International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

Inspection and Testing Methods in Casting.

123 Student, Dept. of Mechanical Engineering, Deogiri College, Maharashtra, India 4 Professor, Dept. of Mechanical Engineering, Deogiri College, Maharashtra, India ***

Abstract Non damaging checking out is one a part of the characteristic of excellent manage and is complementary to different long installed techniques. By definition, non damaging checking out is the checking out of materials, for floor or inner flaws or metallurgical condition, without interferinginanymannerwiththeintegrity oftheclothorits suitability for service. The techniques included are Radiography, Magnetic Particle Crack Detection, Dye Penetrate Testing, Ultrasonic Flaw Detection, Eddy Current and Electro Magnetic Testing. Here on this assignment paintings with the aid of using the usage of the radiography technique of NDT checking out is observed to discover the inner defects of the Al6061 forged specimen that turned into made with the aid of using stir casting technique. The aluminum forged shape worried to mono and multi warmth dealt with at approximately 450 ◦C and 600 ◦C in a muffle furnaceandiscompressedautomaticallywiththeaidofusing the usage of hydraulic press preparations earlier than the quick inspection thru NDT checking out. This approach is appropriate for the detection of inner defects in ferrous and nonferrous metals and different materials. Furthermore, the denser the cloth extra could be the absorption. After the number one level of inspection, maximum of the defects had beenidentifiedwiththeaidofusingtheNDTtechniques.Inthe second one a part of this assignment, SEM photographs may be taken for the compressed casting shape. The structural modifications had been efficiently made at the forged specimen and the bond strength, in addition to hardness had beenadditionallyincreased.Theassessmentturnedintomade amongtheNDTinspectedvaluesandtheSEMmicrostructure. It suggests the clean illustration of the grain shape and the bond strength.

1. INTRODUCTION

Casting technique is one of the earliest steel shaping strategies recognized to human being. It method pouring moltensteelrightintoarefractorymildewhollowspaceand permitsittosolidify.Thesolidifieditemistakenoutfrom the mold both via way of means of breaking or taking the moldapart.Whilecastingtherecanbeloadsofdefects.Itis critical to discover all the ones defects and limit them to nearly illness unfastened solid components. In aluminum castings,structuraldefects,oxidebi filmsandporesarenot unusualplaceduetobadsoftenniceand/ormildewfilling machinedesign. Thesestructural defectshave deleterious

resultsatthetensileelectricityandelongationinadditionto thefatiguelife.Testingandassessmentofsolidmerchandise inafoundryenterprisehasonenumberoneobjective.Itisto ensure that elements being produced virtually meet all requiredspecie cautionsmountedviawayofmeansofthe customer.Useofnon unfavorabletryingoutandassessment asawayofnicemanipulateallowstheindustriestoprovide higher nice merchandise. Nondestructive trying out is appreciably practical in lots of plants, aerospace, nuclear enterprise,armyanddefense,garagetankinspection,pipe andtubeinspectionandcompositedefectscharacterization. Discussedonthispaperinparticularmakesaspecialtyofthe scope of NDT software for composite materials. To make certaintheniceoftheelementsproducedviawayofmeans of introducing WAAM to assess the ability of the present NDTtryingoutbecametargetedviawayofmeansofLopez etal.,theyobservedthatforin techniqueinspectionEddy Current, ultrasonic and thermography are the maximum appropriatetechniquesatthesametimeasEMATorLaser UT have much less hindrance and may be an amazing approach.Bettertechniqueswhichcan beappropriatefor diverse illness identification techniques and its suitability becameexplained.Thetryingouttimeisvirtuallydecreased viawayofmeansoftheusageofEMATisarightdevicefor fatiguecharacterizationforexaminingthecrackinitiationvia on line mode verified via way of means of Dobmann. Adopting the dependable approach for NDT trying out of boilertubesinspectionviawayofmeansofVakhgueltetal.It became concluded that the mixture of wall thinning or overheatingbecamethemostimportantharmmechanism. Twoultrasonictakealookatmeasureshavebeenadvised for early detection of each those harm kinds without eliminatingtubefromtheboiler.

1.1 Literature review:

In each manufacturing run, the foundry will select some samples and put up them to unfavourable trying out. The casting is cut, and the houses of the metallic inspected closely.Thetesterwillsearchfor inclusions,porosity,and shrinkage. Although destructively trying out one casting does now no longer assure whatever approximately the alternativecastingswithinsidetherun,itdoesprovideafeel ofthegeneralpleasantoftheprocedure.Radiographicand ultrasonic technology have reduced the significance of unfavourable trying out, however it's miles nevertheless used to look into the pleasant and make reviews approximately a run. Non unfavourable trying out is performedviawayofmeansoffoundryworkers,clients,and

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

NDTtechnicianstoaffirmtheinnerandoutsidesoundnessof a casting with out unfavorable the casting itself. This techniquemakesuseofthehumaneyetobecomeawareof floor defects, cracks, fueloline evolution, slag or sand inclusions,misruns,bloodlessshuts,andmoldingflaws.This form of castings inspection is undertaken to make sure a elementmeetsdimensionalrequirements/tolerances.This maybeperformedmanuallyorwithacoordinatemeasuring machine(CMM)thatmakesuseofprobestogetveryunique measurements. Finds tiny cracks, pores, or different floor imperfectionsinallkindsofmetalliccastingswhichcouldbe difficulttopeerviawayofmeansoflooking.Thetesterfirst cleansthecastingtoputoffanydebrisofgritordirtthatcan saveyoutheliquiddyefromgoingintocrackswithinsidethe metallic. MPI is like LPI in that it's miles used to discover smallcracksandholesatthefloororshallowsubsurfaceofa casting. However, this procedure can most effective be utilized in castings product of ferromagnetic metallic that maycreateamagneticareametalslikeiron,cobalt,nickel, andanumberoftheiralloys.

Thecastingismagnetized,typicallywithelectromagnets,to beginthetakealookat.Thistakealookatunearthsdefects throughtheusageofexcessivefrequencyacousticstrength transmittedrightintoacasting,inagenerationjustlikethe ultrasoundsutilizedbyscientifictechnicians.Soundwaves tourthruacastingtilltheyhittheotherfloororaninterface ordefect.Anybarrierdisplaysthesoundwaves,whichget betterandarerecordedforananalysttoappearanceat.The sample of the strength deflection can imply the area and lengthofaninnerdefect.Thisnon damagingtakealookat also can be used to take a look at wall thickness, and the nodule rely of ductile iron. Extremely small flaws may be observedwithUTatverymassivedepths,bearinginminda exquisite deal of accuracy and confidence. An skilled technicianmayevenmakeestimatesastothecharacterofan alloy through searching on the acoustic signature of an unknownmetal.X rayscreatepixliketheonesinahealth facility that display damaged bones. The ghostly pix producedthrucastingX Raydisplaydarkishspotsinwhich thereareshrinkagecavities,thesmallbreaksandcrevicesof warmthcracking,orthepinholedotsofporosity.Thesepix assist an skilled metalworker determine if the casting’s mechanical houses are compromised through shrinkage, inclusions,orholesandwhetherornottheymaybeconstant earlierthancastingsareshipped.

1.2 Early history:

Throughoutrecords,metalliccastinghasbeenusedtomake tools,weapons,andspiritualobjects.Metalcastingrecords and improvement may be traced lower back to Southern Asia (China, India, Pakistan, etc). Southern Asia traditions and religions relied closely on statue and relic castings. Theseobjectshadbeenregularlycraftedfromacopperalloy laced with lead. Since the start of metallurgy the bulk of castingshadbeeneasyoneto2piecemoldsoriginalfrom both stone or ceramics. However, there may be proof of

misplacedwaxcastingsinseverahistoriccivilizations.The misplacedwaxmethodoriginatedinhistoricMesopotamia. Theearliestregardedfileofmisplaced waxcastingisaclay pill written in cuneiform withinside the historic town of Sparta,Babylon,whichinparticularinformationhowagood deal wax is wanted to forged a key. The earliest regarded castingswithinsidetheinternationalarchaeologicalfilehad been made in open stone molds. There are varieties of misplacedwaxmethods,directmisplacedwaxapproachand oblique misplaced wax approach. The direct molding approachistomakethewaxclothintotheequalwaxmildew becausethecastingwiththeaidofusinghandordifferent tools; the oblique molding approach is to make the wax mildewviathemildew.Thedirectmoldingapproachcalls forcraftsmentohaveaexcessivetechnicallevel,inanyother case the first class of castings can not be guaranteed. However, the dilemma of guide direct molding is that its performanceissimplytoolowtoreapmassproduction.In this regard, oblique moulding has advantages. In oblique moulding,artisanstypicallymakemouldsfromstone,wood, clayordifferentplasticmaterials.

Earlycivilizationsobservedleadaidedwithinsidethefluidity ofmoltencopper,permittingthemtoforgedextraelaborate designs.Forexample,thedancingfemaleofMohenjodarois acopperalloycastingthatmaximumpossiblymakesuseof themisplacedwaxmethod.

2. EXPERIMENTAL

2.1 Material selection and specimen preparation

Intheoriginalstagethematerialwasboughtgroundedon literature check and experimental plan. originally the aluminum amalgamation was chosen because of light in weight high strength material with further ductile and optimum hardness. The mileage capability of the accoutrements is more and also the cost becomes low compare with other nonferrous accoutrements . So we named Al6061 amalgamation material which is most considerablyusedofthe6000seriesaluminumblends.It'sa proteanheattreatableextrudedamalgamationwithmedium tohighstrengthcapabilities.

Stircastingisanaffordablesystemofmeltingandfabricating the needed essence matrix mixes in which a circulated memberismixedwiththeunderpinningcomplementsfor therecommendedshapesandsizes.Themixingorshiftingof moltenessenceandtheadditionofmountswiththeelectric motorcoupledwiththestirrerplacedvertically abovethe furnacearrangements.Themoltensedimentwasmixedwith the mounts and its complements by mechanical stirring actionbygraphitestirrerrod.It'sfullybringeffectiveand qualitativetoo.Itcontainsmagnesiumandsiliconasmajor alloyingrudimentswhichisshowninTable1,alsohaving viscosityof2700kg/cm3whichisexactlysuitableforhigh strengthlowweightoperations.Theneededshapesofthe instancearecreatedbythestircastingprocess.Thecasting

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

wasdoneinthehightemperaturemoldingfurnacewhichis having the melting temperature range of 900 1200 ◦ C, veritably suitable for makingnon ferrous castings. The casting instance shape was turned back in the form of blockish

2.2 Innovative heat treatment of casted specimen

After completing the casting process through machining thesesampleswerepreparedandit'sinvolvedtoprimary mono heat treatment at a temperature of 450 ◦ C sure as shootingtimewithannealedandquenchedmode.thenthe 600◦ Cinmultiheattreatmentprocesseswasattainedover thesampleswhichwereannealedandquenchedbeforewith monoheattreatment.Completelyfoursamplesoutofeight wereheattreatedbymonoheattreatmentatatemperature of600◦Cwithannealedandquenchedmanner.Inmultiheat treatedstyles,theremainingfoursamplesweretreatedfirst with450◦Calsoafterthecompletionofhardeningbyanneal or quenching those are coming in to the secondary heat treatmentwiththetemperatureof650 ◦ C.theidenticalair hardeningandquenchinghasfollowedaftercompletionof themultiheattreatmentprocess.thewarmthtreatmentwas donebyusingthemufflefurnaceKSM 0012showninFig.2 whichhasusablechambersizeof100mm×100mm×225 mmwiththeoperatingtemperatureof1000◦Coutsideupto 1200 ◦C.

Thesampleswerewellhardenedandtreatedbyusingthe annealing and quenching stages the least bit situations of formingtemperatures.Thesecondaryheattreatedsamples weretreatedwiththetemperatureof600 ◦C.It'llmotivate theProcessbywhichdistortedgrainsofcoldorhotforming essence.Werereplacedbythenewstrainfreegrainsduring thisfreshheattreatment.Itbecomesthefabricmoreductile, hardnessandmelioratedgrainstructure.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

2.3. Measurement of hardness and NDT testing on hot pressed specimen

Afterthecompletionofwarmthtreatments,thespecimens weresuddenlyinvolvedfortherecentpressingbyusingthe Universal Testing machine FIE Universal 2001 (UTE). The specimenswereinvolvedduringthishotpressingbyUTM withthegraduallyappliedcompressiveloadof400KNbefore quenchingandannealingasshowninFig.3.

The displacement and cargo values are noticed from the electronicdisplaywithintheoutputresponsepanelofUTM. subsequently the specimens were suggested for hardness measurementasshowninFig.4.Defectlesscastingspecimen were prepared successfully by the casting of pure Al6061 alloymaterialandalsotheheattreatmenthighlyremovedall theinnerstressesanddefectsofthespecimen.

Betterhardnesswereidentifiedtheflexibilityofresistingthe hundredsamongvarioussampleswhichisclearlyagreedthat morehardnessischancedinmultiheattreatedsamplescom paredwiththemonoheattreatedsamples.ByusingBrinell andRockwell hardnesstester, theBHNandRHN values of everyhardenedspecimensweremeasuredbyusingsteelball intender with the load of 2000 kg. By measuring the impression of indentation to spot the values of BHN in a straightforwardmanner.

Thedefectswerealsoidentifiedbytheradiographymethod ofNDTwhichisclearlyassuredthatthenodefectslevelof outputs after the specimen met these reasonably heat treatments.Thescanningmicroscope(SEM)readingswere collectedforthehighlightedcastedpieceforfindingthegrain strength and particle size in a very micro level of observations. Finally, the SEM readings of the sample specimens and NDT results of the identical were analyzed andthereforethereadingsweretabulated.

3. RESULTS

During the new forming process of Al 6061amalgamation casting with none mounts the samples were prepared by casting.Twoheattreatmentprocesseswerefollowedafter therecentpressingthroughthepressactioninUTMmachine. Theinstanceconsistencewasreducedfromitsoriginalshape thankstomoderateamountofappliedcargoof400KN.The formingtemperaturesweremaintainedas600 ◦Cand450◦ C. The forming temperatures grounded on the respectable situationsofmeltingtemperaturesofaluminumblendsand its castings which is precisely near 650 ◦ C. There are two stagesofhotpressingandwarmthtreatmentswereinitiated similarasmonoheattreatmentandmultiheattreatmentfor the constant pressing force of 400 KN. within the primary stageofmonotreatment,thecastedinstancehottedatthe temperatureof600◦CwithinthemufflefurnaceKSM MF01 asshowninFig.2whichhastemperaturerangeofmaximum 1000◦C.Afterreachingtheannealingtemperatureof600◦C which is sort of grasped as liquid result the instance incontinentlyinvolvedinhotpressingbyusingFIEUniversal testing machine 2001( UTE) as shown inFig. 3. the recent instancewaspressedandalsoannealedsureholdingtimefor gettingfurtherhardnessandgoodmechanicalparcelswere attained. During the quenching process the new instance weredippedintothewaterresult.

Thenthedeportationswerecalculatedfromitsoriginalthick ness of every instance after briskly pressed and it's mentioned in Table 2. The distortion situations were well prognosticatedthroughthedynamicanalysissoftwaretool Deform 3D. These prognosticated graphical values of deportations are compared with the measured change in consistence values. We've to calculate the relegation as change in consistence of the new presses specimen under colorful heat treatment processes3.1. Calculation of displacementvariation

Here the displacements were calculated from its initial thickness of each specimen after hot pressed and it is mentioned in Table 2. The deformation levels were well predictedthroughthedynamicanalysissoftwaretoolDeform 3D. These predicted graphical values of displacements are comparedwiththemeasuredchangeinthicknessvalues.We havetocalculatethedisplacementaschangeinthicknessof the hot presses specimen under various heat treatment processes.

3.1. Simulation results of hot forming

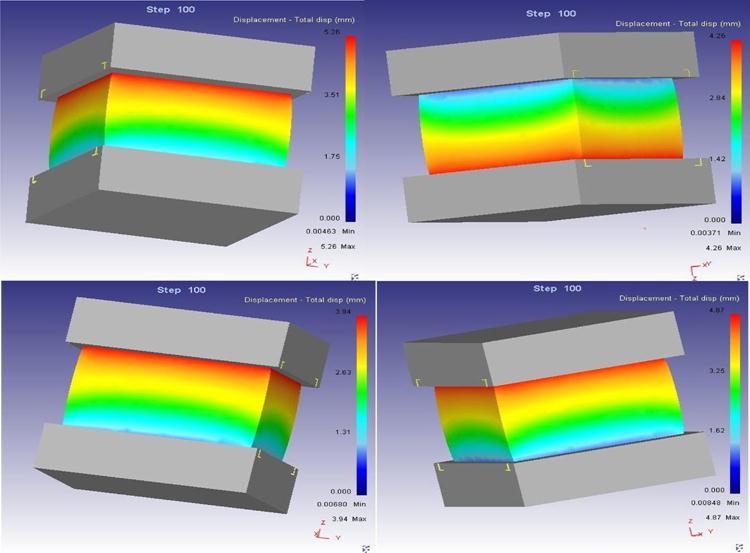

Fig. 5 Simulationresultsofdisplacementsoncastingsfor 450 ◦Cand600 ◦C(P=400KN).

Using Colorful duplications of hot forming by using the dynamic simulator Deform 3D. In this simulation the primarywaytheinputparametersofcompressingloadsand boundaryconditionswereadded.Theaccoutrementsparcels alsomentionedasAl6061amalgamationfromthematerial librarywhichisautomaticallyincludedallthedatarelatedto the material actions. After the process steps got over the instancemodelimportedandthereplicationsituationsare

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

tobeset.Afterthecompletionofboundaryconditions,the portableandfixedjawswereindicated.multihuedloadsand forming temperatures are also given as input parameters. The stress values and deportations were linked as affair responsesaftercompletionoftheiterativesimulations.Then the less relegation was recorded as3.94 for the annealed multiheattreatedsampleasshowninlargerdeportations were attained during the mono heat treated samples. The variation among all the trials, these two heat treatments were showed easily the least values of variation0.61,0.94 was attained during the multi heat treatment stage at a temperatureof650 ◦ Cforthecargoof400KN.

3.2. Comparison of hardness in hot pressed specimens

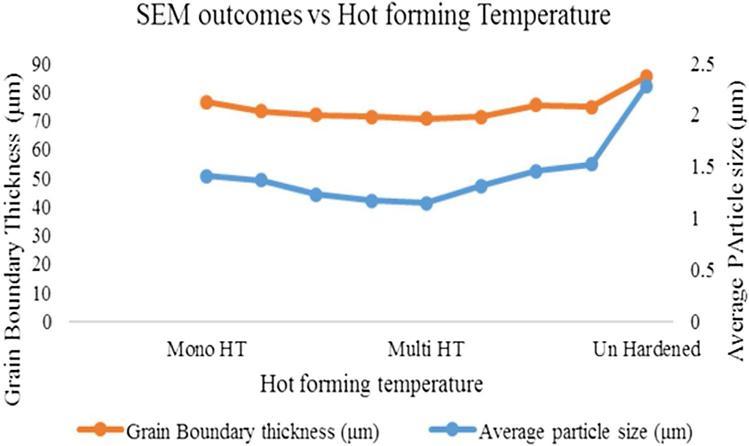

It'sverifiedthattheprognosticatedvaluesofrelegationin dynamicsimulationtooldistort3Dinhotforming,thedis placementvariationisminimalduringthemultiheattreated instance examination because of change in consistence varyingdependsontheheatingtemperaturesatabout600◦ C. The grain boundary consistence and flyspeck size were recorded minimum due to the hot compressed multi heat treatedAl6061samples.Thestrainratebecomeshighused tochangetheflyspecksizeminimum.Morecompliancesof flyspecksizereduction,grainboundarystrengtheningand highhardnesswereconcededgoodinmultiheattreatedhot pressingofAl6061castingsamples.Therewerenofurther blightswerelinkedinNDTamongthebothmonoandmulti heattreatedcastingsamples.Aftertheheattreatmentand hot forming is over, the hardness of each instance were calculatedandthecompliancesarementionedinTable3as shown over. Both Brinell( BHN) and Rockwell hardness( RHN) testing were done on the treated instance in both situations of forming stages. Then we easily linked the hardness of multi heat treated instance has got awful hardness111.81 BHN and65.365 RHN, independently. Compared with the mono heat treated instance advanced hardnesswereachievedinthevariationof2.5125hardness numberwiththemultiheattreatedinstance.It'snotedthat thelowerhardnessvalueswererecordedinthenon heat treated instance as99.25 BHN and58.77 RHN. Advanced hardness was attained on the quenching instance in the multiheattreatable.

3.3. Observation of NDT report

Nondestructivetestingisusedinaselectionofsettingsthat securitiesanexpansivechoiceofanartificialexertion,with new NDT styles and operations, being uninterruptedly established. Nondestructive testing styles are regularly functional in diligence where a failure of a module would beget important hazard or fiscal loss, similar as in transportationandpressurevessels.Inbothannealingand quenching, the heat treatments were fulfilled at the temperaturesof450and600 ◦ C.Theheattreatedsamples observedfromtheNDTresults,there'snointernal blights wereobservedbecauseofaddedheatwiththecompressive goodsof400KNcargousedforthedevelopmentofrefined

grainstructure.Theninthisworkeachinstancehasinvolved intotheradiographicexaminationofNDTtesting.Separate flicks were employed in the shape of 6 cm × 3 cm for the readingstaken.

Theinterpretationoftestresultsisshowednoblights.It's notedthatinTable4partialblightswerelinkedinthenon heattreatablealuminumcastinginstancethroughtheRadio graphictestreport.elsetherewasn'tindeedsingleblights notlinkedduringtheheattreatableannealedandquenched instanceinbothstagesofcompliances.Thiscanbeverified with the microstructure representations as mentioned in Table5.Followingbyhardnesscomparison,thegoodNDT issueswillgiveusclearresultanddatacomparison.

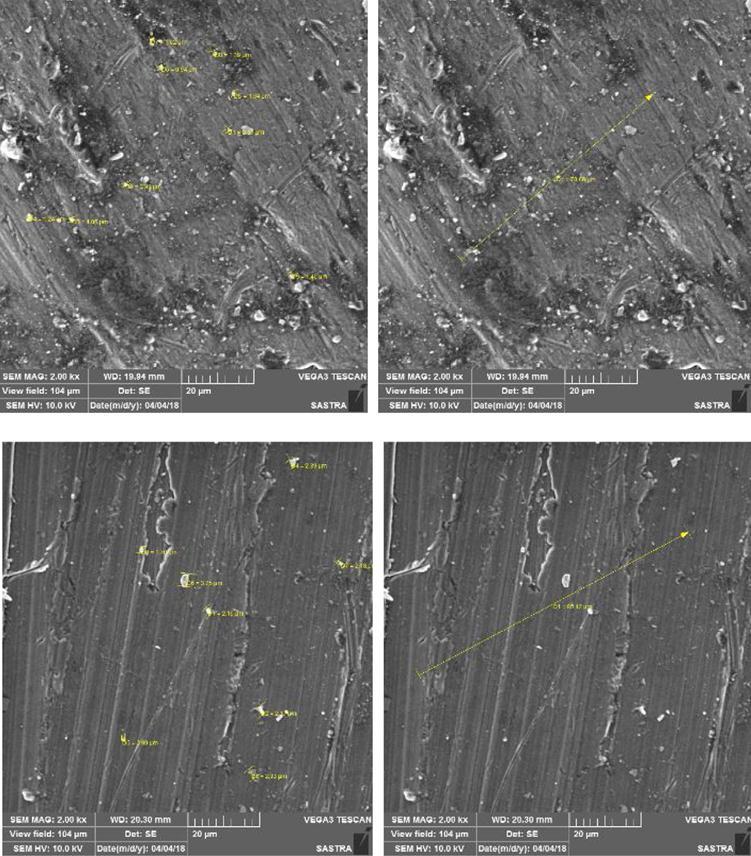

3.4. SEM identification of particle size and grain structure

It'svitalthatthemicrostructuralreadingswerepresentedin Table5.Itrepresentsthevaluesofaverageflyspecksizeand grainboundaryconsistenceinmicromeasures.Theobserved readingsfromthemicrographicalstructurehabittoidentify the flyspeck size measured through the Scanning ray microscope Vega 3 TESCAN as shown inFig. 8. The SEM images showed the detailed structural changes of both discerned casting samples. The stressed samples were involved thoroughthe SEMexamination withtheseparate exaggerationfactorposition.forcolorfulimageinterpretation colorfulreadingswerecapturedfromtheperipheralsofthe set instance. Its grain boundary also noticed as µm as recordedfromSEMimages.also,betterflyspecksize1.1693 µmweresetupduringthequenchingofmonoheattreated primarystageofAl6061castedsamples.

Thegrainboundariesofthenumerouscompliancesalsogot minimalduringthemultiheattreatablecastedinstance.the explanationbehindthesegoodbondstrengthandflyspeck size are the change in consistence by hot compressed instancebyUTM

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072

• Relegation variation is minimal during the multi heat treated instance examination because of change in thick nessvaryingdependsontheheatingtemperaturesatabout 600 ◦ C. This was verified with the relegation values of dynamicsimulationbyDeform3Dformingtool.

• The grain boundary consistence and flyspeck size were recorded minimum due to the hot compressed multi heat treatedAl6061samples.Thestrainratebecomeshighused to change the flyspeck size minimum. This productive material processing applied in the field of aerospace operationsandusedinlightweighthighstrengthfactors

• More compliances of flyspeck size reduction, grain boundarystrengtheningandhighhardnesswereconceded good in multi heat treated hot pressing of Al6061 casting samples. There were no further blights linked among the bothmonoandmultiheattreatedcastingsamples

5. REFERENCE

Fig. 7 SEM images of particle size and grain boundary at 2k×magnification level image of hot compressed specimen bymonoheattreatedandmulti heattreatedcompressesspecimen.

1. Dwivedi SK, Vishwakarma M, Soni A. Advances and researches on non destructive testing: a review advancesandresearchesonnondestructivetesting:a reviewhttp://dx.doi.org/10.1016/j.matpr.2017.11.620

2. LopezA,BacelarR,PiresI,SantosTG,SousaJP,Quintino L. Non destructive testing application of radiography andUltrasoundforwireandarcadditivemanufacturing. Addit Manuf http://dx.doi.org/10.1016/j.addma.2018.03.020

3. Dobmann G. Fatigue monitoring by NDT of austenitic Stainlesssteelatambienttemperatureand300 ◦Cand newAttemptstomonitorafracturemechanicstest.Proc Enghttp://dx.doi.org/10.1016/j.proeng.2014.11.052.

4. MarashiJ,YakushinaE,XirouchakisP,ZanteR,FosterJ. An Evaluation of H13 tool steel deformation in hot forging Conditions. J Mater Process Technol http://dx.doi.org/10.1016/j.jmatprotec.2017.03.026.

Fig. 8 Relationship of SEM outcomes and hot forming temperature.

4. CONCLUSION

• Disfigurement lower casting instance were prepared successfully by the casting of pure Al6061 amalgamation material.Completesurvivalofmaterialtestingwasfulfilled byNDTsystemwhichexplainedthatthehotformingheat treatedsamplescompletelyremovedalltheinternalstresses andblights.

• Hardness dimension helps to identify the capability to repeltheloadsamongthecolorfulsampleswhichiseasily agreedthatfurtherhardnessischancedinmultiheattreated samplescomparewiththemonoheattreatedsamples.

5. Mueller MG, Zagar G, Mortensen A. In situ strength of Individualsiliconparticleswithinanaluminiumcasting. Acta Mater http://dx.doi.org/10.1016/j.actamat.2017.09.058

6. TaoP,ShaoH,JiZ,NanH,XuQ.Numericalsimulationfor Theinvestmentcastingprocessofalarge sizetitanium alloyThin wallcasing.ProgrNatSciMater http://dx.doi.org/10.1016/j.pnsc.2018.06.005

7. Milkell P. Groover, “Fundamentals of Modern Manufacturing:Materials,Processes,andSystems”,John WileyandSons,NewJersey,4th edition,2010.

8. PaulDeGarmo,J.T.Black,RonaldA.Kohser,“Materials and Processes in Manufacturing”, Wiley, 10th edition, 2007.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

9. https://en.m.wikipedia.org/wiki/Casting#:~:text=Casti ng%20is%20a%20manufacturing%20process,mold%2 0to%20complete%20the%20process

BIOGRAPHIES

Vinay Ganesh Dandage. Student, Dept. of Mechanical Engineering, Deogiri College, Aurangabad Maharashtra, India.

Omkar Choudhari. Student, Dept. of Mechanical Engineering, Deogiri College, Aurangabad, Maharashtra, India.

Tushar Chavan. Student, Dept. of Mechanical Engineering, Deogiri College, Aurangabad, Maharashtra, India.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal