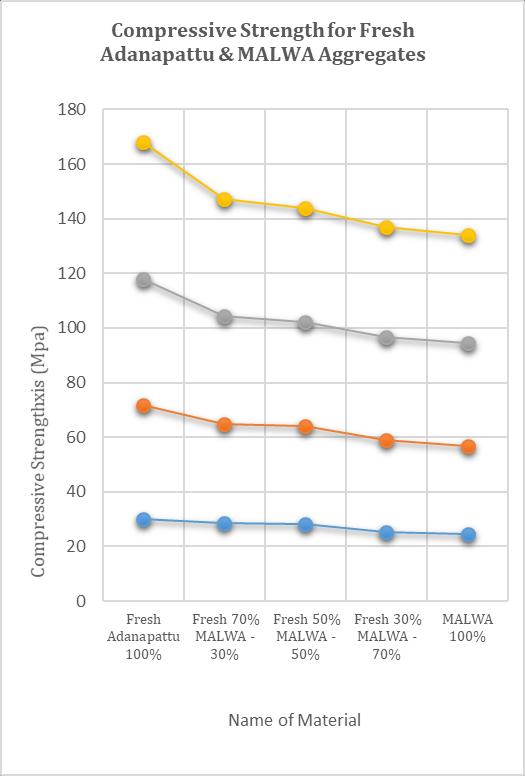

AftercuringtheConcreteCubesweretestedafter7,28,60& 90days.Compressivestrengthineachcaseissummarizedin Tables8,9&10andshowninfigures7,8&9fordifferent cases.ItisseenthatalltheconcreteMixesattainmorethan DesignCompressivestrengthie20MPa.Itisalsoseenthat there is considerable gain in strength even after 28 days. FiguresshowthatCompressivestrengthoffreshandrecycled concrete aggregate (RCA) (100%) is similar. However, strengthwithBrickandMALWAAggregateisminimum.Itis seenthateventheMALWAandrecycledaggregateattainsfull designstrengthanditgainsstrengthevenafter28days

TABLE 8 Compressive Strength With 5 types of aggregate

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Average60day strength MPa 46.09 36.47 45.53 34.31 37.76

Average90day strength MPa 49.82 39.09 48.2 38.49 39.56

Avg. Weight of cubes Kg 8.467 7.776 8.01 7.426 7.61

Density of concrete g/cc 2.509 2.304 2.373 2.200 2.255

Impermeability Coeff. (10 04) (asdefined) 5.09 3.28 3.03 2.97 1.71

TABLE 10 Compressive Strength With Fresh Adanapattu & MALWA Aggregates

Units

Figure 9 - Compressive Strength of concrete mix for 5 basic aggregates

TABLE 9 Compressive Strength With Fresh Adanapattu & RCA Aggregates

Units

Fresh Adanapattu 100%

Fresh 70% RCA 30%

Fresh 50% RCA 50%

Fresh 30% RCA 70%

RCA 100% TM 2 TM 7 TM 6 TM 8 TM 3

Average 7 day Strength MPa 30.08 28.14 30.23 29.5 30.11

Average 28 day Strength MPa 41.88 40.15 40.58 38.32 38.48

Average60day strength MPa 46.09 42.34 44.38 40.38 45.53

Average90day strength MPa 49.82 49.18 48.56 44.42 48.2

Avg. Weight of cubes Kg 8.467 8.253 8.187 8.116 8.01

Density of concrete g/cc 2.509 2.445 2.411 2.425 2.373

Impermeability Coeff. (10 04) (asdefined) 5.09 5.14 5.62 5.65 3.03

Fresh Adanapattu 100%

Fresh 70% MALWA 30%

Fresh 50% MALWA 50%

Fresh 30% MALWA 70%

MALWA 100% TM 2 TM 11 TM 9 TM 10 TM 4

Average 7 day Strength MPa 30.08 28.47 28.27 25.45 24.59

Average28day Strength MPa 41.88 36.18 35.69 33.45 32.12

Average60day strength MPa 46.09 39.73 38.04 37.84 37.76

Average90day strength MPa 49.82 42.78 41.93 40.09 39.56

Avg. Weight of cubes Kg 8.467 8.17 8.07 7.866 7.61

Density of Concrete g/cc 2.509 2.421 2.391 2.331 2.255

Impermeability Coeff. (10 04) (asdefined) 5.09 2.11 1.75 1.84 1.71

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Permeability of concrete is determined using method described in “Specifications for Road & Bridge Works”ofIndianRoadCongress.Forthis3cylinders,having dimensionsof150mmdiameter&160mmheightwerecast and cured for 28 days. They were fixed in permeability apparatusshowninfigure12.Waterpressureof7Kg/cm2 wasappliedfor96hoursinthePermeabilityApparatus.

It is found that such concrete with recycled aggregateorMALWAcanachievethestrengthupto20 25 MPa(equivalentto1:1 1/2:3concreteMix).Suchstrengthis sufficientfornormalConstructionofBuildingsetc.

Each cube was weighed and density of concrete was calculated.Thevariationofdensityineachcaseisalsogiven inTables8,9&10.Itisalsoshowninfigure10forfivebasic aggregates.Itisseenthat densityismaximumwhenfresh Adanapattuaggregateisusedanditisminimumwhenbrick aggregateisused.Themaximumdensityis2.509g/ccand minimum is 2.20 g/cc. RCA shows a density of 2.373 g/cc andMALWAaggregateas2.255g/cc.Itisseenthatdensity withMALWAisabout90%andofRCAisabout95%offresh aggregatewhichisquitehigh.

1. Theshapeofcrushedcubesisshowninfigure11.It is seen that the failure pattern of all Recycled Aggregateissimilarasfortypicalfreshaggregate.

2. It is generally seen that the failure occurs at the interface of aggregate & mortar for fresh Adanapattu & RCA, while as any where for Local, MALWA&BrickAggregates.

3. Brick Aggregate and Plaster lumps pieces are brokeninMALWA&brickaggregates.

After96hourscylindersweretakenoutofM/Cand splitunderlineloadinCompressionTestingMachine.The depth of penetration of water in cylinder was observed & measuredaswellasvolumeofwaterlostfromoriginallevel intheintaketubeisrecorded.Theresultsareinterpretedas:

1. Measure the depth of penetration of water in permeability cylinder at several places and find averagedepth.

2. Coefficient of impermeability is calculated as volumeofwaterlostinthetubedividedbyvolume ofconcretepenetratedwithwateri.e.

Impermeability coefficient = vol. of water lost in tube / (AveragedepthofwaterpenetrationinconcretexX areaof cylinder).

Atypicalsplitcylindershapeisshowninfigure13.Inthis

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Formulation of guidelines, specifications and Codal provisions.

Inbriefthefollowingarethemainadvantagesofusing MALWAinConstruction.

Figure,theeffectofwaterpenetrationisshownattopand markedbyline.Theimpermeabilityofconcrete,asdefined above, is plotted in figures 14. This shows the changes in coefficientofimpermeabilityordepthofwaterpenetration forfivebasicaggregates.Inthecaseofbrickaggregateitis maximum. For RCA, the value is similar to ADANAPATTU aggregate&MALWAaggregateismorethanthis.

Although, it is environmentally beneficial to use MALWA & RCA in construction, however the current legislationandexperiencearenotadequatetosupportand encourage the use of recycled demolished waste in India. Lack of awareness, guidelines, standards and lack of confidence in Architects, Engineers & user agencies is a major cause for poor utilization of MALWA or Recycled Aggregate in construction. Further, the acceptability of recycled aggregate is impeded for structural applications duetothelackoftechnicalknow howlikeporosity,effectof sulphate and chloride, impurities and large variation in qualityetc.Inviewofabove,thereisurgentneedtothetake followingmeasures:

Sensitization/ dissemination or knowledge of demolition waste towards its utilization in construction.

Preparation and implementation of techno legal clausesincludinglegislations,guidance,

Penalties etc. for disposal of construction waste on roads and delineation of dumping areas for pre selection,treatment&transportofMALWA.

National level support on research studies on Solid waste disposal & MALWA utilization with different proportions.

Preparation of techno financial document, financial support for introducing MALWA in construction including assistance in transportation, establishing recyclingplant,RMCPlantetc.

Figure 14 - A typical shape of split cylinder

1. DisposalofMALWAbecomeseasier.

2. It can generate work for unemployed people like collectingMALWAbyRagpickersetc.,anddeposititat ReadyMixedConcreteBatchingPlants.AtypicalReady MixConcretePlant(RMCPlant)isshowninFigure15.

3. Itcankeeptheroadsandstreetscleanbynotdumping MALWA on the road side. This will also minimize the accidentsonRoadsbecauseoffewerobstructions.

4. RMCPlantswillbeabletogetsomerawmaterialfreeof costexcepttheymaypaylittletransportationcost.

5. StonequeriesorHillockswillbelessaffectedandhence environment can be preserved. Resulting floods and droughtswillbeminimized

6. It will save the natural resources like Hillocks, River Pebbles etc from extinction and thus Deforestation of hillyareaswillbeminimized.

7. Finermaterialpassingthrough4.75mmISsievecango backtoriverbedsinthesametruckswhichbringsand fromriverbed.

8. Wecanmakeconcreteblocks,likeclaybricksetcoutof thistypeofconcrete. BymakingbricksoutofMALWA Concrete,themanufactureofconventional claybricks canbe reduced&hencetop Soil,whichissuitable for Agriculture,canbeconserved.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Based on the present investigations on MALWA & RecycledAggregates,thefollowingconclusionsaredrawn.

Itispossibletoproduceagoodconcreteusingthe MALWA & RECYCLED AGGREGATE with partial modification in water and cement contents for appropriatelocations.

waste as recycled aggregate in India”, The Indian ConcreteJournal,January,2006.

All types of aggregate attain full design Strength. EvenBrickaggregateandMALWAalsoattainsfull designstrength,thoughitsstrengthisminimumout ofvarioustypesofAggregatesstudied.

The work has been carried out in the site laboratory of OrientalStructuralEngineersPvt.Ltd.Poondiankuppam Sattanathapuram Project the State of Tamil Nadu under NHDPPhase IV.Authorsarethankfultothemandstaffof Poondiankuppam Sattanathapuram Section Private Ltd., theConsultantandOSEPLstafffortheirhelp.

Concrete with MALWA, Brick & RCA absorbs a higher amount of water than Conventional Aggregate.

Study shows that MALWA & Recycled Aggregate (RCA) can be easily used in construction of buildings, concrete paving blocks & tiles, making similartoClayBricks,flooring,approachlanes,sub baseconcretecourseandinhighwaysfordrylean concrete(DLC)etc.

Partialorfullreplacementofcoarseaggregatesin concrete by recycled aggregates and MALWA generally lowers the compressive strength approximatelyupto20 30percent.Butitcanstill beusedforconcreteuptoM25strength.

StudiesontheChemicalandmechanicalproperties of the MALWA & RECYCLED Aggregate must be done for variation of proportions and their properties.

1. Marek,C.R.Gallaway,B.M.andLong,R.E.,“Lookat Processed Rubble It is a Valuable Source for Aggregates”, Roads and Streets, Vol. 114, No. 9, p 82 85,Sept. 1971.

2. Barra, M and Vazquez, E, “Properties of Concrete with Recycled Aggregates : Influence of the Properties of the Aggregates and Their Interpretation”,Proceedings oftheInternational SymposiumorganizedbytheConcreteTechnology Unit, London,1998

3. Ghosh,S.N.,“ProgressinCementandConcrete”,Pt. I, Vol. I: Science & Technology, Thomas Telford, 1992

4. Rao, Akash, Jha, K. N and Misra, Sudhir, “A frameworkforuseofconstructionand demolition

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified