International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

1

2,3,4

Abstract - In Indian Agriculture, Generally tractors or cultivator machines are commonly used for ploughing. Before this method farmers uses the traditional method this is time consuming and hardworking and costly. So we are intro ducing a new machine. This Machine useful for agriculture in India is of a much larger level. All machine high price and useful for agriculture but not affordable to farmers. So we have created a new machine with this problem in mind to increase the maximum weed removal capacity of the tiller blade in the new design. We have added some extra parts to this machine to help improve the maximum weed removal efficiency. First removing parts are three long tiller blades for tilling operation for Creates favorable environment for crop growth and the second part is cutter attachment for crop and grass cutting. This machine performs both tilling and crop cutting operations.

Key Words: Battery,Blade,Cutter,Tiller,Cutter

In India currently farmers are unhappy to spend money for ploughing operation because of raise in petrolpricedaybyday.Tosolvethisproblem,wemadean electricpowertillerandcuttermachinewhichispowerby battery to electric motor. The battery is ecofriendly and easilyrecharge.Thepowertillerismainlyusedinfarming operation for preparing a seedbed on upper level of land. Theportablepowertillerisnotonlythelargesoilmixingca pacitycomparedtotheothermachinebutalsogoodweed cuttingcapability.

In a market various power tiller machine is availableanditisoperatedoninternal combustionengine. Itrunningonenginethepetrolordieselisneededitisbig problem,becausethistillermachinecreatesapollutionin environmentanditisdangerousforhumanhealth.Tosolve thisproblemwemakethisportableelectricpowertillerand cutterma chine.

Thisiscost effectiveandpollutionfree.inthis portable electric power tiller we added some more useful accessories, which are wheel attachment and cutter attachmentisusedtocutthegrowedcropinsoilandgrassin gardening.

***

InFormakingfarmerslifecomfortableduring tillingwork,EarlierfarmerswereusingTraditionalfarming methodwhichistimeconsuming,hardworkingandcostly, henceweintroducenewtechnology.Normally,themachines areusedfortheagriculturaluseinIndiawhichisofhigher stage.Allmachineswereusedinfarmarehighpriceandnot reasonabletofarmers, henceto overcomethistrouble we weremakethismodel.Thisworkingmodelofpowertilleris Reducing man power & Rescuing the risk. This machine reduce the cost, improve the soil properties. This battery operated power tiller reducing the use of fossil fuel and improvingtheproductivityofagriculture.

InFarminghasbeenanimportantpartofthe humanbeingecosystem.However,conventionalagricultural methods need a lot of human effort and are very time consuming. Agriculture tilling is one of the most labor demandingoperationsinagriculture.Physicaltilingoffields isverytoughtaskwhiletractorsincurhighinvestmentalong with heavy fuel use costs. This low cost portable battery charged electric power tiller and cutter machine is a one stopnewsolutiontodeveloptheconventional agriculture methodsoffarming,asitreducesthehumaneffort,atavery smallpriceusingmotorizedtillingmechanism.

1) To replace the use of non renewable energy source and to make use of other renewable energysource.

2) Thismaydecreasetheinvestmentonfuel,andits price.

3) Thesemakefarmingmoreeffectiveandeasier.

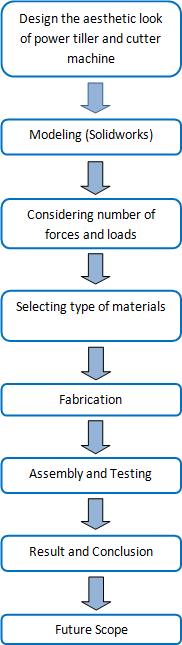

Followingisthemethodologyusedtodesign andfabricateourportableelectrictillerandcuttermachine.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

4.1

Fig 3:FlowChart

After doing research on the several material properties, the most feasible material is select ed for the portableelectrictillerandcuttermachine.Weinvestigatedfor the characteristics which are taken into account, which including machinability, durability, strength, weight, availability, and material cost. A mate rial with sufficient strengthischosen to ensurethat theframe ofthe portable electric tiller and cutter machine does not fail under the strainexerted.Rectangularironpipehasbeenusedforthis project.

Fig -4.1:Electrichubmotor

RatedVoltage:24VDC, OutputPower:250W RatedSpeed:3300rpm,ReductionRation:9.78 TeethOnSprocket:9

4.2 Two Wheeler Wheel Rim

Fig 4.2:Twowheelerwheelrim

Spoke:36, RimDiameter:49Cm SpokeLength:18.5Cm, RimWidth:6.8Cm

Fig -4.3:Controller

Type:BrushController RatedVolt:24V, RatedPower:250Watt

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

4.8 Shaft

Fig 4.4:Wheelangle

AngleType:RightAngle Length:3.5Cm, Breadth:9Cm

Fig 4.8:Shaft Material:MileSteel, Length:27Cm 4.9 Cutter

Fig 4.9:Cutter

Fig 4.5:Lithium ionbattery

Voltage:24V, Current:7.5Ah 4.6 Nut, Bolt & Screw

ShapeofBlade:CircularShape, Material:StainlessSteel NumberofBlade:28 4.10 Chain, Sprocket & Bearing

Fig 4.6:Nut,boltandscrew NutType:Plain, BoltType:Grade0, ScrewType:TrussHead 4.7 DC Motor

Fig 4.7:DCmotor

Voltage:12V, RatedSpeed:6500rpm

Fig 4.10:Chain,sprocket&bearing

ChainLength:134Cm, ChainPin:53 SprocketDiameter:18.5Cm, SprocketTeeth:43

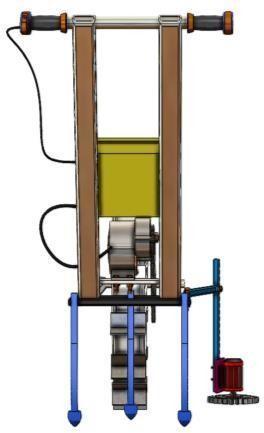

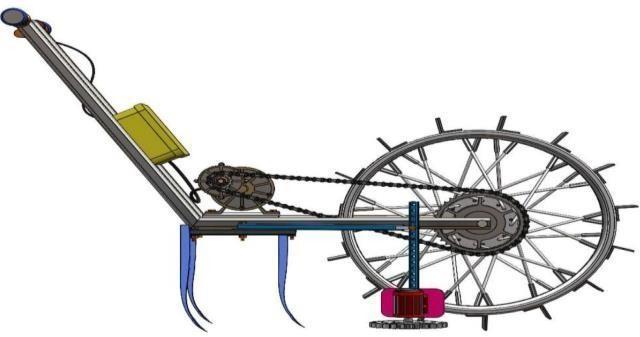

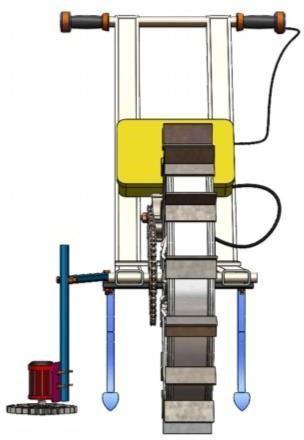

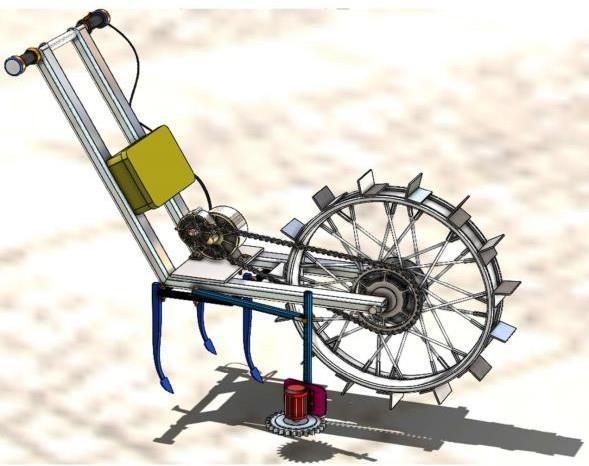

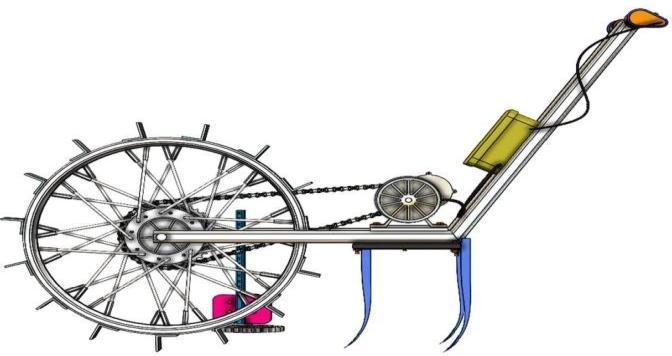

The virtual model is created by using solidworks modeling software to analyze the model. The dimensionareconsideredas perthe physical model anda rough diagram of the portable electric tiller and cutter machineisdrawn.Thencreatea3Dmodel.

This portable electric power tiller and cutter machineisoperatedonbatterypower.Thetillermachineis runningonelectricmotorwhichusesachainandsprocket mechanism arrangement to drive the bike wheel rim. A lithium ion battery is used to power hub motor with tiller bladethroughsoil.Thetillerbladeallowforeasyandnarrow tillingaccuratelyasneededforfarmingandonleftsideofthe machine is cutter attachment isattached for crop or grass cutting.Whilecuttingoperationweremovetillerbladeand attach wheel attachment for easy work. The machine is portable due to simple in construction of machine the maintenanceisveryless.Thepriceofmachineisverylowas comparedtootherICengineoperatedtillermachinesoasthe farmerscanpurchasethemachineeasily.

Themachinemakesuseofabikewheelrimwith welded angles to provide efficient gripping on agriculture soil. The wheel rim design is developed to provide a firm grippingonagriculturelandstrongsufficienttodragthetiller machinebladewhiletillingprocess.Aswitchisprovidedon the right side of handle is used to switch on or off the machine.Themachineisrunbyanelectrichubmotorwhich usesachainandsprocketmechanismarrangementtorunthe pullingbikewheelrim.

Alithium ionbatteryisusedtopowerthehub motorwithaforcecapableofpullingthetillerbladethrough agriculture soil. The three J Shaped tiller blade allow for simple,easyandnarrowtillingexactlyasneededforfarming. Thelightweightandportabledesignoftillermachinemakes iteasytohandleandcontrolthedirectionofmachinearound inanyvehiclesorbyhandfortransportingthemachine.This tiller machine provides a smart new fuel free system for farmingandgardening.Thistillermachineprovidesasmart newfuelfreesystemforfarmingandgardening.ThisMachine Works2to3hours. Fig 6.1:TillerBlade&CutterAttachment

Fig -6.2:Wheelattachment

Following the selection of materials that are light in weight, durable, and readily available, such as reactangular iron pipe. Several machining processes are performed on the material. Clamps, Handle, supports, reactangularironframes,andotherelementsaretillerblade and cutter blade manufactured. In the fabrication , we do cutting, drilling, welding and shaping operations. Other operationsarebendingoftillerblade.Bench wiseclampingis used to prepare the clamps. This all operation done in fabricationof projectoverallmakingcostofthismachineis Rs9506only.

1) Itneedschargingwhenbatteryrunsout.

2) Cleanaftereveryuse.

1) Inagriculturefieldforpreparationforseedsowing.

2) ForPlougging.

3) Weedremoval.

4) Forsofteningland.

5) Forharvestingsmallcrops.

6) Forcultivationofsoil.

7) Soilpreparationforseedsowing.

8) Cropcutting.

9) Unwantedgrasscutting.

10) Anumberofcommonweedingtoolsaredesignedto easethetaskofremovingweedsfromgardensand lawns.

1) Various processes along with ploughing could be donesuchasseedingandsprayingbyaddingmore attachments.

2) Moreoperationscanbeincludedtothemachinelike pesticidesprayer,tillerandmanyothermachines forvariousoperaions.

3) Bymakingmodificationsamemachinewithableto changing the different rotary tool for different purpose example rotary tool for cutting purpose, diggingpurpose.

4) Bymakingfurthermodificationusinglargepower generatedsolarpanel.

5) Bymakingmodificationinincreasingthespeedof themotor.

1) AutomaticOperation.

2) BatteryPowerednofuelneeded. 3) Portableandeasytooperate. 4) Cost effectiveascomparedtoatractor. 5) Replacementforanimalpowerandhumaneffort. 6) Simpleindesign. 7) Easytomaintain. 8) Cheapincost. 9) Pollutionfree. 10) Eco friendly 11) Userfriendly 12) Ithaslowrunningcost.

Today in the world fuel prices and environmental pollution increases day by day. So control environmental pollution, to save fuel and bio product this projectisdesign.Forthismodelrequireslowinvestmentat thestartingstagebutitsgivesmoreenergyoutputwithlow maintenance.Ournewprojectdevelopedbatterypoweredis minimizingtheharmfuleffortofmanualtiller.Hereinour projectweconcludethatbyusingthismachinewereduce the farming cost, animal use, and air pollution and manpower.Ourmainobjectiveistohelpthefarmers.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Weexpressorheartiestacknowledgementto all those who supported us and provided guidance whilst completion of this project. We would like to take this opportunitywithgreatpleasuretoexpressourdeepsenseof gratitudetowardsourguideProf.Shailendra.R.Zaveriforhis valuable guidance and incessant encouragement and cooperation extended to us during this dissertation work. We would like to say special thanks to our Hon. Head of Mechanical Department, Dr. Pravin A. Potdukhe and the incharge of Shri. Shankar Thamke Sir for giving their valuabletime.

[1] AshviPatelandDhanashreeIngle“Design&Fabrica tion ofPowerTillerbyUsingScooterEngine”.Interna tional Journal of Disaster Recovery & Business Conti nuity: journal.vol.11,No.3May2020.

[2] R.magesh Kumar and M.Mayakannan, “Design and Fabrication of Battery Operated Weeder Machine” In ternational Research Journal of Engineering and Technology,vol.07,no.05,IRJET 2020,May 2020.

[3] A.ZakariyahandA.M.EI Okene, “Modificationofport able power tiller for small scale weeding operation,” JournalofEngineeringResearchandReport,JERR vol. 20,no.08,June2021.

[4] AshishKumar,“SolarPowerTiller,”InternationalJour nalofScientific&EngineeringResearch,vol.9,Issue.10, Octomber 2018.

[5] TrikeshwarMPradhan,“Solaroperatedelectricpower tillerwithdetachablehandleandwheel,“International JournalofInnovationsinEngineeringandScience,Vol6, No.1 2021.

Prof. Shailendra. R. Zaveri, Guide of project “Design And Fabrication of Portable Electric Tiller and Cutter Machine” and Associate Professor of Depart ment of Mechanical Engineering at Rajiv Gandhi College of Engi neering Research and Technolo gy, Chandrapur, Maharashtra. They having 25+ years of teach ingexperience.

Mr. Shilkumar. M. Patil ,Project Group Leader of “Design And Fabrication Of Portable Electric Tiller And Cutter Machine”. He is currently pursuing final year of Bachelor of Technology in the Mechanical Engineering at Rajiv Gandhi College of Engineering Research and Technology, Chandrapur, Maharashtra. Aside from that, he is a innovator with enthusiasm and strong analytical skills. with the technical knowledge he eager to work in automobileindustry.

Mr. Nikhil R. Chahande, cur rently pursuing final year of Bachelor of Technology in the Mechanical Engineering at Rajiv Gandhi College of Engineering Research and Technology, Chandrapur, Maharashtra. Apart from that He aims to obtain a deeperunderstandingofvarious automobiletechnologiesbyusing hisexpertiseandtalents.

Mr.Prashant P. Dharne, currentlypursuingfinal yearof Bachelor of Technology in the MechanicalEngineeringatRajiv Gandhi College of Engineering Research and Technology, Chandrapur,Maharashtra.